Patents

Literature

88results about How to "Compliance with emission requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

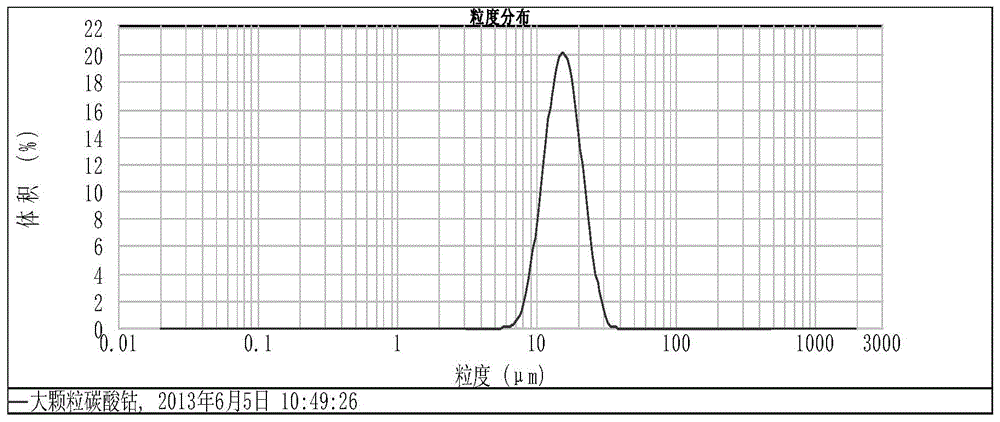

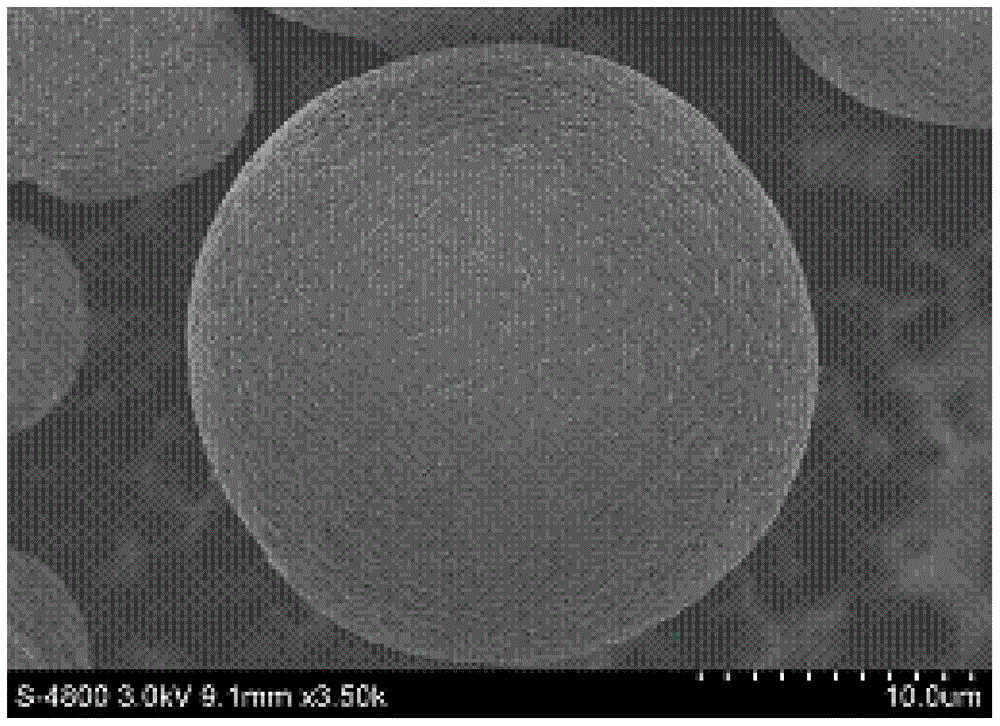

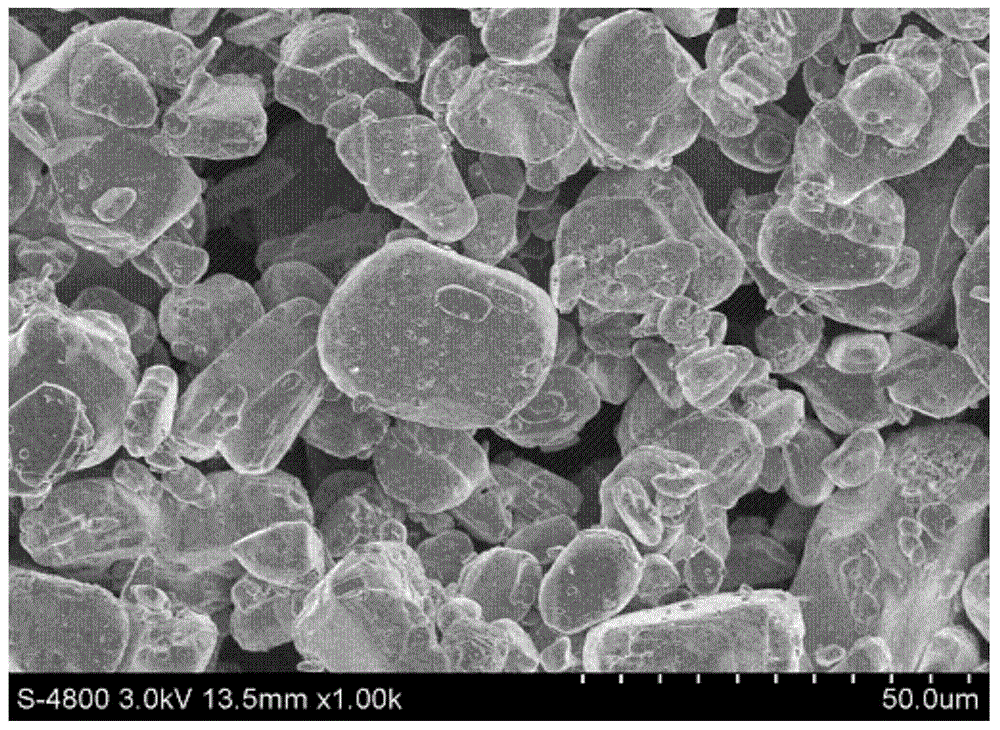

Method for continuously producing large-particle spherical cobalt carbonate

The invention relates to a method for continuously producing large-particle spherical cobalt carbonate. The method comprises the following steps: manufacturing a turbid liquid containing small-particle-size cobalt carbonate seed crystal and manufacturing a turbid liquid containing large-particle spherical cobalt carbonate, stirring the turbid liquid containing the small-particle-size cobalt carbonate seed crystal and the turbid liquid containing large-particle-size cobalt carbonate to form a mixed liquid, carrying out solid-liquid separation, washing and filter pressing to obtain a filter cake as a large-particle cobalt carbonate filter cake, drying the filter cake, and repeatedly operating to obtain the large-particle cobalt carbonate powder. According to the method disclosed by the invention, the small-particle-size cobalt carbonate seed crystal is adopted to control the particle size of the large-particle cobalt carbonate in reaction mother liquor, so that the degree of sphericity of cobalt carbonate produced by continuous production can be ensured to be high, the particle size can be stably controlled within the range of 15+ / -0.5 microns, and the consistency and the stability of the particle size of the large-particle spherical cobalt carbonate through large-scale continuous production can be realized; the method is simple in process, easy to operate and low in cost, and can provide the high-quality raw material for producing high-end lithium cobalt oxide; the carbonate is used as a precipitant, so that the environment can be optimized; the production efficiency can be improved, and the wide application prospect can be achieved.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

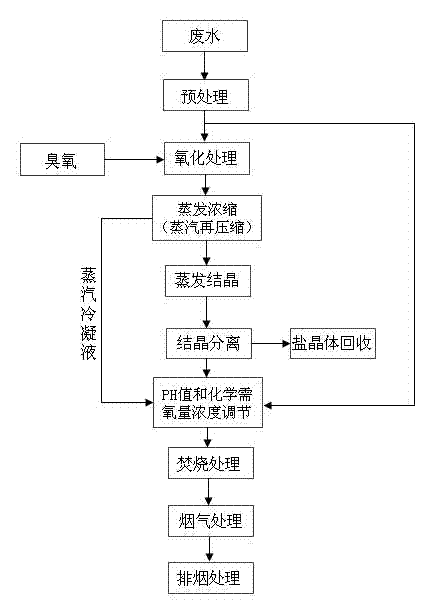

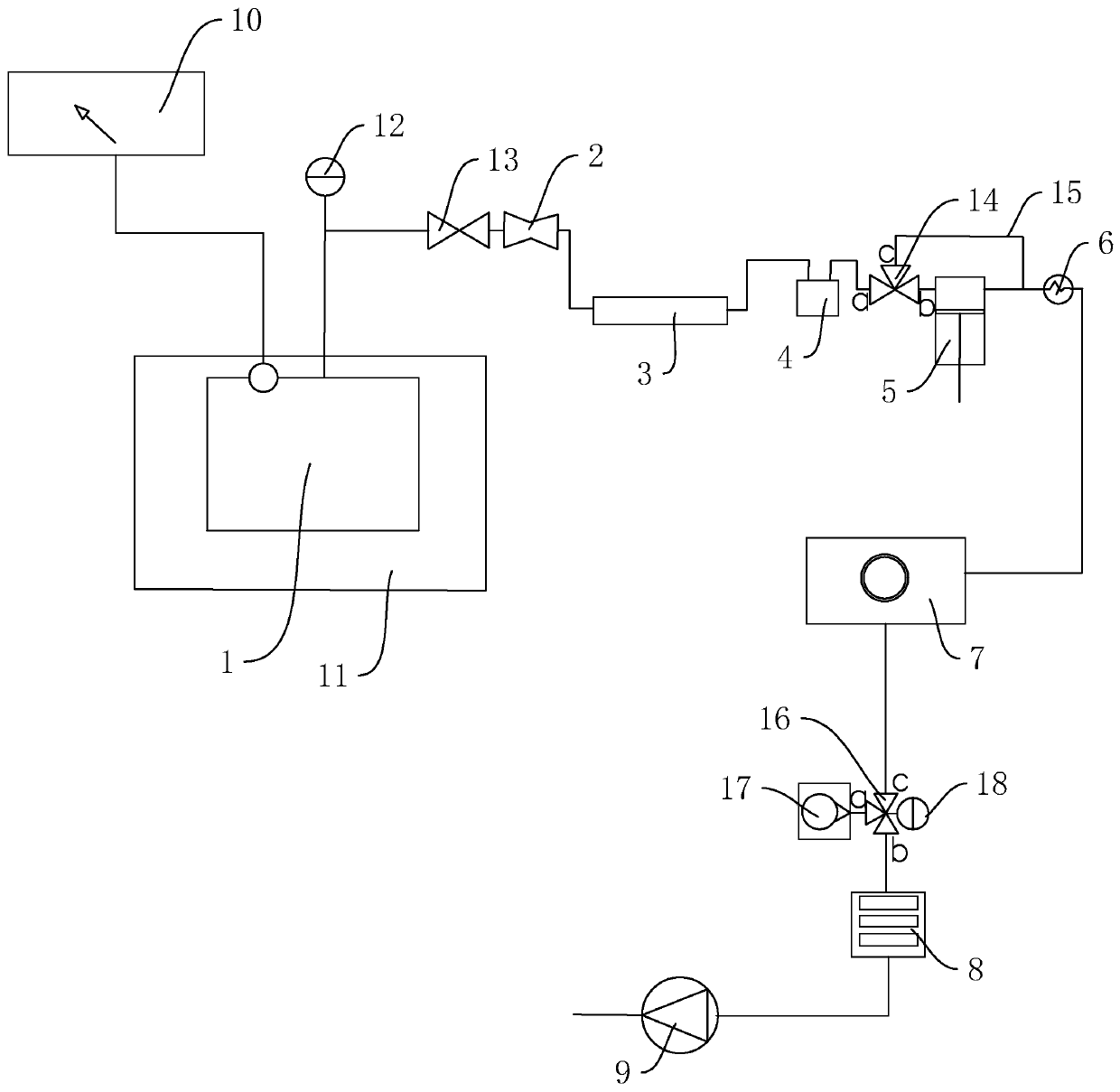

High-concentration organic salt-containing wastewater treatment method adopting steam recompression technology

ActiveCN103588338ATo achieve the purpose of thorough treatmentCompliance with emission requirementsWater/sewage treatment by centrifugal separationMultistage water/sewage treatmentHigh concentrationEvaporation

The invention relates to a wastewater treatment method, in particular to a high-concentration organic salt-containing wastewater treatment method adopting the steam recompression technology. The high-concentration organic salt-containing wastewater treatment method is characterized by comprising the steps of pretreatment, evaporation concentration, evaporation crystallization, crystallization separation and the like, wherein the evaporation concentration step is implemented according to the steam recompression technology: conveying wastewater into a mechanical recompression evaporator and concentrating the wastewater into a saline saturated or over-saturated solution through steam heating. According to the method, live steam is only fed into the mechanical recompression evaporator at the initial use, and the mechanical recompression evaporator can be used for recompressing secondary steam produced by wastewater evaporation, so that enough heat sources can be supplied to concentration of the subsequent fed wastewater, and the live steam is not required to be fed at the subsequent use; therefore, the energy can be greatly saved, and the treatment cost can be reduced.

