Preparation method and preparation device for synthesis ammonia prereduction catalyst

A preparation device and a technology for synthesizing ammonia, applied in the direction of catalyst activation/preparation, ammonia preparation/separation, chemical instruments and methods, etc., can solve problems such as incomplete passivation process, affect production, shorten catalyst service life, etc., and achieve simplified operation Difficulty, reduce power consumption, avoid the effect of unstable air intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

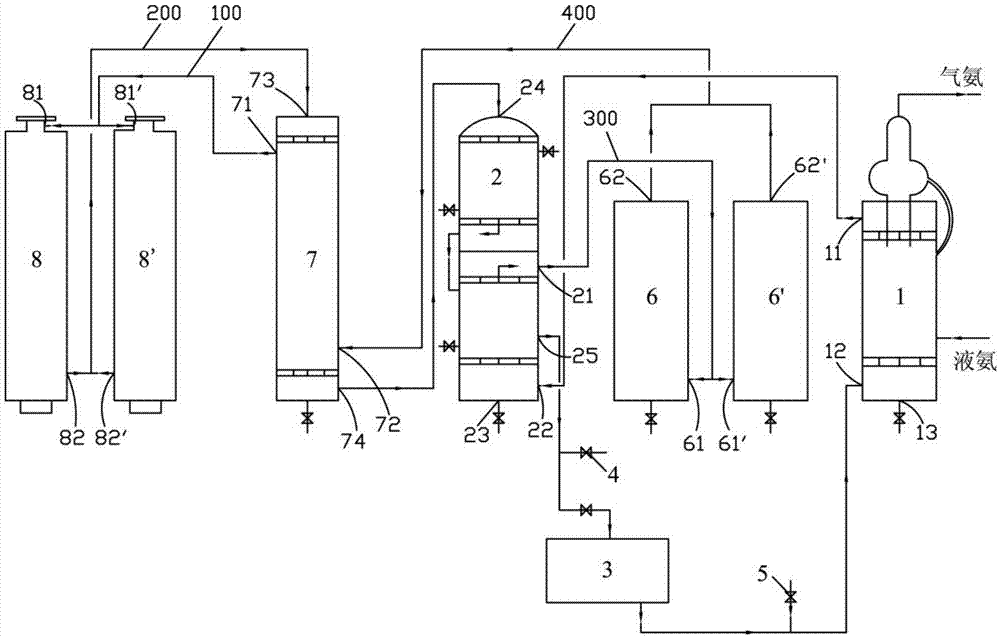

[0032]The preparation device of synthetic ammonia pre-reduction catalyst of the present invention, it comprises, ammonia condenser 1, it is provided with gas outlet 11, gas inlet 12 and the water outlet 13 that is positioned at the bottom up and down; Water condenser 2, it is provided with gas outlet 21 up and down , gas inlet 22 and the water outlet 23 that is positioned at the bottom, and its top offers circulation gas inlet 24, and the bottom offers circulation gas outlet 25; The gas inlet 22 of described water condenser 2 is connected the gas outlet of described ammonia condenser 1 by pipeline 11. Circulator 3, its inlet is connected to the circulating gas outlet 25 of water condenser 2 through a pipeline, and the pipeline is communicated with the air source through the vent valve 4; its outlet is connected to the gas inlet 12 of ammonia condenser 1 through a pipeline, and the pipeline is connected to the gas inlet 12 of the ammonia condenser 1 through a pipeline. The gas v...

specific Embodiment

[0037] (1) Start-up: First, perform gas replacement on the entire system (pipelines, reduction towers and other equipment). Firstly open the air supply valve 5, and replace at normal pressure for 10 minutes, then close the vent valve 4, and perform constant pressure replacement. Pressurize to 0.1MPa and close the air supply valve 5, open the vent valve 4 to empty, then pressurize to 0.1MPa, and then empty. So repeated replacement 3 times. After measuring the O2 concentration in the system gas ≤ 0.2%, pressurize to 0.5MPa, and test the pressure to check for leaks. After the system is completely normal, start the main power supply, turn on the cooling water of the circulator 3, turn on the circulator 3, adjust the speed to 400 rpm, and heat up with electricity.

[0038] (2) Nitrogen and hydrogen enter the ammonia condenser 1 and the water condenser 2 successively at first, then enter the first and second dehydration towers 6 and 6 ', and then enter the heater 7 (in this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com