Method for optimally controlling overall economic benefit of wet desulphurization device

An economical and optimal control technology, applied in neural architecture, genetic laws, biological neural network models, etc., can solve the problems of inability to fully automatic operation, lag, low sensitivity, etc., to avoid excessive SOX concentration, overcome hysteresis, The effect of low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In the present invention, all the representations of "the amount of XX" can be expressed in various ways such as volume, mass, and amount of substance, and it is only necessary to ensure that the dimension is correct during the calculation process. Similarly, "XX's flow" can be expressed in various ways such as volume flow, mass flow, and substance flow; "XX's concentration" can be expressed in various ways such as volume fraction, mass concentration, and substance concentration. To proceed, it is only necessary to ensure that the dimensions are correct during the calculation.

[0053] In this embodiment, all "amount of XX" is mass, all "flow rate of XX" is mass flow, and all "concentration of XX" is mass concentration. SO X to SO 2 to count, the remaining types of SO X can be ignored.

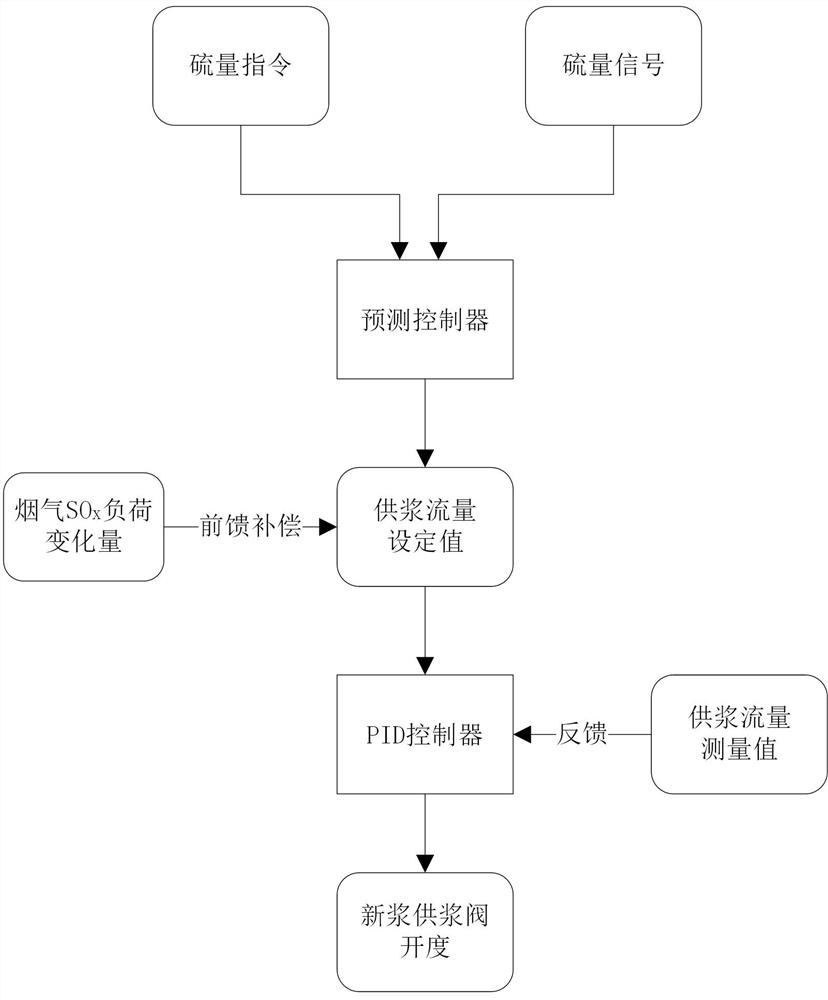

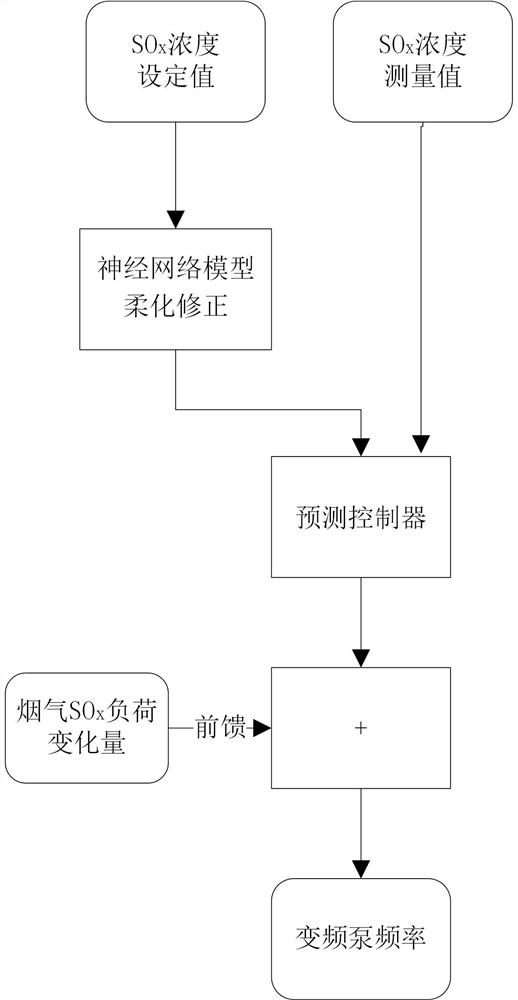

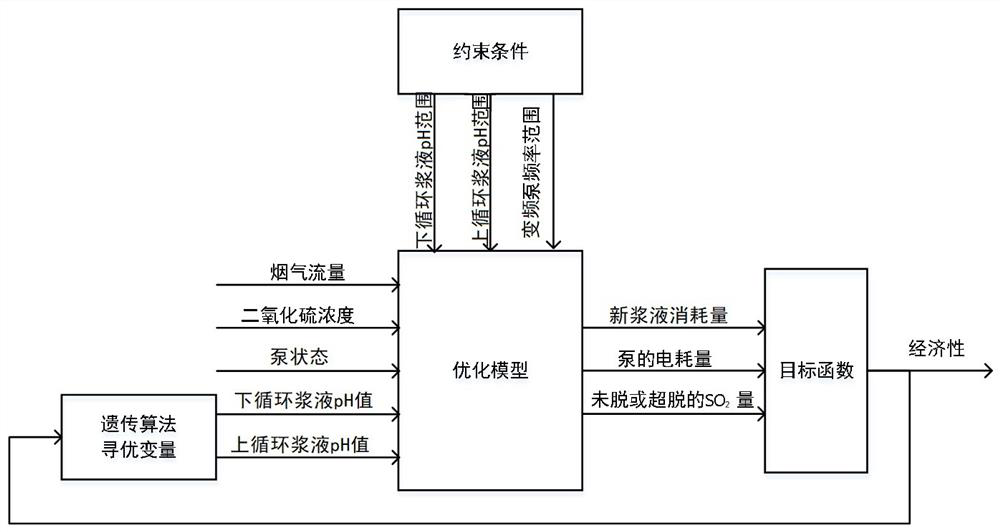

[0054] An optimal control method for the overall economic benefit of a wet desulfurization device, which is used to minimize the sum of the material cost and energy consumption cost...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com