Owner:JIANGSU QUANNENG ELECTROMECHANICAL EQUIP ENG LTD BY SHARE LTD

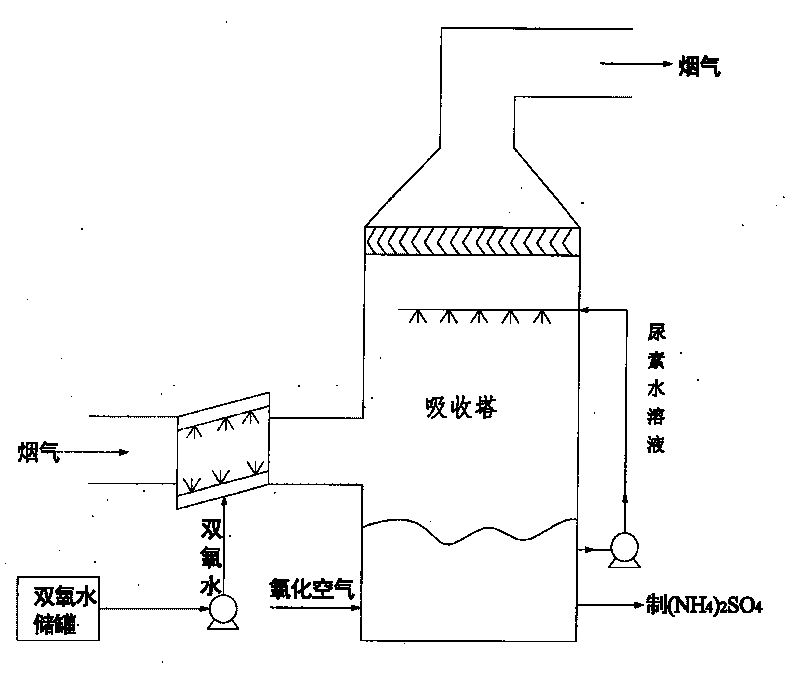

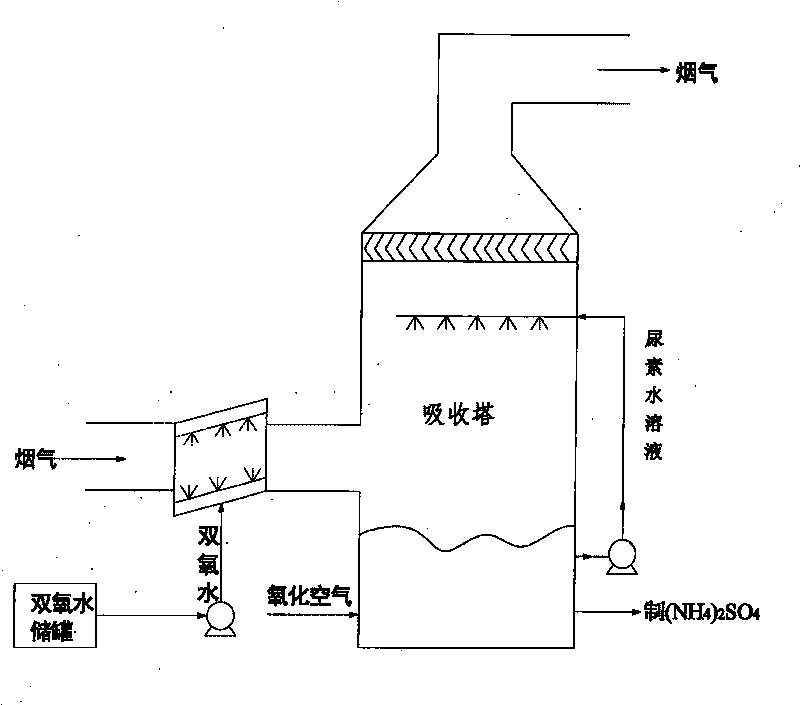

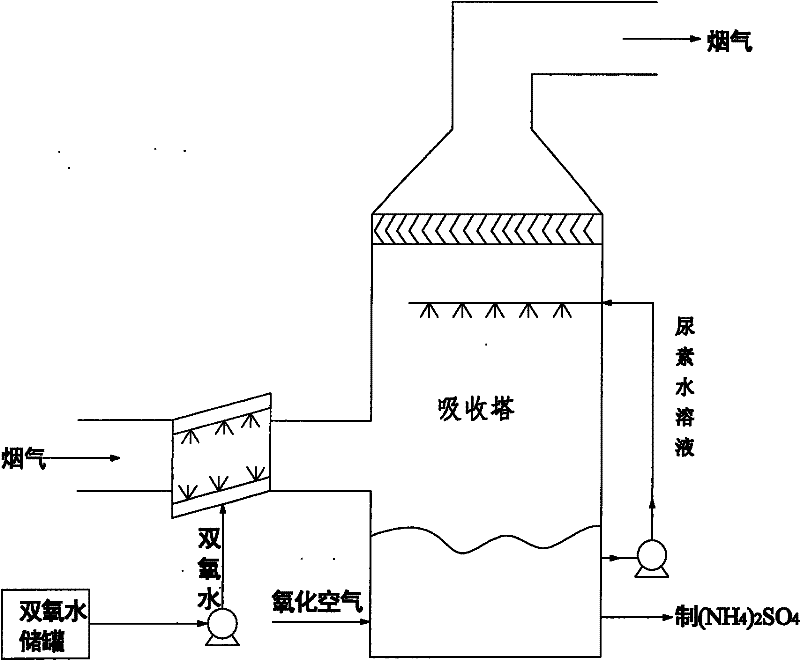

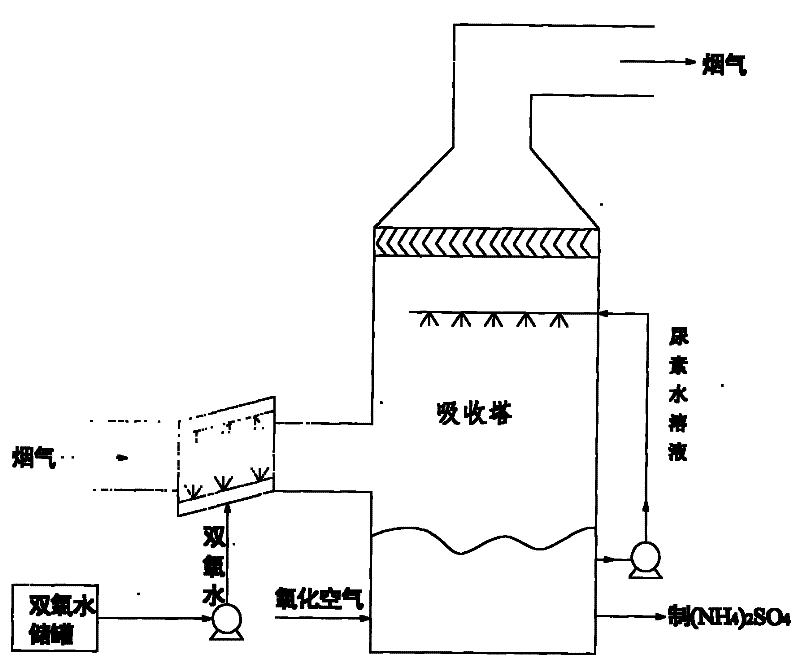

Coal-fired flue gas denitration and desulfurization method combined with urea wet method

ActiveCN101708419AImprove denitrification rateGood chemical stabilityLighting and heating apparatusDispersed particle separationUreaAqueous solution

The invention discloses a coal-fired flue gas denitration and desulfurization method combined with the urea wet method. The method comprises the following steps: spraying 50wt% of hydrogen peroxide at the coal-fired flue gas inlet of a absorption tower while keeping the molar ratio of H2O2 to NO to be 2-3, so as to oxidize NO in the coal-fired flue gas to NO2 and increase the oxidization degree of NOX; and perform denitration and desulfurization simultaneously by using the urea aqueous solution in the absorption tower. The method of the invention increases the denitration rate of the coal-fired flue gas denitration and desulfurization combination technology by increasing the oxidization degree of NOX and the temperature of the absorption solution. The method has simple technology, convenient operation and management, no secondary pollution and good environmental and economic benefits.

Owner:GUODIAN ENVIRONMENTAL PROTECTION RES INST CO LTD +1

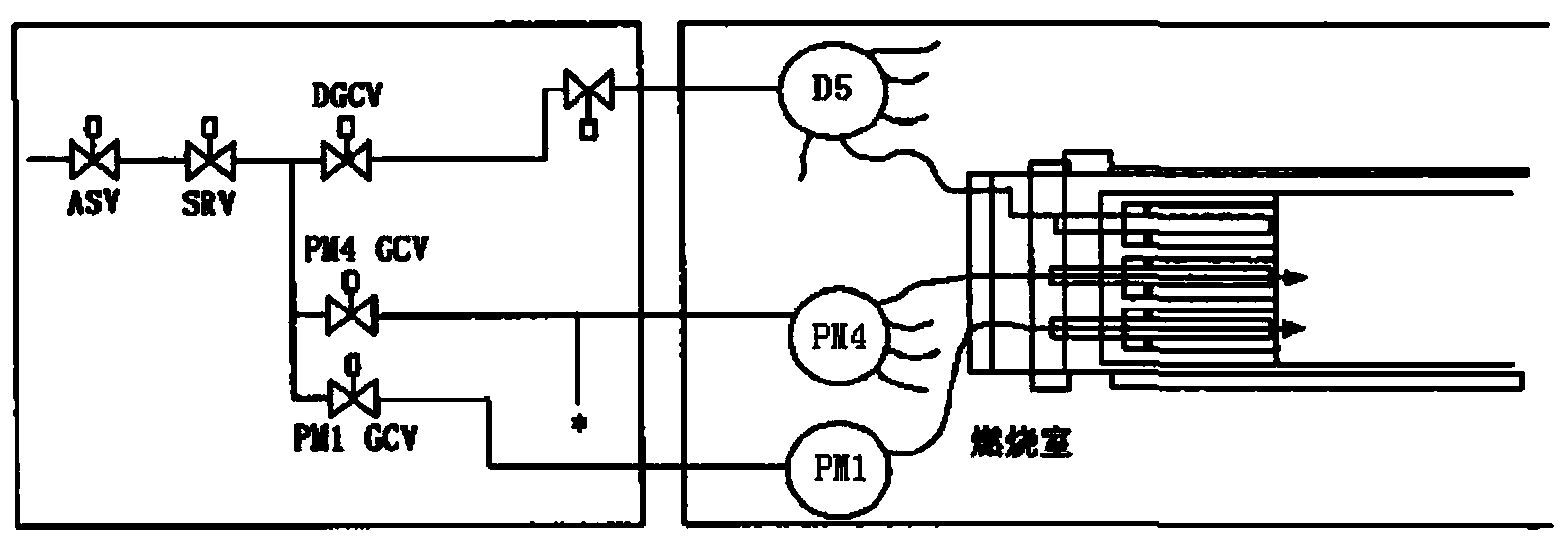

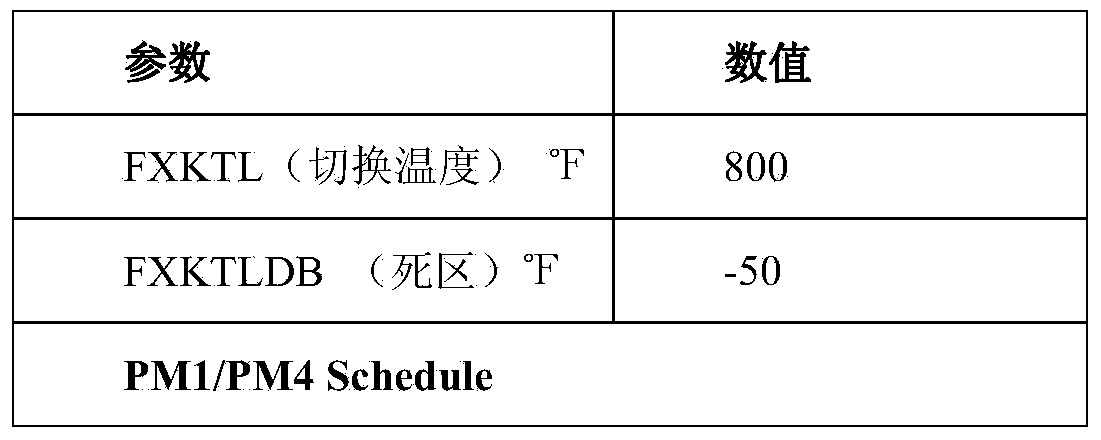

Gas turbine engine dry-type low-NOx combustion adjustment method

ActiveCN103410618AGuaranteed uptimeStable emissionsTurbine/propulsion fuel controlCombustion systemGas turbines

The invention discloses a gas turbine engine dry-type low-NOx combustion adjustment method. According to the analysis of the combustion situation, the method is used for adjusting the D5, PM1, PM4 of a DLN-2+ combustion system as well as a purge air control value in real time through the adjustment of control constant until the combustion dynamic pressure monitoring result and the NOx and CO emission both have appropriate values. According to the invention, the combustion of a modern gas turbine engine adopting a premixed combustion technique is optimized and adjusted; the running state of the modern gas turbine engine is improved; the running stability of the modern gas turbine engine is enhanced; the damage to the heat parts of the gas turbine engine is relieved; influences of heat value variation and environment temperature variation on the operation of the gas turbine engine are prevented.

