Patents

Literature

49results about How to "Increase the amount of spraying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

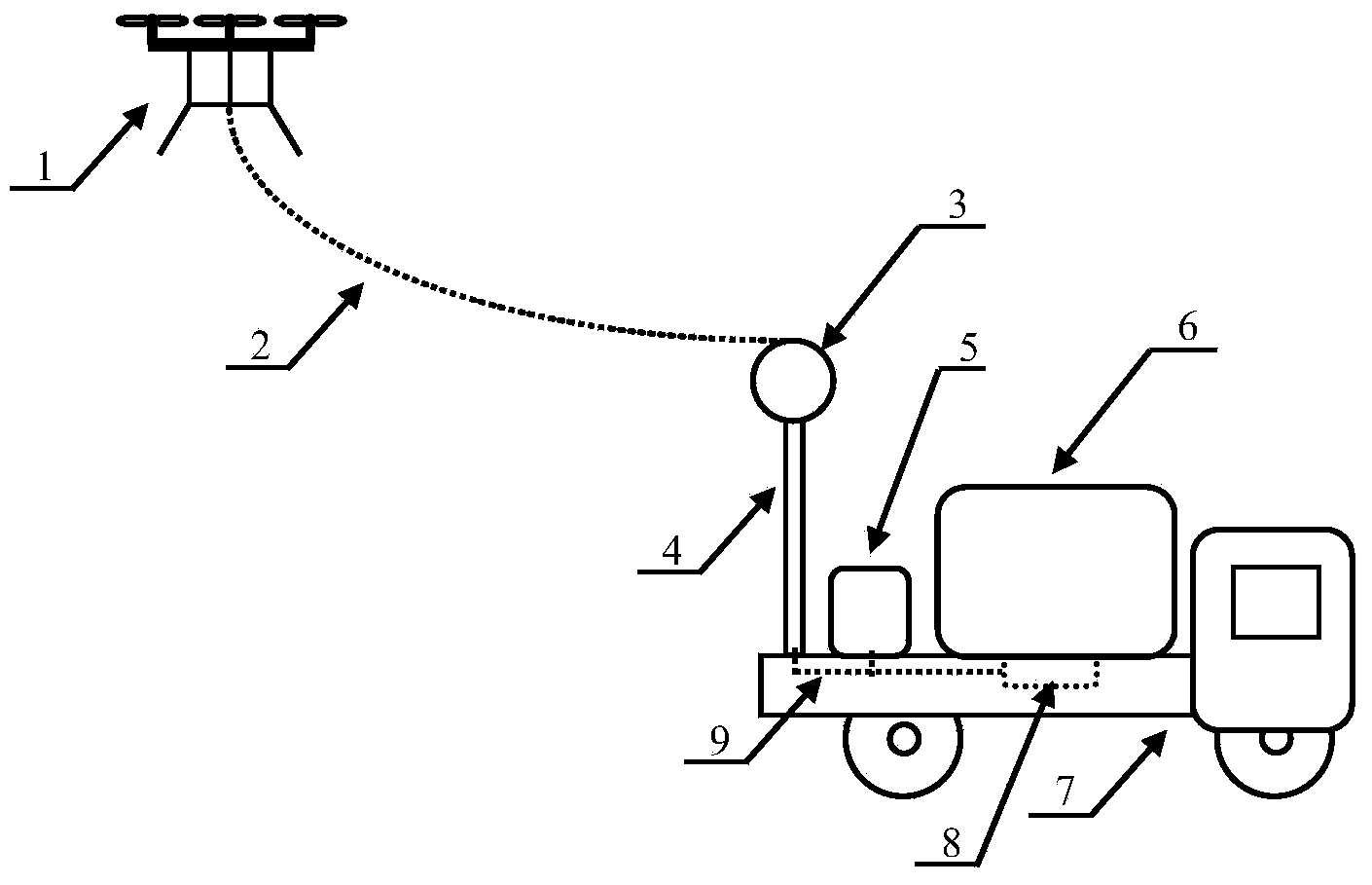

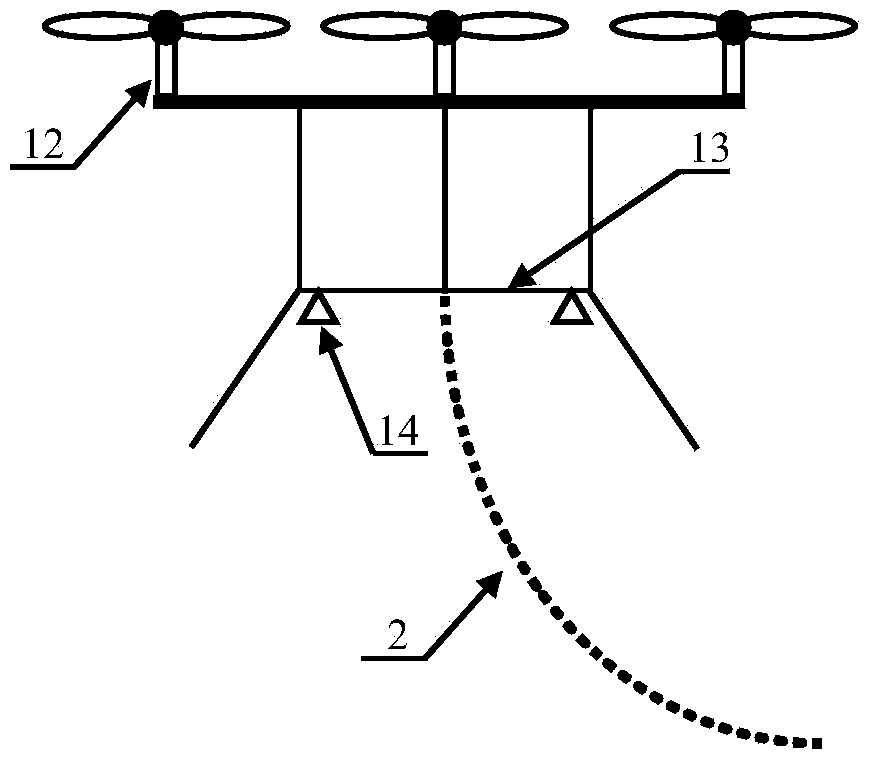

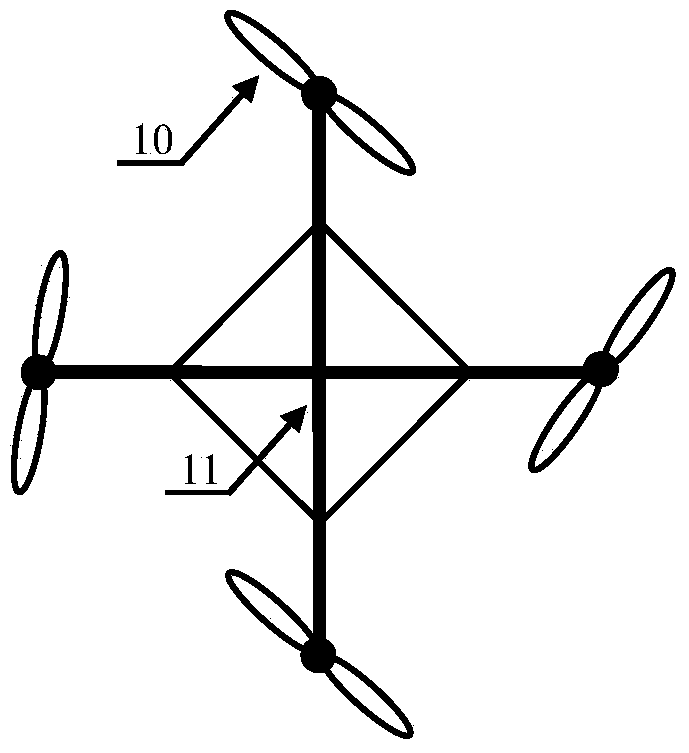

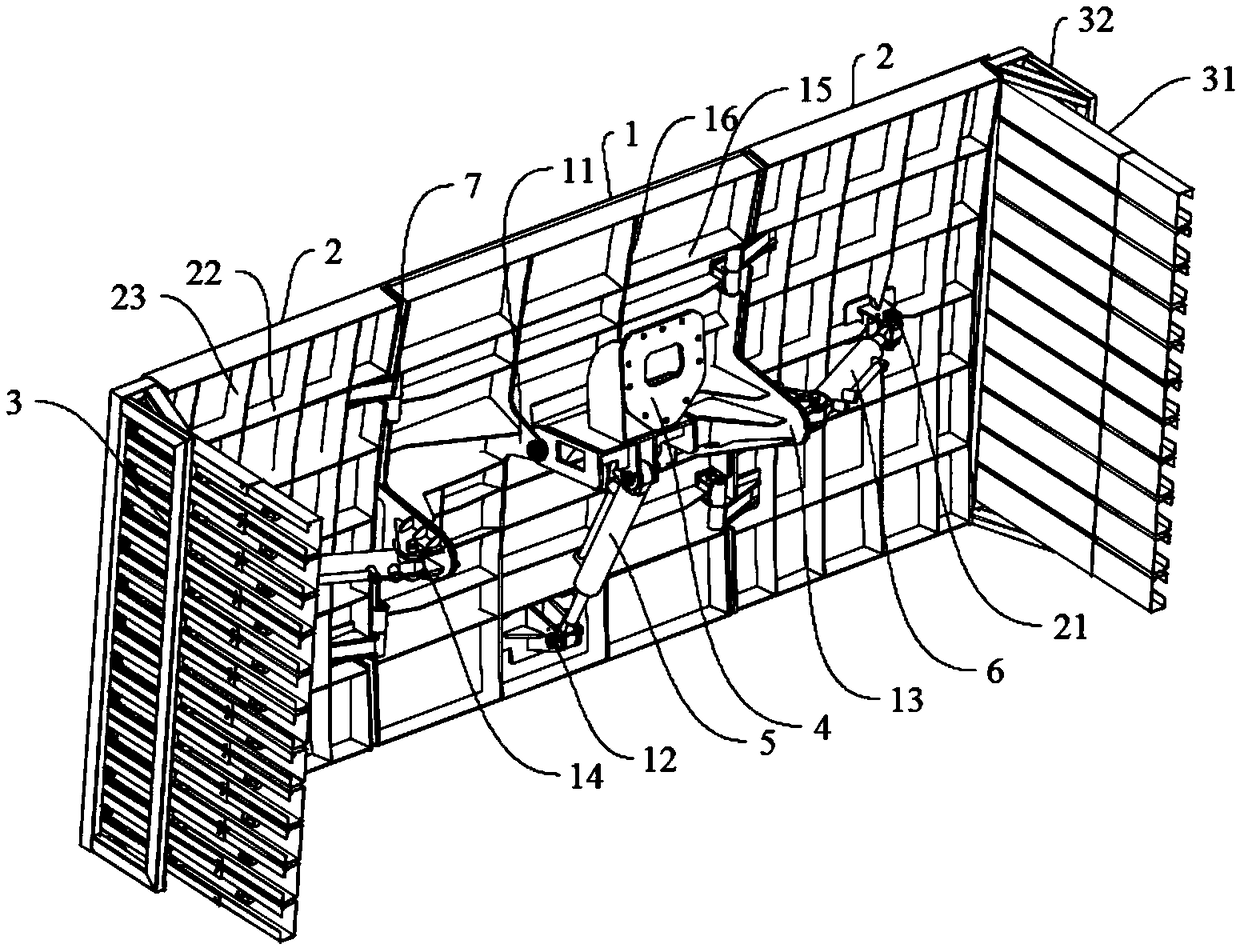

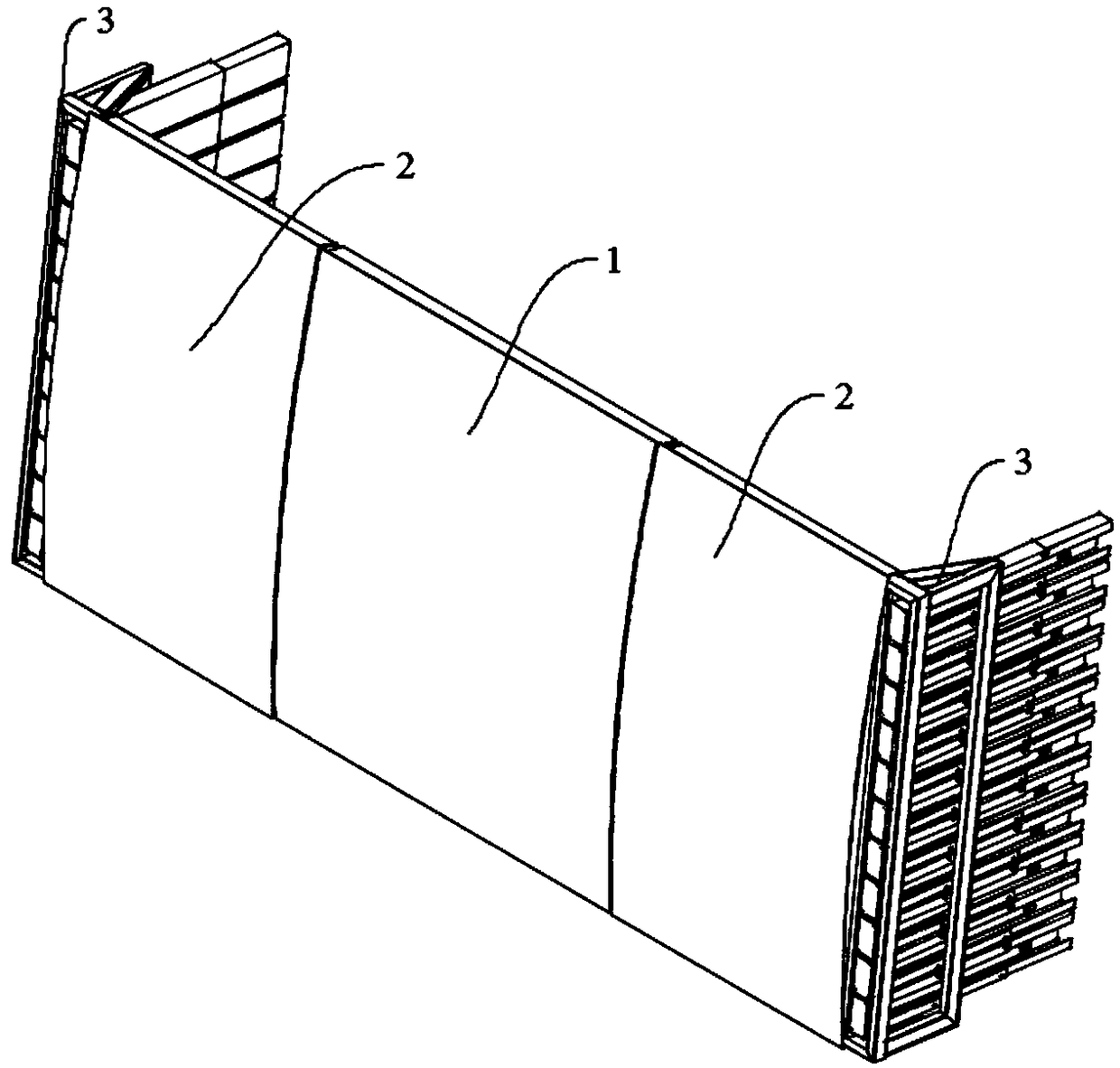

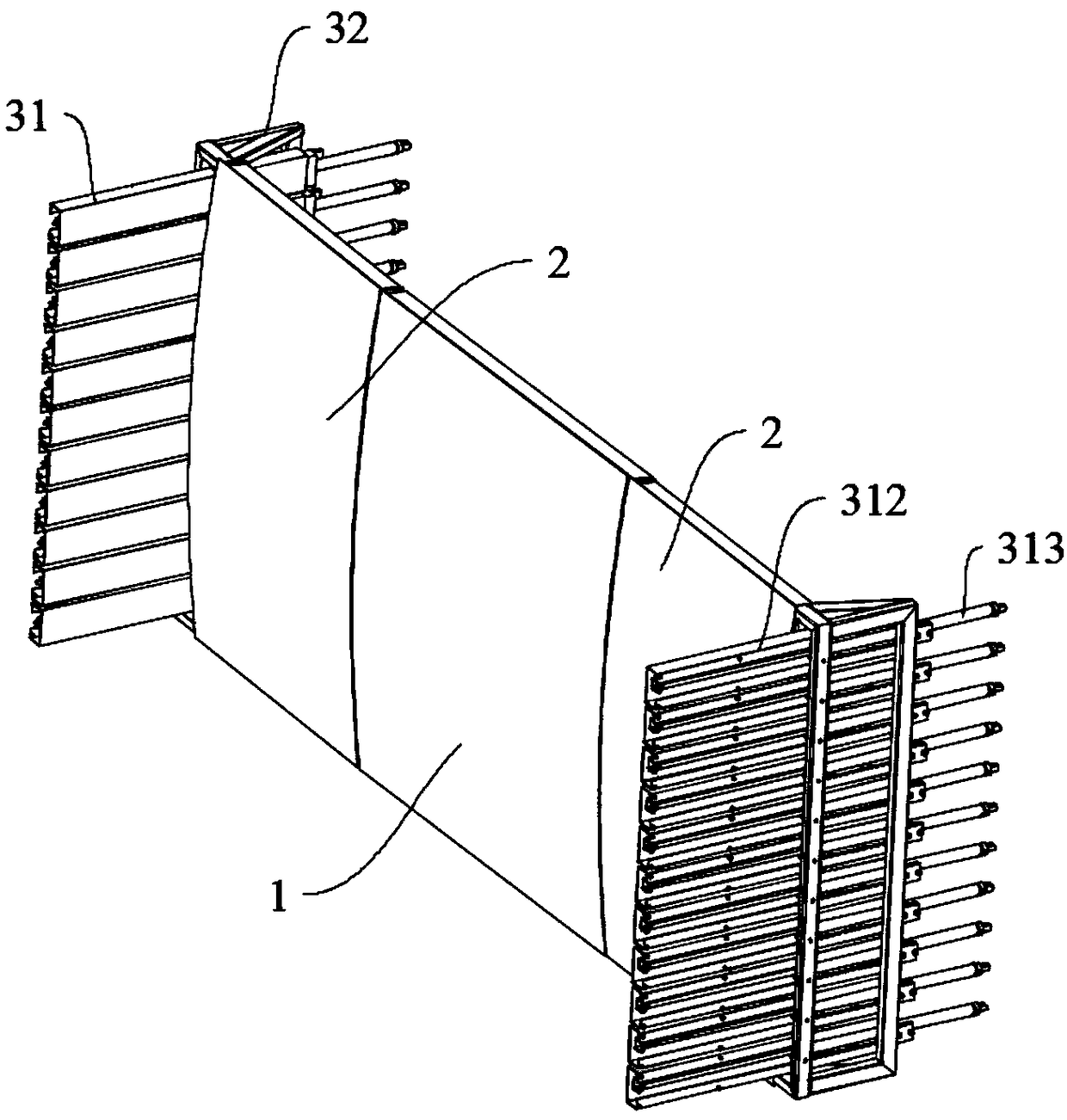

Air-ground combined agricultural spraying device and application thereof

InactiveCN103754368ASolve the problem of long-distance ground transportationOptimize joint operation effectAircraft componentsInsect catchers and killersAgricultural engineeringPropeller

