Distributive dust purifying device for grinding machine

A dust purification and grinding machine technology, which is applied in grinding/polishing safety devices, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of poor dust removal effect of dust removal devices, and achieve to overcome poor dust removal effect and improve utilization. rate, and the effect of avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

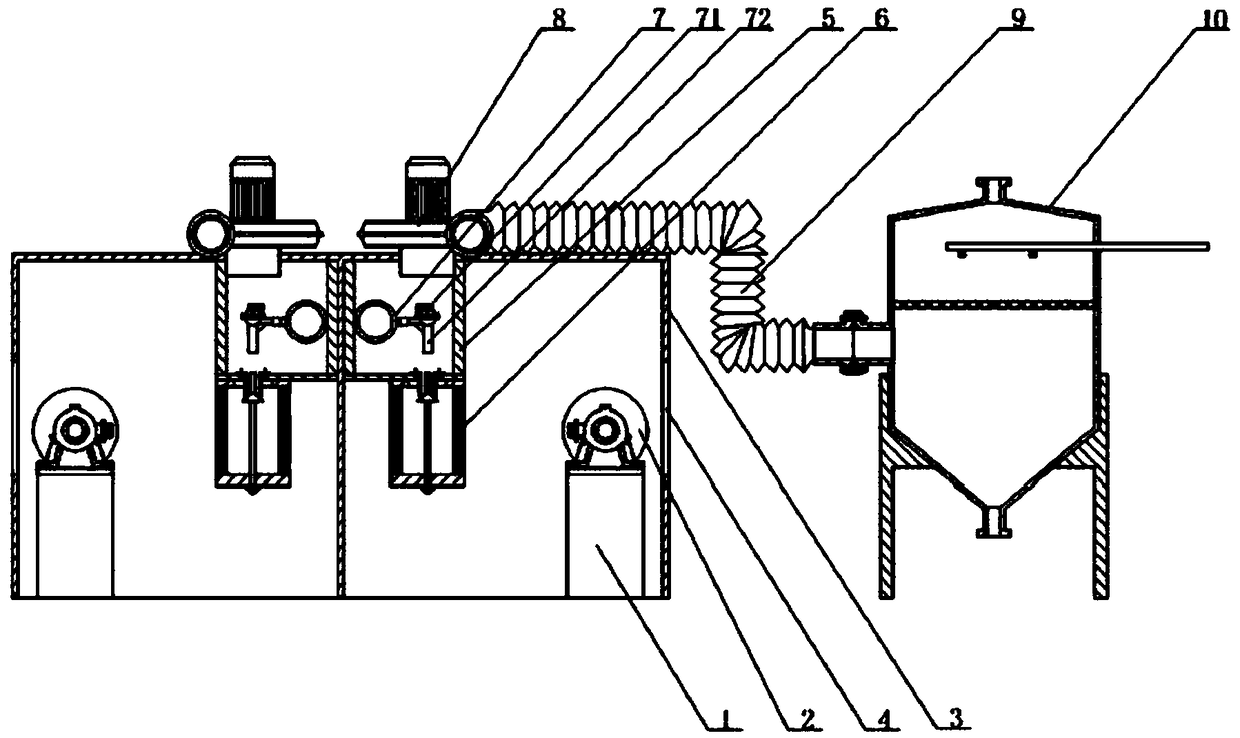

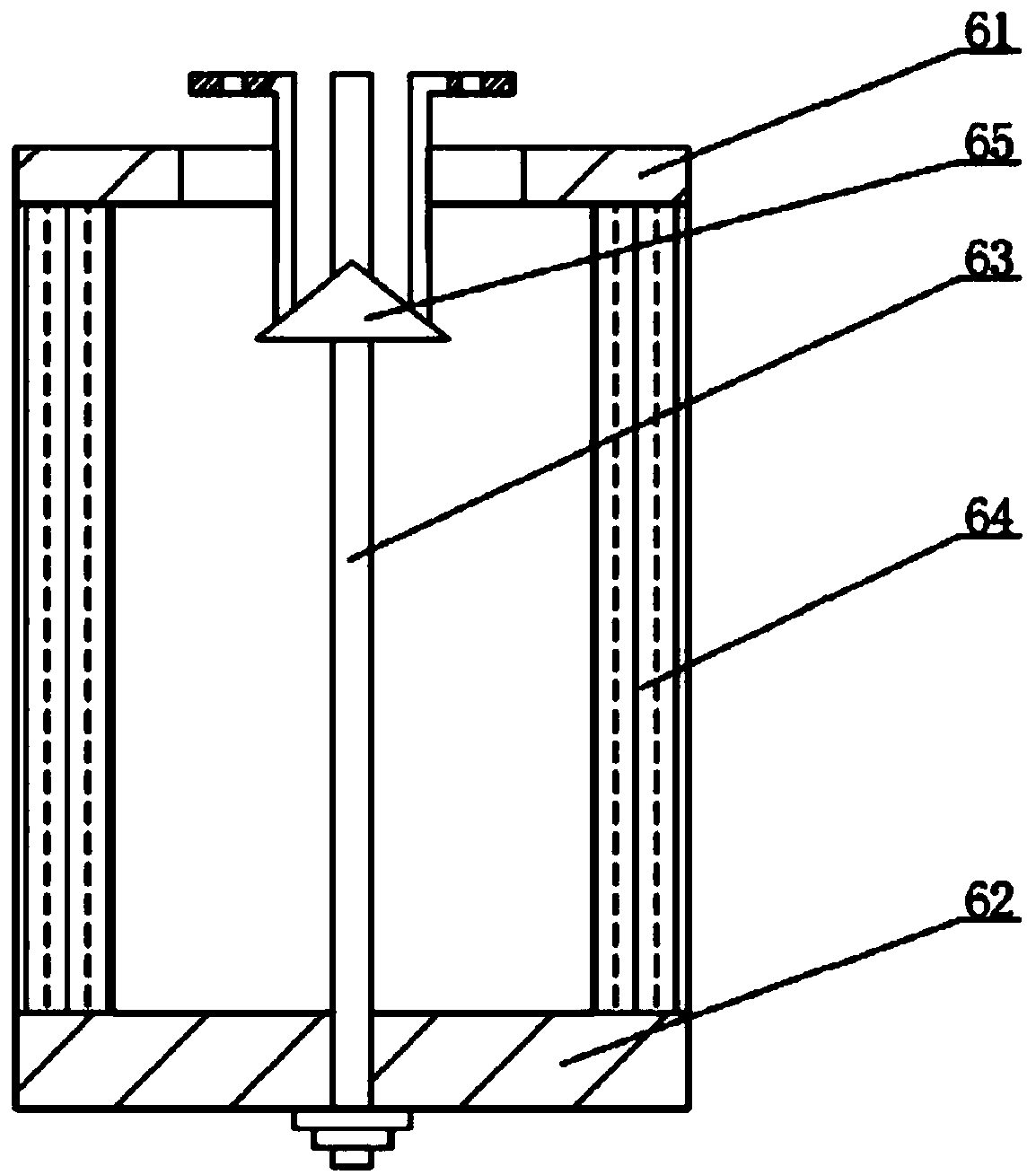