Owner:SHANGHAI MINGHUA ELECTRIC POWER TECH & ENG +2

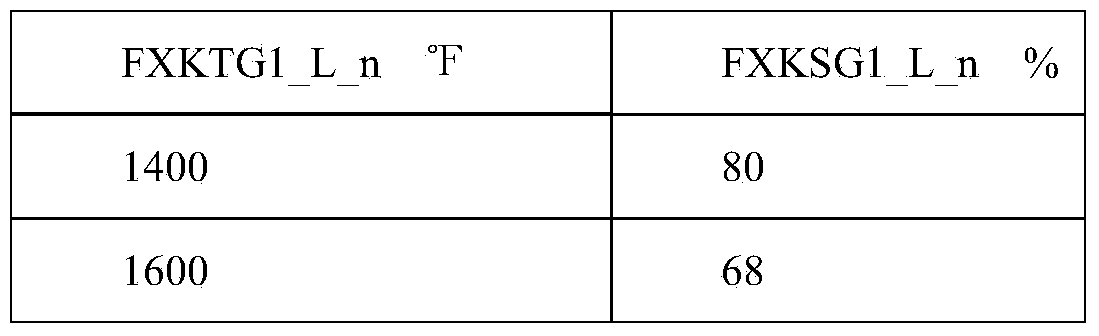

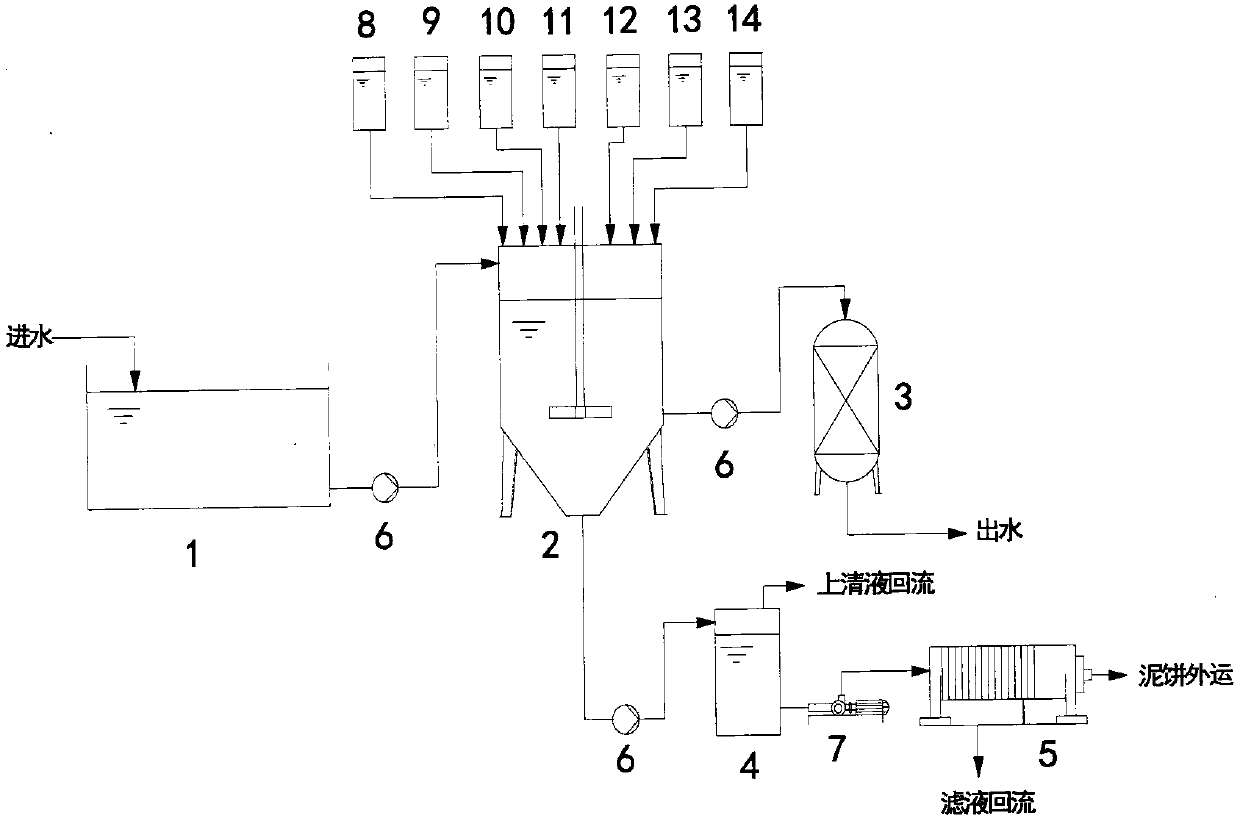

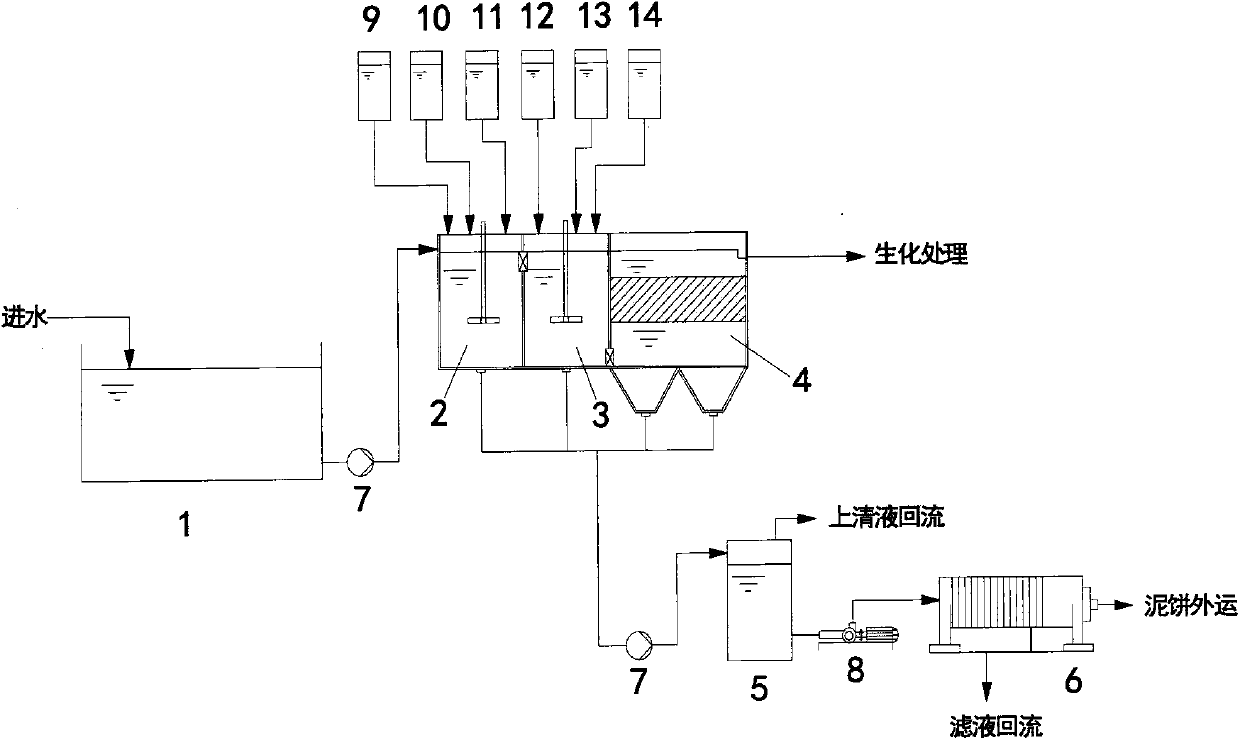

Process for treating and recycling mine acid heavy metal wastewater

InactiveCN103771630ASolubility product constant is smallCompliance with emission requirementsMultistage water/sewage treatmentActivated carbonSludge

The invention discloses a process for treating and recycling mine acid heavy metal wastewater. The process comprises the steps of collecting the mine acid heavy metal wastewater and then introducing the mine acid heavy metal wastewater into an integrated reactive precipitation system, and completing the processes of feeding chemicals, stirring, reacting, flocculating and precipitating; treating a supernatant in a reaction tank with activated carbon and then recycling as cleaning water; and concentrating sludge slurry at the lower part of the reaction tank and then forming the concentrated sludge into mud cakes for outward transportation and treatment. The mine acid heavy metal wastewater can be recycled after being treated through the process, and as a result, discharge of pollution is reduced, and the usage amount of water resources is also reduced.

Owner:HANGZHOU SHUANGBO ENVIRONMENTAL PROTECTION TECH

Process for treating and recycling alkaline wastewater containing zinc and chromium ions

InactiveCN103771631ACompliance with emission requirementsSolubility product constant is smallMultistage water/sewage treatmentActivated carbonSludge

The invention discloses a process for treating and recycling alkaline wastewater containing zinc and chromium ions. The process comprises the steps: introducing wastewater to an integrated sequencing batch reaction tank; then, finishing dosing, stirring, reacting, flocculating and settling processes; treating a supernatant liquid in the reaction tank by using activated carbon, and then, recycling the supernatant liquid as cleaning water; and concentrating the sludge slurry at the lower part of the reaction tank, and then, preparing the sludge slurry into mud cakes to be outwards transported and treated. The alkaline wastewater containing the zinc and chromium ions can be recycled as water after being treated by using the process provided by the invention. The process has the advantages of high efficiency, simplicity, convenience, economy, practicability and the like and can be used for simultaneously realizing economic, societal and environmental benefits.