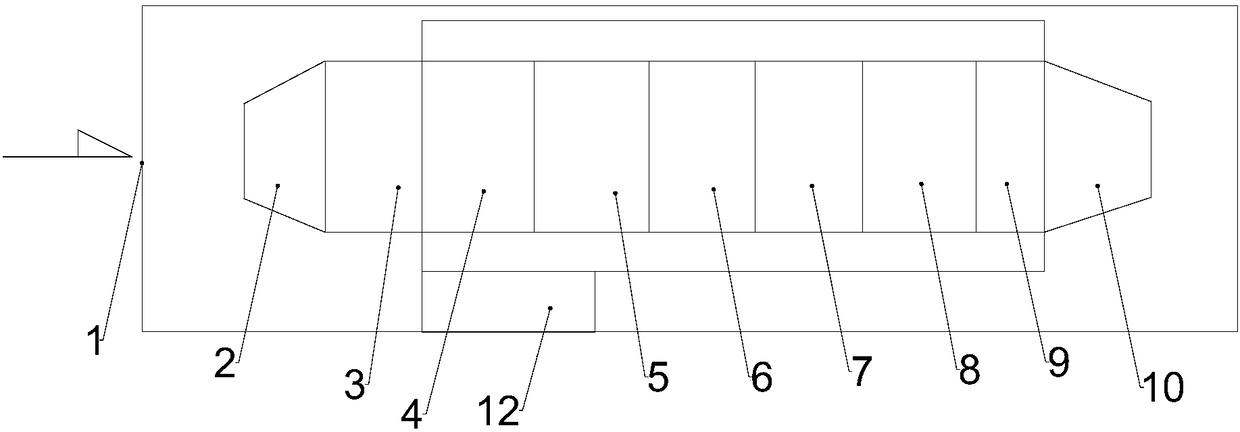

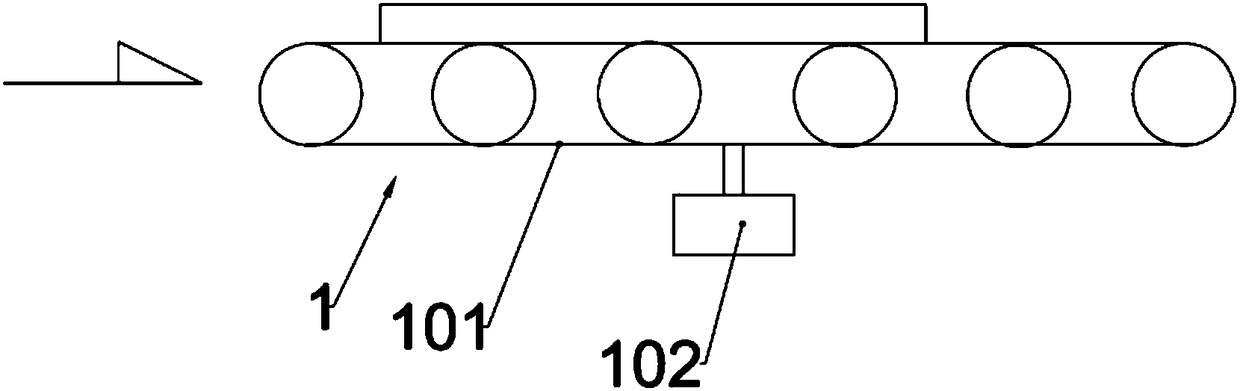

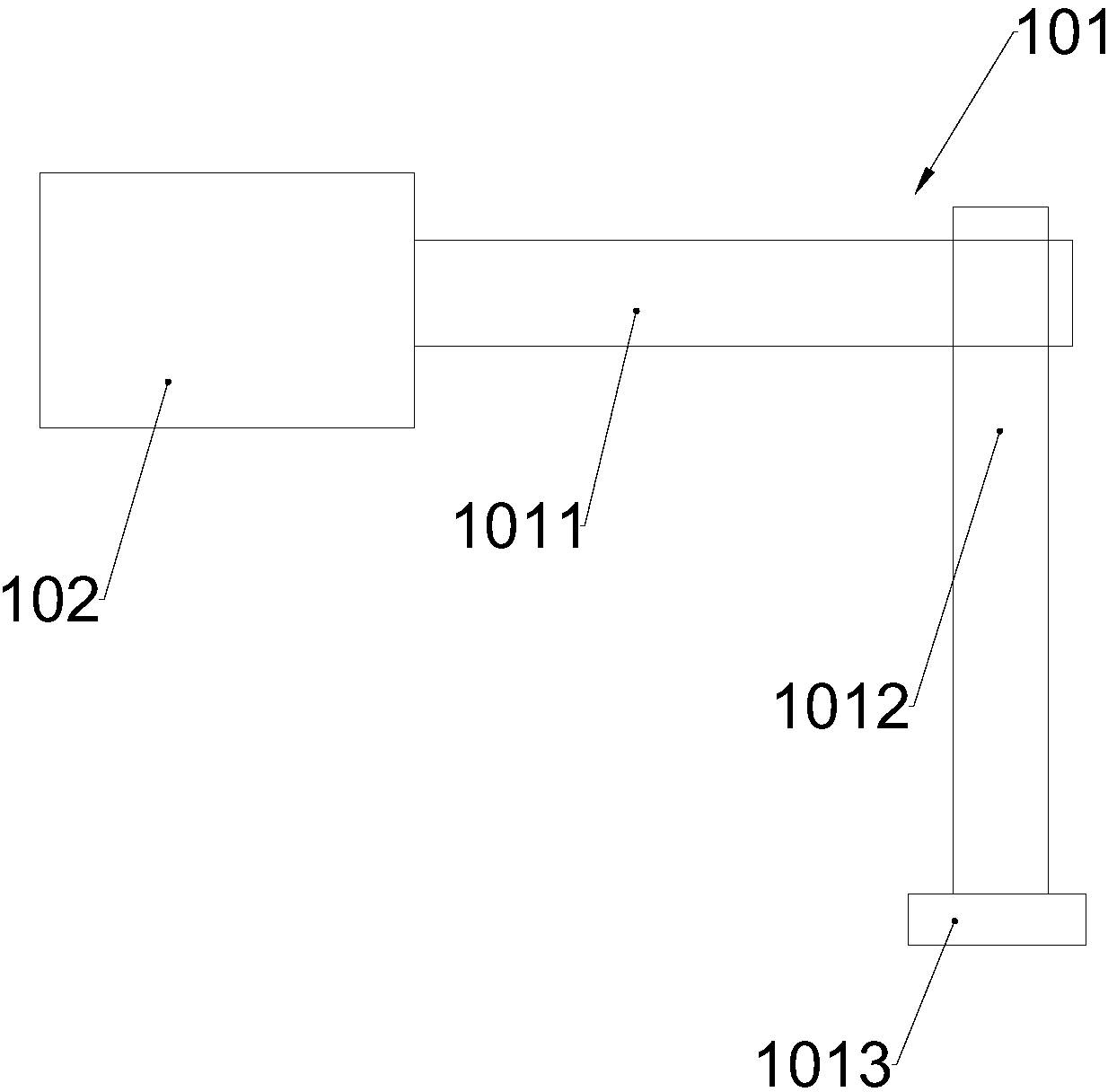

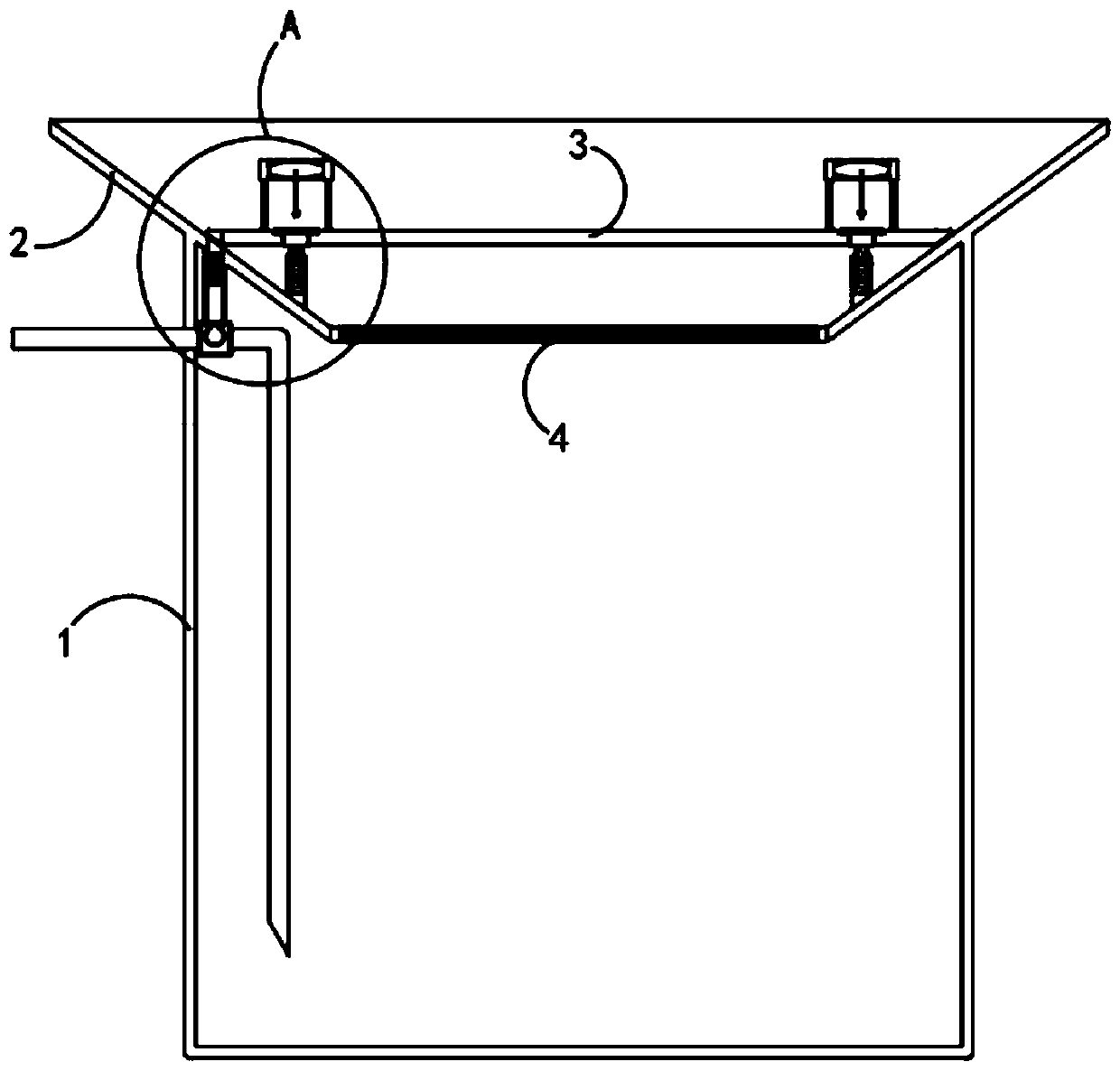

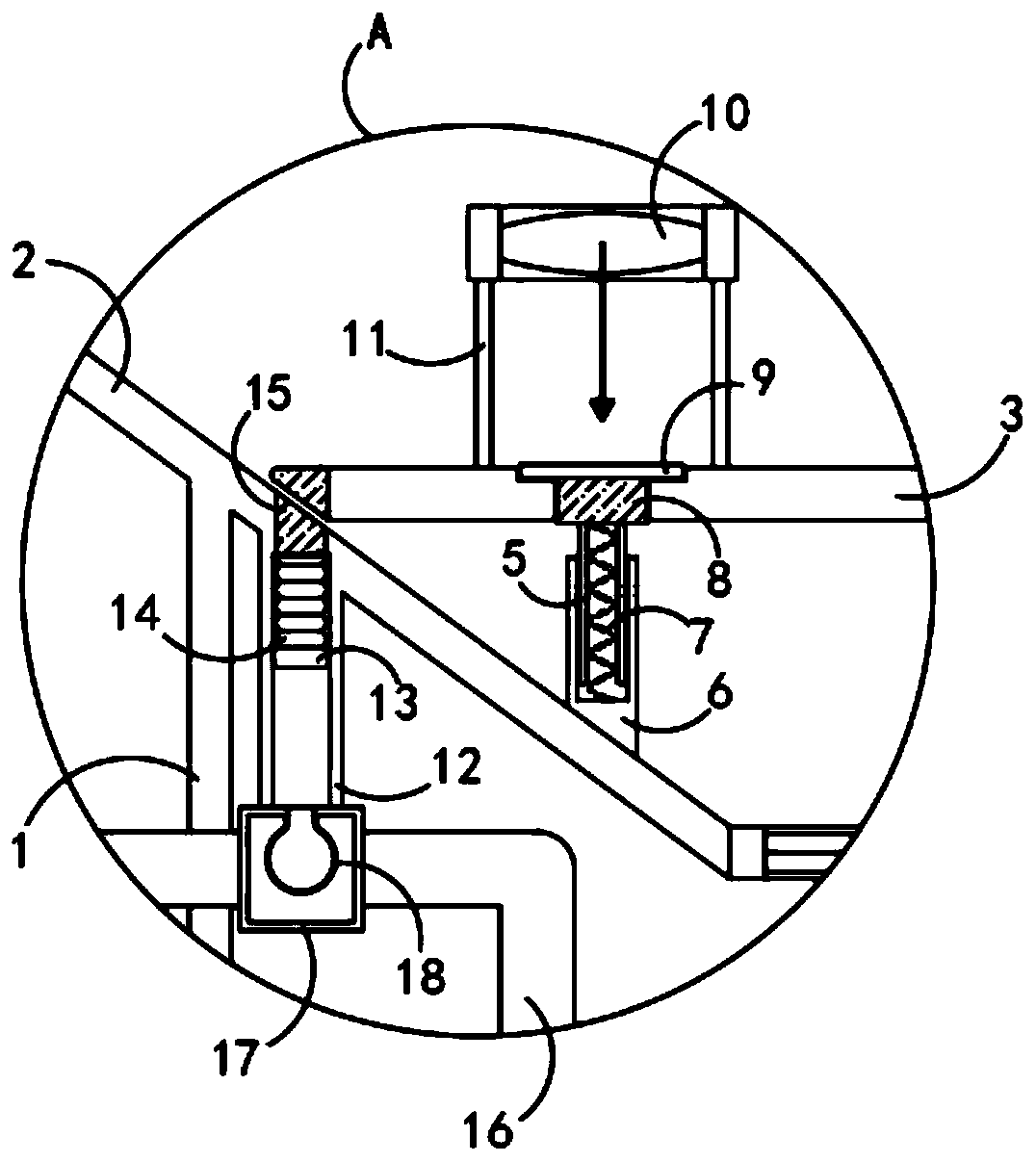

The invention discloses an air-ground combined agricultural spraying device and application of the air-ground combined agricultural spraying device. The air-ground combined agricultural spraying device comprises an aircraft, connecting pipelines, a winch mechanism, a winch mechanism supporting rod, a power system, a liquid pesticide storage tank, a transport vehicle, a pressure pump, an inner passage, a propeller, a propeller beam, a propeller drive motor, an aircraft bracket and spray heads. According to the air-ground combined agricultural spraying device, the large-size heavy liquid pesticide tank, the pressure pump and the power system are installed on the transport vehicle, a spraying mechanism is installed on the small unmanned rotorcraft, and an air device and a ground device are connected through hoses and wires. In this way, aerial spraying in a limited area within ultra-long auto-hover time is achieved, and meanwhile long-distance ground transportation of an aircraft is achieved.

Owner:SOUTH CHINA AGRI UNIV

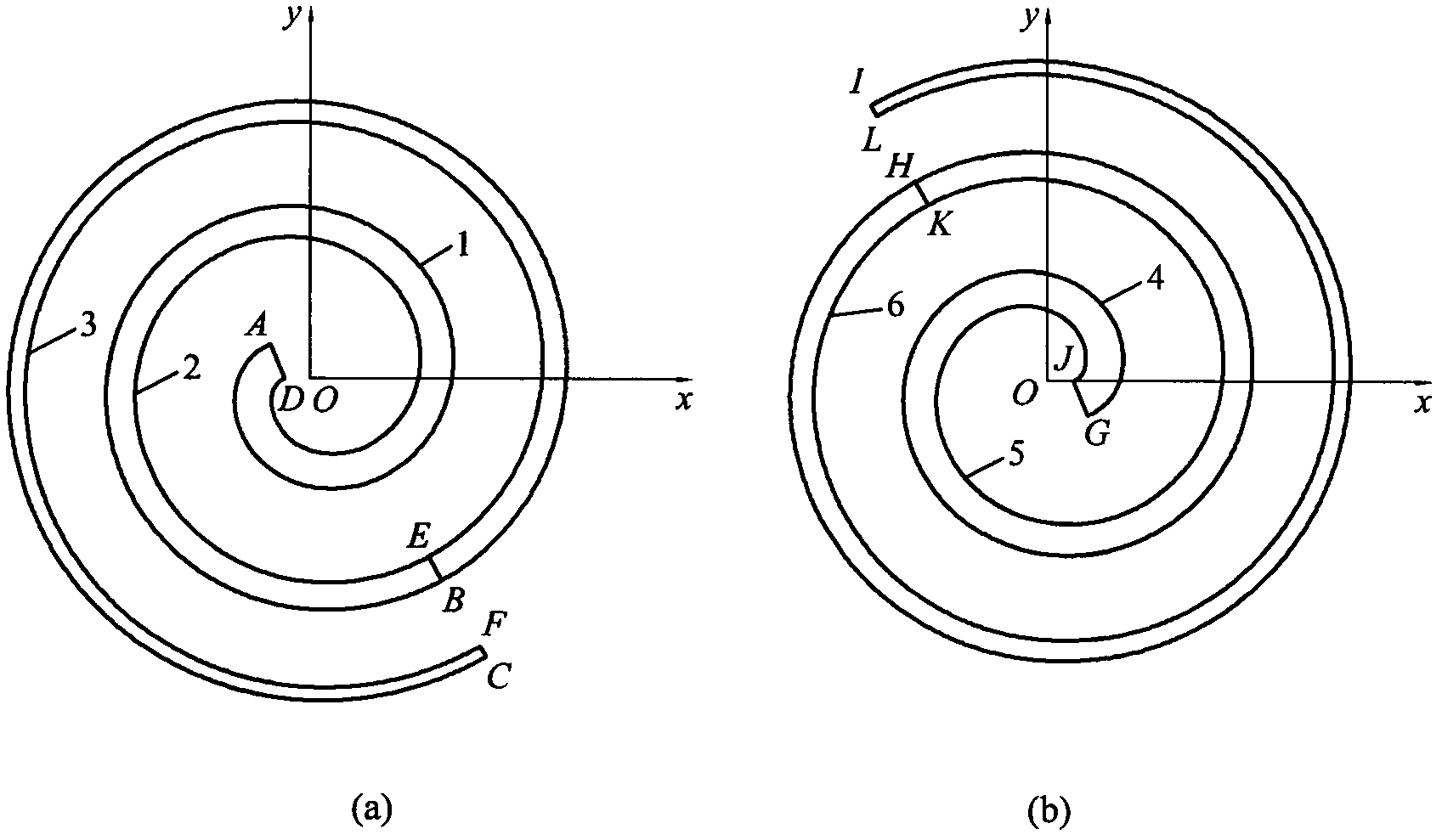

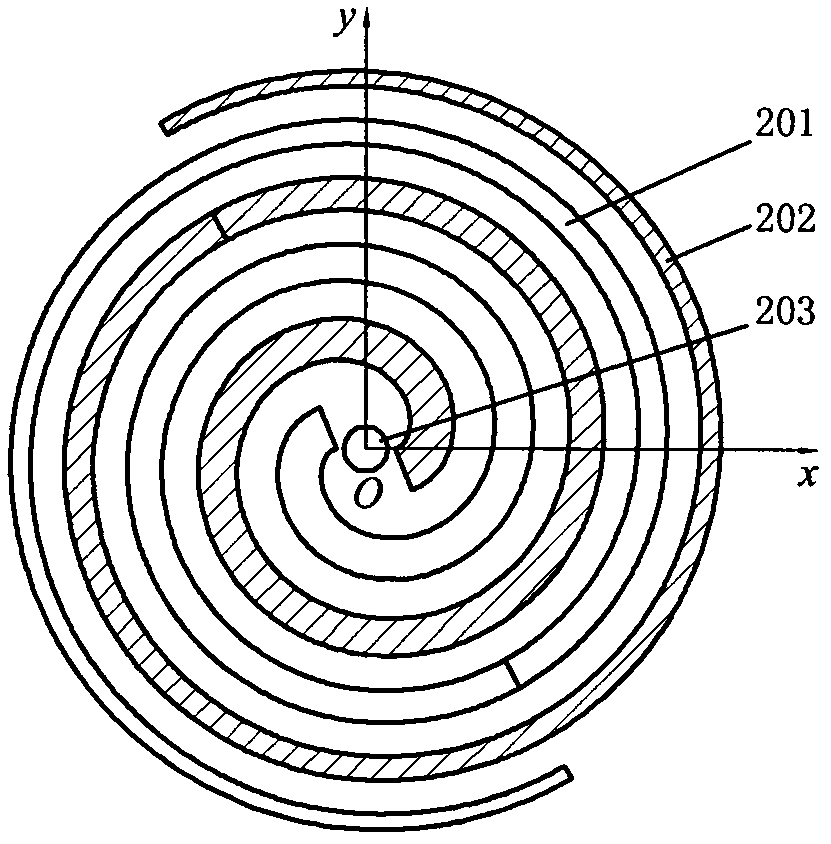

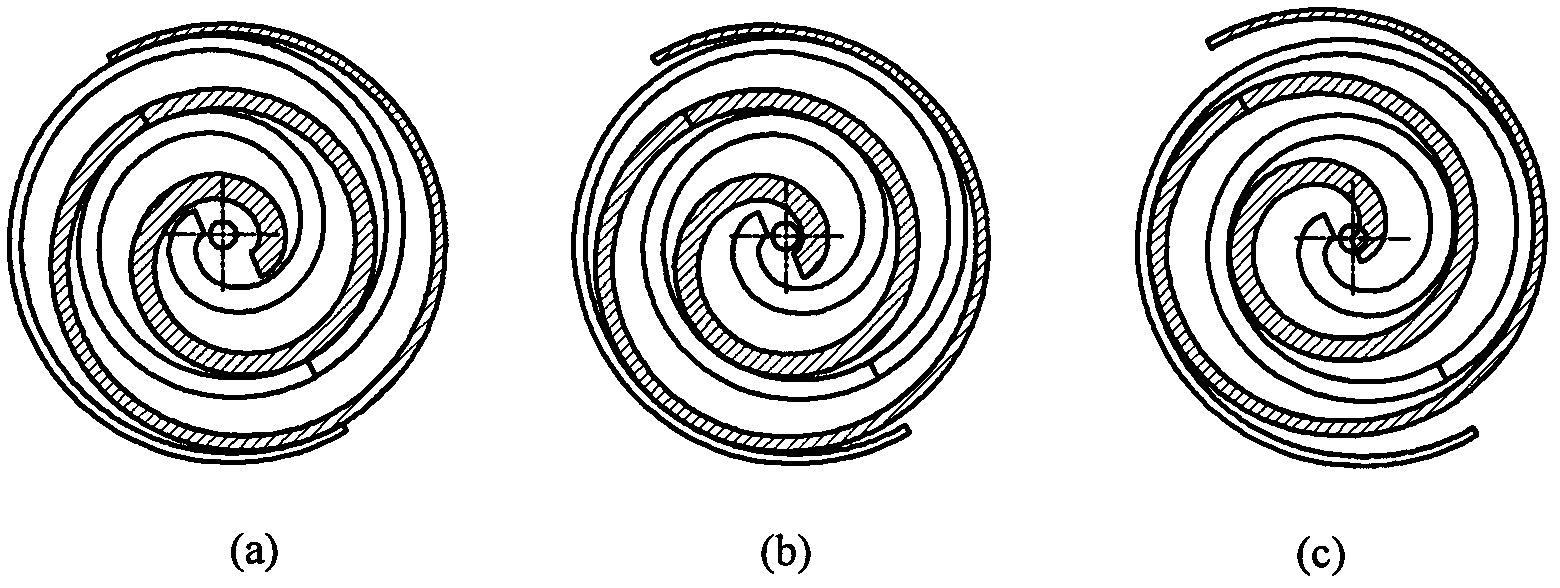

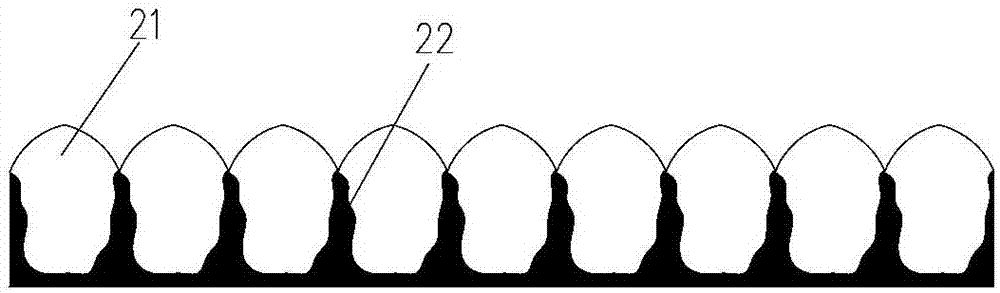

Scroll wrap profile of liquid-injected scroll compressor

InactiveCN103047135AStrong enoughExtended service lifeRotary piston pumpsRotary piston liquid enginesInvoluteEngineering

The invention relates to a scroll wrap profile of a liquid-injected scroll compressor. Outer profiles of a static scroll wrap and a dynamic scroll wrap are composed of a section of a variable diameter base circle involute, and the inner profiles of the static scroll wrap and the dynamic scroll wrap are composed by smoothly connecting a variable diameter base circle involute at a center part and normal equidistant curves of the variable diameter base circle involute of the outer ring. The scroll wrap refers to a scroll wrap with compression chamber variational meshing clearance and the wall thickness of the scroll wrap changing gradually. The meshing part close to a central air outlet of the compression chamber is provided with the meshing clearance which forms a pressure unloading channel to the air outlet with small clearance internal leakage, so that the problems of surge pressure in the compression chamber or liquid impacting which are produced by incompressible liquid with relatively large spraying volume. The meshing point of a suction cavity formed by the scroll wrap has no meshing clearance, so that the suction cavity is completely isolated from the compression chamber; at the same time, the wall thickness of the scroll wrap changes thinner gradually from the center to the outer ring, so that the central part of the scroll wrap has enough strength; and the wall thickness at the outer ring of the scroll wrap is relatively thin, so that area utilization rate of a scroll plate is effectively increased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

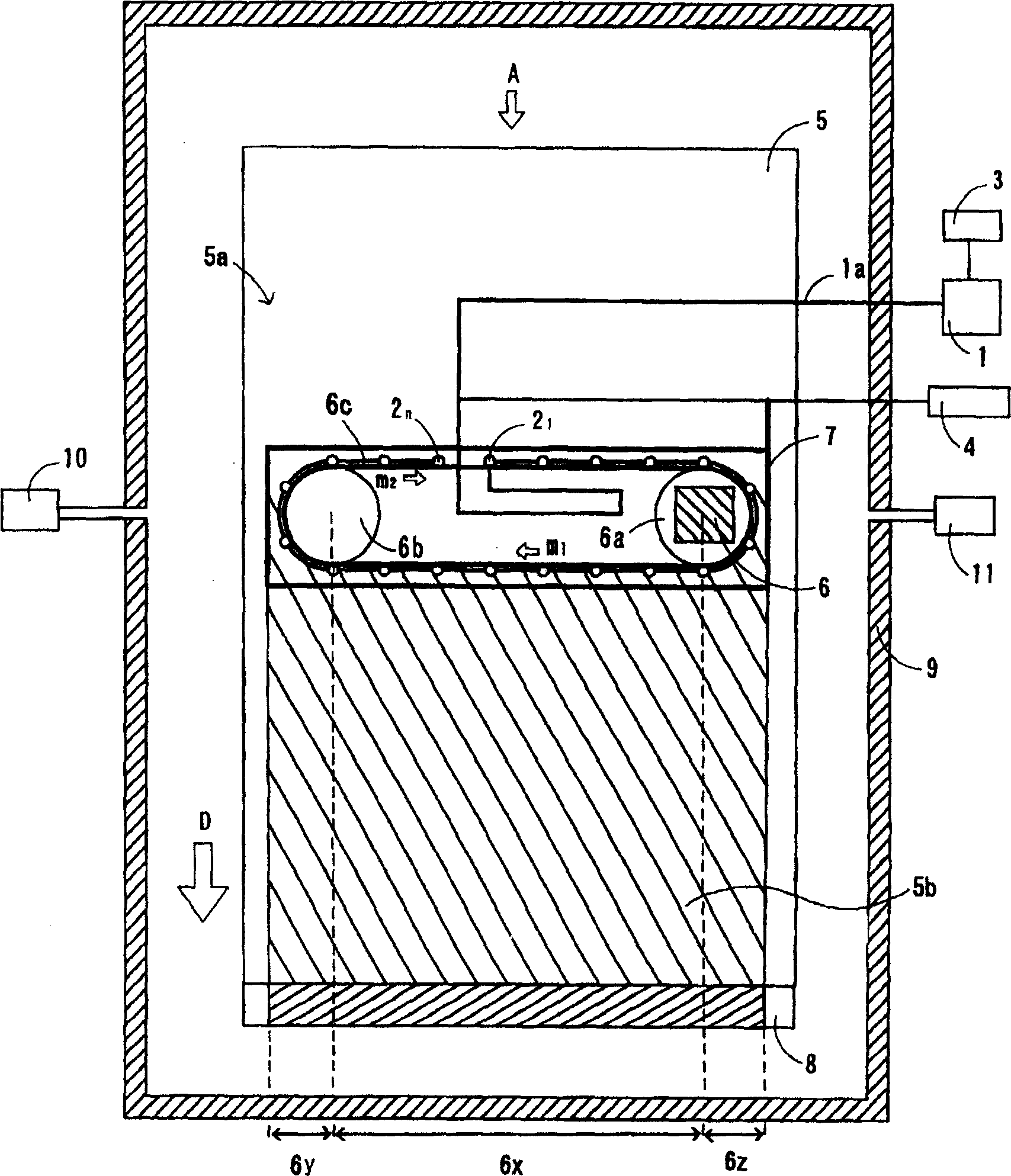

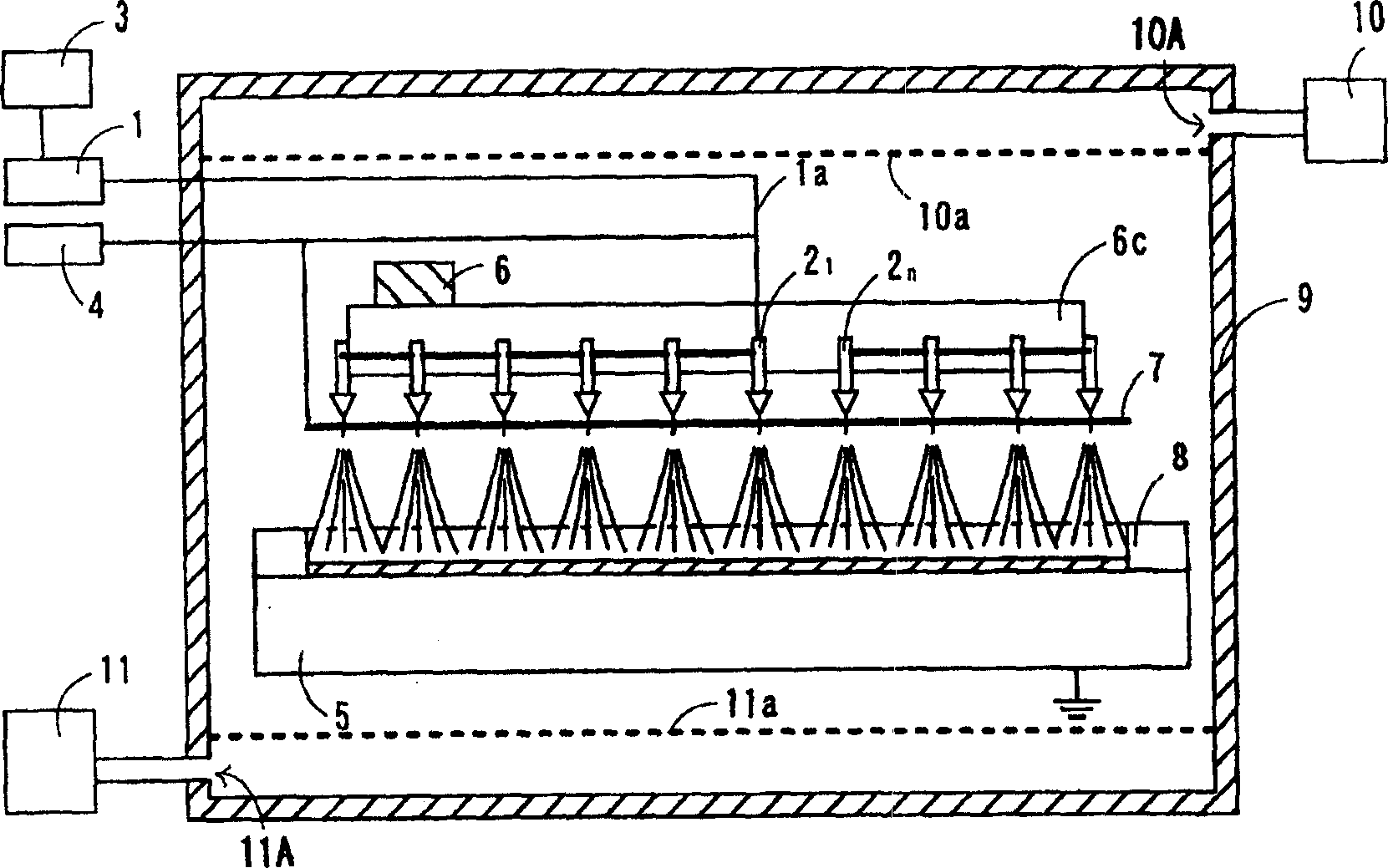

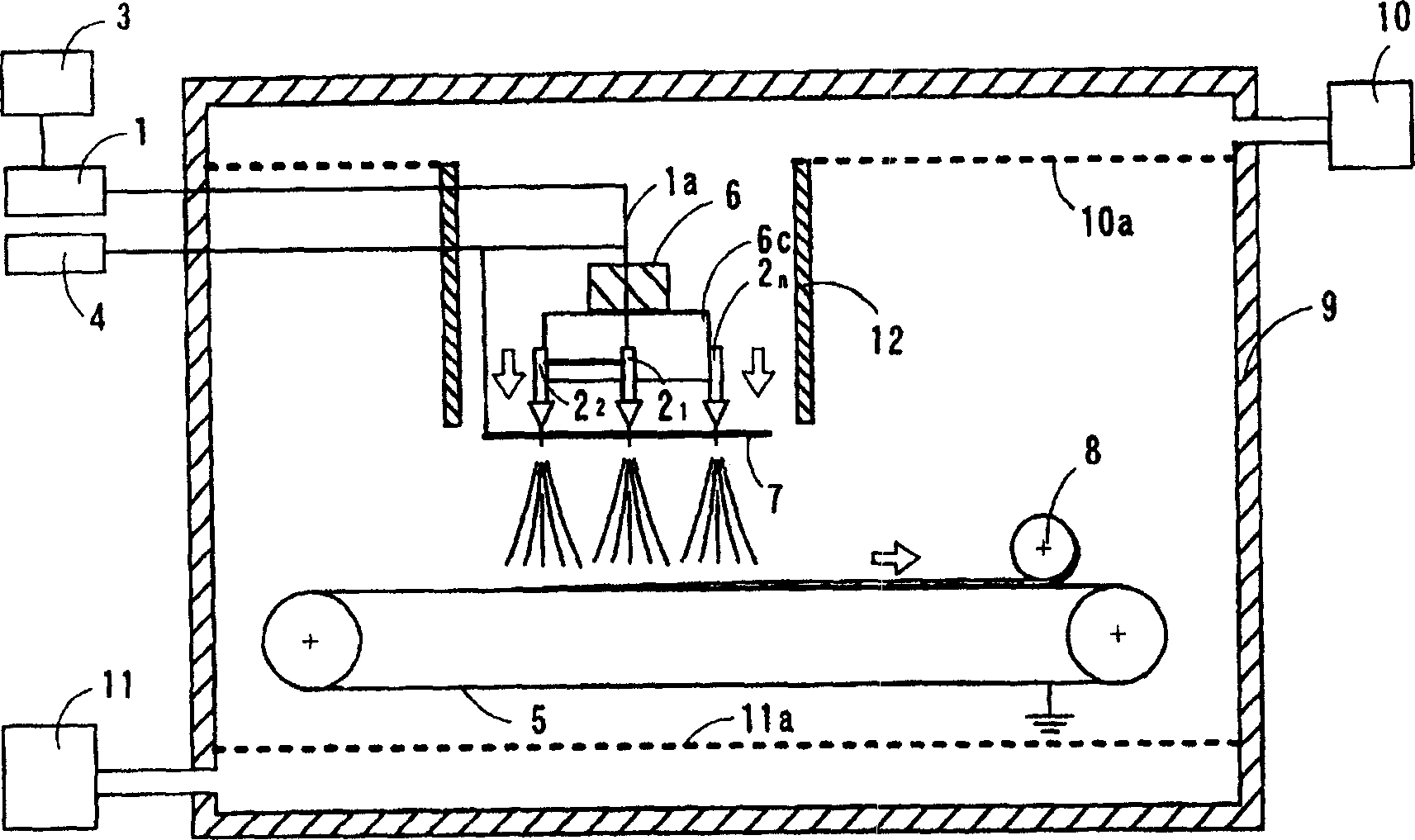

Method and apparatus of producing fibrous aggregate

InactiveCN1749450AUniform mechanical strengthUniform amount of fiberFelting apparatusDry spinning methodsLinear motionFiber

The present invention discloses a method for manufacturing a fiber aggregate, comprising: a supplying and jetting step of supplying the spinning stock solution from the spinning stock solution storage part to the spinning stock solution ejection part through a supply pipe, and spraying the spinning stock solution from the spinning stock solution ejection part ; Fiber gathering process, the above-mentioned spinning dope that is sprayed out acts on an electric field to make it stretch and fiberize, and the fibers obtained are directly gathered on the collection surface of the collector, and the above-mentioned collection surface is moved in a certain direction while forming A fiber aggregate; it is characterized in that: the above-mentioned spinning dope ejection part is carried on a support body that can move around a circular orbit between a pair of rotating shafts, and the direction of motion in the linear motion region of the above-mentioned circular orbit is the same as that of the above-mentioned The spinning dope is jetted from the spinning dope jetting section while the above-mentioned support body is looped at a constant speed in a state where the width direction of the collecting surface is aligned.

