Washing production method for crude nitrochlorobenzene

A technology for nitrochlorobenzene and a production method, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of large floor space, large amount of phenol-containing wastewater, and large number of equipments, and saves equipment. Investment, reducing water consumption, good washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

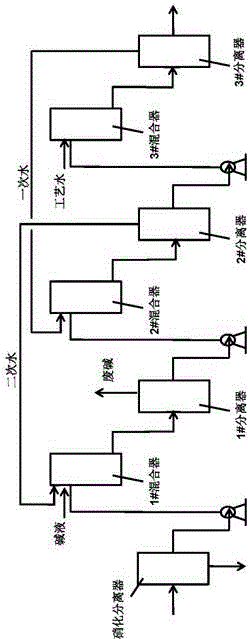

[0017] Crude nitrochlorobenzene at a temperature of 75°C 9.3m 3 / h, 20% concentration of sodium hydroxide 0.3 m 3 / h and secondary water enter the 1# static mixer with a diameter of 150mm and a length of 2m, and control the pressure at 0.2MPa. After being fully mixed and neutralized in the 1# static mixer, it enters the 1# separator, and the material in the 1# separator stays The time is 10 minutes, the upper inorganic phase is treated with waste alkali, the lower organic phase and the primary water from the outlet of the 3# separator enter the 2# static mixer and are mixed and washed, and the pressure is controlled at 0.2MPa. The washed material enters the 2# separator. The material residence time in the 2# separator is 10min, the upper aqueous phase enters the 1# static mixer, and the lower organic phase and fresh process water are 5.4 m 3 / h enters the 3# static mixer for mixing and washing, the washed material enters the 3# separator, the upper layer water of the 3# separ...

Embodiment 2

[0019] Crude nitrochlorobenzene at a temperature of 75°C 9.3m 3 / h, 30% concentration of sodium hydroxide 0.2 m 3 / h and secondary water enter the 1# static mixer with a diameter of 150mm and a length of 2m, and control the pressure at 0.2MPa. After being fully mixed and neutralized in the 1# static mixer, it enters the 1# separator, and the material in the 1# separator stays The time is 20 minutes, the upper inorganic phase is treated with waste alkali, the lower organic phase and the primary water from the outlet of the 3# separator enter the 2# static mixer and are mixed and washed, and the pressure is controlled at 0.2MPa. The washed material enters the 2# separator. The material residence time in the 2# separator is 20min, the upper aqueous phase enters the 1# static mixer, and the lower organic phase and fresh process water are 6.4 m 3 / h enters the 3# static mixer for mixing and washing, the washed material enters the 3# separator, the upper layer water of the 3# separ...

Embodiment 3

[0021] Crude nitrochlorobenzene at a temperature of 70°C 10.8m 3 / h, 30% concentration of sodium hydroxide 0.3 m 3 / h and secondary water enter the 1# static mixer with a diameter of 150mm and a length of 2m, and control the pressure at 0.2MPa. After being fully mixed and neutralized in the 1# static mixer, it enters the 1# separator, and the material in the 1# separator stays The time is 20 minutes, the upper inorganic phase is treated with waste alkali, the lower organic phase and the primary water from the outlet of the 3# separator enter the 2# static mixer and are mixed and washed, and the pressure is controlled at 0.2MPa. The washed material enters the 2# separator. The residence time of the material in the 2# separator is 20min, the upper aqueous phase enters the 1# static mixer, and the lower organic phase and fresh process water are 6.5 m 3 / h enters the 3# static mixer for mixing and washing, the washed material enters the 3# separator, the upper layer water of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com