Owner:HANGZHOU SHUANGBO ENVIRONMENTAL PROTECTION TECH

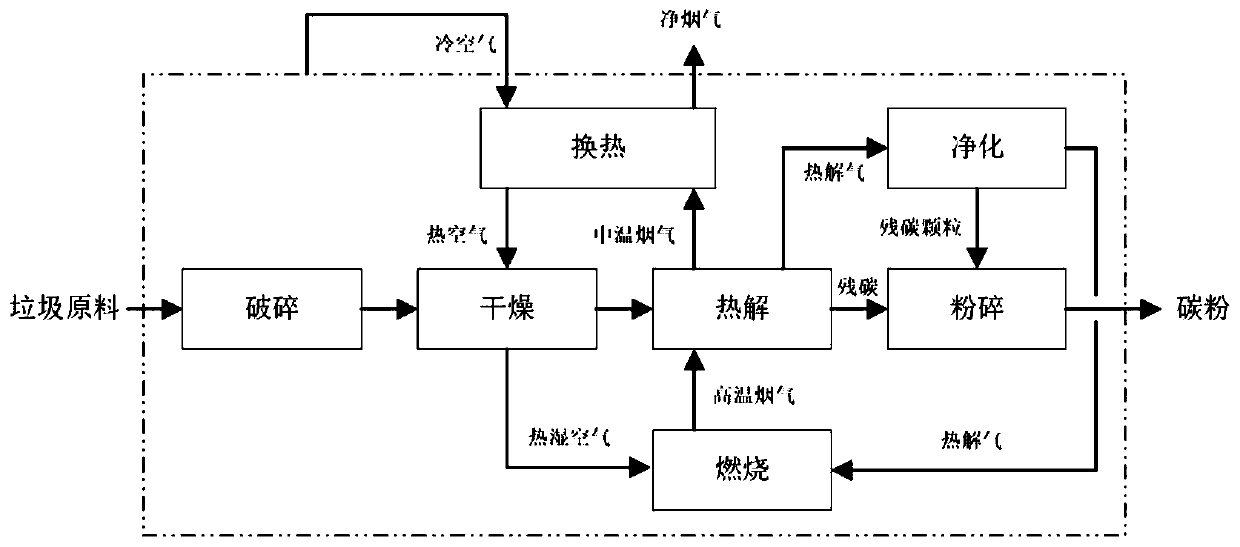

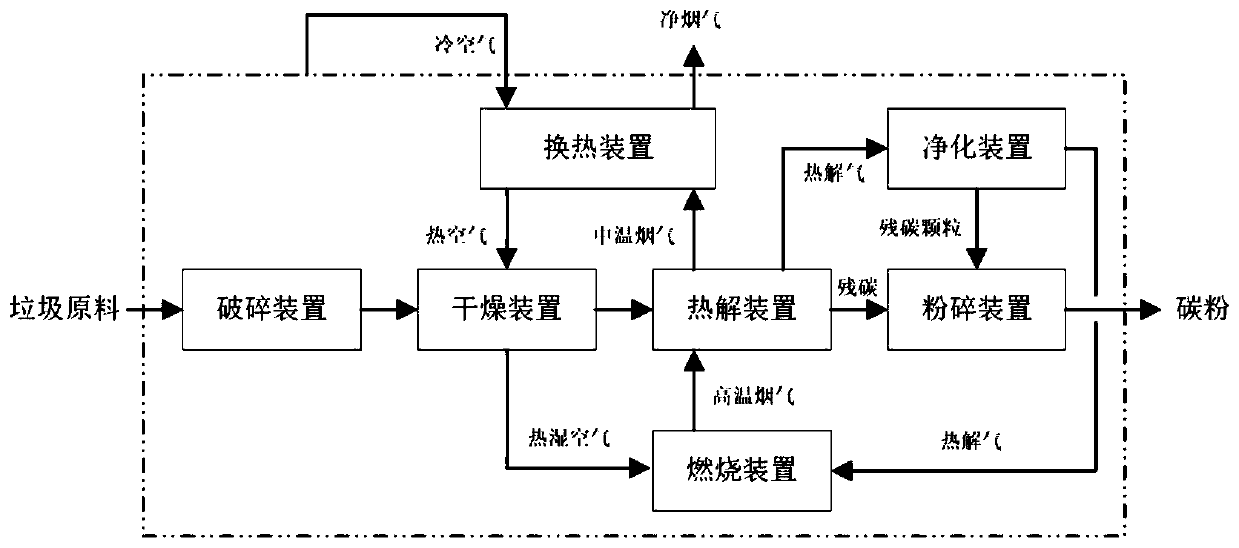

High-water-containing domestic garbage rapid resource cleaning treatment method and system

ActiveCN110883050AHigh calorific valueNo emissionsSolid waste disposalCarbon preparation/purificationPollutionDust abatement

The invention discloses a high-water-containing domestic garbage rapid resource cleaning treatment method and system. The method comprises the following steps that (1) breaking is carried out, specifically, a garbage raw material containing 50% - 80% water is broken to particles with the size smaller than 50 mm; (2) drying is carried out, specifically, the broken garbage makes contact with hot air15 - 60 min; (3) pyrolysis is carried out, specifically, dried garbage with the temperature of 80 - 105 DEG C makes contact with high temperature flue gas 15 - 60 min, and the pyrolysis is carried out when the temperature of the garbage is increased to 300 - 600 DEG C; (4) purification is carried out, specifically, and after pyrolysis gas with the temperature of 150 - 300 DEG C is subjected to high-temperature dust removal and desulfurization, residual carbon particles and gas are obtained; (5) low-nitrogen combustion is carried out, specifically, hot and humid air with the temperature of 120- 200 DEG C generated in the step (2) and gas with the temperature of 150 - 300 DEG C are combusted, and the temperature of the obtained high-temperature flue gas is adjusted to 600 - 800 DEG C and fed into the step (3); (6) heat exchange is carried out, specifically, cold air and medium-temperature flue gas with the temperature of 300 - 400 DEG C generated in the step (3) are subjected to indirect heat exchange, and obtained air with the temperature of 200 - 300 DEG C is fed to step (2), and flue gas with the temperature of 120 - 160 DEG C is discharged; and (7) crushing is carried out, specifically, residual carbon and the residual carbon particles obtained in the step (3) are mixed and crushed. The high-water-containing domestic garbage rapid resource cleaning treatment method and system have the characteristics of compact process, high integration degree, small system occupied area, flexible installation mode, in-situ conversion, no odor emission and no secondary pollution..

Owner:BENGBU COLLEGE

Multiple-effect composite refining flux for removing impurities in aluminum and aluminum alloy melt and application

ActiveCN105803215AEvenly dispersedAccelerates the process of adsorbing slag inclusionsPowder mixtureSlag

The invention discloses a multiple-effect composite refining flux for removing impurities in aluminum and aluminum alloy melt. Raw materials of the multiple-effect composite refining flux comprise, by weight, 50%-70% of aluminum fluoride AlF3, 15%-25% of magnesium chloride MgCl2, 2%-10% of sodium borate Na2B4O7 and 1%-15% of potassium chloride KCl2. All the raw materials are dried industrial grade powder products, and the purities of all the raw materials reach 99.5% or above. After the matched raw materials are added into a ball mill for ball milling for 10-15 min, the raw materials are screened through a screen with the meshes being 100-325, and the powder mixture grain size distribution requirements are that 35%-50% of powder with the grain size being 90-125 [mu]m, 20%-25% of powder with the grain size being 60-90 [mu]m, 8%-10% of powder with the grain size being 40-60 [mu]m, and 35%-50% of powder with the grain size being smaller than or equal to 40 [mu]m. The prepared flux is packaged in a sealed mode for standby application after inspection. The multiple-effect composite refining flux provided by the invention has the good capacity for removing the metal impurities and oxide inclusion, the problem that metal impurities in the aluminum and aluminum alloy melt are over standard is solved, and the flux has the better impurity and slag inclusion removing capacity, and has the multiple effects and the multiple purposes.

Owner:广元中孚高精铝材有限公司

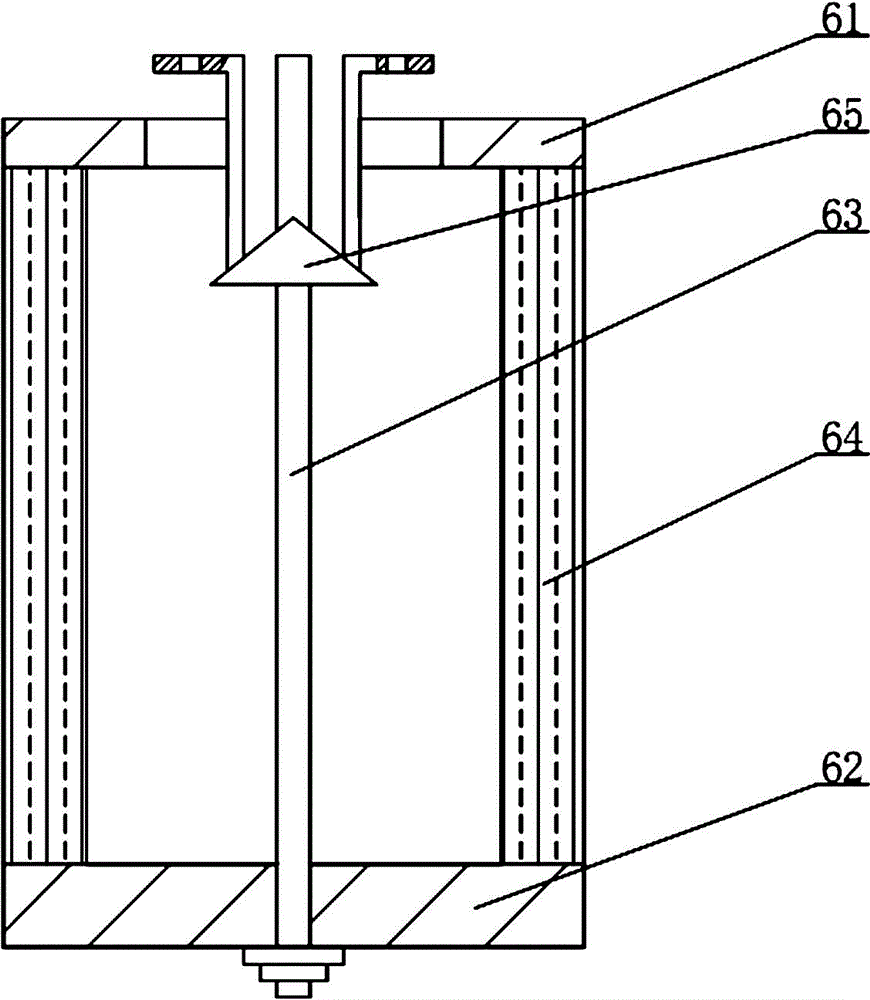

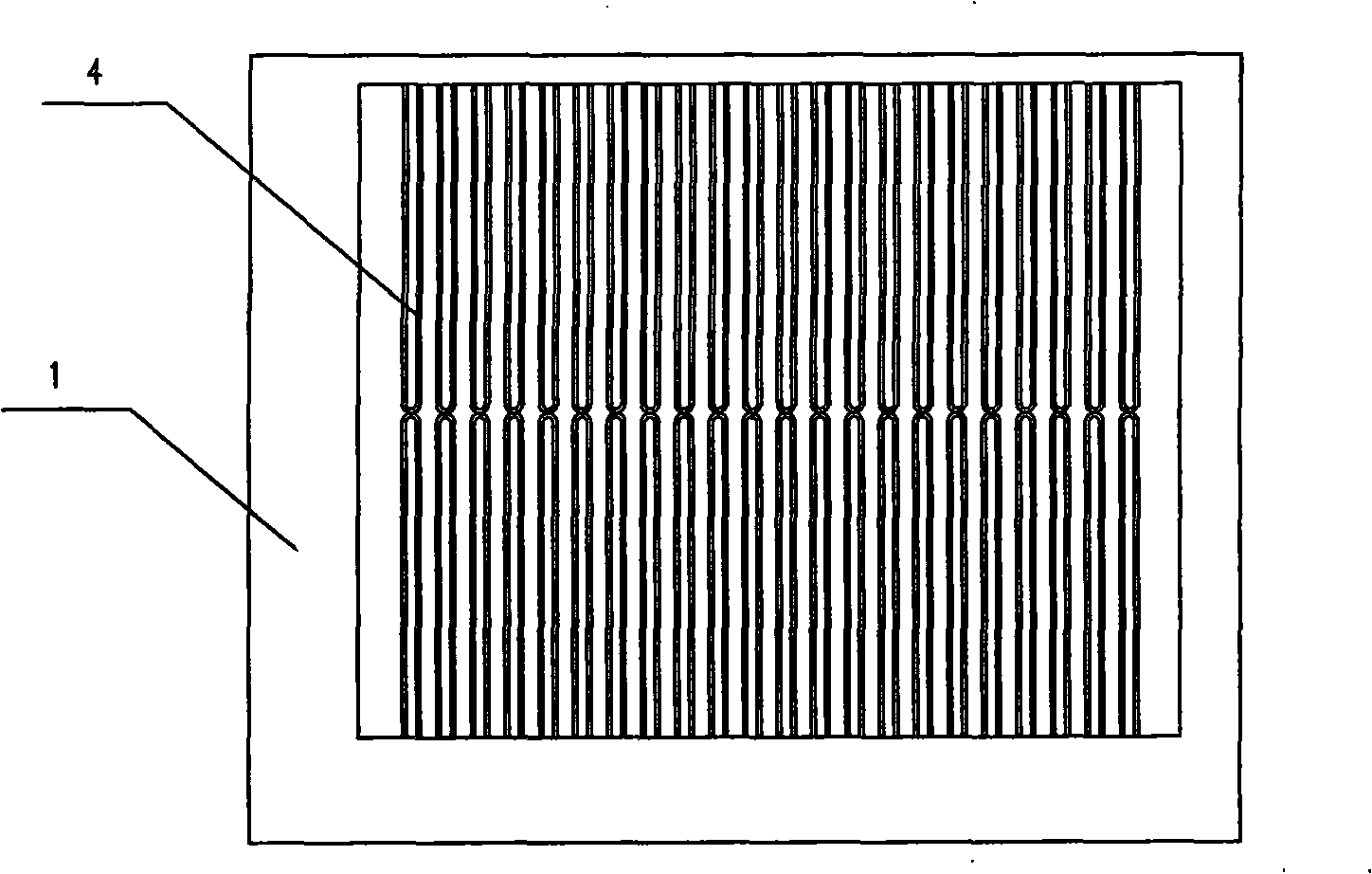

Hot air circulation and exchange enameled oven

InactiveCN102074317AWell mixedLower the targetInsulating conductors/cablesCombustion chamberEvaporation

The invention discloses a hot air circulation and exchange enameled oven, which comprises a hearth and a heat radiation device arranged in the hearth. The enameled oven is characterized in that: the hearth is sequentially provided with an evaporation zone, an assimilation zone and a drying zone, wherein the upper part of the evaporation zone is provided with a mutually communicated catalytic combustion chamber, the catalytic combustion chamber is provided with an air inlet / outlet, the lateral part of the catalytic combustion chamber is provided with an air homogenizing device, and a passage formed in the air homogenizing device is mutually communicated with the drying zone. The enameled oven has reasonable structure, uniform airflow direction and temperature, energy conservation, environmental friendliness and good popularization value.