Owner:JAPAN VILENE CO LTD

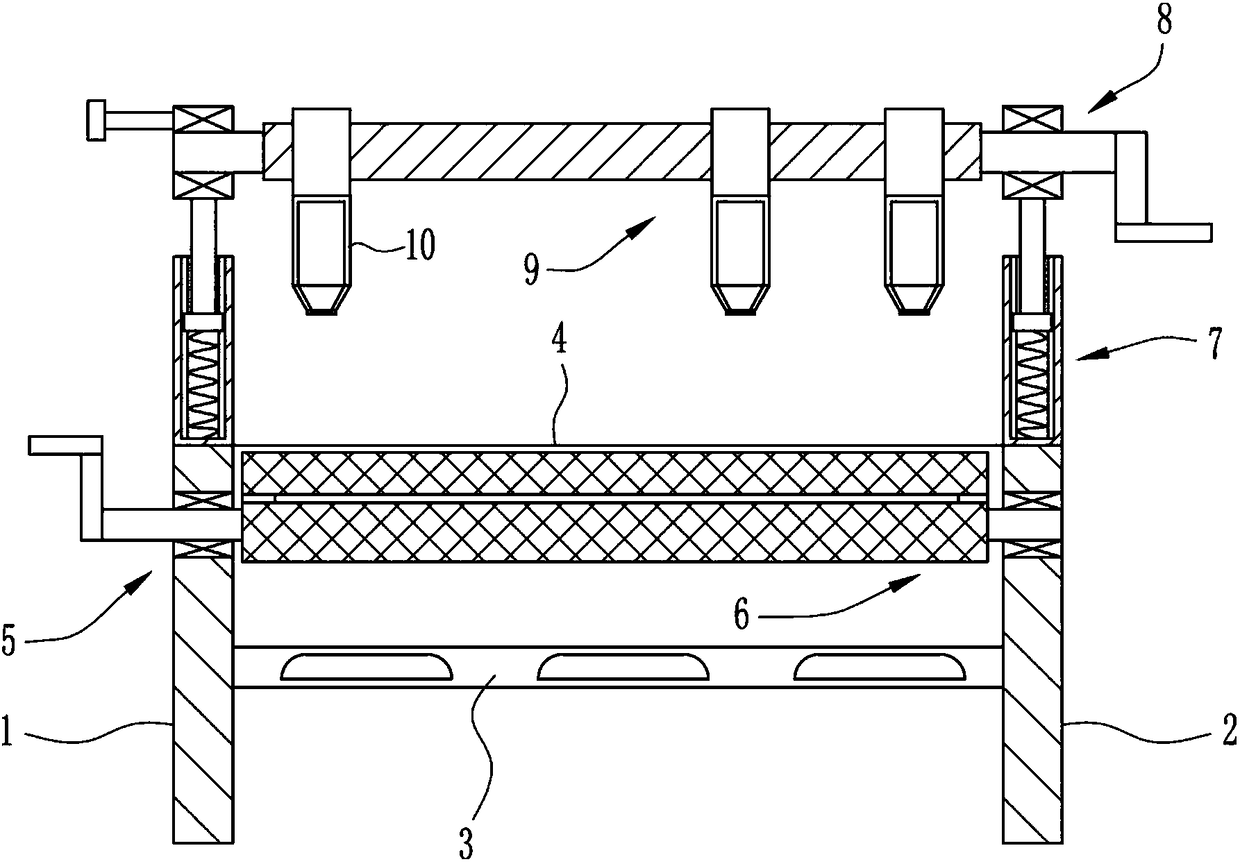

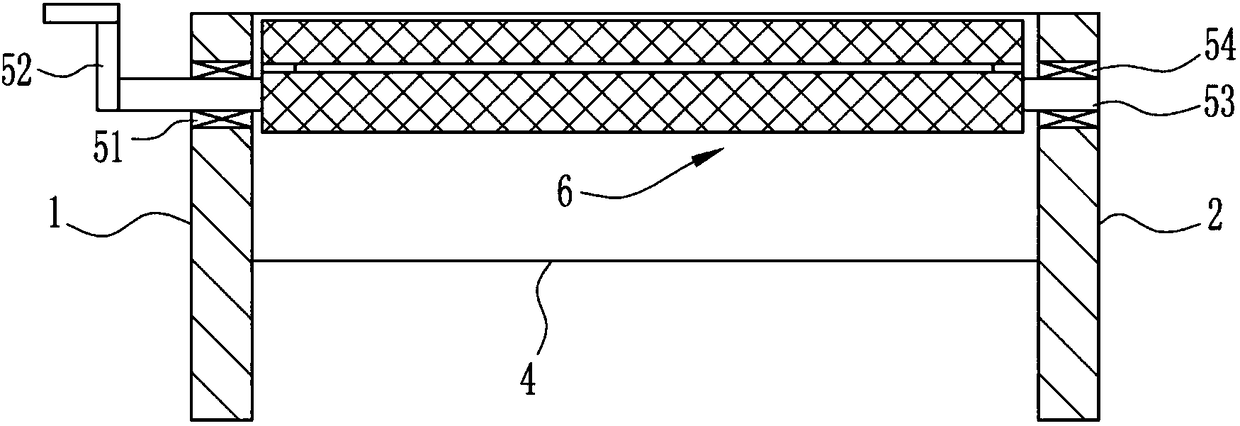

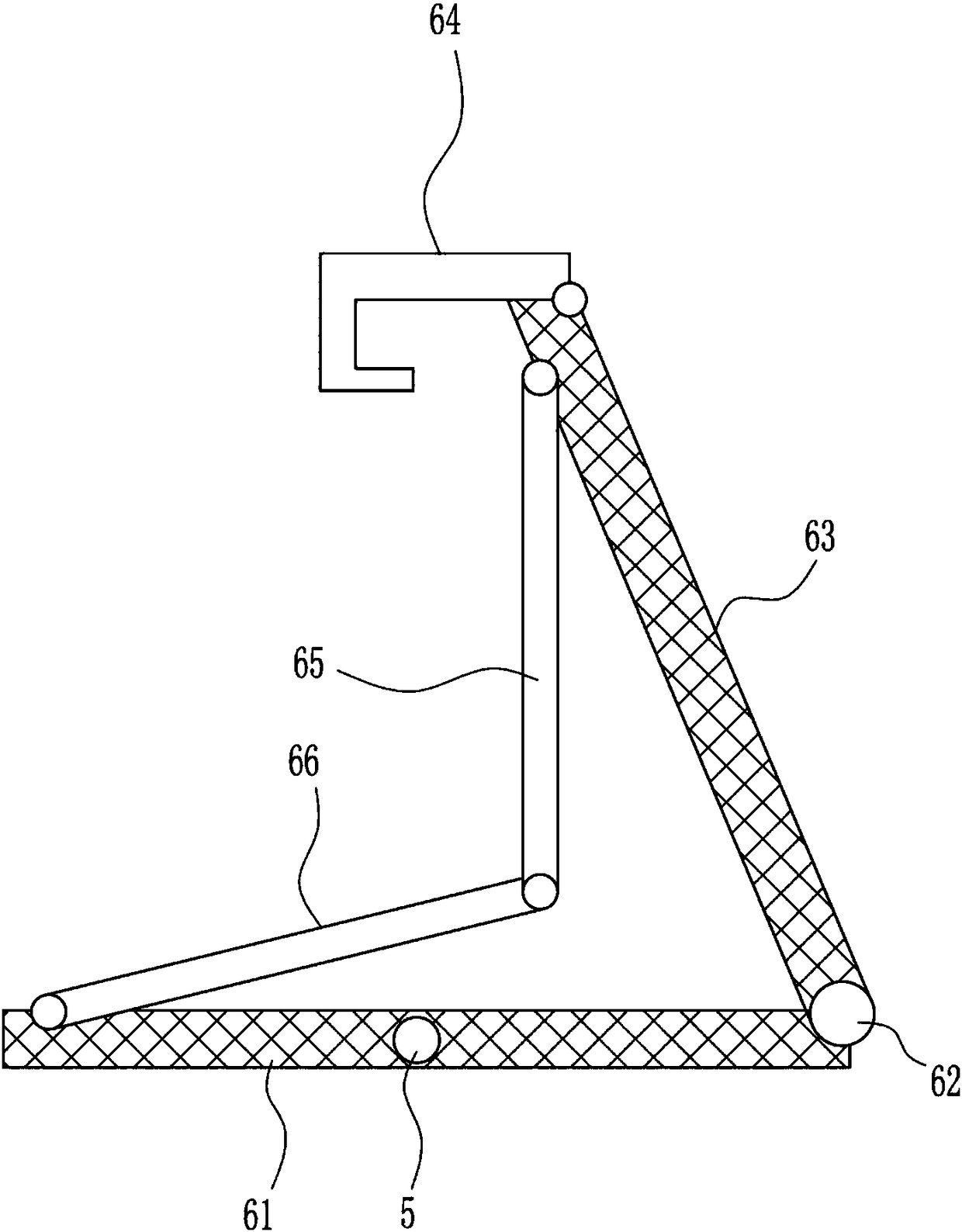

Meat baking grill for food processing

The invention relates to a grill, in particular to a meat baking grill for food processing. The meat baking grill for food processing can bake meat conveniently and adjust taste of the meat conveniently. In order to solve the technical problem, the meat baking grill for food processing comprises a first support, a second support, a baking plate, a mounting box, an overturning component, a clampingcomponent, a lifting component, a swinging component, a seasoning spreading component and a condiment; and the mounting box is fixedly connected to the first support and the second support, the baking plate is fixedly connected to the inner bottom surface of the mounting box, the overturning component is fixedly connected to the first support and the second support, and the clamping component isin transmission connection with an outputting end of the overturning component. Effects of baking meat conveniently and conveniently adjusting the taste of the meat are achieved.

Owner:杨馨蕊

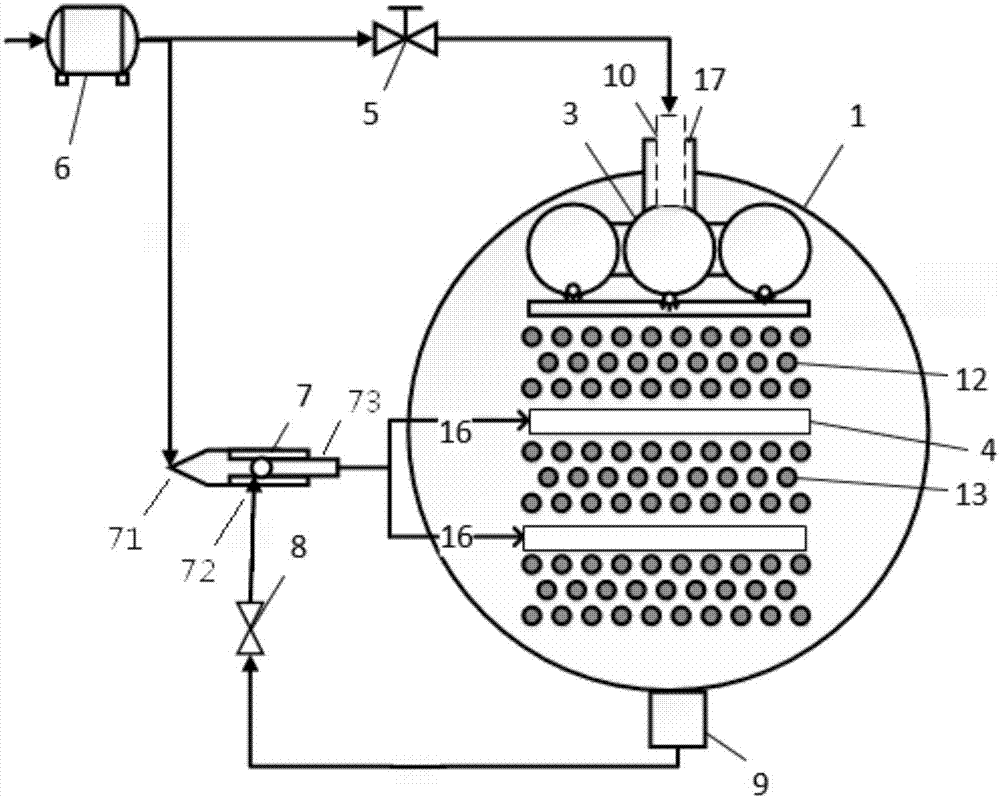

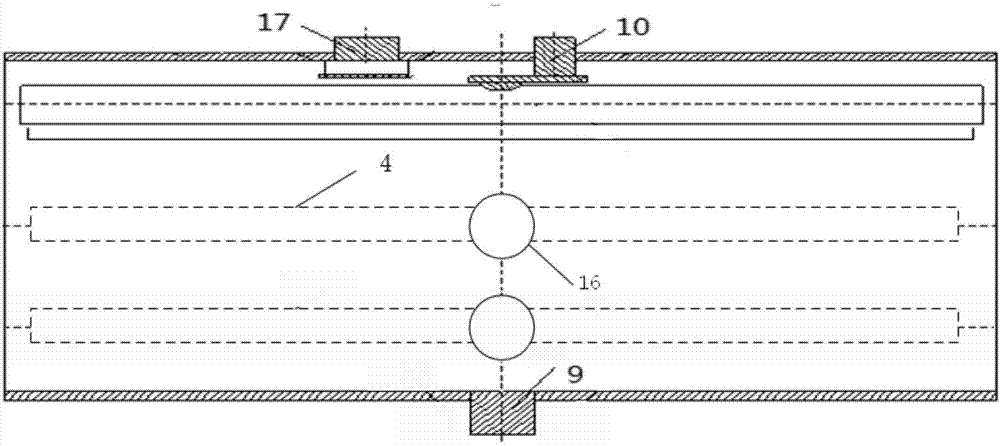

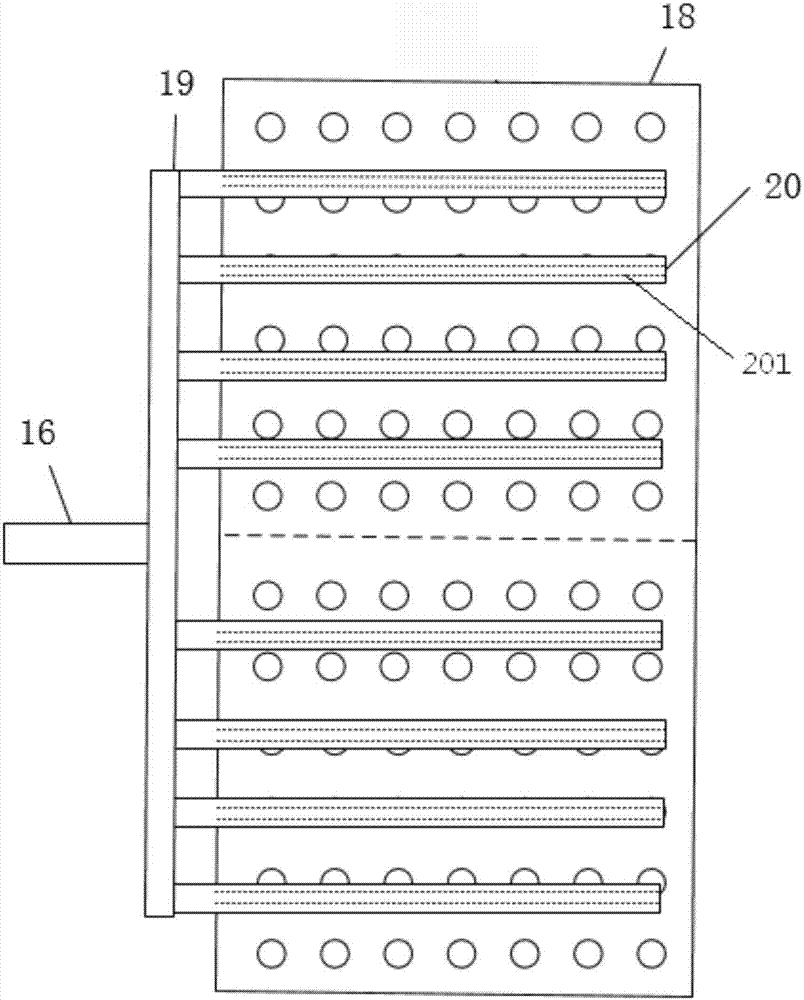

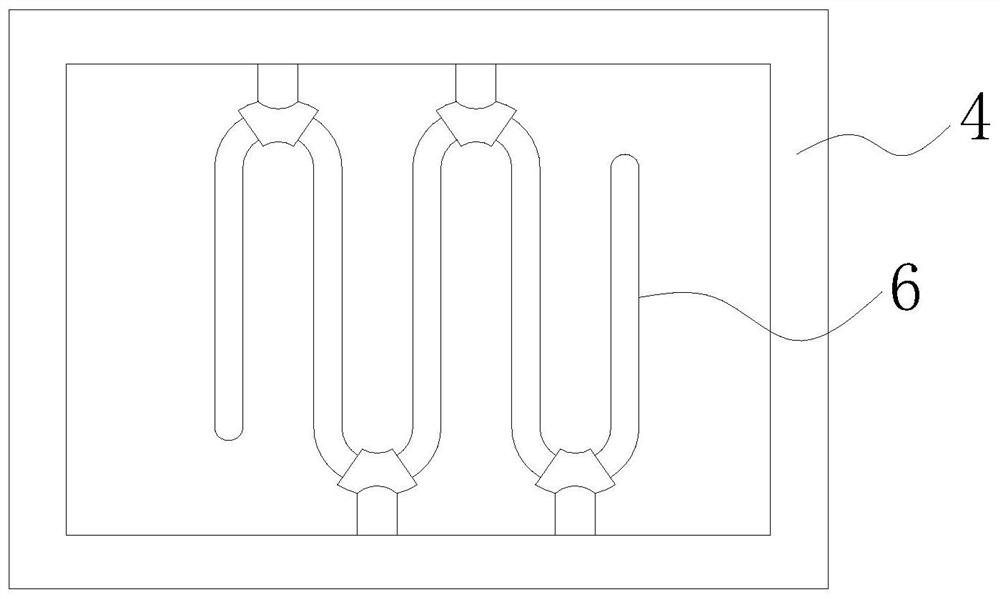

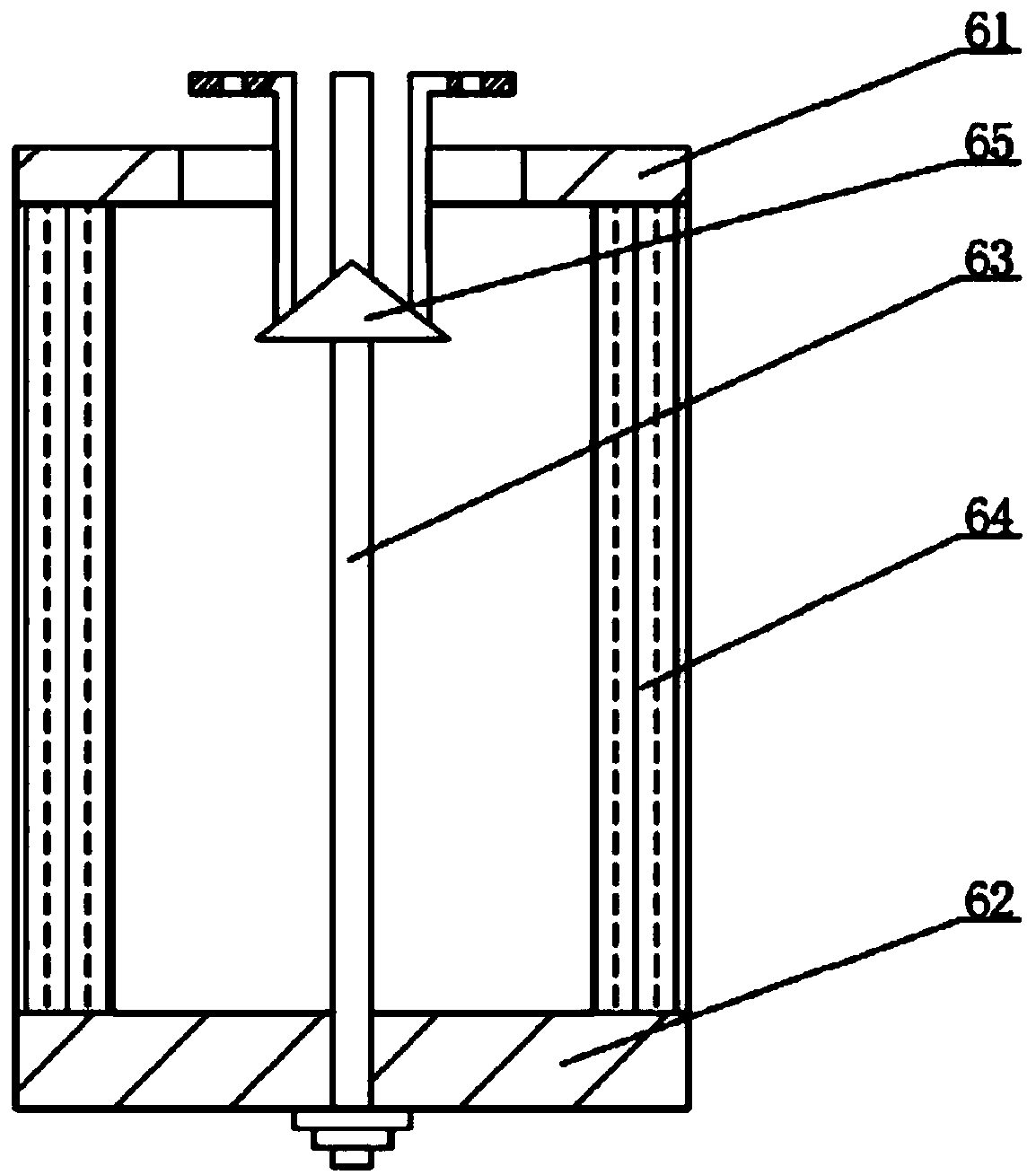

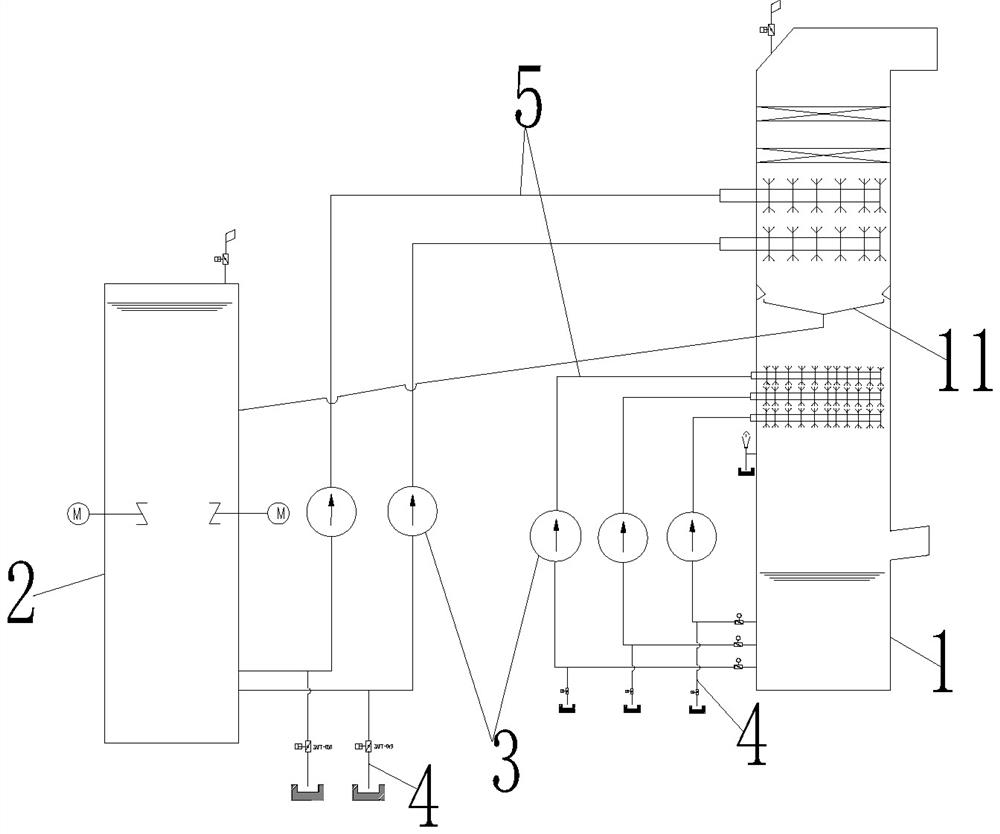

Horizontal tube falling film evaporator

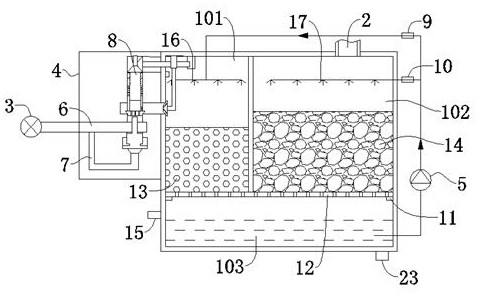

ActiveCN107490212AImprove heat transfer effectIncrease the amount of sprayingEvaporators/condensersAgricultural engineeringHigh pressure

The invention discloses a horizontal tube falling film evaporator. The horizontal tube falling film evaporator comprises a shell; the shell is connected with a high-pressure liquid storage unit; a first-level liquid distributor and a first-level heat exchange tube bank are arranged in the shell; a plurality of second-level liquid distributors are arranged below the first-level heat exchange tube bank, and a second-level heat exchange tube bank is correspondingly arranged below each second-level liquid distributor; and an ejector is connected to the bottom of the shell and comprises a high-pressure inlet, an ejection inlet and a mixing outlet, the high-pressure inlet is connected with the high-pressure liquid storage unit, the ejection inlet is connected with the bottom of the shell, and the mixing outlet is connected with the second-level liquid distributors. According to the horizontal tube falling film evaporator, an ejector circulating device is adopted to suck unevaporated liquid refrigerant at the bottom of the evaporator into the second-level liquid distributors, cycle spraying of the liquid refrigerant is achieved, thus the distribution uniformity of the refrigerant on the outer surfaces of the tube banks on the lower portion of the evaporator is improved, and the purposes of eliminating dry spots outside a tube and enhancing the overall heat exchange performance of the evaporator are achieved.

