Continuous vapor deposition equipment

A technology of equipment and linear evaporation source, which is applied in vacuum evaporation plating, sputtering plating, ion implantation plating, etc., can solve the pollution of evaporation environment, affect the running time and output of evaporation equipment, and effectively evaporate the interference point source scope and other issues to achieve the effect of solving pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

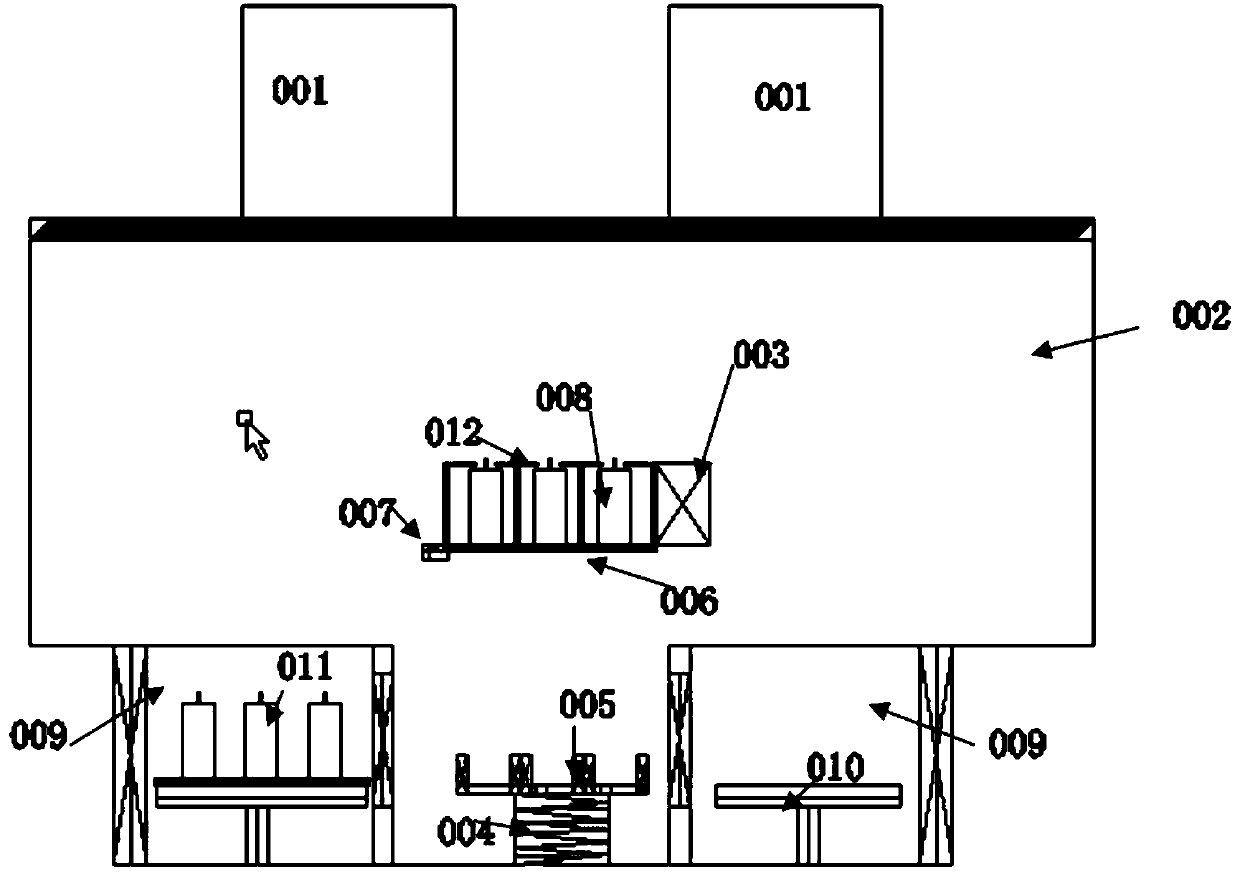

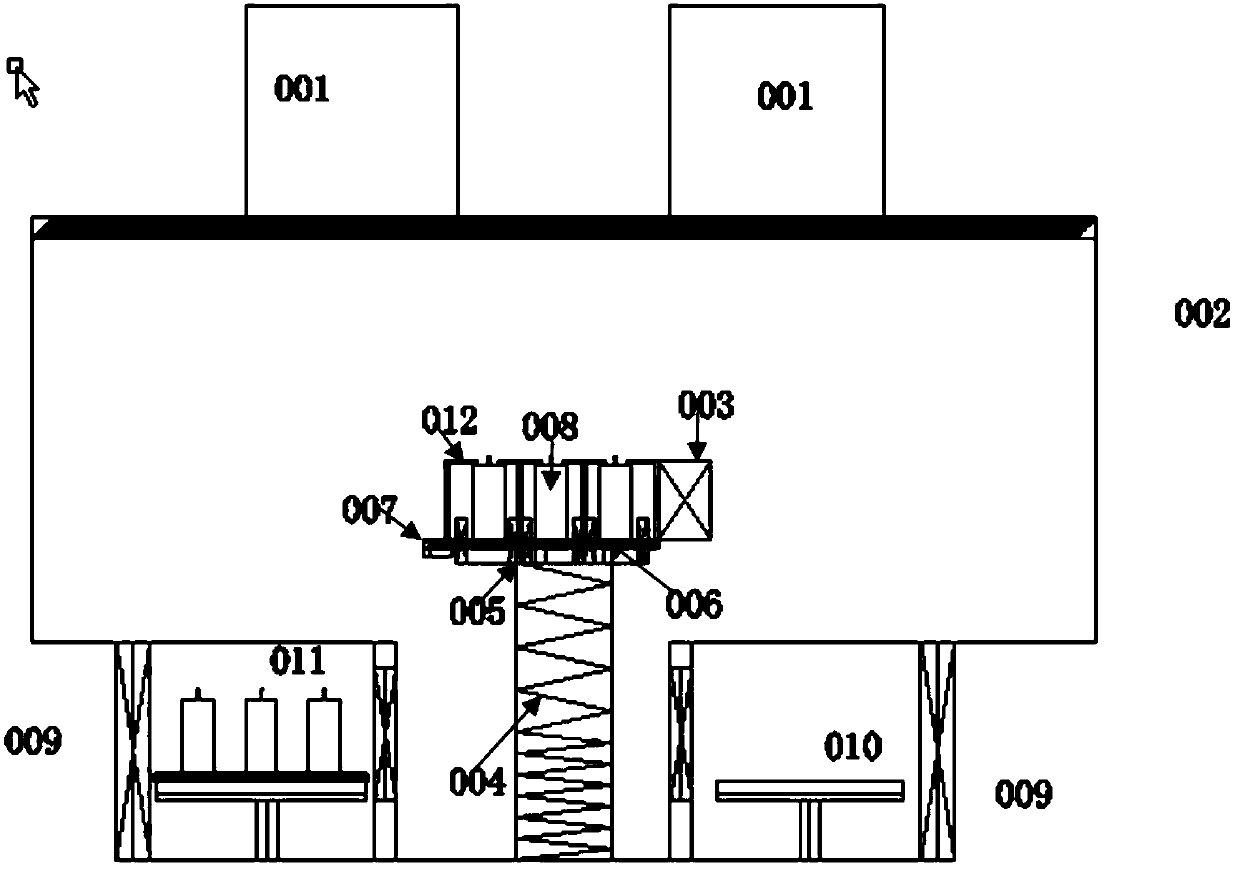