Owner:林兆欣

Pretreatment technology of hot-galvanizing wastewater

InactiveCN103771629AOrganic load reductionReduce energy consumptionWaste water treatment from metallurgical processMultistage water/sewage treatmentSludge cakeChemical oxygen demand

The invention discloses a pretreatment technology of hot-galvanizing wastewater. The pretreatment technology comprises the following steps: introducing the wastewater into a continuous reaction precipitation system, dosing, stirring, reacting, flocculating and precipitating; and carrying out further biochemical treatment on supernatant in a reaction tank, so that after meeting discharge standards, the supernatant is discharged, and concentrating sludge slurry at the lower part of the reaction tank so as to prepare sludge cakes, externally transporting the sludge cakes and treating. After the hot-galvanizing wastewater is treated by the pretreatment technology, zinc ions and phosphate radical ions meet the discharge standards, the COD (Chemical Oxygen Demand) value is substantially reduced, and the pressure of an organic load of a follow-up biochemical treatment system is greatly reduced; the pretreatment technology of the hot-galvanizing wastewater is high-efficiency, reliable, economic and practical.

Owner:HANGZHOU SHUANGBO ENVIRONMENTAL PROTECTION TECH

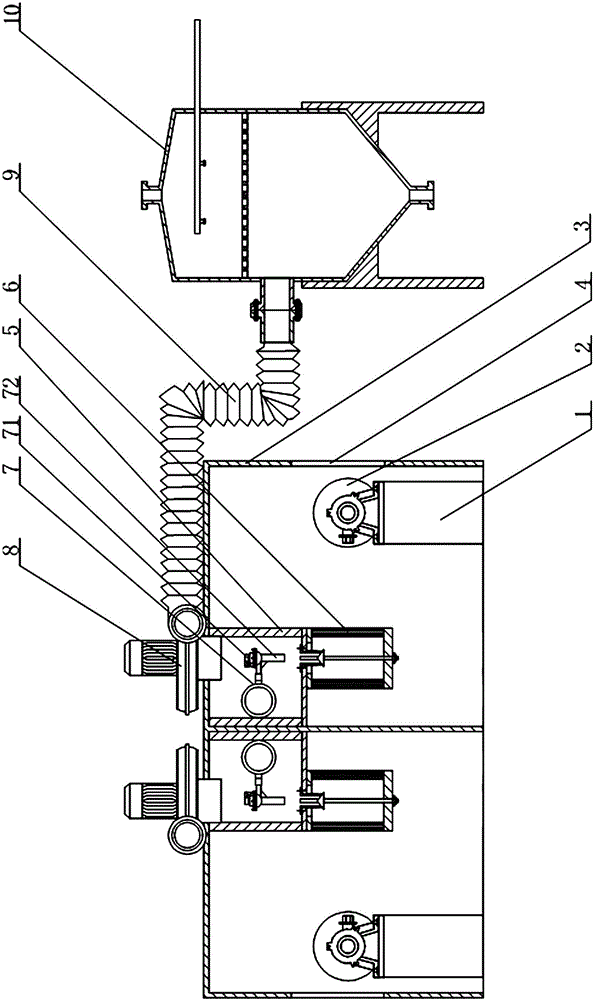

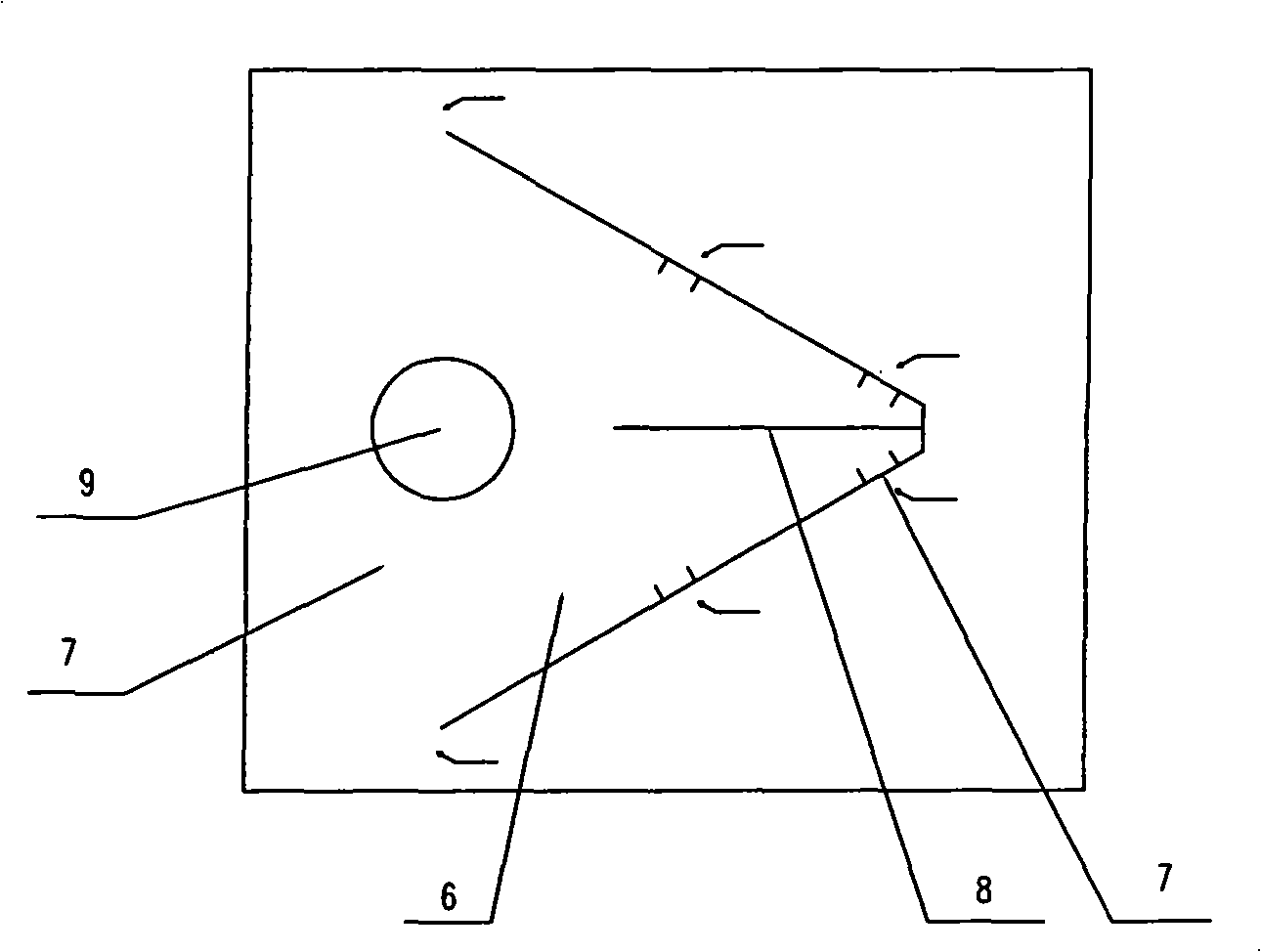

Grinding wheel machine dedusting device

InactiveCN104308742ACompliance with emission requirementsWill not polluteCombination devicesGrinding/polishing safety devicesEngineeringAir emission

The invention relates to a grinding wheel machine dedusting device and mainly solves the problem that a dedusting device on an existing desk-type grinding wheel machine is poor in dedusting effect. The grinding wheel machine dedusting device is characterized in that grinding wheel machines (1) are disposed in a negative pressure chamber (3), the side walls of the negative pressure chamber (2) are provided with windows (4) corresponding to grinding wheels (2), isolating chambers (5) are arranged at the top in the negative pressure chamber (2), the lower end of each isolating chamber (5) is connected with a filter (6), a blowback device (7) is fixed in each isolating chamber (5), and fans (8), a hose (9) and a spraying dust collector (10) which are positioned outside the negative pressure chamber (2) are sequentially communicated above the isolating chambers (5). Devices like the semi-closed negative pressure chamber, the filters and the spraying dust collector are adopted, chippings and dust generated when the grinding wheel machines work can be completely adsorbed into the negative pressure chamber and do not pollute workshop environment, dedusting effect is good, and air emission requirements are met.

Owner:佛山市顺德区顺世龙机械设备有限公司

Spray tower and electrostatic dust-removing, desulfurizing and denitrating device

InactiveCN101468280ACompliance with emission requirementsReduce humidificationCombination devicesFlue gasSpray tower

The invention relates to a spray tower electrostatic dusting removal desulphurization and denitration device, which mainly comprises a spray tower and an electrostatic processor, wherein the electrostatic processor comprises a humidity and temperature adjuster, an activation device and an ammonium salt collector; the humidity and temperature adjuster, the activation device and the ammonium salt collector are arranged in the same shell; and a humidifying temperature adjusting area of the humidity and temperature adjuster, an ammonification activating area of an ammonification activation device, an oxidation synthesizing area of an oxidation synthesizer, and an ammonium salt collecting area of the ammonium salt collector are arranged in the shell sequentially along the airflow direction. By adopting the structure, the spray tower is used to perform dust removal so that the flue dust content accords with the discharge requirement, and a wet dust removal process is used to humidify the flue gas so as to reduce the humidification amount for the subsequent process; the subsequent humidity and temperature adjuster, the activation device and the ammonium salt collector are combined together organically to save connecting pipelines between the devices so that the structure is more compact, the airtightness is improved, the ground is saved, and the maintenance is more convenient. The spray tower electrostatic dusting removal desulphurization and denitration device is mainly applied to the dusting removal, the desulphurization and the denitration of the flue gas.