Owner:NANJING NORMAL UNIVERSITY

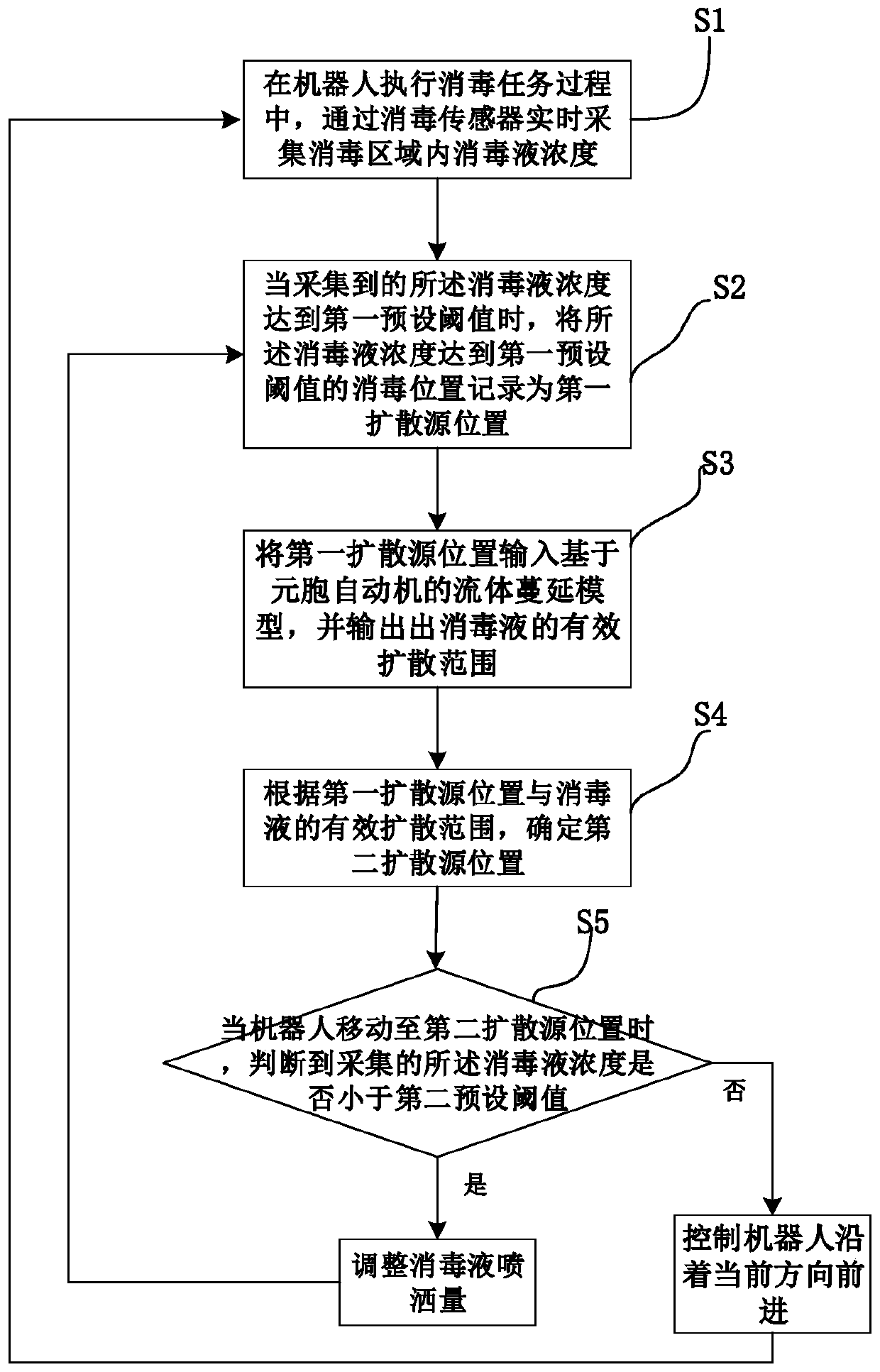

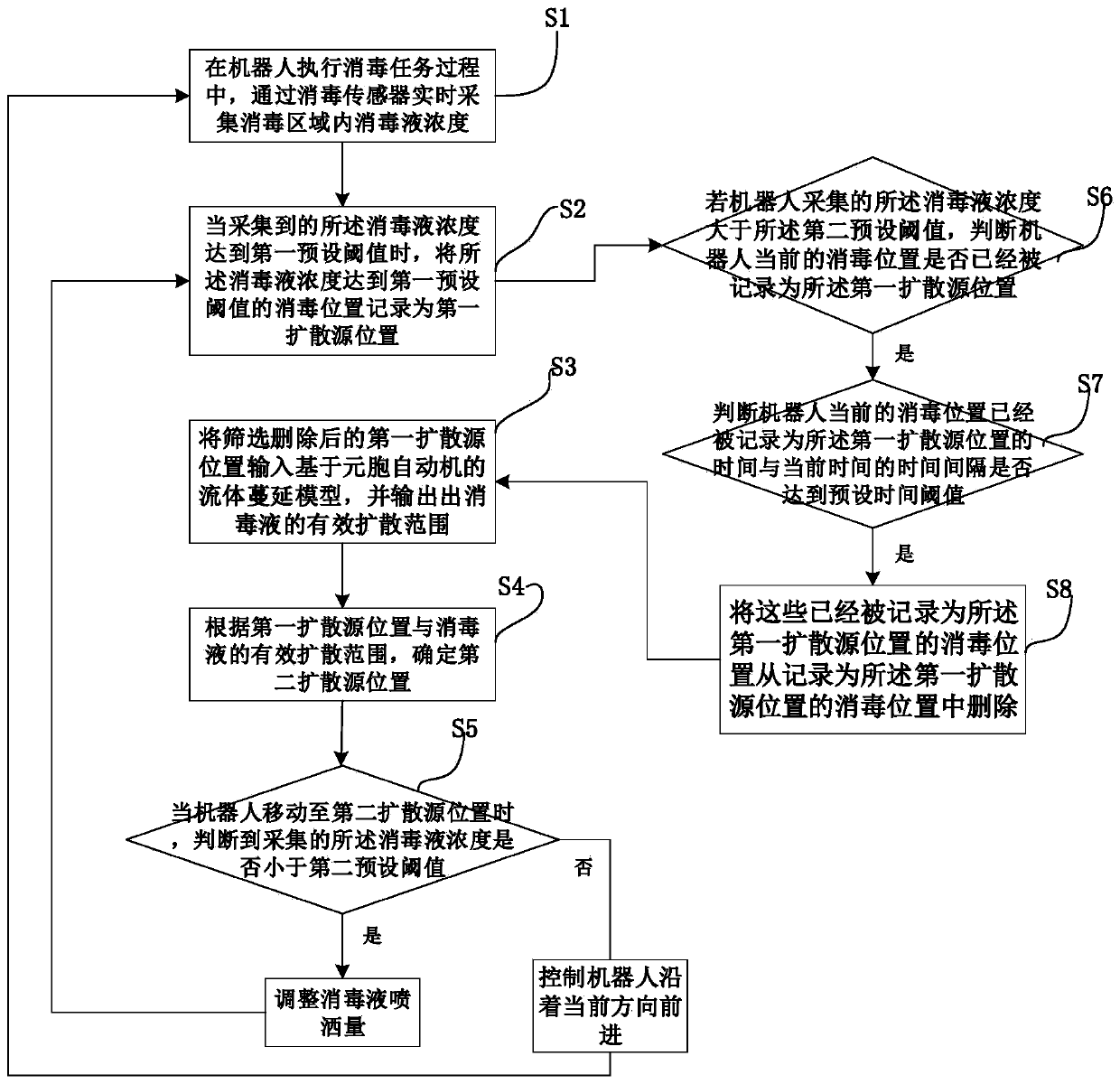

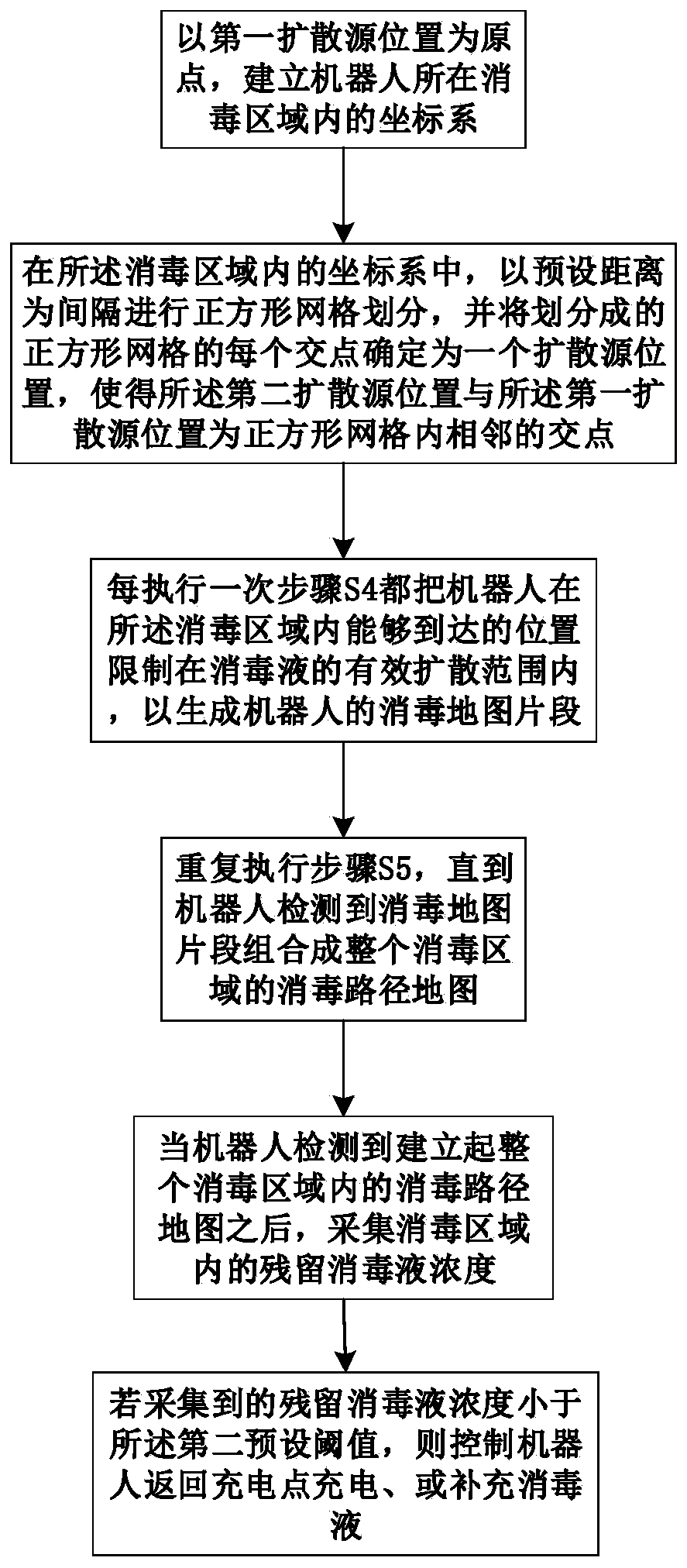

Disinfection method with robot

ActiveCN111317846AGuaranteed validityAvoid re-sterilizationLavatory sanitoryAtomized substancesCellular automationSimulation

The invention discloses a disinfection method with a robot. The method comprises the following steps: S1, the robot collects concentration of a disinfection solution in a disinfection area in real time through a disinfection sensor; S2, when the collected concentration reaches a first preset threshold value, recording a disinfection position where the concentration reaches the first preset threshold value as a first diffusion source position; S3, inputting the position of the first diffusion source into a fluid spreading model based on a cellular automata, and outputting an effective diffusionrange of the disinfection solution; S4, determining a second diffusion source position according to the first diffusion source position and the effective diffusion range of the disinfection solution;S5, when the robot moves to the second diffusion source position, judging whether the collected concentration of the disinfection solution is smaller than a second preset threshold value, if so, adjusting the spraying amount of the disinfection solution, returning to step S2, otherwise, controlling the robot to advance along the current direction, and returning to step S1; wherein the first preset threshold value is larger than the second preset threshold value.

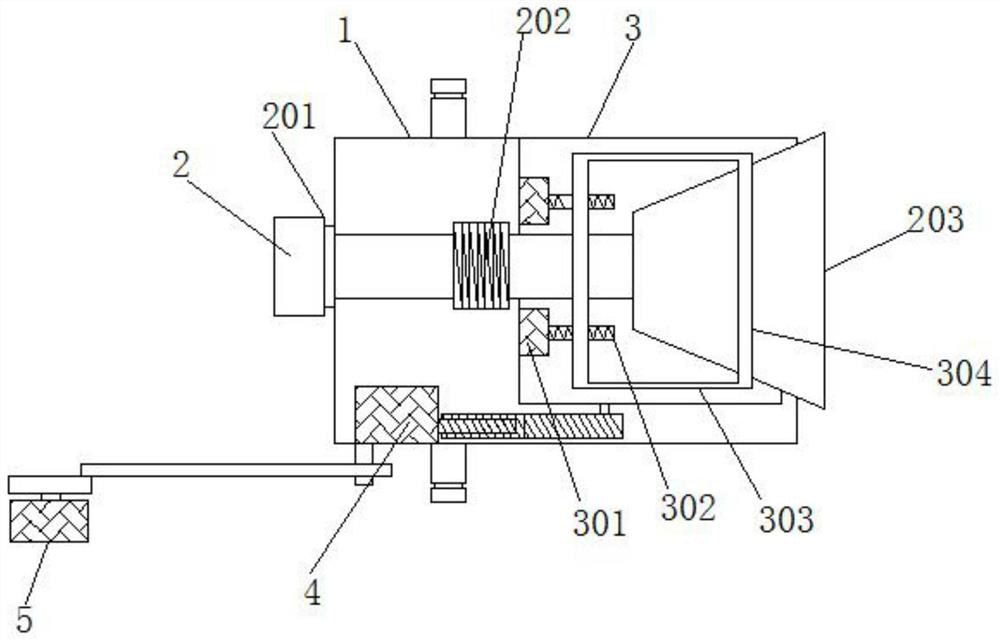

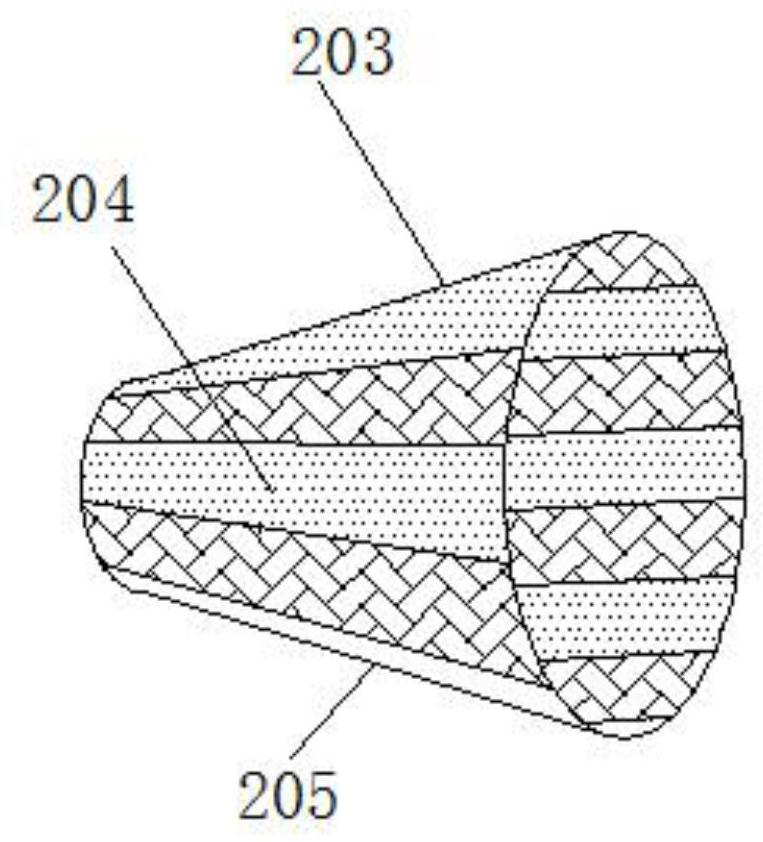

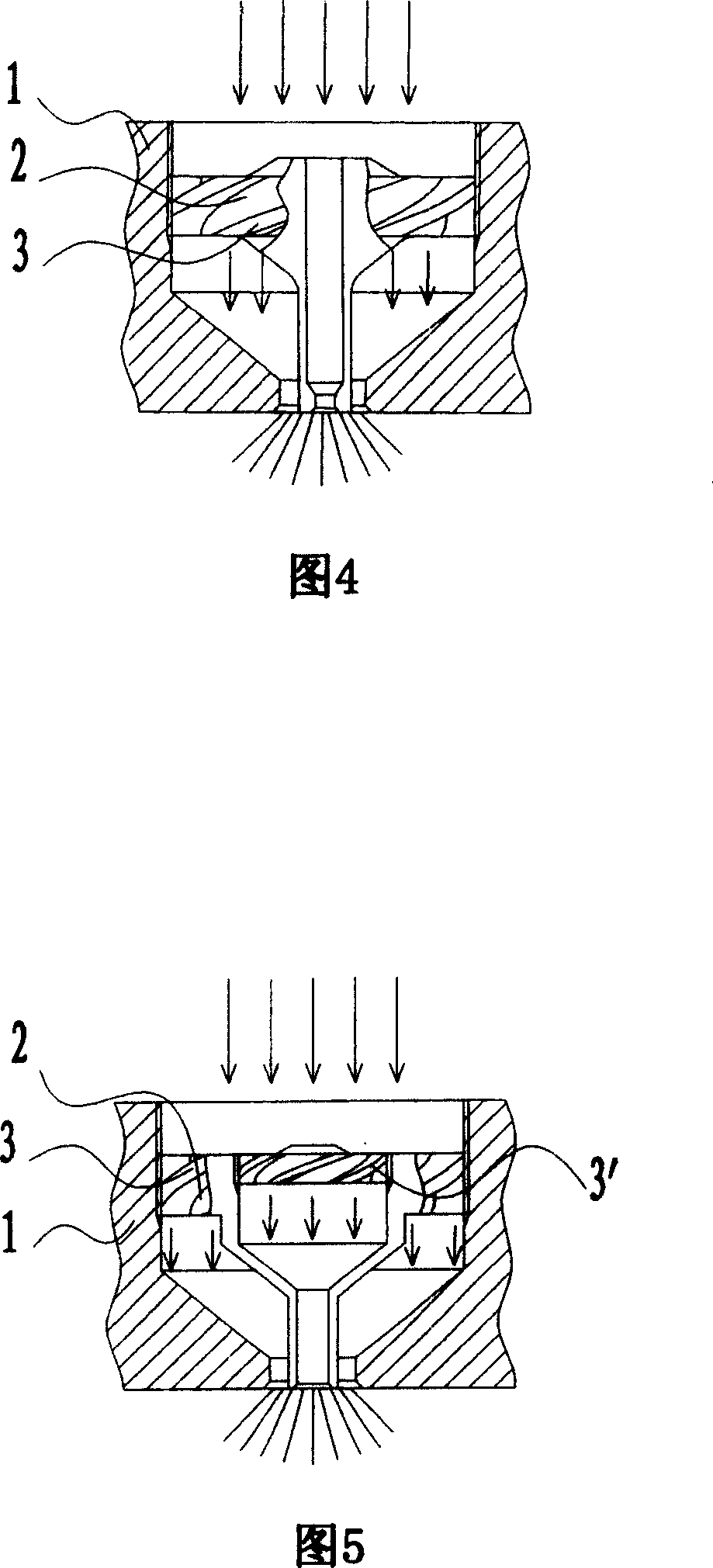

High-speed high-pressure spiral nozzle

InactiveCN101607233AReduce energy lossIncrease the amount of sprayingSpray nozzlesSpiral bladeHigh pressure

The invention relates to a high-speed high-pressure spiral nozzle, which is characterized in that the nozzle consists of a shell and a core body; the nozzle is made of stainless steel through cast forming; the shell is in a water-glass shape; the external contour of the shell is a round or eight-angle polygonal body; the whole shell is divided into a thread section, a transition section, a contraction section, a throat channel and a diffusion section; a big end provided with an inner thread in a glass hole is the thread section; the surface of the transition section is a round hole matched with the outer circle of the core body; the contraction section is a conical hole; the upper end of the throat channel is in arc transition connection with the lower end of the contraction section; the diffusion section is positioned in an outlet of the throat channel and is in a bellmouth shape; the middle of the core body is provided with a vertical plate; and two sides of the core body are provided with double-line spiral blades connected with the transition section of the shell through the vertical plate of the core body. The high-speed high-pressure spiral nozzle has the characteristics of low spray-body energy loss, large spray amount, stable uniform spray area and insusceptibility to blockage. The nozzle is made of stainless steel and has the advantages of wear resistance, corrosion resistance, long life span and wide application range.

Owner:洪梅

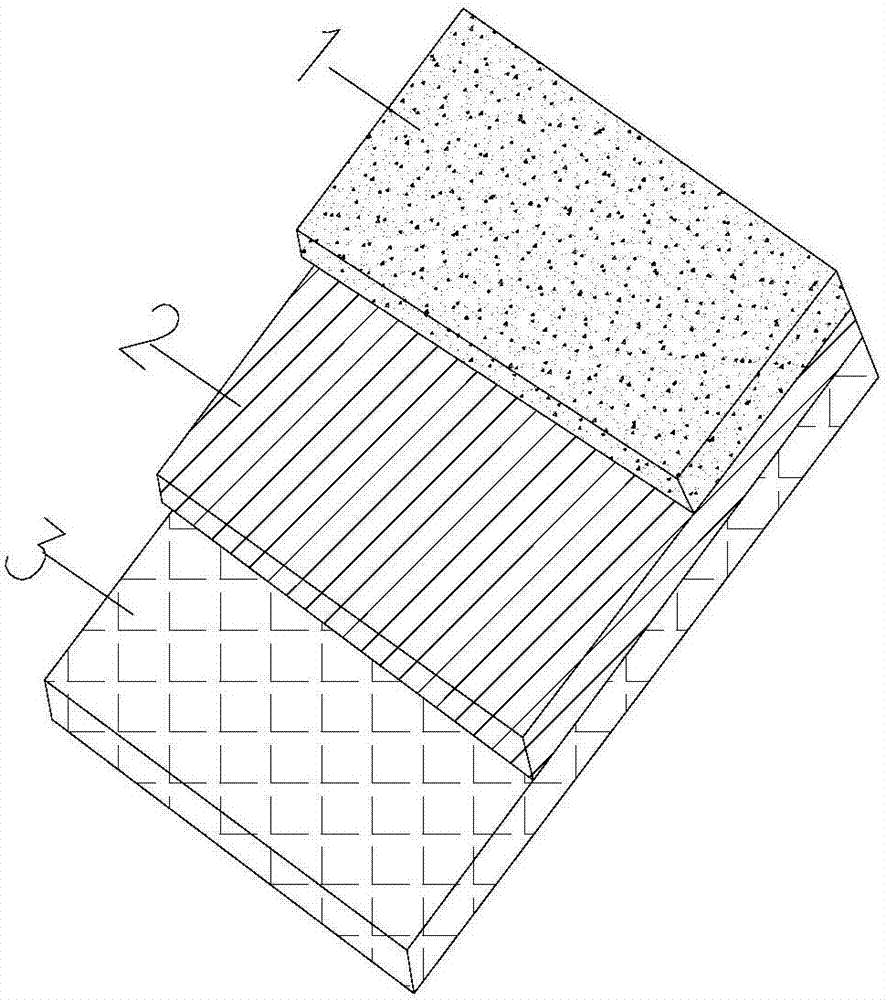

Interlayer structure construction method of asphalt pavement

The invention discloses an interlayer structure construction method of an asphalt pavement. The interlayer structure construction method includes the following steps of cleaning an under bearing layer of the pavement; sprinkling rubber asphalt; sprinkling rubbles; and rolling into the shape. The interlayer structure construction method of the asphalt pavement has the advantages of being high in bonding strength between layers, good in water tightness, excellent in anti-shearing performance, deferring reflection cracks, convenient to construct, low in comprehensive cost and the like. By adoption of the interlayer structure construction method of the asphalt pavement, construction work can be done without closing to traffic or closing to traffic for a short term, therefore, the interlayer structure construction method of the asphalt pavement can not only be suitable for a bonding layer between asphalt surfaces of newly-built roads, but also particularly suitable for repairing and maintaining projects for asphalt surfaces of urban roads.