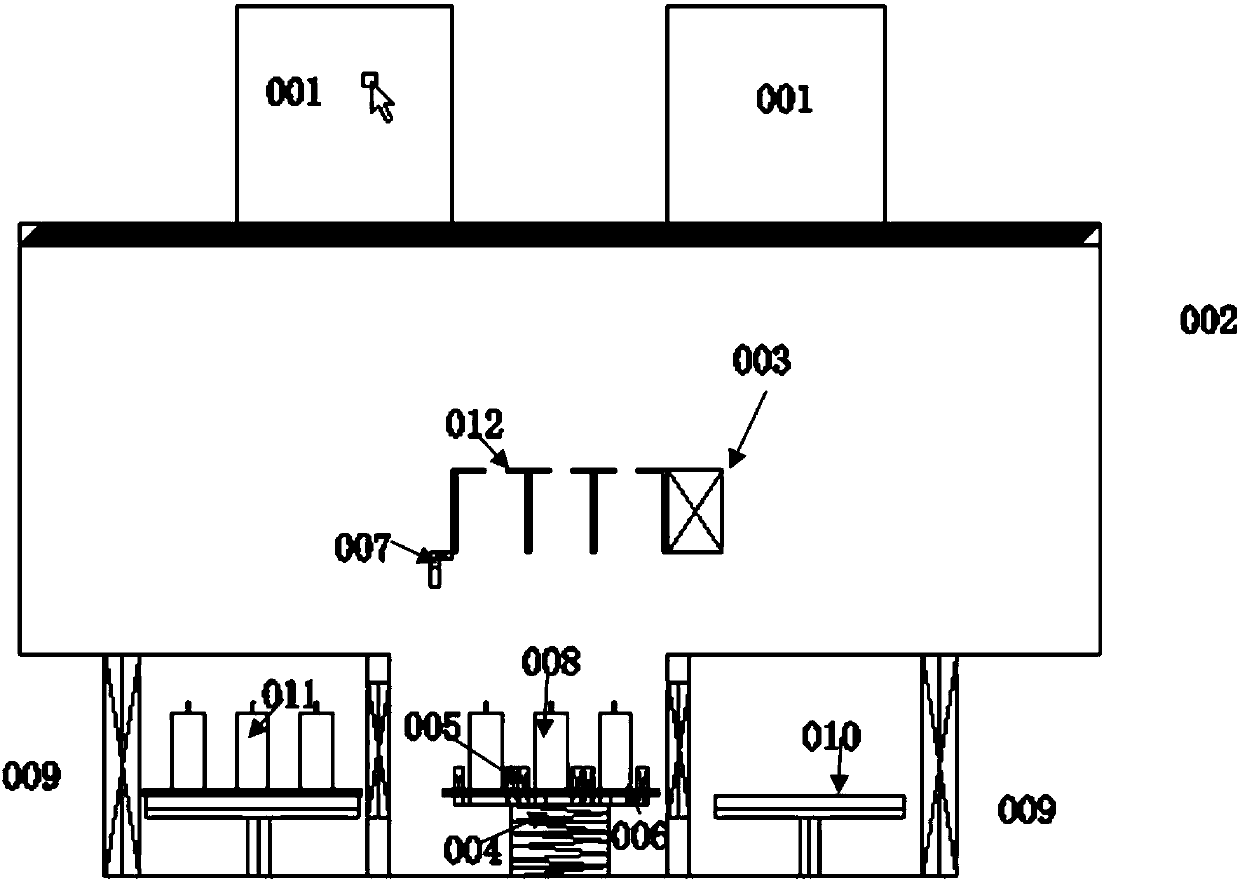

[0027] This embodiment provides a continuous evaporation equipment, such as Figures 1 to 4 As shown, it includes a main cavity 002 and a linear evaporation source located in the main cavity 002, a linear crucible carrying platform 006 carrying a linear crucible, a lifting unit 004, a clamp unit 007, and two linear crucible vacuum conversion The cavity 009 and the handling unit 010 respectively located in the linear crucible vacuum conversion cavity 009, wherein the linear crucible vacuum conversion cavity 009 is used to place the linear crucible carrying platform 006, and the handling unit 010 is used for The linear crucible carrying platform 006 is transferred between the linear crucible vacuum conversion cavity 009 and the lifting unit 004, and the lifting unit 004 is used to disengage the linear crucible carrying platform 006 or put it into the linear crucible carrying platform 006. An evaporation source, the clamp unit 007 is used to fix the linear crucible carrying platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com