Owner:HAISIBOTE BEIJING SCIENE & TECH

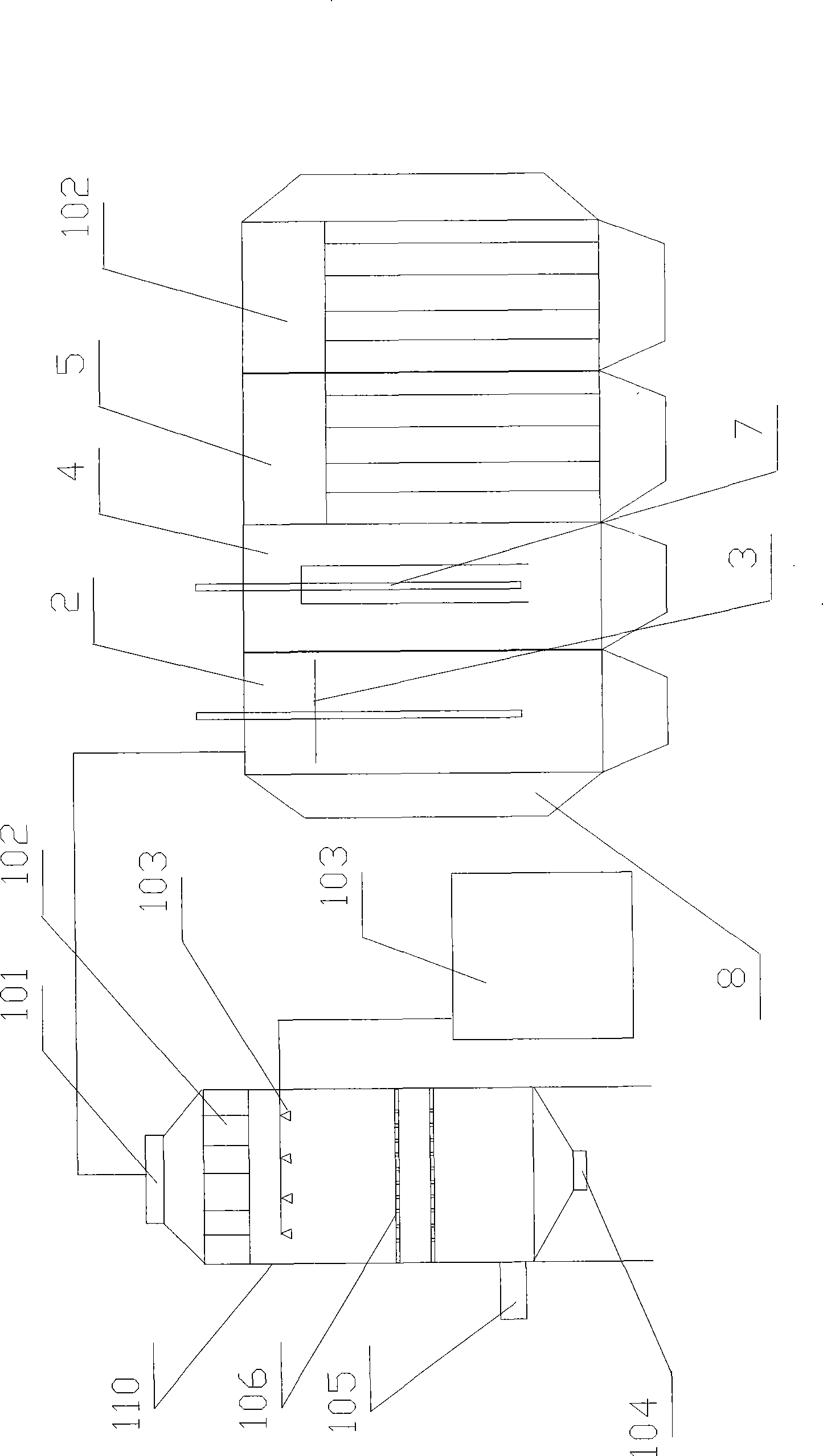

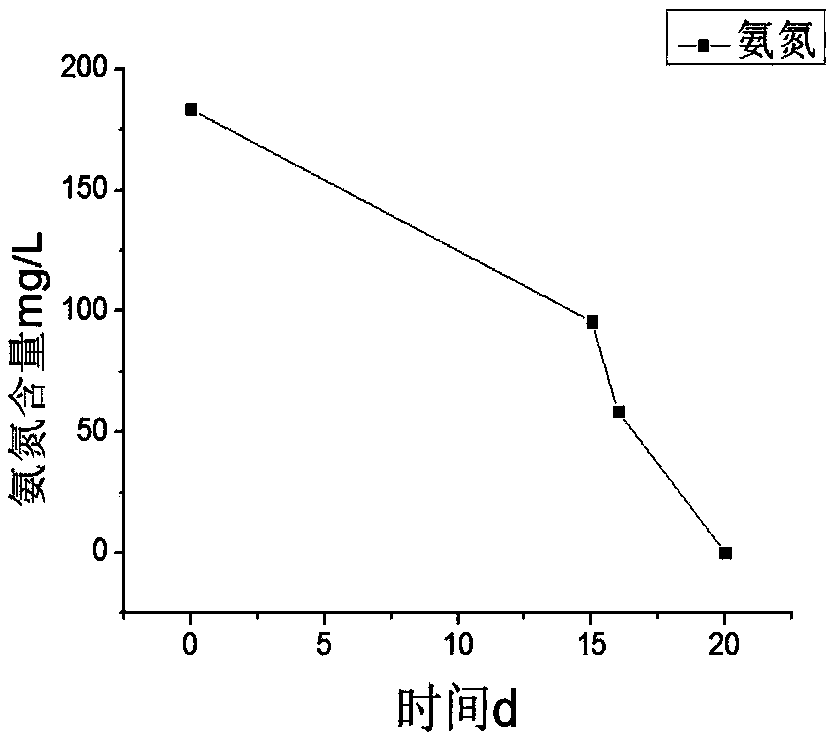

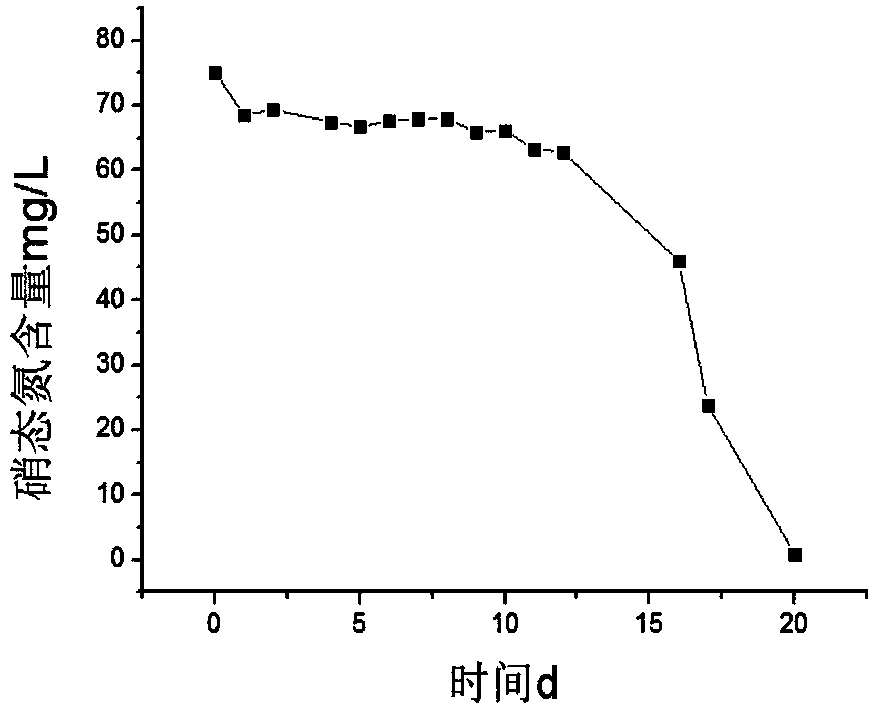

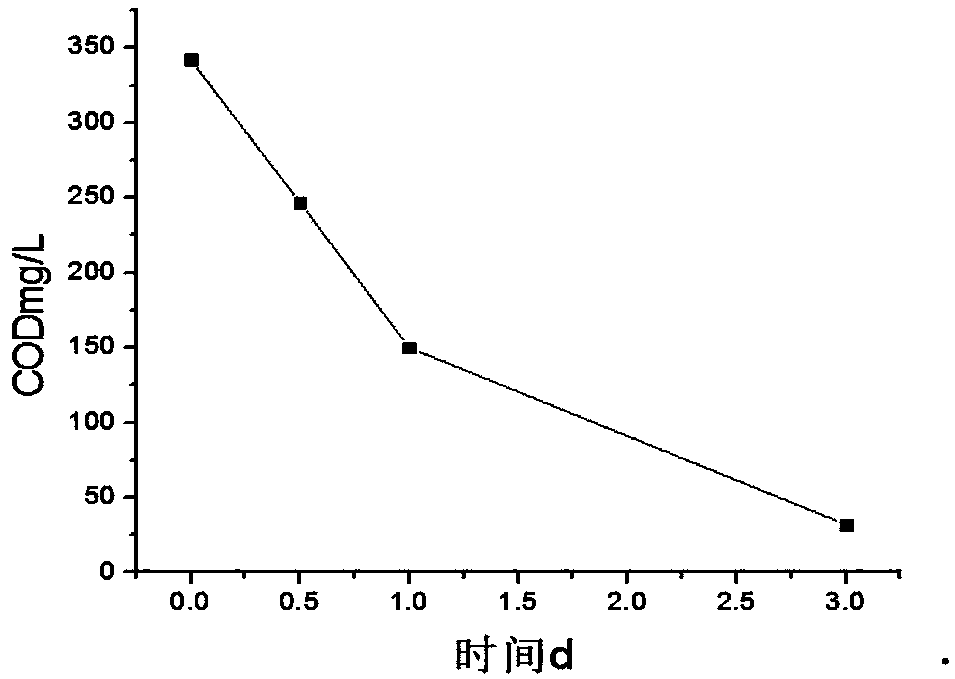

Method for treating high-nitrogen and low-carbon rare earth ore mining wastewater step by step by using microalgae and activated sludge

ActiveCN108585208AIncrease absorption rateNo phosphorus residueWaste water treatment from quariesWater treatment compoundsActivated sludgeRare earth

The invention discloses a method for treating high-nitrogen and low-carbon rare earth ore mining wastewater by using microalgae and activated sludge and belongs to the technical field of sewage treatment. The method for treating rare earth ore mining water comprises the following steps: 1) regulating the ratio of nitrogen and phosphorus in the rare earth ore mining wastewater to (0.5-1.5):(2-3) byusing a phosphorus-containing compound to obtain to-be-purified wastewater; 2) adding enriching microalgae into the to-be-purified wastewater to carry out purification treatment, and separating algaefrom water to obtain primarily-purified water; and 3) adding activated sludge into the primarily-purified water to carry out purification treatment again to obtain purified water. The wastewater is treated by using scenedesmus and chlorella in the method for treating high-nitrogen and low-carbon rare earth ore mining wastewater by using microalgae and activated sludge, so that the contents of ammonia nitrogen and total nitrogen in the wastewater can be effectively reduced, COD additionally added during microalgae treatment is subjected to purification treatment again by the activated sludge,so that the COD value is reduced to 32mg / L, and the wastewater meets a discharge requirement of the first level A of the discharge standard for pollutants from an urban wastewater treatment plant.

Owner:江西智汇环境技术有限公司

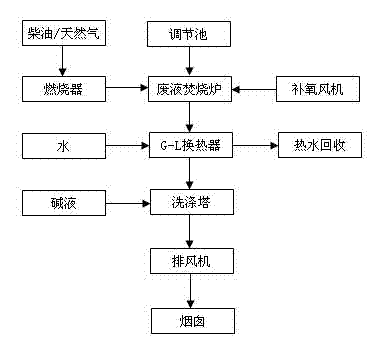

Phenol water treatment technique and device for gas furnace

InactiveCN101062796AEffective handlingReduce loadWater/sewage treatment by heatingIncinerator apparatusPhenolsWater treatment

The invention discloses a phenol water treatment technology of gas furnace and device in waste water disposal domain, which is characterized by the following: proceeding heat exchange with air and lower branch gas; touching with atomized phenol water; evaporating the phenol in the phenol water; burning the phenol; making the device comprise two-section coal-gas producer and phenol water pool; equipping with cyclone saturation tower, shell-and-tube heat exchanger, air pump and phenol water pump. This craft and device possess the advantages of energy-saving and environment protection, which can diminish the pollution for environment.

Owner:山东万丰煤化工设备制造有限公司

Magnesium alloy desilicon flux and production method

Besides magnesium chloride 15-30%, potassium chloride 15-30%, calcium fluoride 10-20%, barium chloride 8-12% and magnesium fluoride 10-25% etc. the chemical constituent of fusing agent has titanium compound 10-20% and carbonate 1-10% being added. Magnesium chloride and potassium chloride etc. is added into the warmed up crucible. With the magnesium chloride etc. being melted, calcium fluoride andmagnesium fluoride is added to the crucible. The fusing agent is made through procedures of heating up, stirring and pouring in bulk, then the procedures of crushing, milling and sifting out as well as with titanium compound and carbonate being added. The invented magnesium alloy provides the advantages of remarkable effect of removal of silica and excellent deslagging performance as well as improving mechanical property and corrosion-resisting properties.