Owner:北京特希达交通勘察设计院有限公司

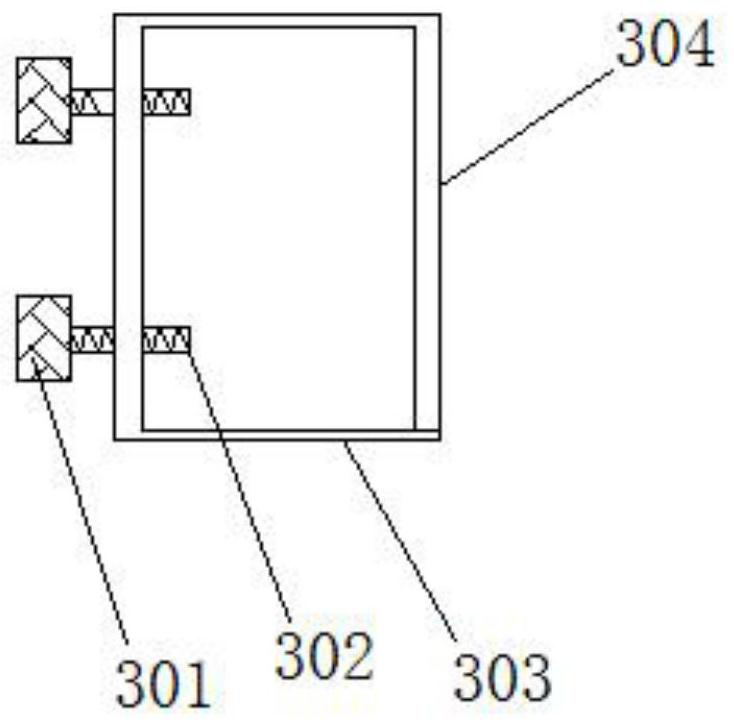

Combined template mechanism for mold spraying

PendingCN109372550AIncrease the amount of concrete pouredImprove spraying efficiencyUnderground chambersTunnel liningEngineering

The invention discloses a combined template mechanism for mold spraying. The combined template mechanism comprises a template group which is formed by connecting more than two single templates in thetransverse direction and / or the vertical direction in a foldable / turnover manner. An integrated template formed after the template group is unfolded can be matched with an excavated rock surface to form at least one mold cavity. The template group is connected to a machine frame or a carrier, and unfolding-folding control mechanisms are arranged between the single templates of the template group. The overall area of the mold cavity enclosed by the template group and a steel arch on the excavated rock surface is increased, and the amount of concrete sprayed after single movement of the template group is increased. Meanwhile, the problem of concrete leakage caused by cracks between steel arch and rock surface and between the template group and the steel arch is effectively avoided. Through a newly designed side mold mechanism, a mold cavity is formed directly among a template mechanism, the side mold mechanism and the rock surface, and the efficiency of mold spraying pouring is further improved.

Owner:SICHUAN LANHAI ENG EQUIP MFG CO LTD

Washing device

InactiveCN108212921AImprove yieldAvoid poor useCleaning using liquidsOrganic electroluminescenceEngineering

The invention relates to the technical field of base plate washing, and discloses a washing device, which comprises a conveying mechanism for conveying a base plate to be washed along a first direction, and an ultrasonic washing unit, a drug liquid washing unit, a two-fluid washing unit, a pure water washing unit and a drying unit opposite to the conveying mechanism and sequentially arranged alongthe first direction. Therefore, the washing device is used for washing the base plate to be washed through multiple washing steps, so that a polishing solution remained on the surface of the base plate can be thoroughly washed, the yield of the base plate is improved, and the occurrence of the phenomenon that a use effect of an organic electroluminescence device is poorer due to the polishing solution remained on the base plate is avoided.

Owner:ZAOZHUANG VISIONOX ELECTRONICS TECH CO LTD

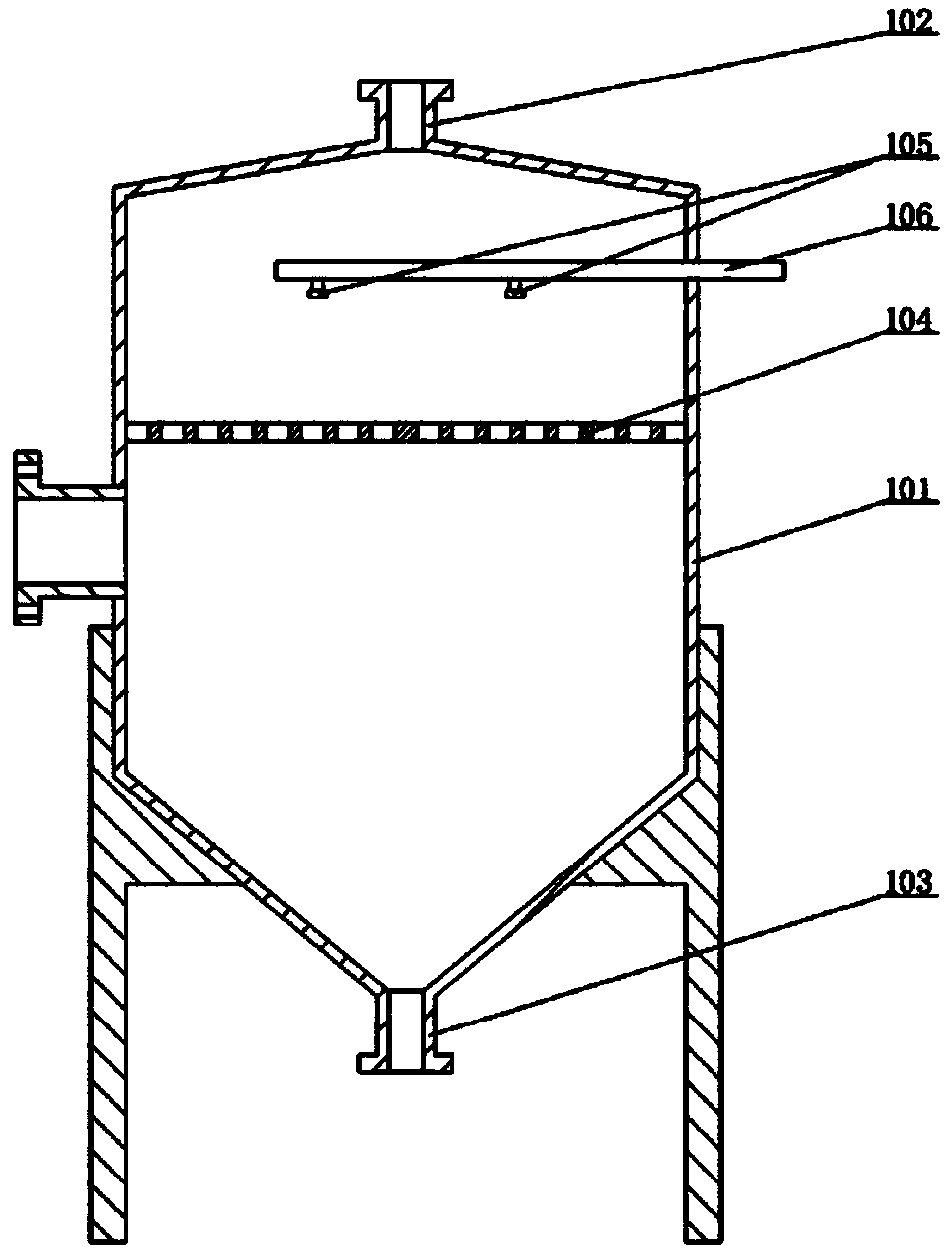

Water storage tank having function of saving water resources, for garden irrigation

ActiveCN111387028AReduce evaporative lossAchieving tightnessGeneral water supply conservationWatering devicesWater storageWater storage tank

The invention discloses a water storage tank having a function of saving water resources, for garden irrigation. The water storage tank having the function of saving water resources, for garden irrigation comprises a water storing part and a control part, wherein the water storing part is used for storing rainwater; the control part is used for controlling the opening and closing of the water storing part; the water storing part comprises a tank body, a water inlet plate and a cover plate; a water inlet is formed in the upper side of the tank body; the water inlet plate is funnel-shaped and ismounted at the water inlet; the shape of the cover plate is the same as that of a cross section of the water inlet plate; the control part is mounted between the cover plate and the water inlet plate; the control part comprises a plurality of telescopic pipes, first memory alloy springs and first heat conducting blocks; the telescopic pipes are perpendicularly arranged, and two ends of each telescopic pipe are fixedly connected with the cover plate and the water inlet plate; and each first memory alloy spring is arranged in the corresponding telescopic pipe, and one end of each first memory alloy spring is connected with the corresponding first heat conducting block. Through the adoption of the water storage tank having the function of saving water resources, for garden irrigation disclosed by the invention, the effect of automatically opening and closing the cover plate is realized; in a sunny day, the side wall of the cover plate is in contact and propped against the water inlet plate, so that the inner part and the outer part of the tank body are isolated, the sealing effect is realized, and the evaporation loss of moisture in the tank body is greatly reduced.

Owner:厦门大标建设有限公司

Liquid atomizing device and liquid atomizing method

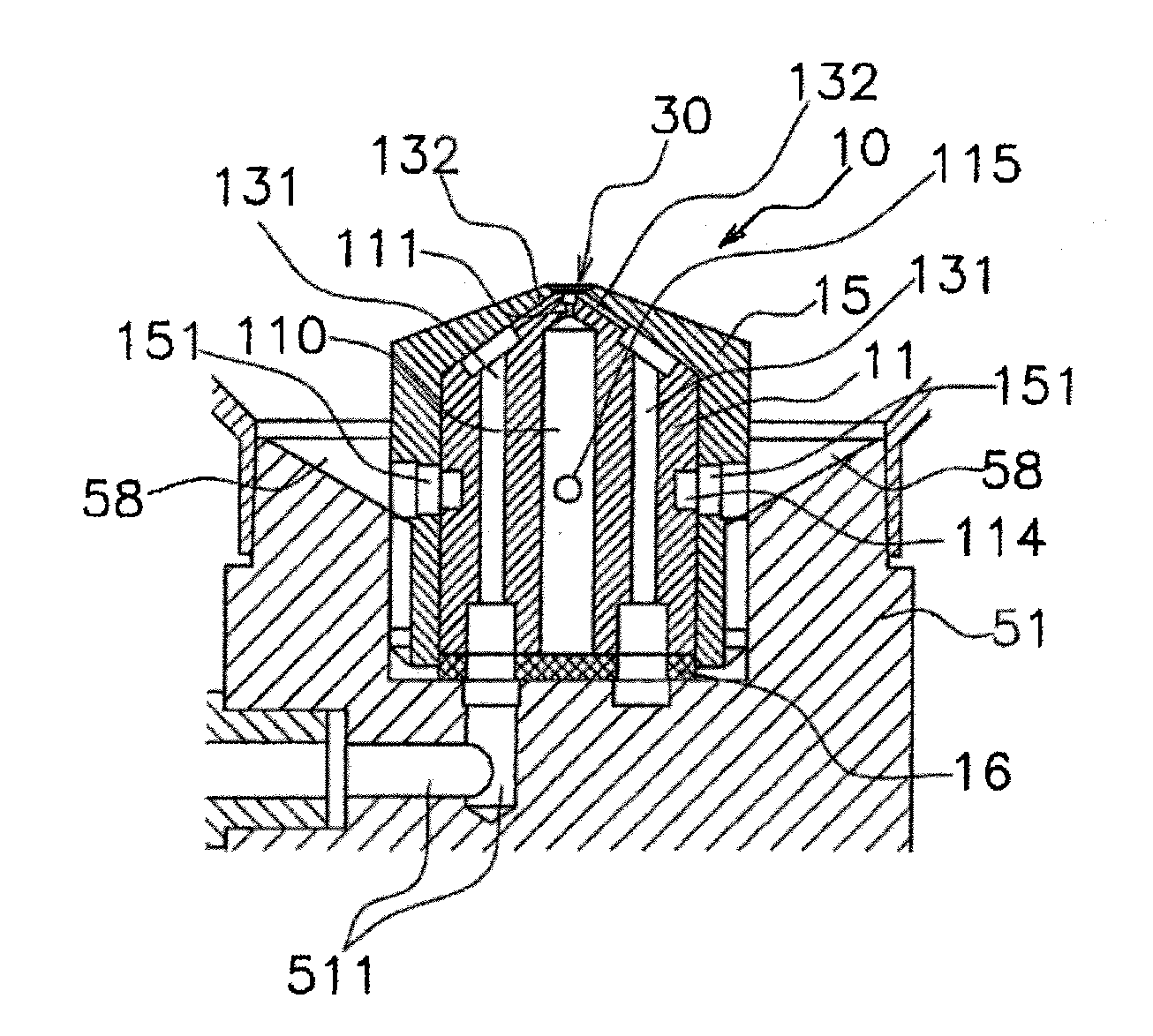

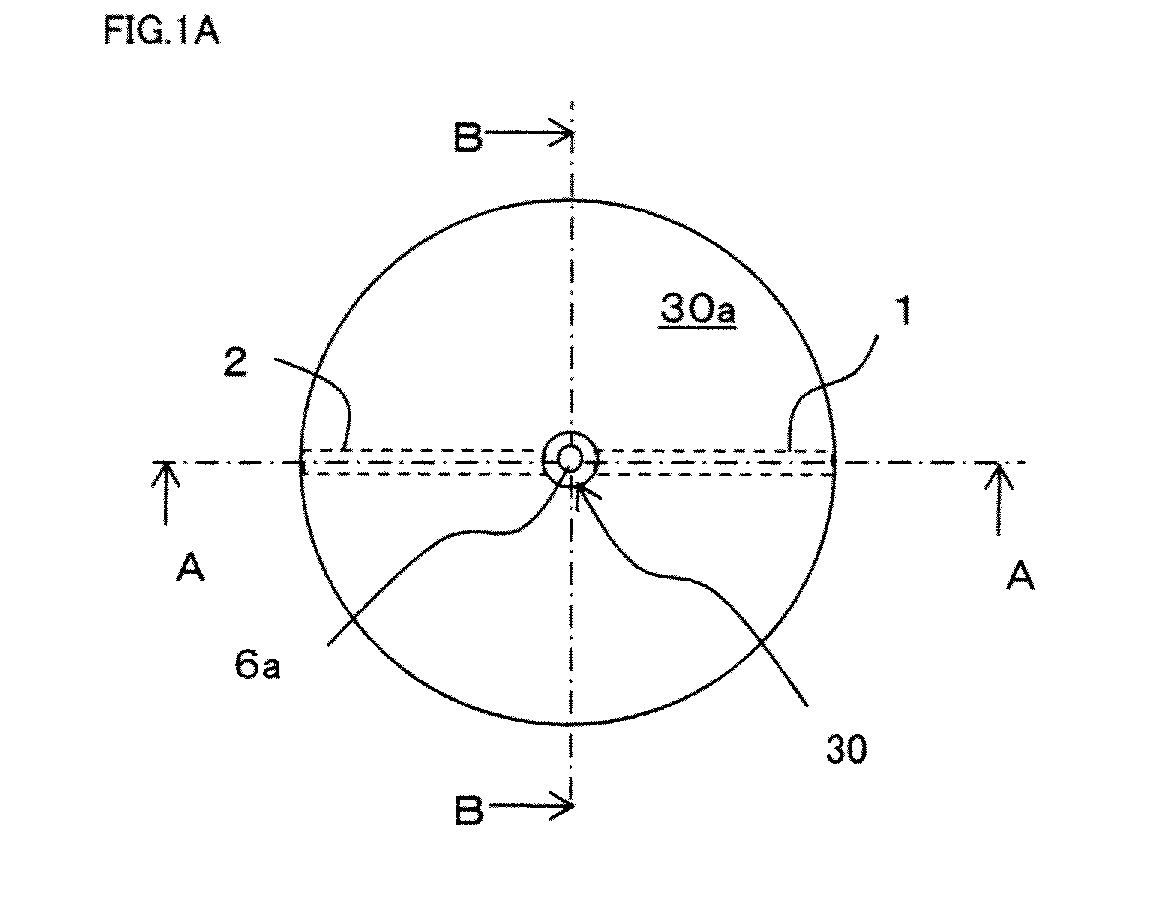

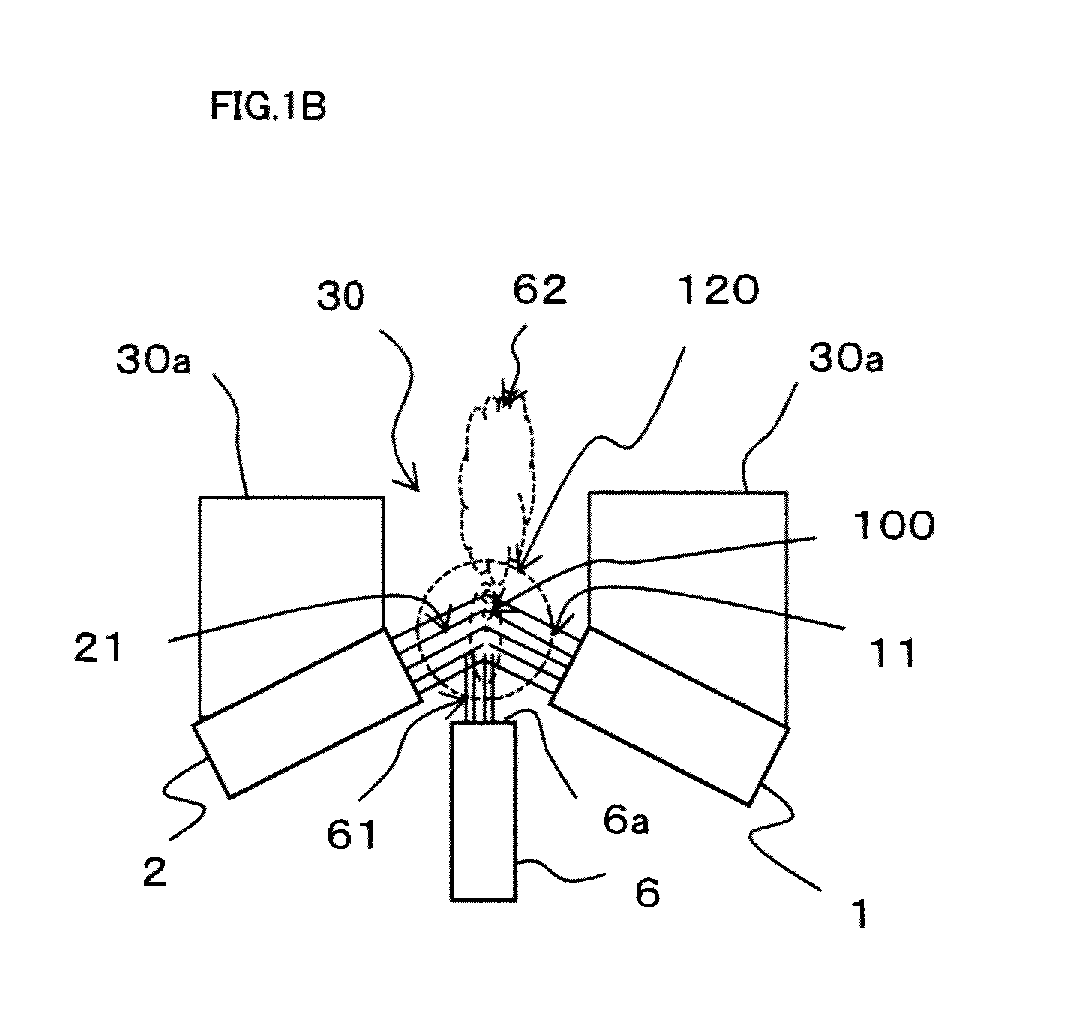

A liquid atomization device includes a nozzle body. The nozzle body includes: a first gas spray portion and a second gas spray portion for spraying two gas flows; a liquid passage having a passage through which liquid flows by formation of the two gas flows sprayed by the first gas spray portion and the second gas spray portion; a gas-liquid mixture area where the gas flow sprayed from the first gas spray portion and the gas flow sprayed from the second gas spray portion are made to collide against liquid which flows from the liquid passage to atomize the liquid; and a spray outlet for spraying mist atomized in the gas-liquid mixture area to outside.

