Heat-seal positioning system of printer ink cartridge

A positioning system and printer technology, applied in printing and other directions, can solve the problems of damaged printing effect, inability to print, poor toner sealing effect, etc., to improve speed and efficiency, and avoid the effect of dumping probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

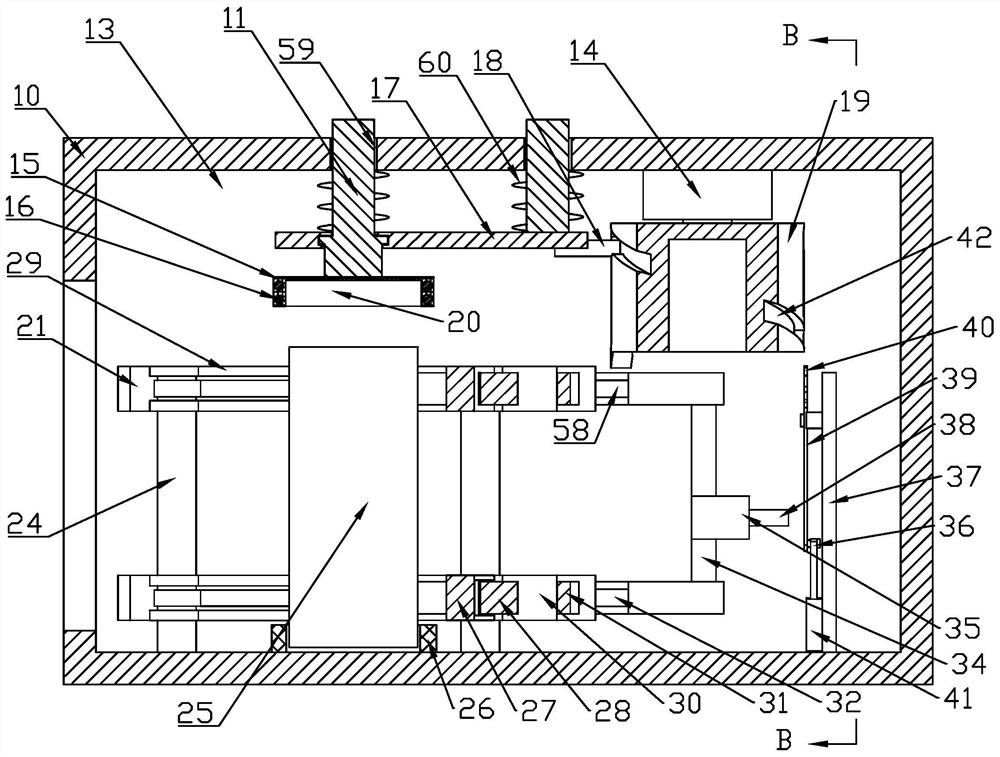

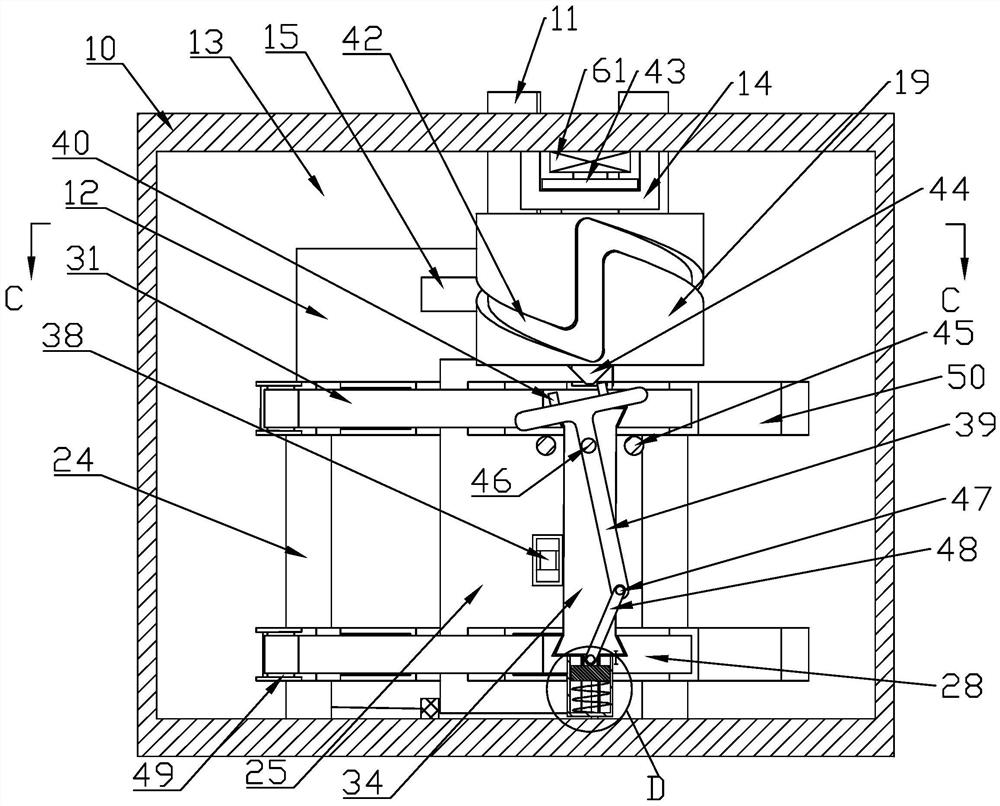

[0022] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0023] Such as figure 1 As shown, a heat-sealing positioning system for a printer cartridge includes a housing 10, which is characterized in that the housing 10 is provided with an inlet and outlet 12, the housing 10 is provided with a cavity 13, and the housing 10 is provided with a short circle Holes 59 and short circular holes 59 are slidably provided with long cylinders 11, connecting springs 60 are connected between the long cylinders 11 and the housing 10, the upper side of the housing 10 is fixedly provided with a motor 61, and the upper surface of the cavity 13 is fixedly provided with U-shaped sheet metal 14, the lower surface annular array of cavity 13 is fixedly provided with fixed bar 24, and the lower side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com