Owner:SHANGHAI JIAO TONG UNIV

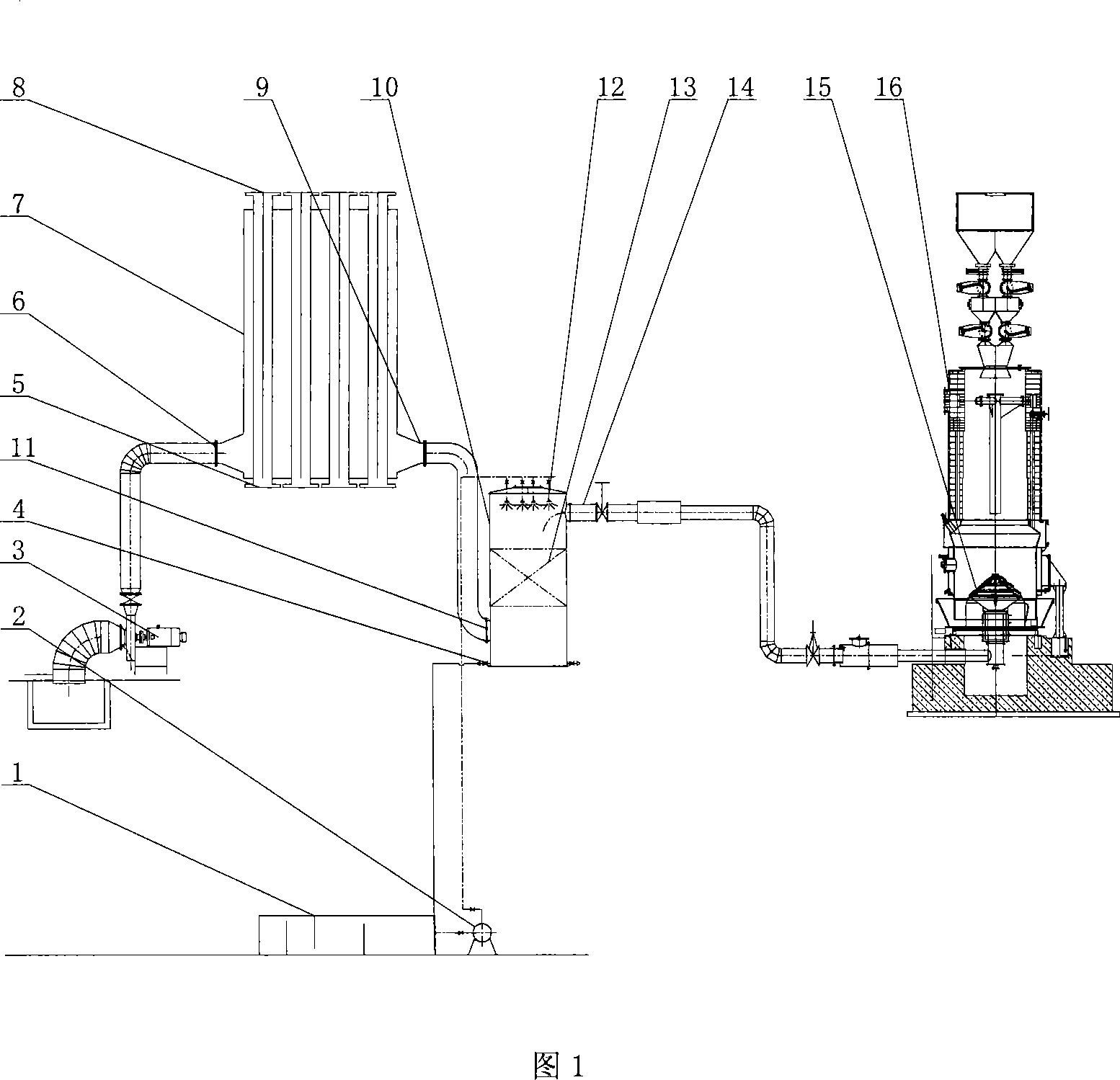

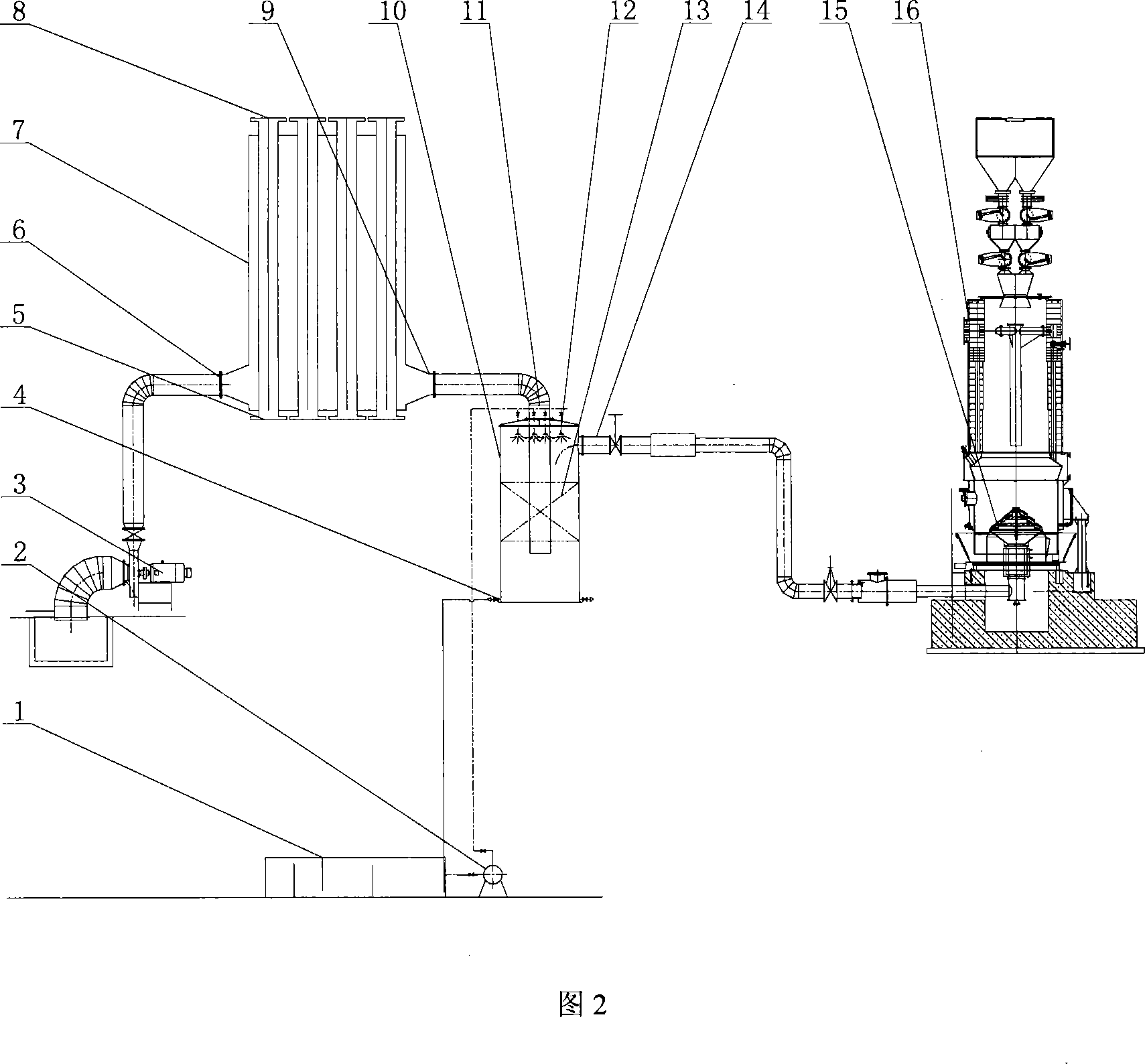

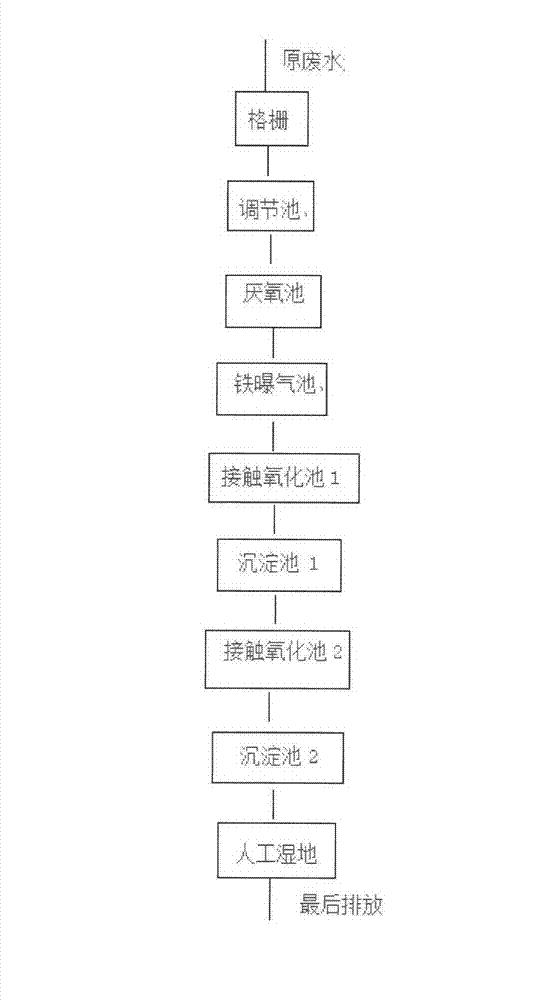

Printing and dyeing wastewater processing method

InactiveCN102849897AReduce outputReduce processing costsMultistage water/sewage treatmentWaste water treatment from textile industryConstructed wetlandGrating

The invention provides a printing and dyeing wastewater processing method. The method comprises the following steps: allowing raw wastewater to respectively go through a grating, an adjustment pool, an anaerobic pool, an iron aeration pool, a first contact oxidation pool, a first sedimentation pool, a second contact oxidation pool, a second sedimentation pool and a constructed wetland; and discharging, wherein sludge generated in the iron aeration pool, the contact oxidation pools and the sedimentation pools backflows to the anaerobic pool for internal digestion. The method completely which adopts a biological process and thoroughly discards general physical and chemical processing processes has the advantages of no need of the addition of chemical drugs comprising a coagulant or the like, less sludge output, and low processing cost. The printing and dyeing wastewater processed through the technology completely accords with a discharge requirement.

Owner:KUNSHAN WANFENG GARMENT

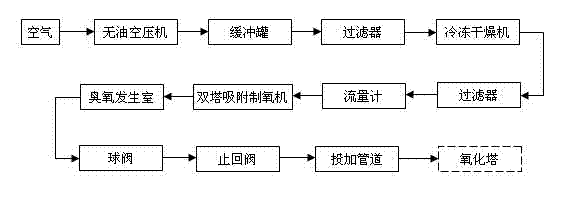

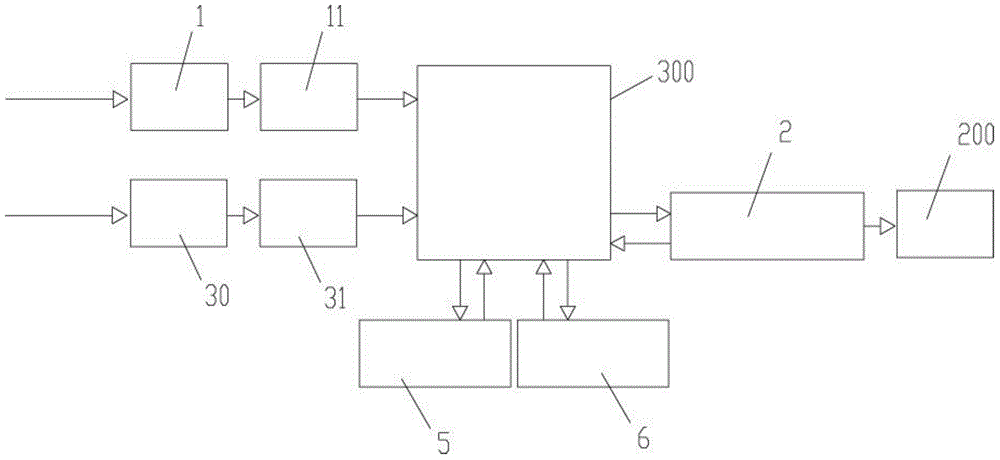

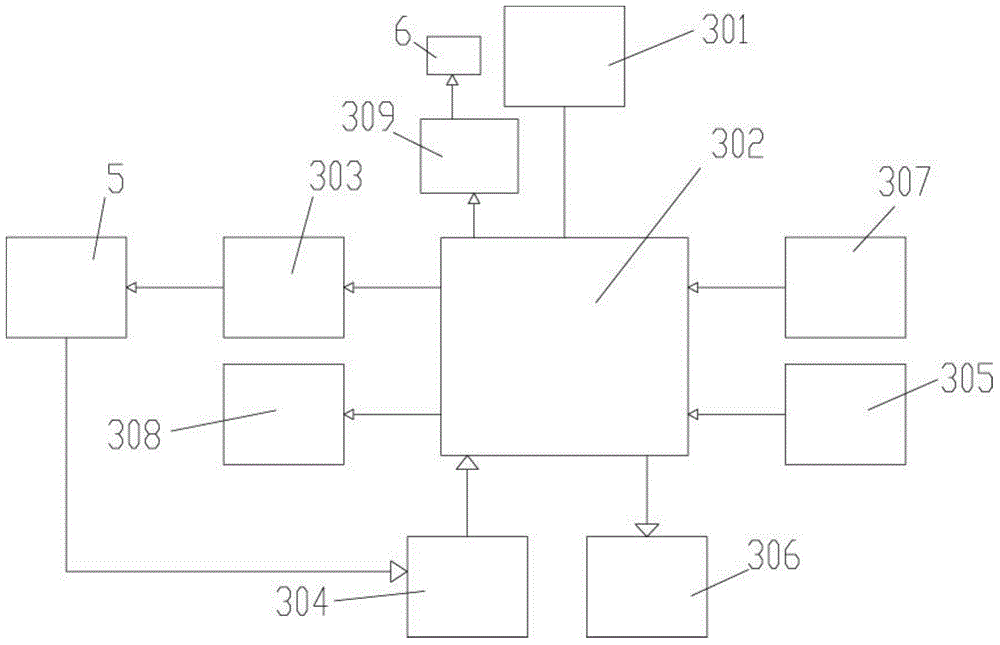

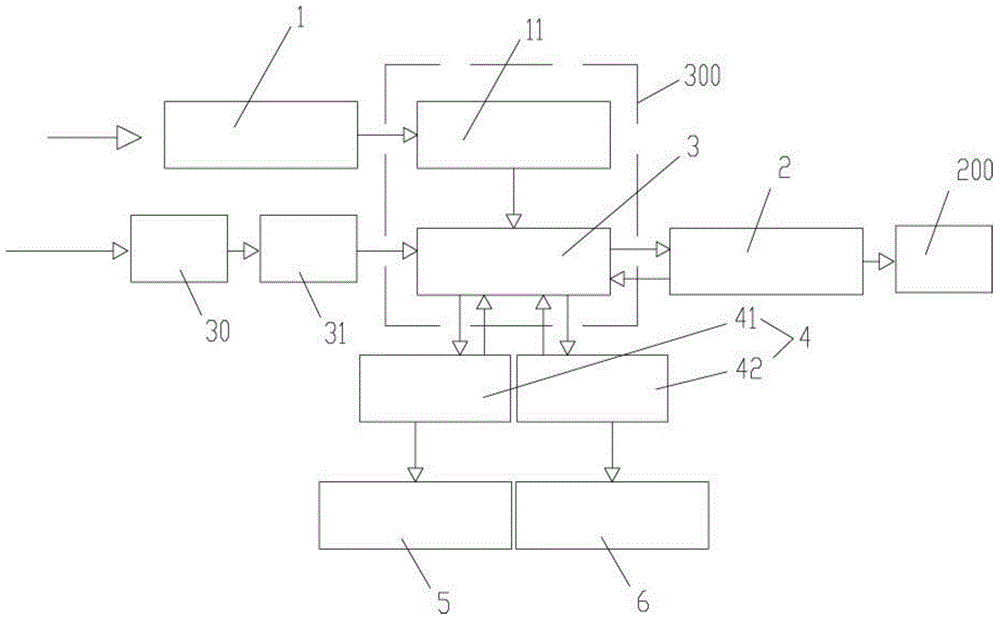

Online oil-gas recovery intelligent control system

InactiveCN105480929AReduce pollutionReduce maintenance costsLiquid transferring devicesAtmospheric emissionsLiquid ratio