Owner:NOZZLE NETWORK

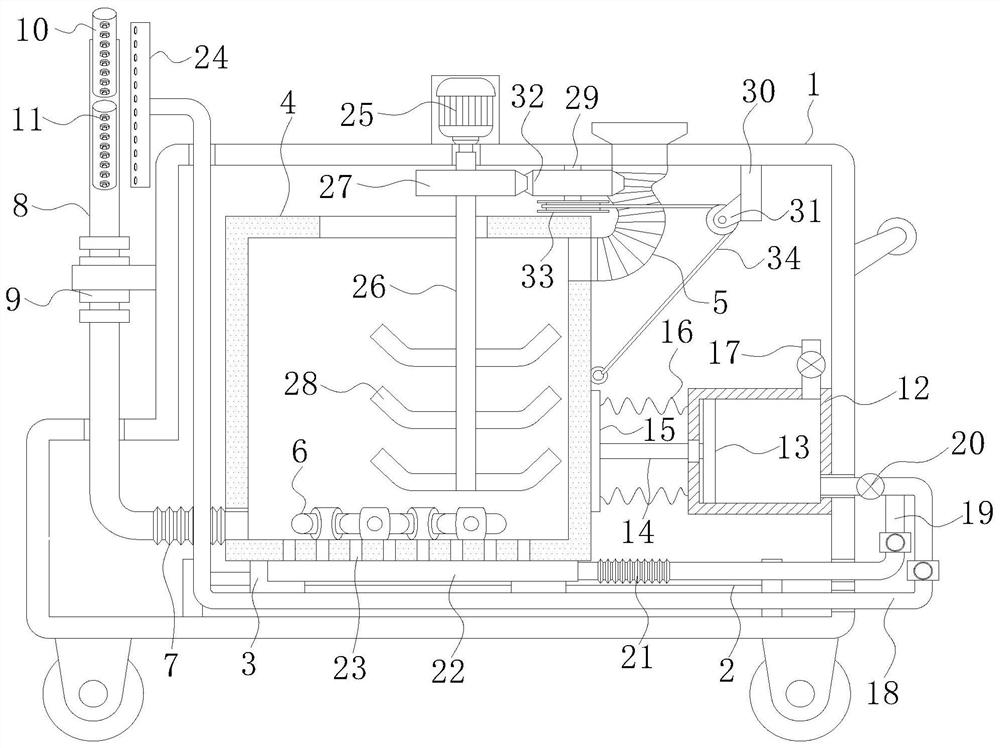

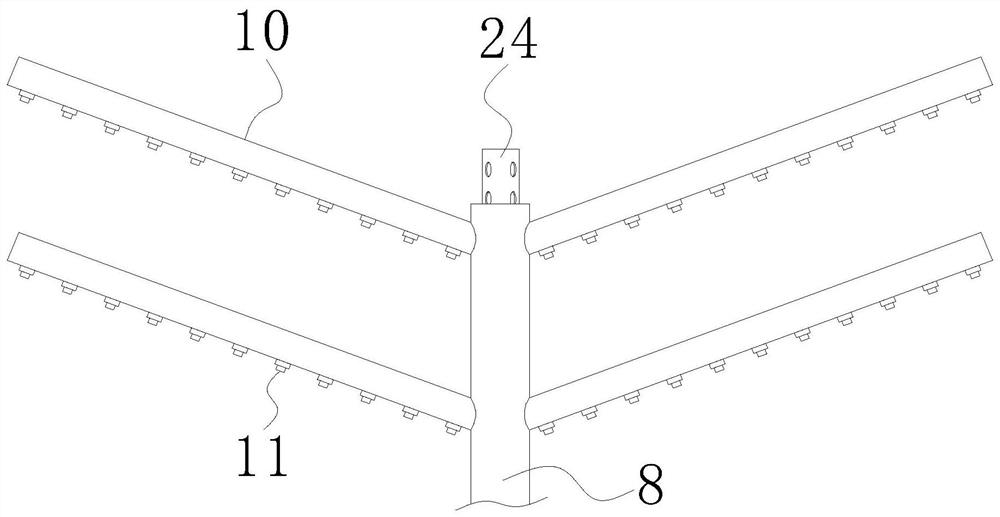

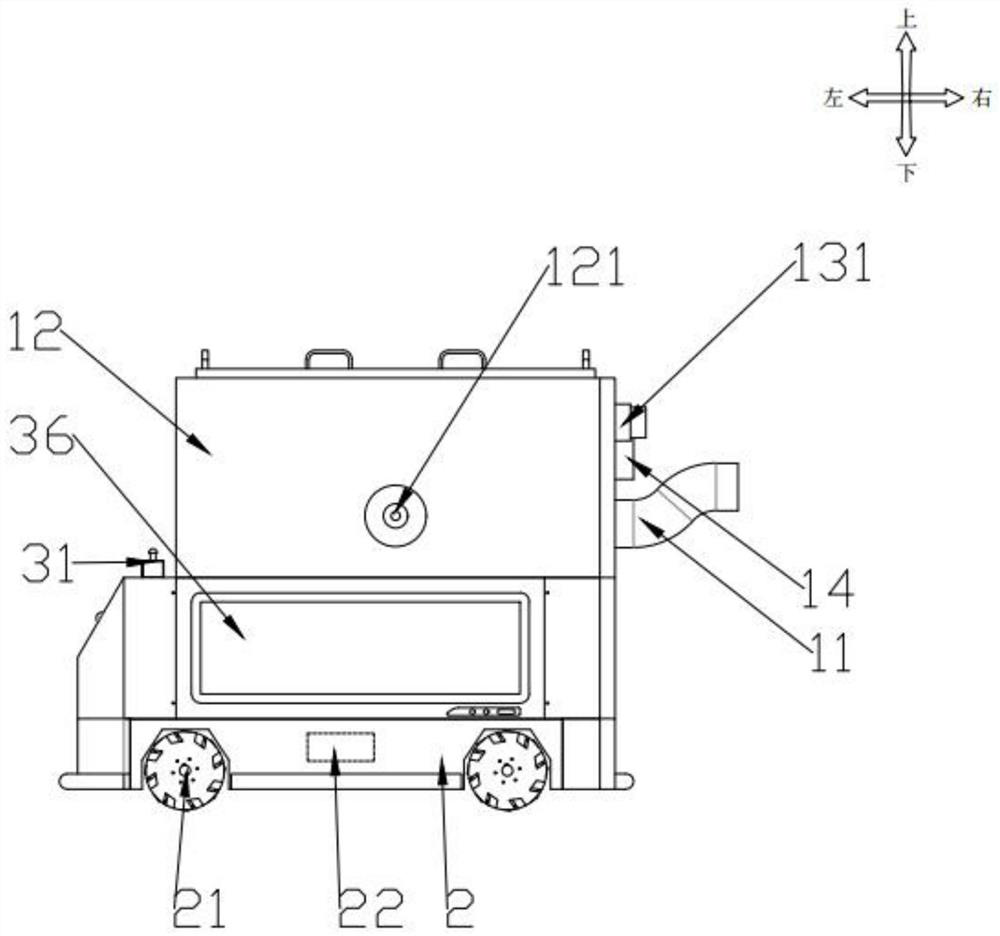

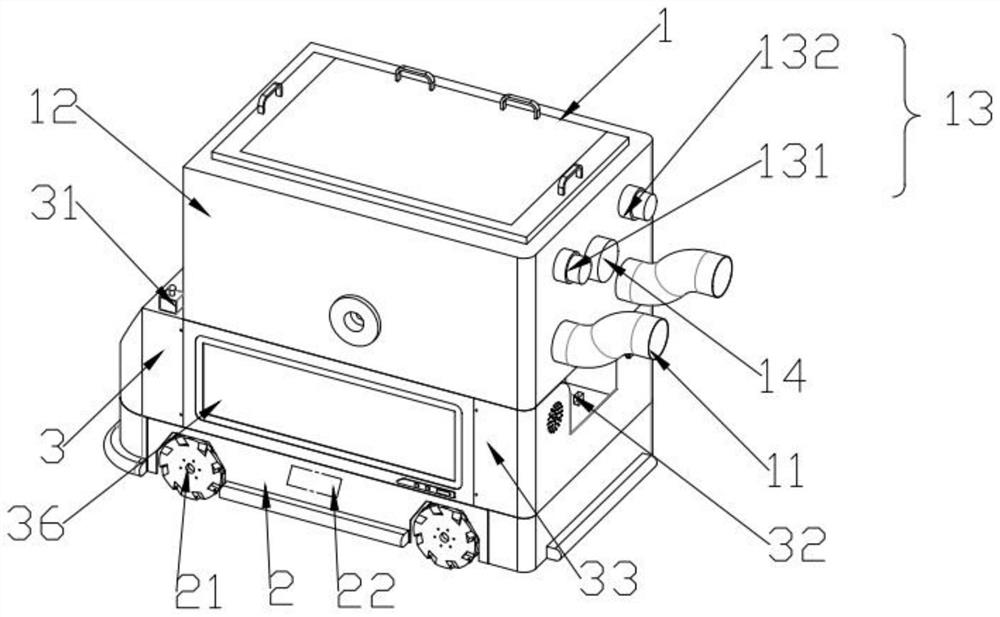

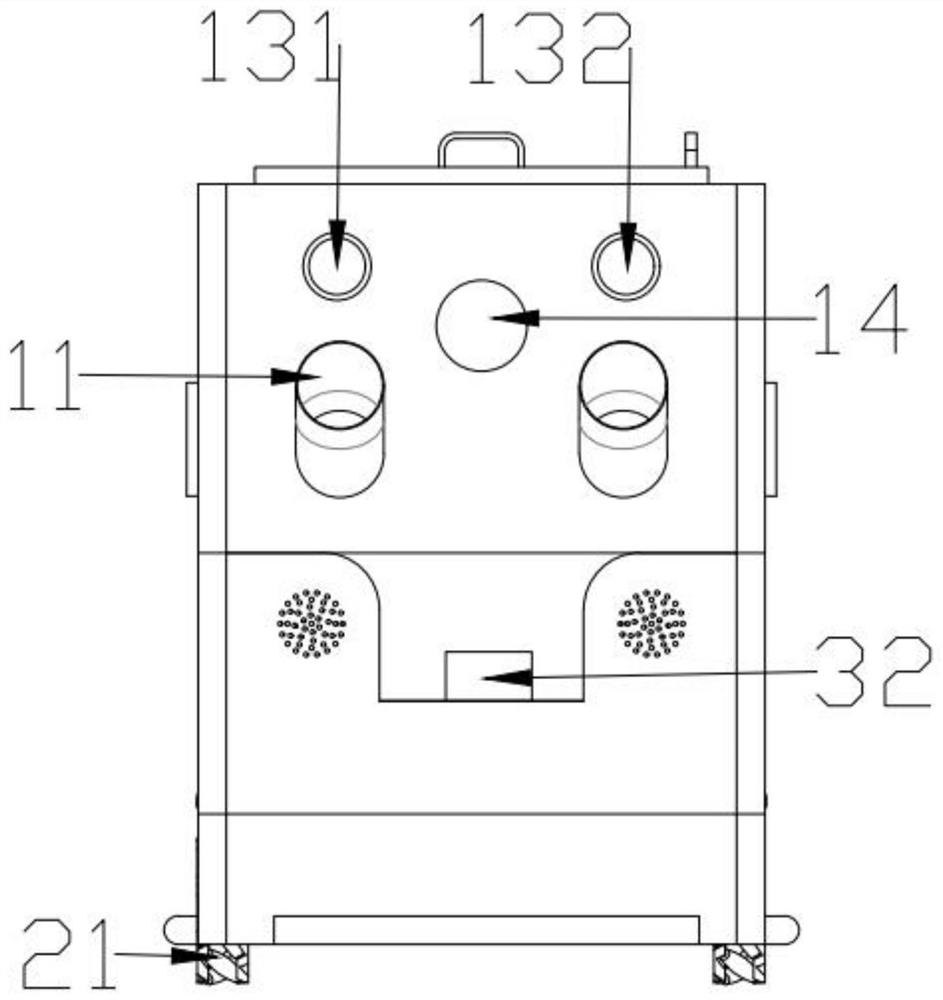

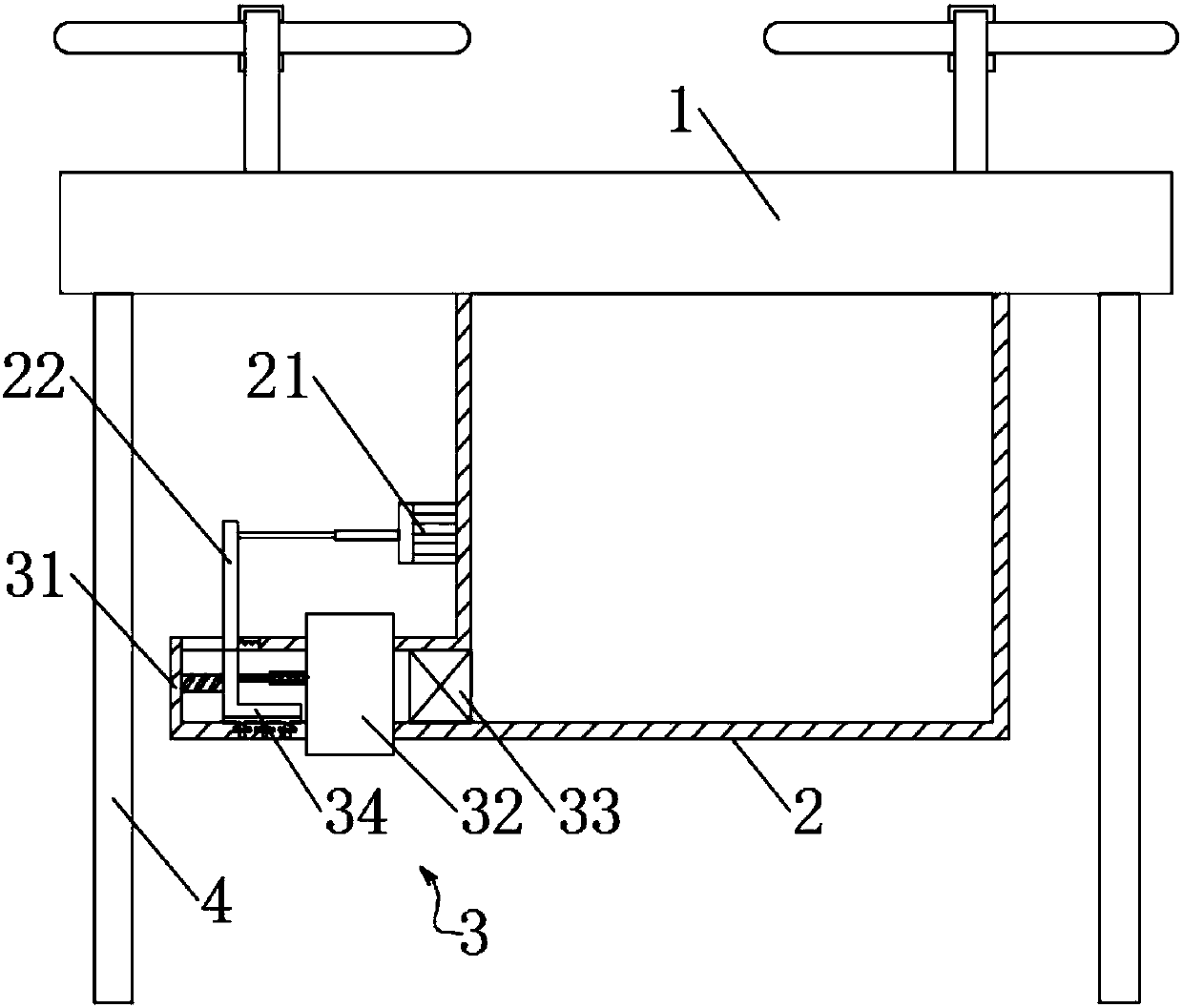

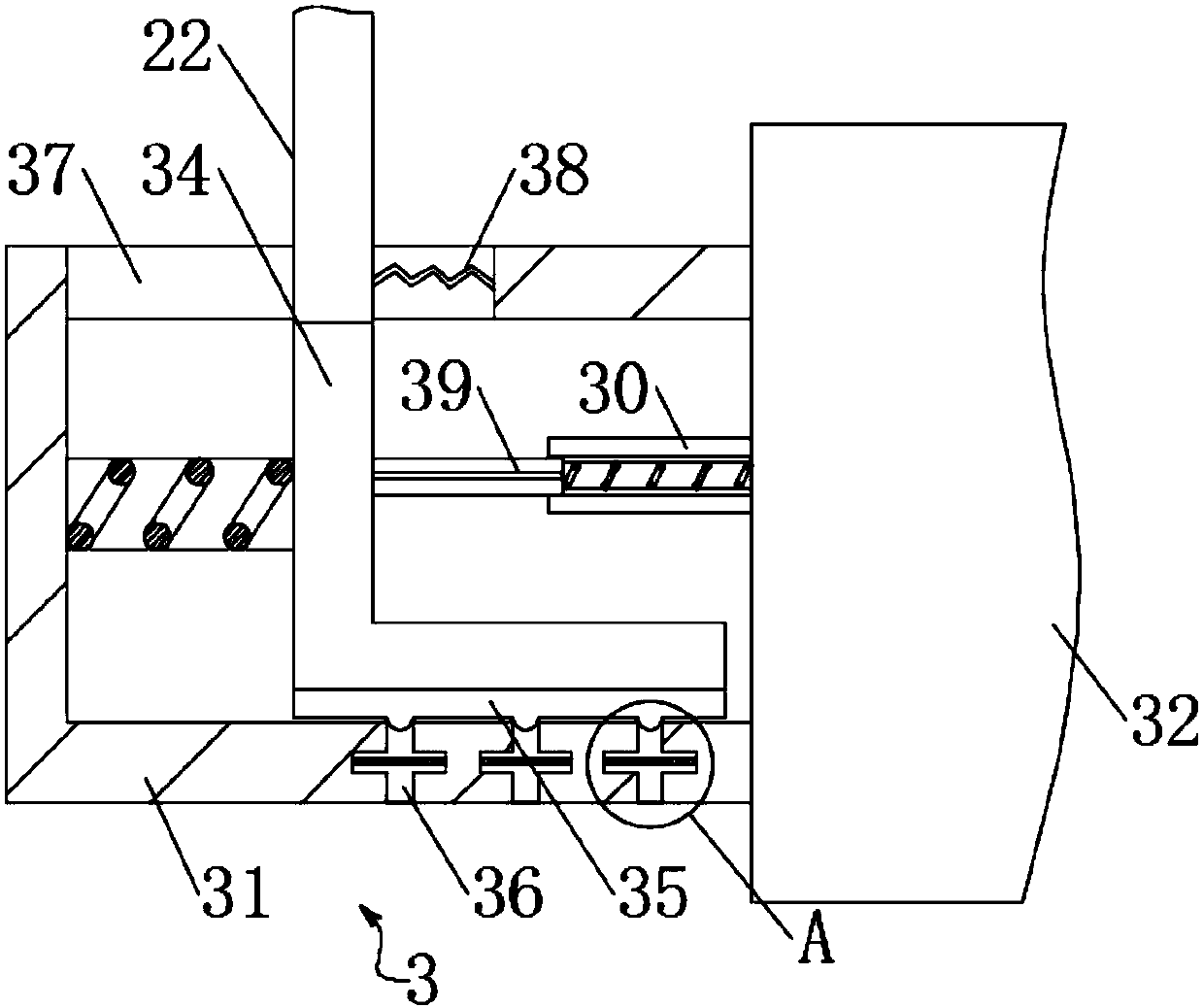

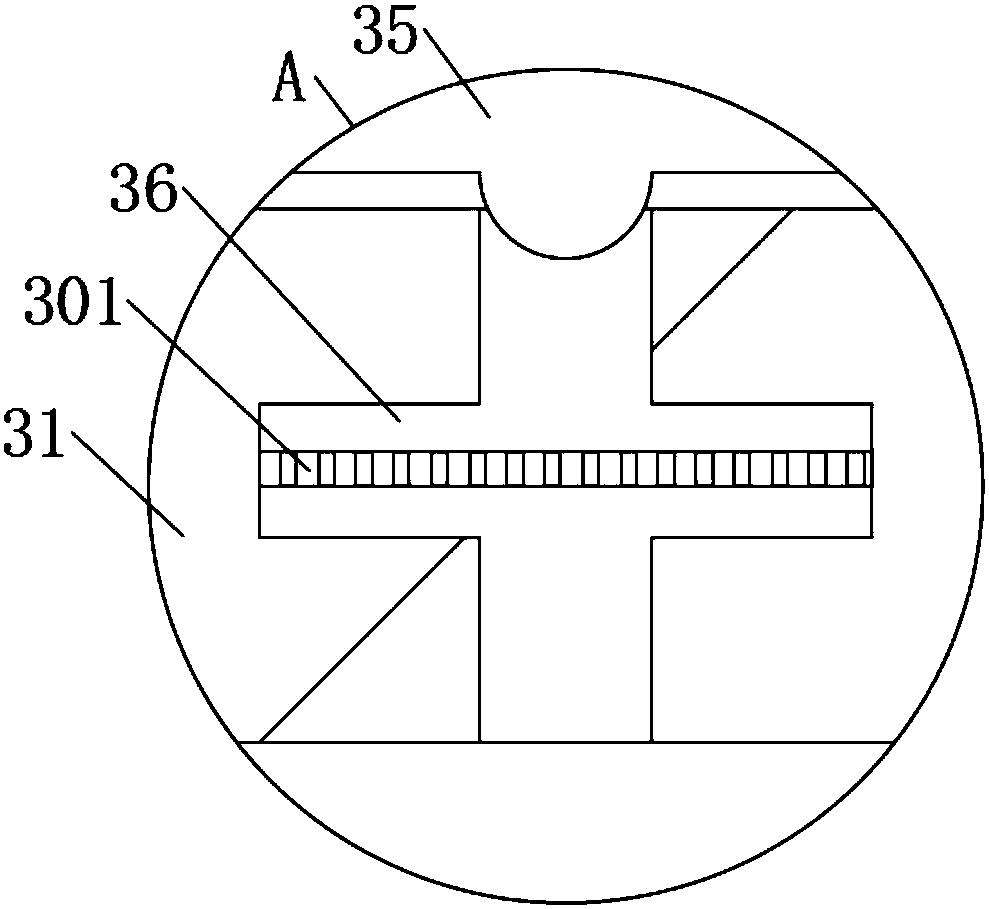

Henhouse disinfection vehicle

InactiveCN112494701AReduce laborComprehensive disinfectionSpraying apparatusLavatory sanitoryAgricultural engineeringStructural engineering

The invention relates to the technical field of henhouse disinfection vehicles, and discloses a henhouse disinfection vehicle. The henhouse disinfection vehicle comprises a vehicle box body, wherein rolling wheels are fixed at four corners of the bottom of the vehicle box body; a feeding hole is formed in the top of the vehicle box body; two sliding rods are fixedly arranged on the inner bottom wall of the vehicle box body through two groups of fixing blocks; sliding sleeves are movably connected to the outer circular surfaces of the sliding rods in a sleeving manner; a batching box is fixedlyarranged among the tops of the four sliding sleeves; a through opening is formed in the top of the batching box; a hose is arranged between the upper end of the right side wall of the batching box and the feeding hole in a communicating manner; and a heating pipe is fixedly arranged between the lower ends of the front inner wall and the rear inner wall of the batching box. The henhouse disinfection vehicle disclosed by the invention solves the problems that the existing henhouse disinfection spraying work efficiency is low, the manual labor amount is large, spraying is not uniform enough, andfixed large-scale spraying disinfection equipment is high in cost and cannot perform selective spraying, so that a henhouse part cannot be thoroughly disinfected, and the health of broiler chickens is influenced.

Owner:安徽众盛农业发展有限公司

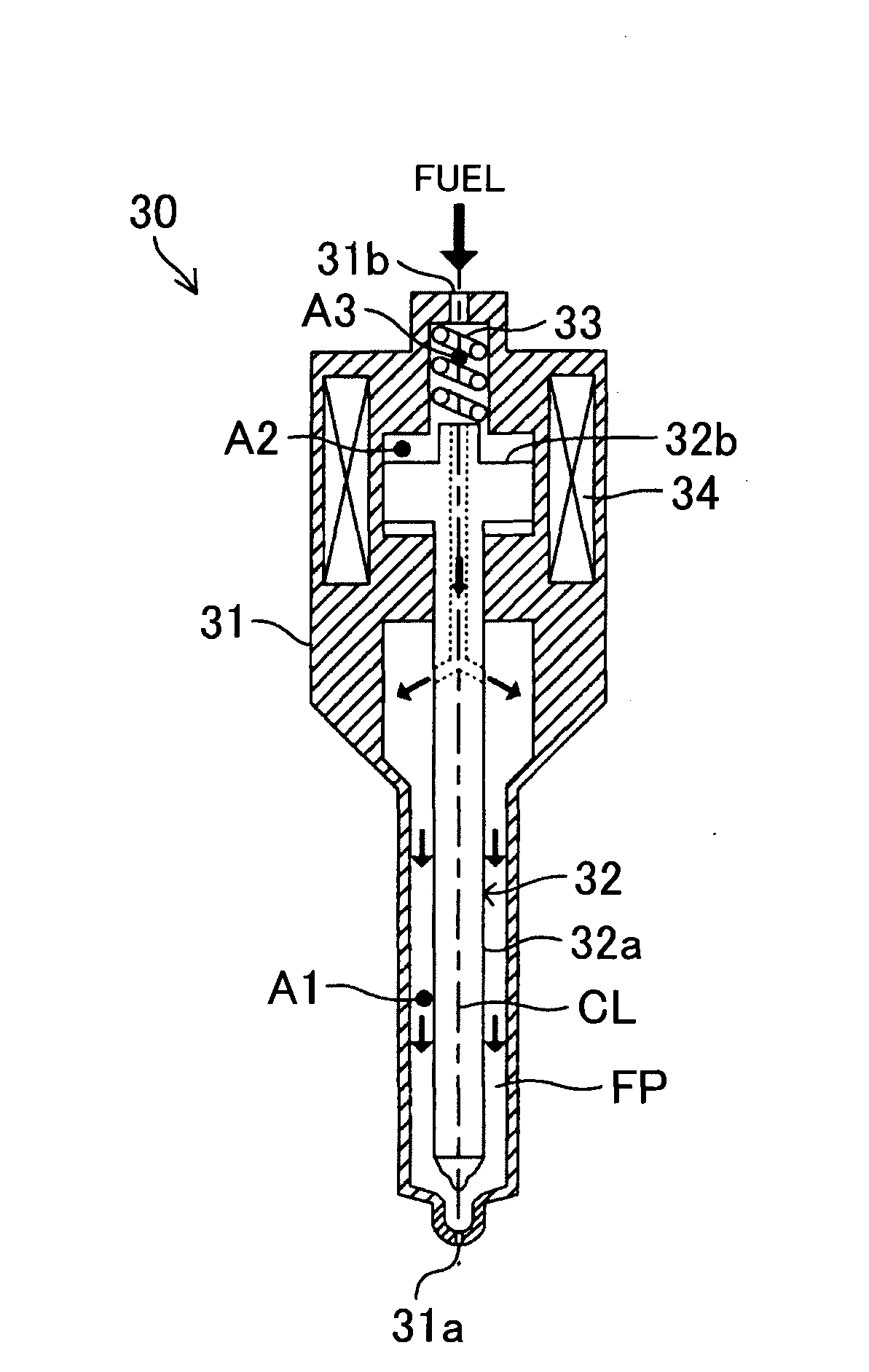

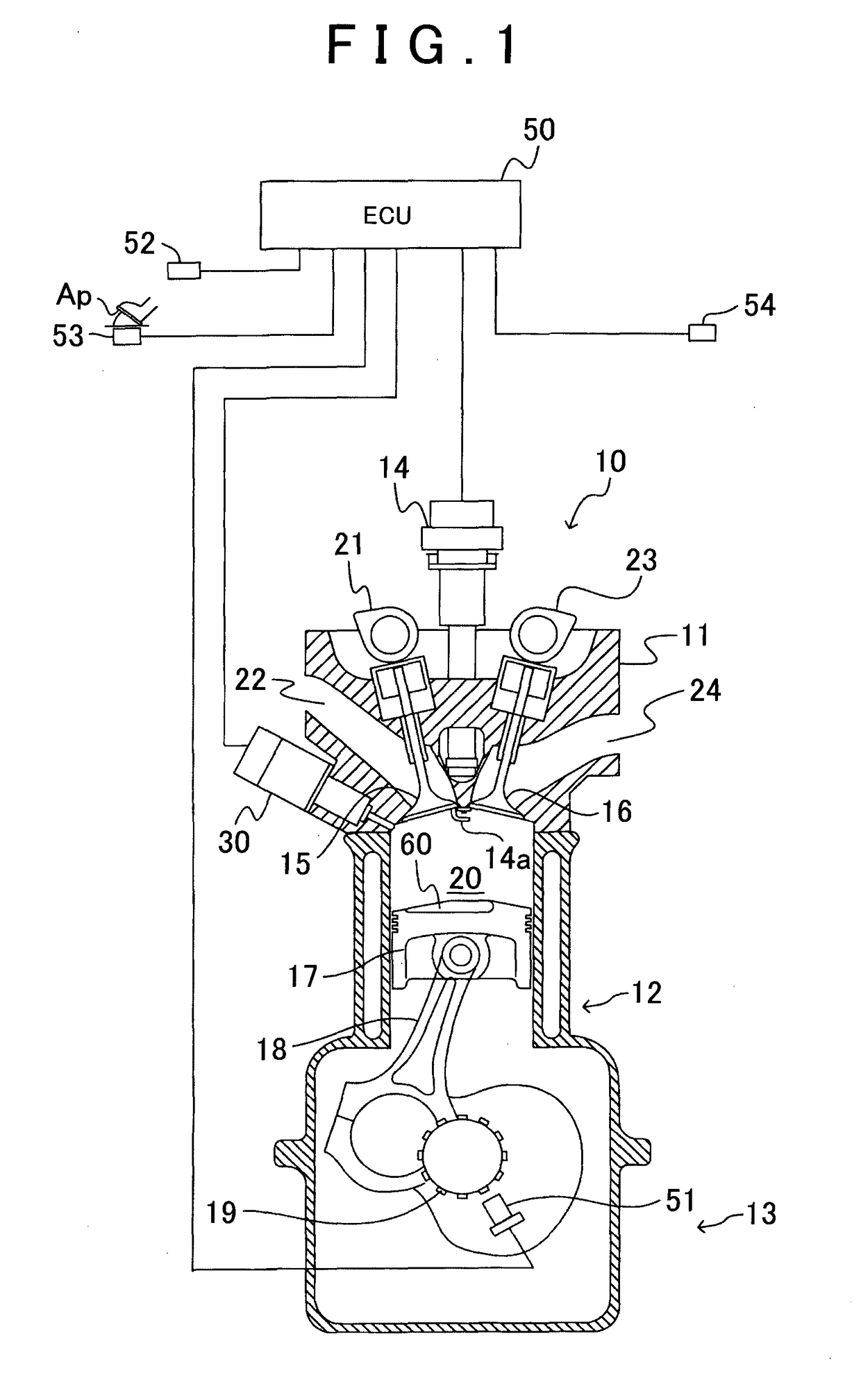

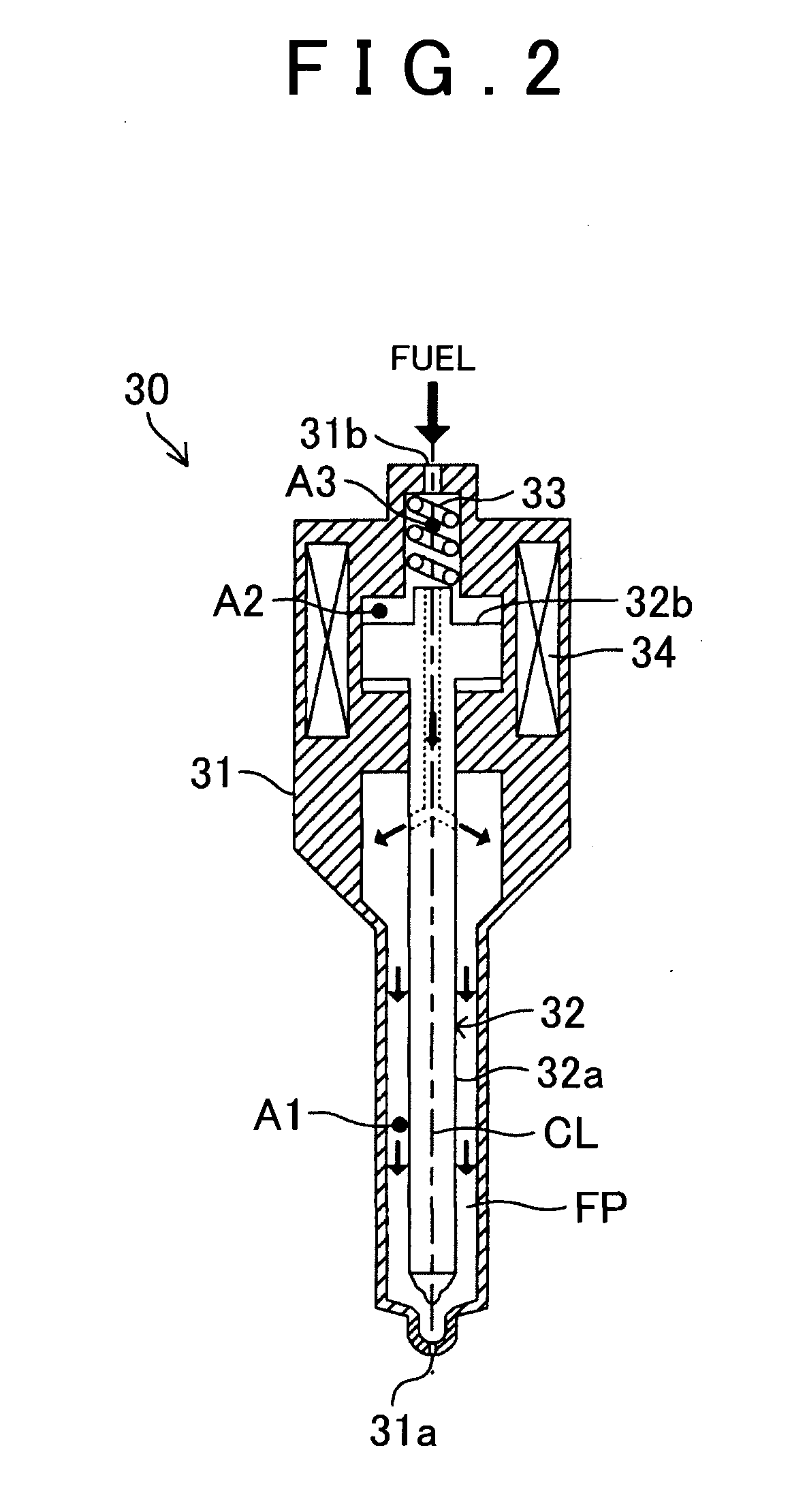

Fuel injection control apparatus for internal combustion engine

InactiveUS20170145943A1Reduce momentumImprove combustion performanceElectrical controlInternal combustion piston enginesTop dead centerExternal combustion engine

In an in-cylinder injection spark-ignition internal combustion engine, in which fuel is injected toward a cavity formed in a crown surface of a piston, when split injection for dividing and injecting the fuel for plural times is performed during a compression stroke, an arrival lift amount that is a maximum value of displacement of a valve body of a fuel injection valve during fuel injection is set as a larger value at least in a first period as a crank angle of the internal combustion engine approaches compression top dead center.