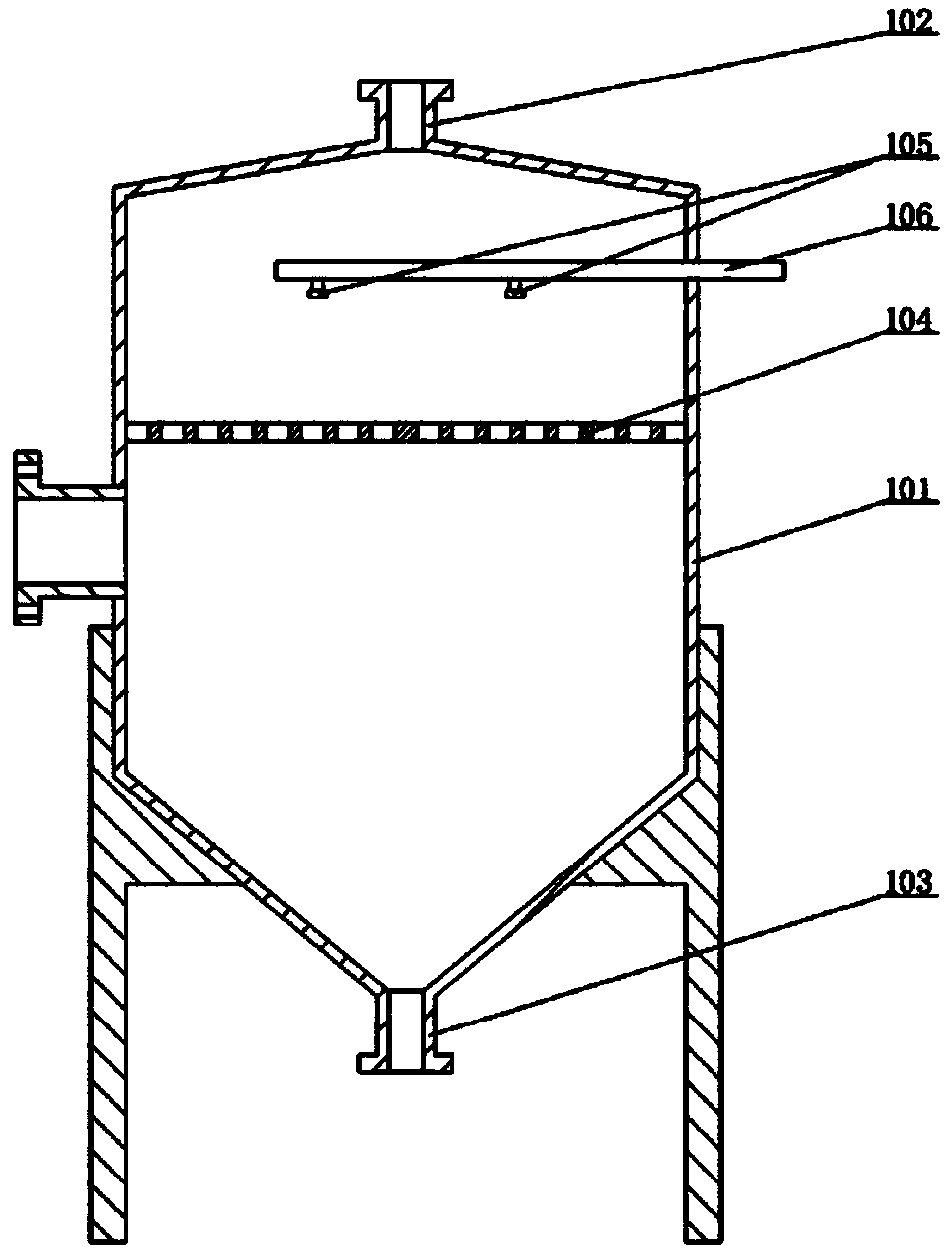

[0020] like Figure 1 to Figure 4 As shown, a distributed dust purification device for a grinder, a grinder 1 with a grinding wheel 2, the grinder 1 is placed in a negative pressure chamber 3, multiple grinders 1 can be installed, or the negative pressure chamber 3 is divided into several, the side wall of the negative pressure chamber 3 is provided with a window 4 corresponding to the grinding wheel 2, the top of the negative pressure chamber 3 is provided with an isolation chamber 5, and the lower end of the isolation chamber 5 is connected with a filter 6 to isolate A blowback device 7 is fixed inside the chamber 5 , and the upper part of the isolation chamber 5 is connected to the fan 8 outside the negative pressure chamber 3 , the hose 9 and the spray dust collector 10 in sequence.

[0021] The blowback device 7 is composed of a pulse solenoid valve 71 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com