Owner:TOYOTA JIDOSHA KK

Patrol disinfecting robot with iris and face recognition

InactiveCN111991593AExpand the spraying rangeIncrease the diameterLavatory sanitoryChemicalsIris recognitionComputer science

The invention discloses a patrol disinfecting robot with iris and face recognition. The robot comprises an atomization assembly, a moving assembly and a sensing assembly, wherein the atomization assembly is arranged over the sensing assembly, and the moving assembly is arranged under the sensing assembly; the atomization assembly comprises an atomization nozzle and a main body, and the atomizationnozzle is rotatably mounted on the right side surface of the main body; the diameter of the atomization nozzle is 15 to 20 cm; and the sensing assembly comprises an infrared temperature detector, aniris recognition sensor and a controller, the infrared temperature detector is arranged on the upper surface of the sensing assembly, the iris recognition sensor is arranged on the right side surfaceof the sensing assembly, and the controller is arranged in the sensing assembly. The robot has the advantages that the working efficiency is high, autonomous navigation can be performed, the sprayingamount is large, and the coverage range is wide.

Owner:广东德九新能源有限公司

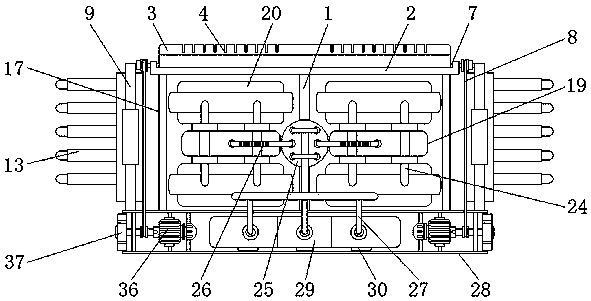

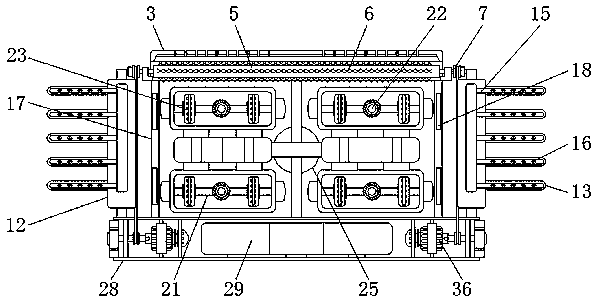

Spraying device of unmanned aerial vehicle for pesticide spraying operations

InactiveCN107600429AReasonable structureFunctionalAircraft componentsLaunching weaponsAgricultural engineeringHigh pressure

The invention discloses a spraying device of an unmanned aerial vehicle (UAV) for pesticide spraying operations. The spraying device of the UAV comprises a pesticide box, the spraying device and supporting legs which are all arranged on a UAV body, wherein the pesticide box is connected to the bottom of the UAV body; the supporting legs are fixedly arranged at four corners of the bottom of the UAVbody; the spraying device is arranged at the left end of the pesticide box; and the spraying device comprises a spraying box, a sealing plate and spraying holes. The spraying device of the UAV achieves the purpose of increasing the amount of pesticide spraying by controlling the sealing plate to move to the left to reveal most of the spraying holes without the need for decelerating the UAV so asto replace a method for increasing the amount of pesticide spraying by speed control and repeating spraying in the prior art, thereby accelerating the process of agricultural operations. When pesticides are sprayed, the pesticides are atomized in a rotating manner under the cooperation among the spraying holes, atomizing plates and a high-pressure pump, so as to increase the spraying area at one time and increase the efficiency of the pesticide spraying of the UAV, so that the spraying device of the UAV is suitable for popularization.

Owner:李志达

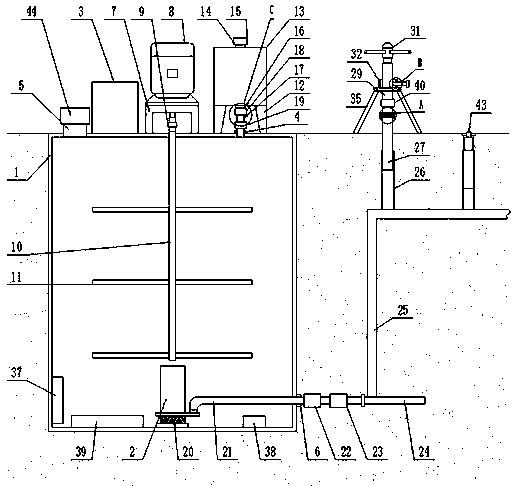

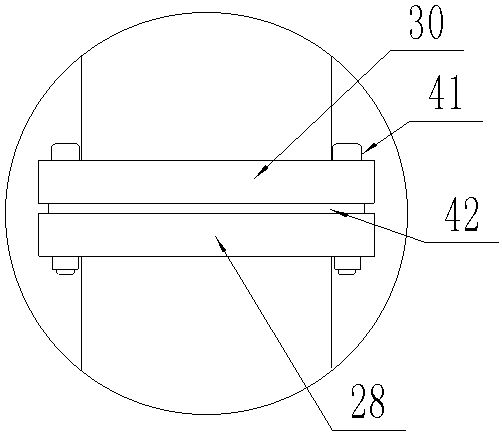

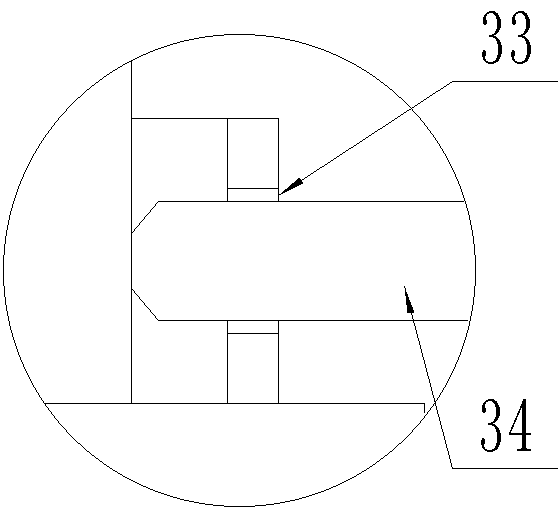

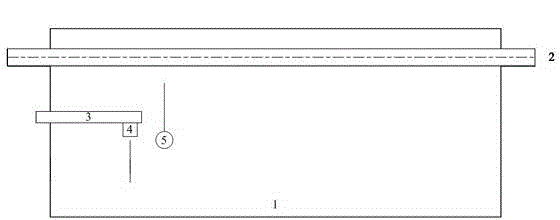

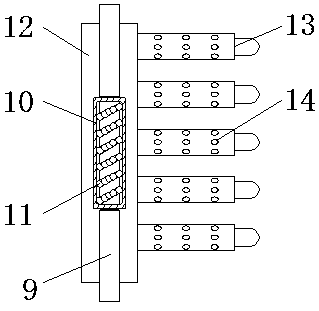

Detachable underground pesticide spraying equipment

ActiveCN109619080AIncrease the amount of sprayingPrevent freezingTransportation and packagingRotary stirring mixersThreaded pipeCoupling

The invention discloses detachable underground pesticide spraying equipment, which comprises a stirring box, a stirring device, a dosing device, a submerged pump, a spraying device, a supporting device and a control box, wherein the lower end of the stirring box is buried in a farmland in a hidden mode; the stirring device comprises a motor bracket, a rotating motor, a coupling, a rotating shaft and a stirring blade, wherein the dosing device is composed of a dosing tank bracket, a dosing tank, a dosing cover, a dosing pipe, an electromagnetic flowmeter and a first electromagnetic valve; the water outlet end of the submerged pump is connected with a water outlet pipe, wherein the extending end of the water outlet pipe is sequentially connected with a second electromagnetic valve, a one-wayvalve and a multi-way pipe in series; the multi-way pipe is connected with a plurality of branch water pipes; the branch water pipes are connected with a first threaded pipe; the first threaded pipeis connected with the second threaded pipe; the spraying device comprises a spraying water pipe, a second flange plate and a rotary spray head, and the spraying device is fixed by the supporting device. The detachable underground pesticide spraying equipment has the advantages of simple structure and strong practicability.

Owner:龚永祥

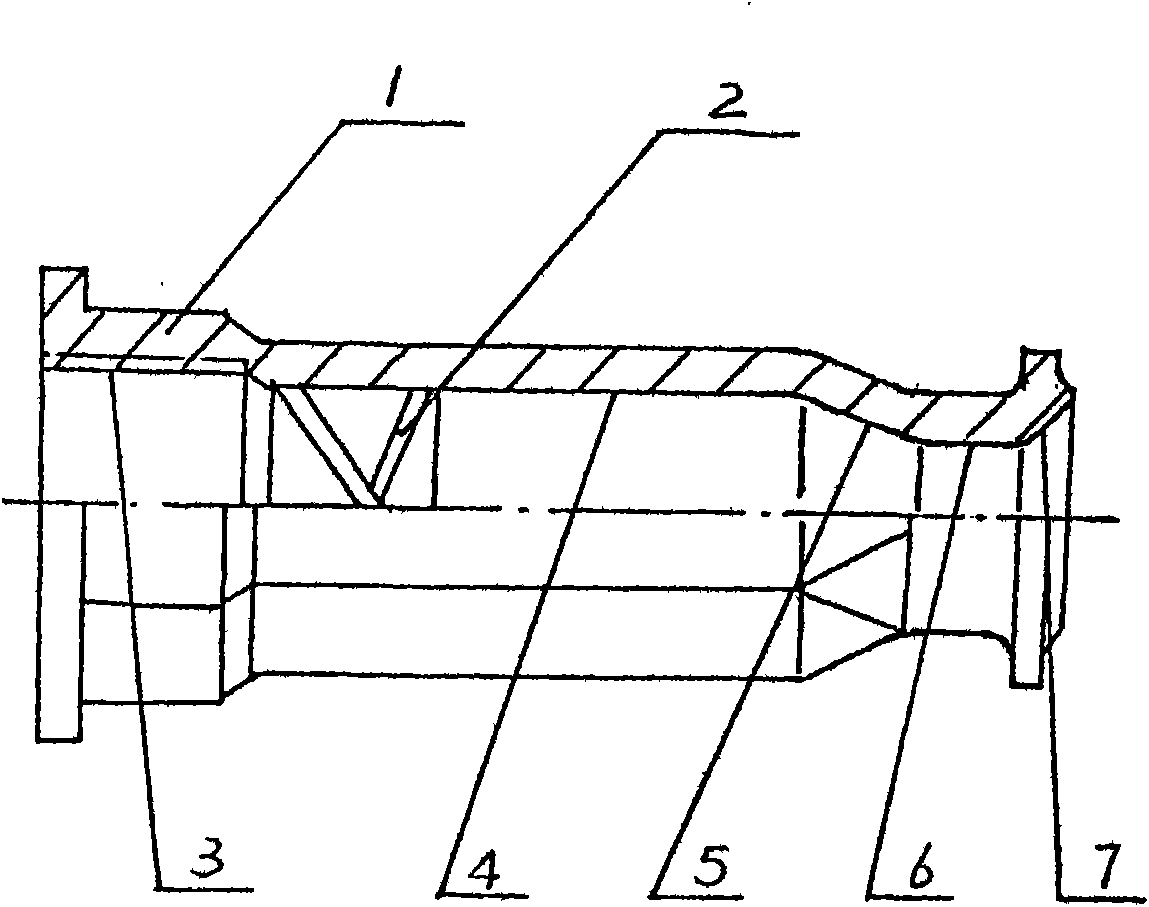

Granulator comprising double tubular reactors and application thereof in diammonium phosphate production

ActiveCN104860283AAvoid wear and tearExtended service lifePhosphatesAlkali orthophosphate fertiliserNuclear engineeringDiammonium phosphate

The invention provides a granulator comprising double tubular reactors. A main beam is arranged on the upper part of the granulator. A No.1 tubular reactor and a No.2 tubular reactor are respectively arranged on the two opposite sides of the granulator. According to the No.1 tubular reactor, an ammonia distributor is inserted into a granulator feed layer through a plow-type steel part welded on the main beam. A liquid ammonia delivery pipe is arranged on the end of the No.1 tubular reactor positioned on the outer side of the granulator. According to the No.2 tubular reactor, an ammonia distributor is inserted into a granulator feed layer through a plow-type steel part welded on the main beam. A liquid ammonia delivery pipe is arranged on the end of the No.2 tubular reactor positioned on the outer side of the granulator. A washing liquid circulation tank is respectively connected to the upper parts of the No.1 tubular reactor and the No.2 tubular reactor through tubular reactor feeding pumps. The working pressure of the equipment is lower than that of single tubular reactors. A blocking frequency is substantially reduced. Single tubular reactor purging frequency is reduced to once per shift. A cylinder scale phenomenon close to a spray point is inhibited.

Owner:HUBEI LIUGUO CHEM IND

Plate type control method adopted in process of producing aluminum alloy plate through cold rolling method

ActiveCN108057721AReduce temperature riseEnsure consistencyProfile control deviceAluminium alloyBending force

The invention discloses a plate type control method adopted in the process of producing an aluminum alloy plate through a cold rolling method. According to the type of a machined aluminum alloy, the middle target value and the middle spraying quantity of a cold rolling machine are firstly given, and then in the coiling process, along with decrease of the uncoiling diameter, the roll bending forceof the cold rolling machine is reduced step by step, and the given value of the middle spraying quantity is increased. In the method, according to constant changing of the uncoiling diameter, the rollbending force and the spraying given value are changed, specifically, in the operation process, along with constant decrease of the uncoiling diameter, the positive bow given value of a work roll isreduced synchronously, meanwhile, the middle spraying quantity is increased, the degree of camber of a strip is reduced by reducing the given value of the roll bending force, and force borne by the strip is reduced; and meanwhile, temperature increase of the middle of the work roll is reduced by increasing the spraying quantity of the middle of the strip, the influence of increase of the degree ofcamber of the work roll on the plate type of the strip is reduced, and therefore consistency of plate types of a whole coil of the aluminum alloy strip is guaranteed.

Owner:中铝河南洛阳铝加工有限公司

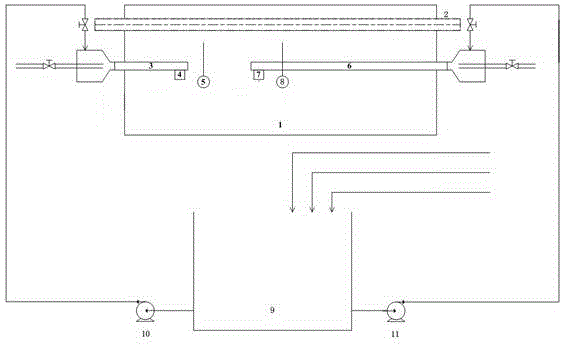

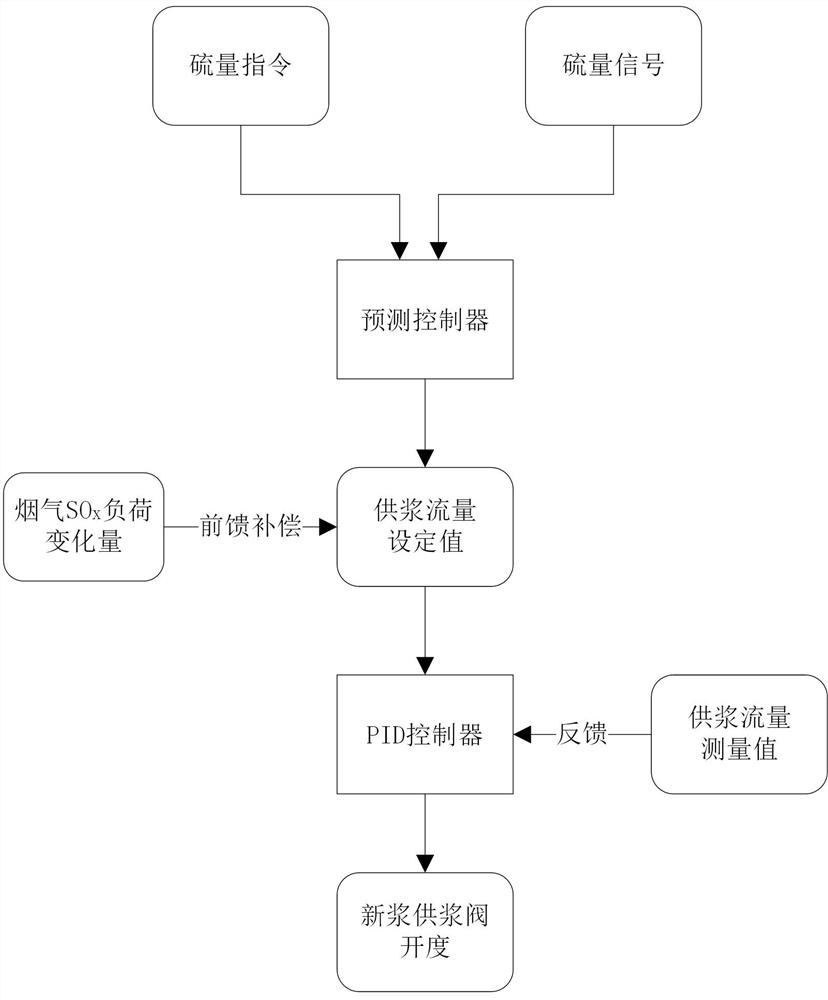

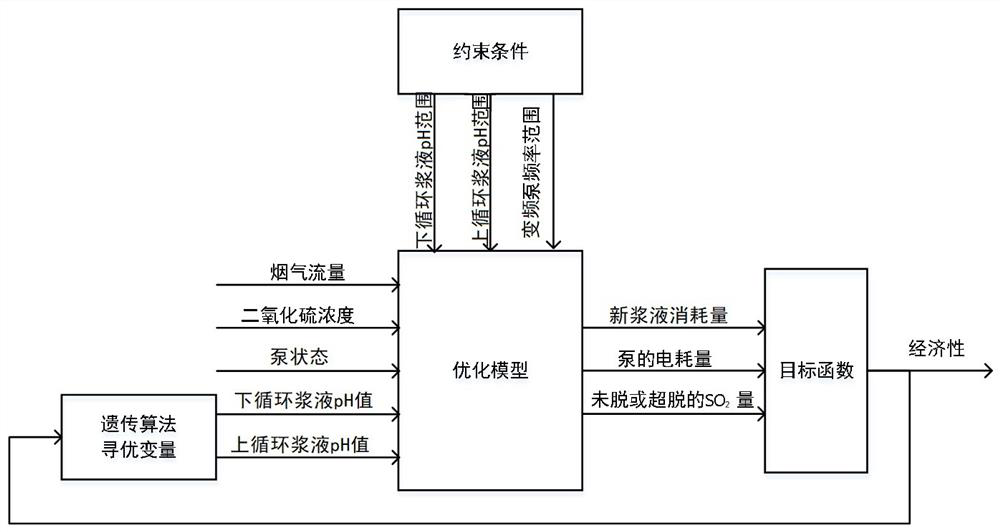

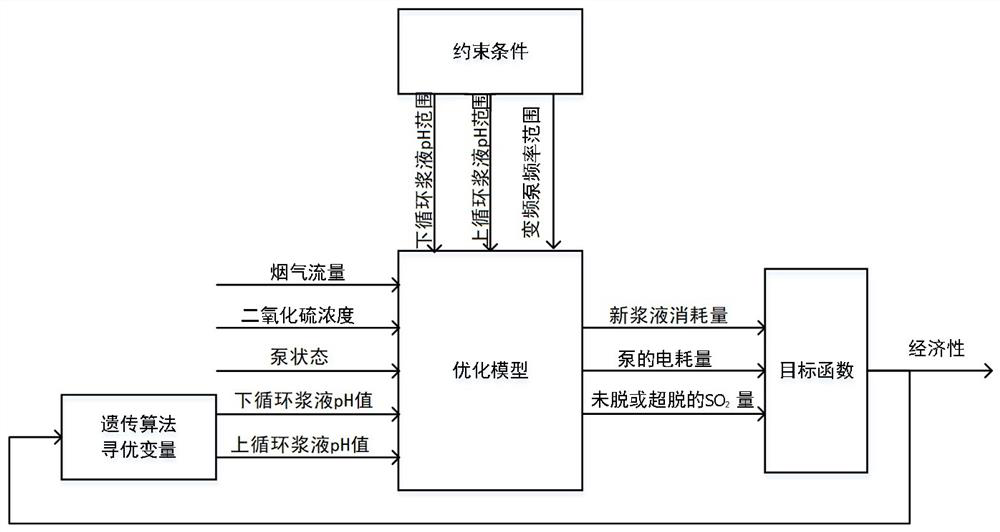

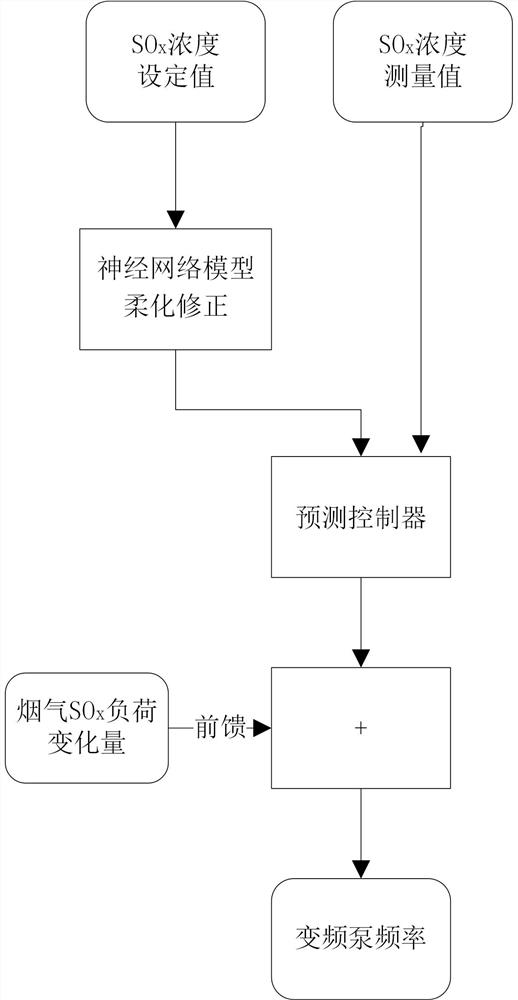

Method for optimally controlling overall economic benefit of wet desulphurization device

ActiveCN113593653ALow running costReduce frequencyChemical property predictionChemical processes analysis/designFluid phaseFlue gas

The invention relates to the technical field of waste gas purification by a semi-liquid phase method, and discloses a method for optimally controlling the overall economic benefit of a wet desulphurization device, which is used for minimizing the sum of the material cost and the energy consumption cost of the desulphurization device on the premise of ensuring the desulphurization effect when a gypsum method is adopted for desulphurization so as to realize the minimum index of the operation cost. The method comprises the following steps: step 1, controlling the flow and pH value of sprayed slurry in each slurry circulation loop by adopting a prediction controller, so that the desulfurization device operates in a state that the SOX concentration of flue gas at an outlet of an absorption tower is stabilized at a set value; wherein the prediction controller for controlling the flow of the spraying slurry is marked as a spraying quantity prediction controller, and the prediction controller for controlling the pH value of the spraying slurry is marked as a pH prediction controller; and step 2, adjusting set values in the spray quantity prediction controller and the pH prediction controller to minimize the sum of the material cost and the energy consumption cost of the desulfurization device.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

A kind of purple yam cultivation planting method

ActiveCN104221670BGerminate as soon as possibleImprove the speed of germination and emergenceHorticulturePlant TubersSeedling

Owner:葛建

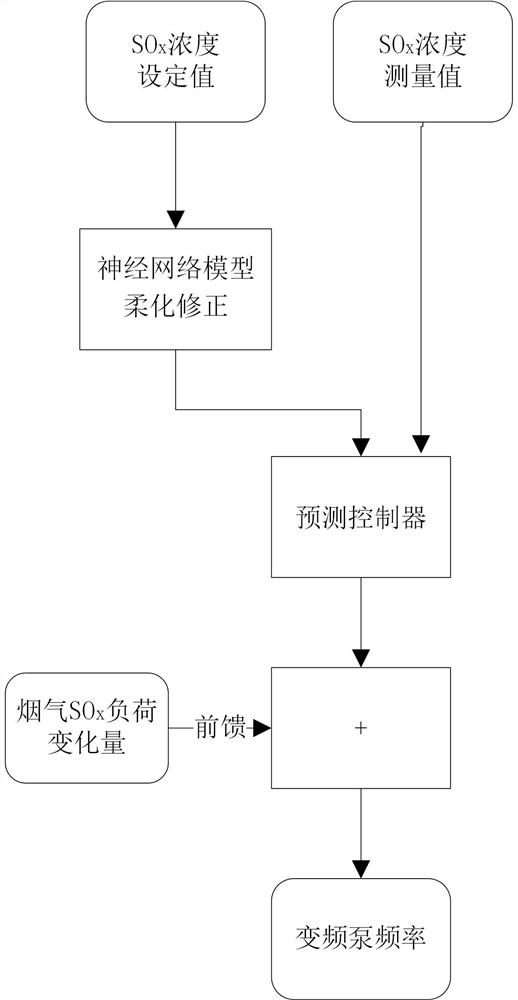

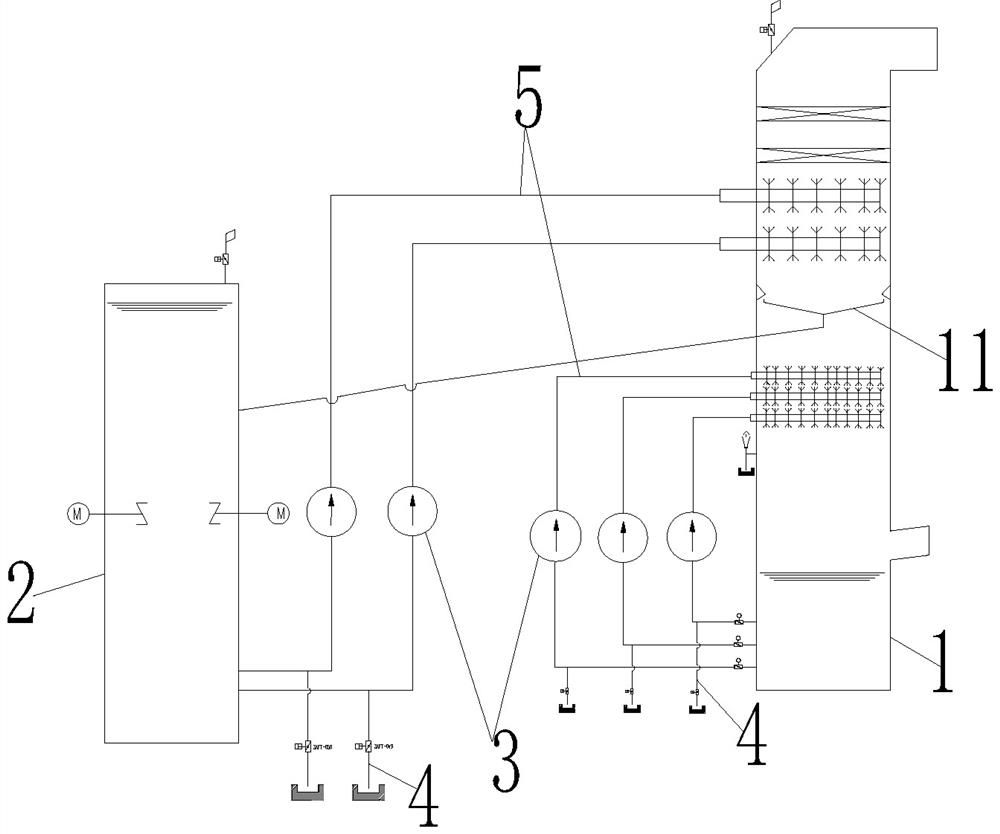

Wet desulphurization spraying amount and spraying slurry pH value coupling control optimization method

ActiveCN113655824ALow running costReduce frequencyControlling ratio of multiple fluid flowsChemical variable controlFluid phaseFlue gas

The invention relates to the technical field of waste gas purification through a semi-liquid phase method, and discloses a wet desulphurization spraying amount and spraying slurry pH value coupling control optimization method which is used for controlling the pH value of spraying slurry in a slurry circulation loop when a gypsum method is adopted for desulphurization. The influence of each manipulated variable in the desulfurization device on the desulfurization effect and the operation cost is solved through fractional factorial design, and then the combination of manipulated variables enabling the operation cost of the whole desulfurization device to be the lowest is solved by using an optimization algorithm on the premise of meeting the desulfurization effect, so that the pressure red line operation of the whole desulfurization device is realized, and the operation cost is the lowest; according to the method, the frequency of the variable-frequency circulating pump is as low as possible by adopting a closed-loop replacement method, so that the allowance for quick adjustment after the SOX content at the outlet of the desulfurization device fluctuates is reserved, and quick adjustment can be realized by increasing the frequency of the variable-frequency pump after the SOX load in the flue gas is increased.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG +1

A spray head of a fertilizer spreader that is easy to adjust the angle

ActiveCN111034443BQuick connectionFirmly connectedPressurised distribution of liquid fertiliserGear wheelAgricultural engineering

Owner:阜阳市春丰农机有限责任公司

Air pollution control washing tower convenient to control

PendingCN114028887AImprove quality and efficiencyImprove purification effectUsing liquid separation agentExhaust fumesWater resources

The invention discloses an air pollution control washing tower convenient to control, and particularly relates to the field of washing towers, the washing tower comprises a tank body, a water tank is fixedly connected to the right side of the lower end of the outer surface of the tank body, a support is fixedly connected to the lower end of the outer surface of the tank body and the lower end of the outer surface of the water tank, and a spraying mechanism is fixedly connected to the middle of the interior of the tank body. A control mechanism is fixedly connected to the inner front end of the tank body, a fixing mechanism is fixedly connected to the outer surface of the upper end of the water tank, and the spraying mechanism, a first water pipe, a circulating water pump, a second water pipe, a first guide water pipe, a second guide water pipe, a sealing ring, a connecting circular plate, a waterproof electric push rod, a connecting circular ring, a sealing belt, an atomizing nozzle and a main purifying nozzle are fixedly connected to the outer surface of the upper end of the water tank. Through cooperation of the structures, the water spraying amount of the spraying structure can be accurately controlled, waste of water resources and spraying agents is reduced, waste gas pollutants can make full contact with an aqueous solution through cooperation of the spraying structure, and therefore polluted gas is better treated.

Owner:SHANGHAI ACADEMY OF ENVIRONMENTAL SCIENCES

A kind of purple sweet potato cultivation planting method

InactiveCN104186167BGerminate as soon as possibleImprove the speed of germination and emergenceHorticultureLongitudinal planePlant cultivation

The invention discloses a method for cultivating and planting purple sweet potatoes, which belongs to the technical field of purple sweet potatoes and comprises the following steps: (1) pretreatment of seed potatoes; (2) arranging seedlings of seed potatoes and tubers; (3) management of purple sweet potato seedlings; (4) ) Purple sweet potato seedling cutting cultivation; (5) Purple sweet potato field growth management; (6) Purple sweet potato harvest. Using the method of the present invention to plant purple sweet potatoes can ensure that seed potatoes can germinate and emerge as soon as possible; can eliminate the germination dead spots on the surface of purple sweet potatoes in conventional cultivation, and increase the germination rate by about 11.3%. Seed potatoes, reducing costs, planting the longitudinal section of the seed potato tuber obliquely downward, ensuring that the germination and emergence time of the end of the seed potato and the longitudinal section tends to be consistent, increasing the emergence rate of purple potato by about 9.4%; no need to use external power equipment for heating Heat preservation, simple operation process steps, low equipment investment, improve the survival rate and survival quality of purple sweet potato seedlings; the yield per mu is increased by about 7% compared with the traditional method, and the benefit of increasing the income of growers is obvious.

Owner:徐静

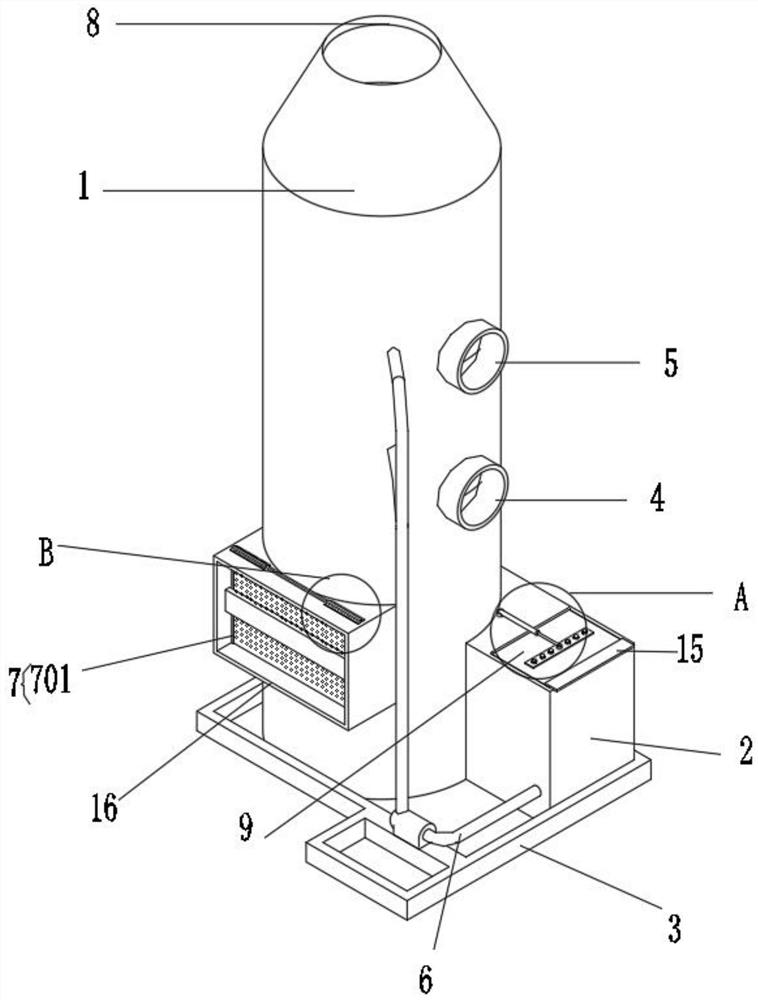

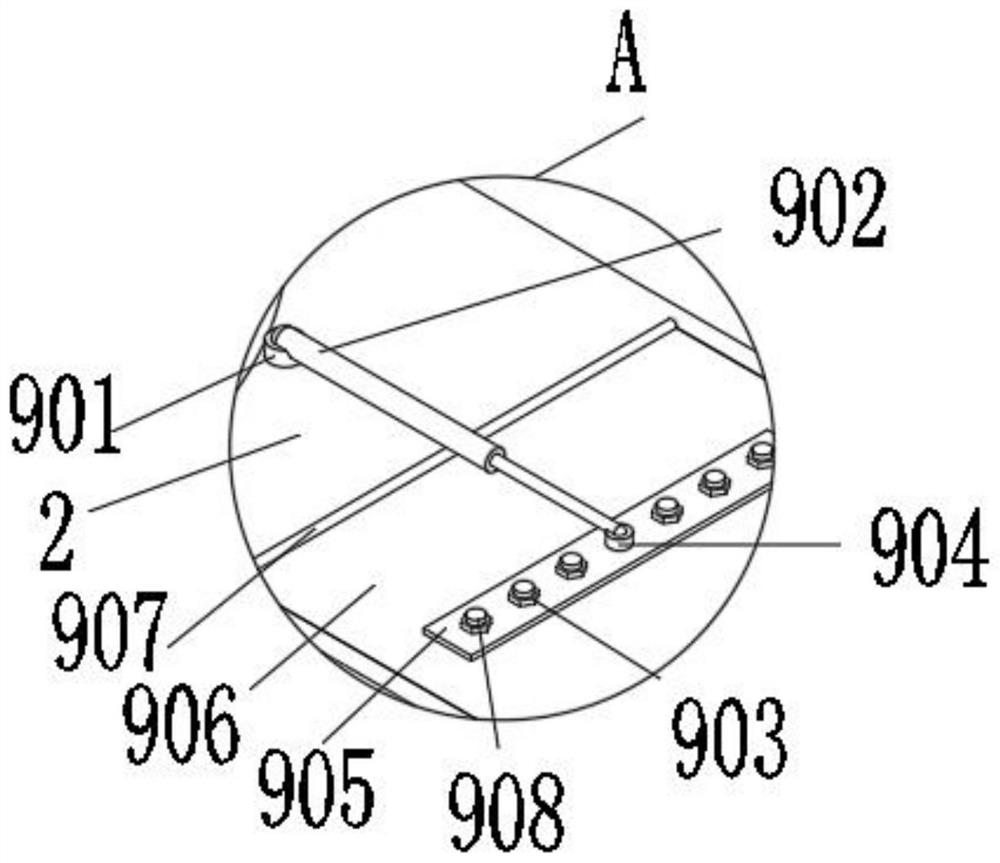

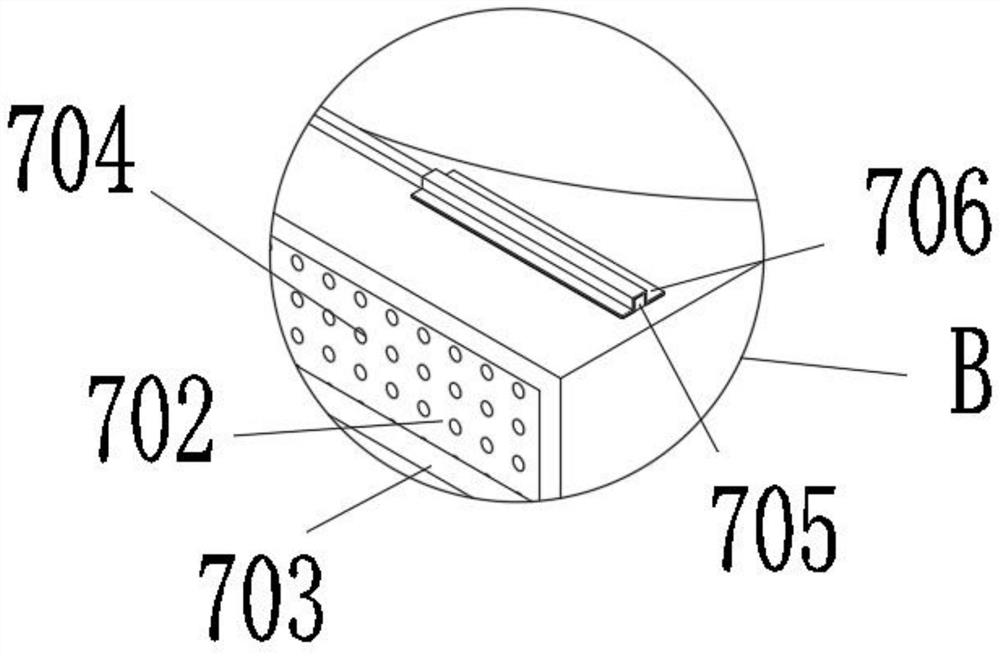

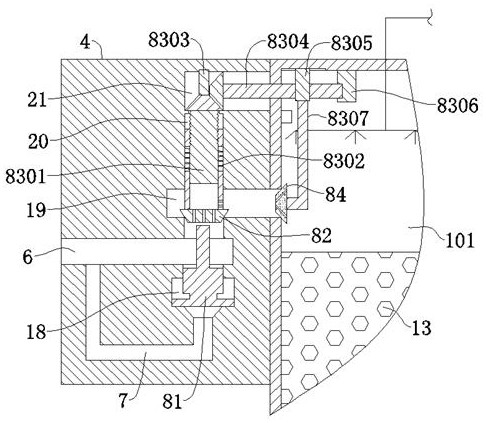

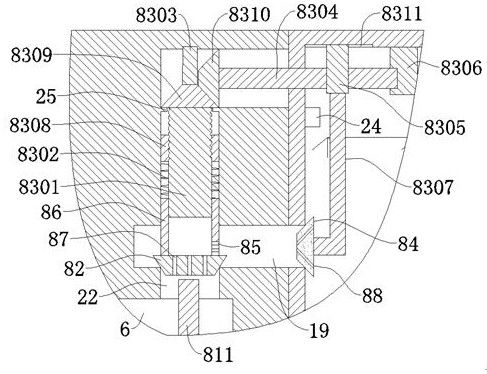

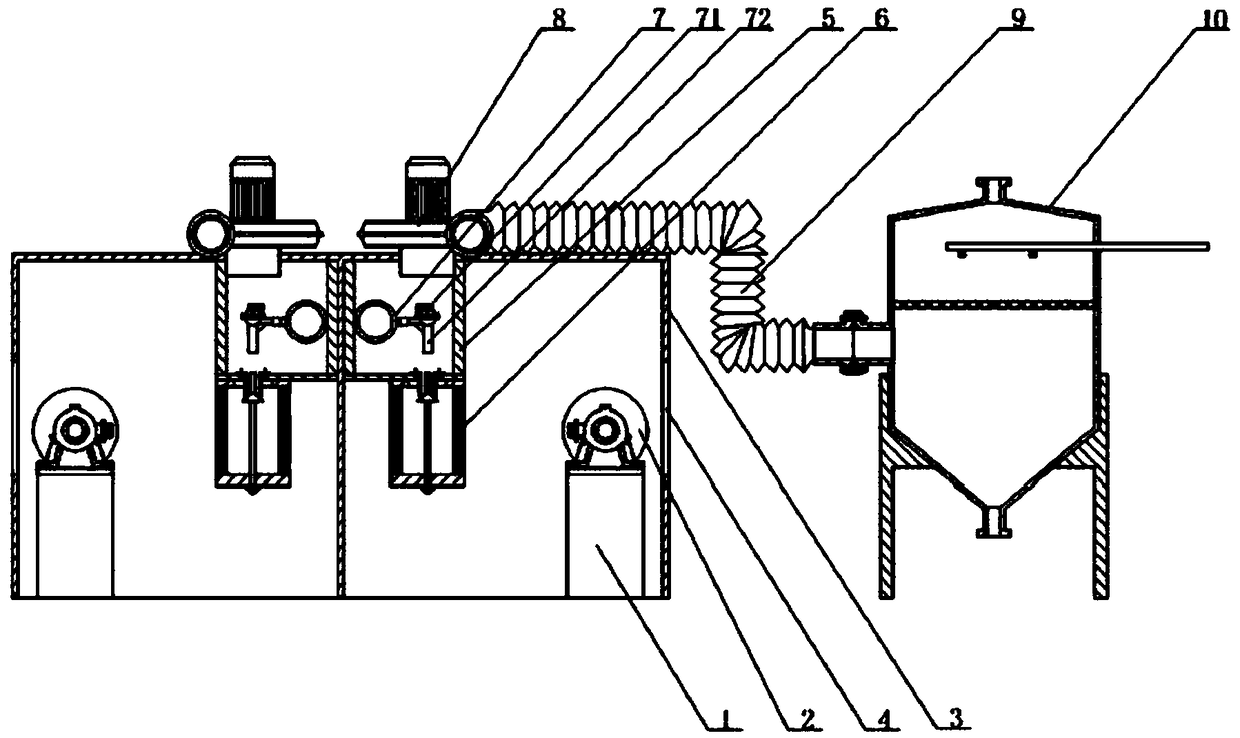

A rapid assembly biological filter deodorization device for sewage treatment

ActiveCN113019115BIncrease the amount of sprayingSolve water problemsDispersed particle separationAir quality improvementGlass fiberBiofilm

The invention discloses a quick-assembled biological filter tank deodorizing device for sewage treatment, belonging to the technical field of sewage odor treatment. The biological filter tank deodorizing device comprises a fan, a biological filter tank body and a water pump, and the biological filter tank body includes a prewash The pool, the biological filter and the water storage chamber also include a fixed block, an air intake control mechanism, a controller, and a displacement sensor; the air intake control mechanism includes a piston head, a driving counterweight, a driving mechanism, a sealing block and a sleeve. The invention can play a good deodorizing effect. The pre-washing tank, the biological filter tank and the water storage cavity are all assembled with skid-mounted modules, and the fan and the fan soundproof box are integrated modules, which can realize the rapid on-site operation of the biological filter tank deodorization device. Assembled, shorten the construction period, put into use quickly, suitable for various engineering projects with different processing volumes. The body of the biological filter is made of glass fiber reinforced plastic composite plates, and the bonding adopts the hand lay-up glass fiber reinforced plastic process.

Owner:HUNAN ZHONGTUO ENVIRONMENTAL ENG CO LTD

Wear-resistant and corrosion-proof agricultural fertilizer touch soil sprinkling irrigation device

InactiveCN108419468APlay a protective effectEasy to adjustSpadesPloughsWear resistantAgricultural engineering

The invention discloses a wear-resistant and corrosion-proof agricultural fertilizer touch soil sprinkling irrigation device. The device comprises a frame main body, pesticide spreading plates and a tailstock, wherein a protective plate is fixed above the frame main body, and a harrow plate is mounted above the protective plate; harrow grooves are formed in the surface of the harrow plate, and a plowing drum is mounted at the back side of the harrow plate; plowing fork teeth are fixed around the plowing drum, and a transmission rod penetrates through the interior of the plowing drum; transmission gear sets are mounted below the transmission rod, and a support rod is fixed at the outer side of each transmission gear set; a through rod is arranged in the middle of each pesticide spreading plate, and the pesticide spreading plates are respectively positioned at the upper and lower sides of a pesticide storing box; and a mixing box is arranged in the tailstock, and the tailstock is positioned below the frame main body. The wear-resistant and corrosion-proof agricultural fertilizer touch soil sprinkling irrigation device can synchronously perform soil plowing and sprinkling irrigation works, has more irrigation positions and more corresponding plowing positions, realizes uniform irrigation and plowing, and can perform direct irrigation on deeper soil.

Owner:汤以骋

Distributive dust purifying device for grinding machine

InactiveCN109015382AAvoid cloggingGood dust removal effectGrinding/polishing safety devicesWater pipeElectromagnetic valve

The invention relates to a machining device, in particular to a distributive dust purifying device for a grinding machine, and solves the problem of weaker dust removing effect in a traditional tablegrinding machine. The device comprises a grinding machine, a grinding wheel, a negative-pressure chamber, a window, an isolation chamber, a filter, an upper support plate, a lower support plate, a middle support frame, an air filter paper, a conical body, a reverse blowing device, a pulse electromagnetic valve, a reverse blowing pipe, a fan, a hose, a spraying dust remover, a tank, an air exhaustport, a settling port, a screen plate, a nozzle and a water pipe. The device cannot pollute the workshop environment, is excellent in dust removing effect, and meanwhile, meets the air exhaust requirements.

Owner:安徽海蚨祥橡胶有限公司

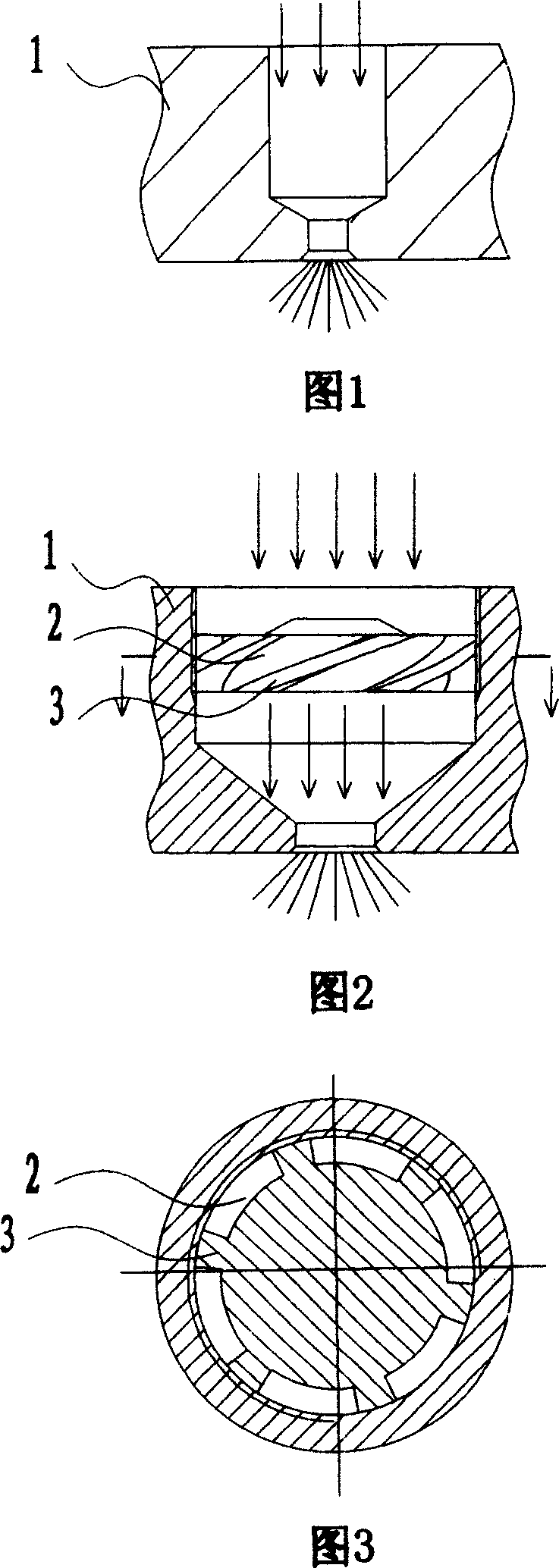

Comperssor nozzle

InactiveCN100348333CIncrease the amount of sprayingImprove atomization effectPositive displacement pump componentsSpray nozzlesWhole bodyEngineering

The invention discloses a kind of compressor spray nozzle. The trait of the invention is: the foundation of the compressor spray nozzle is screw. There is spiral groove or bevel grooev on the round outside. Exit of the spiral groove or the bevel groove connects both upper and bellow ends of spray nozzle. After the spiral groove or the bevel groove is done in the outside of screw, parts of the threads are resected but the left threads can also fix the spray nozzle into the columnar cavity of the compressor body. Certainly, spray nozzle can also be fixed in the columnar cavity of the compressor body by pass-filled coordination. The columnar cavity of the compressor body is usually produced from the compressor body, is one part of the body and they are the whole body. The columnar cavity can be made into a single part and then be fixed on the compressor body. One end of the columnar cavity is conical throttle hole, whose exit is communicated with the working air cavity compressor. The invention is applied for compressors with any exhausting capacity, and result of atomizing is good.

Owner:GUANGDONG GANEY PRECISION MACHINE CO LTD

Sensitive and economical wet desulphurization outlet flue gas SOx concentration control method

ActiveCN113521998AAchieve normal operationAvoid exceeding demandGas treatmentDispersed particle separationFluid phaseFlue gas

The invention relates to the technical field of waste gas purification through a semi-liquid phase method, and discloses a sensitive and economical wet desulphurization outlet flue gas SOX concentration control method which is used for controlling the SOX concentration of flue gas at an outlet of an absorption tower when a gypsum method is adopted for desulfurization, and the spraying amount is changed by controlling the frequency of a variable frequency pump through a prediction controller, so that theSOX concentration of flue gas at the outlet of the absorption tower is adjusted; the prediction controller overcomes the hysteresis quality from frequency conversion to the change of the SOX concentration of the flue gas at the outlet of the absorption tower, so that the adjusting process is more sensitive, red line operation of the desulfurization device can be realized, the SOX concentration of the flue gas at the outlet of the absorption tower is prevented from exceeding the standard in the adjusting process, and the slurry supply flow is prevented from exceeding the demand after the adjustment; and through closed-loop optimization, the variable-frequency pump runs close to the lower limit of the variable-frequency range when the SOX concentration of the flue gas at the outlet of the absorption tower is stable, a large adjusting space is reserved for the single variable-frequency pump, and the adjusting requirement can be met by adopting the single variable-frequency pump.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com