The invention discloses an online oil-gas recovery intelligent control system. The system comprises a gas flow meter and a monitoring host. The gas flow meter is connected to a return gas pipeline of an oil-gas recovery refueling gun in series. A liquid flow meter is connected to an oil circuit of a refueling machine in series. A sensor is arranged in the gas flow meter. An encoder is arranged on the liquid flow meter. The sensor transmits detected data to a control mainboard through a data line. The encoder transmits the detected data to the control mainboard through a data line. The control mainboard processes the received data and then controls the magnitude of flow of an oil-gas recovery pump or the magnitude of gas flow of an oil-gas recovery solenoid valve. The control mainboard transmits the processed data and the received data to the monitoring host for storage at the same time. The monitoring host transmits the gained stored information to a remote master control host. By adopting the online oil-gas recovery intelligent control system, real-time monitoring and intelligent adjustment of oil-gas recovery of a gas station are achieved, the oil-gas recovery gas-liquid ratio can be made to meet the atmospheric emission requirements all the time, air pollution is relieved, and on-line monitoring is achieved.

Owner:JIANGYIN FUREN HIGH TECH

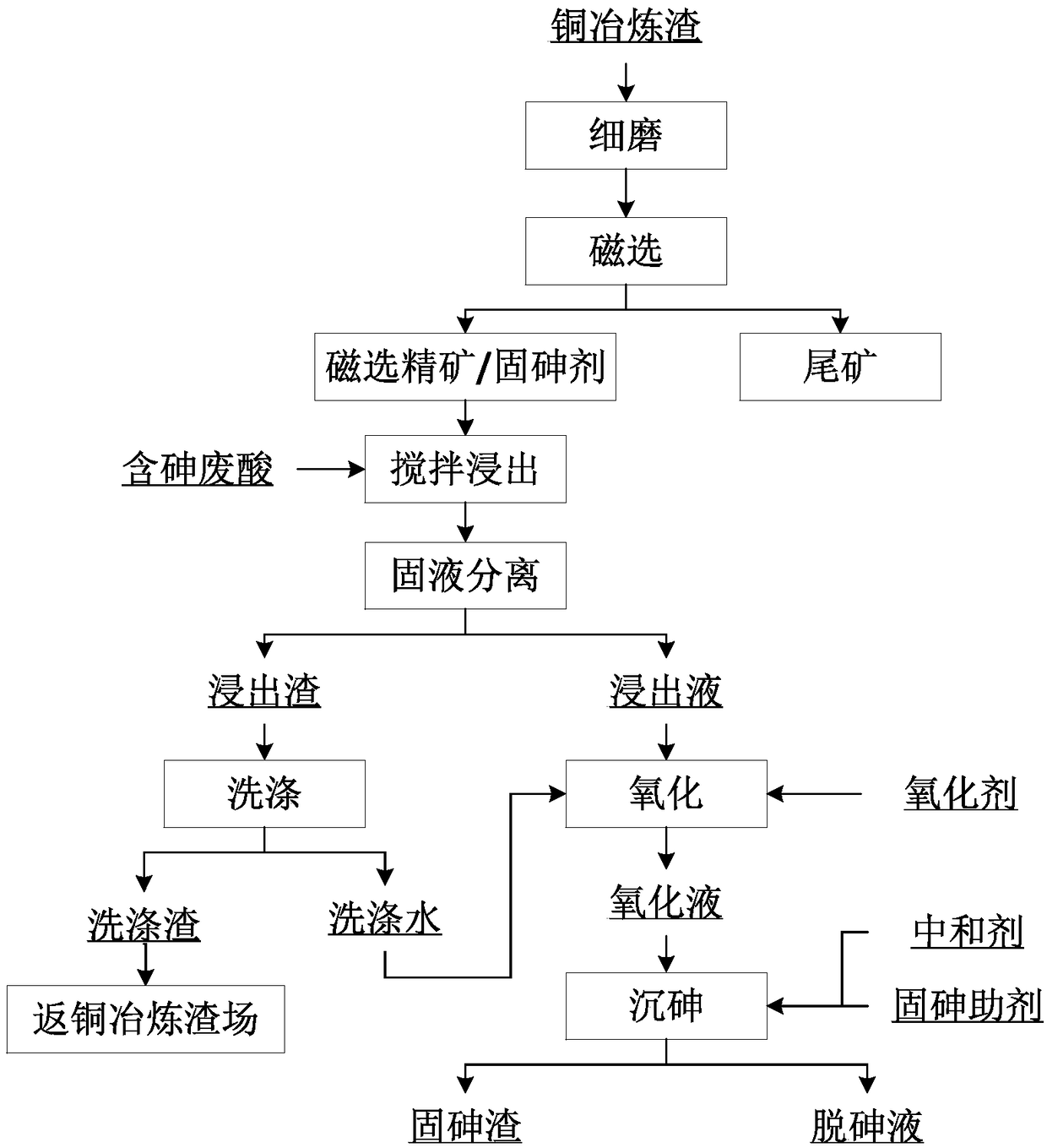

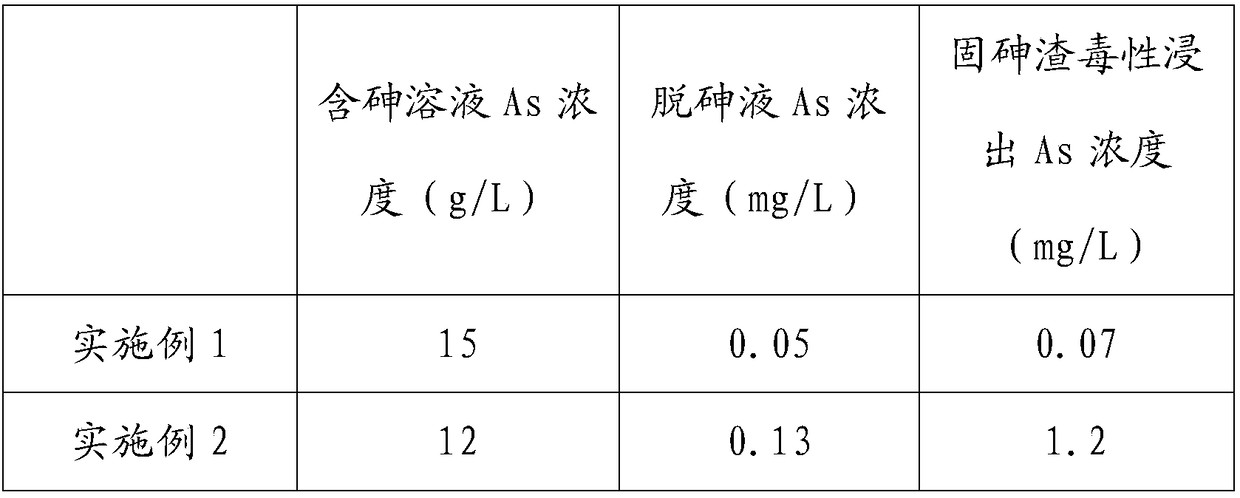

Arsenic-containing waste acid low-cost harmless treatment method

InactiveCN109368854ALow costThe amount of leaching residue is reducedWater contaminantsWaste water treatment from metallurgical processPregnant leach solutionSlag

The invention discloses an arsenic-containing waste acid low-cost harmless treatment method comprising the following steps: the step S1 of finely grinding copper smelting slag and then performing magnetic separation to obtain tailings and magnetic concentrate; the step S2 of adding the magnetic concentrate obtained in the step S1 as an arsenic-fixing agent to arsenic-containing waste acid for stirring and leaching and then conducting solid-liquid separation to obtain a leaching solution and leaching slag; the step S3 of adding industrial water to the leaching slag obtained in the step S2 for washing, pumping washing water obtained into the leaching solution obtained in the step S2 and returning obtained washing slag to a copper smelting slag field; the step S4 of adding an oxidizing agentto the leaching solution with the pumped washing water obtained in the step S3 to obtain an oxidizing solution; the step S5 of adding a neutralizing agent and an arsenic-fixing aid to the oxidizing solution obtained in the step S4 to carry out arsenic precipitation and then conducting solid-liquid separation to obtain arsenic-fixing slag and an arsenic removal solution. The method has simple process, low cost, good effect and good economic and environmental benefits.

Owner:紫金铜业有限公司 +1

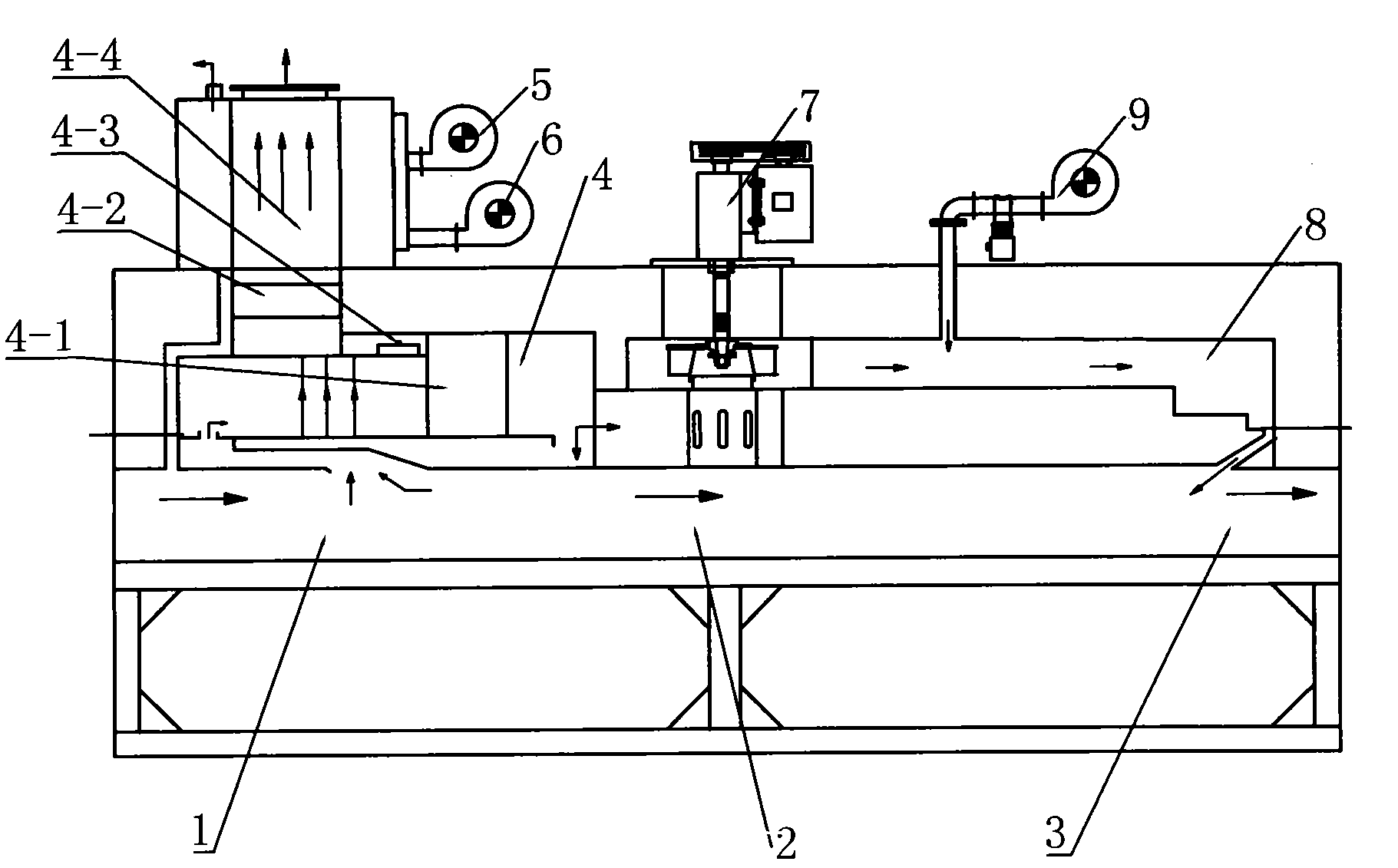

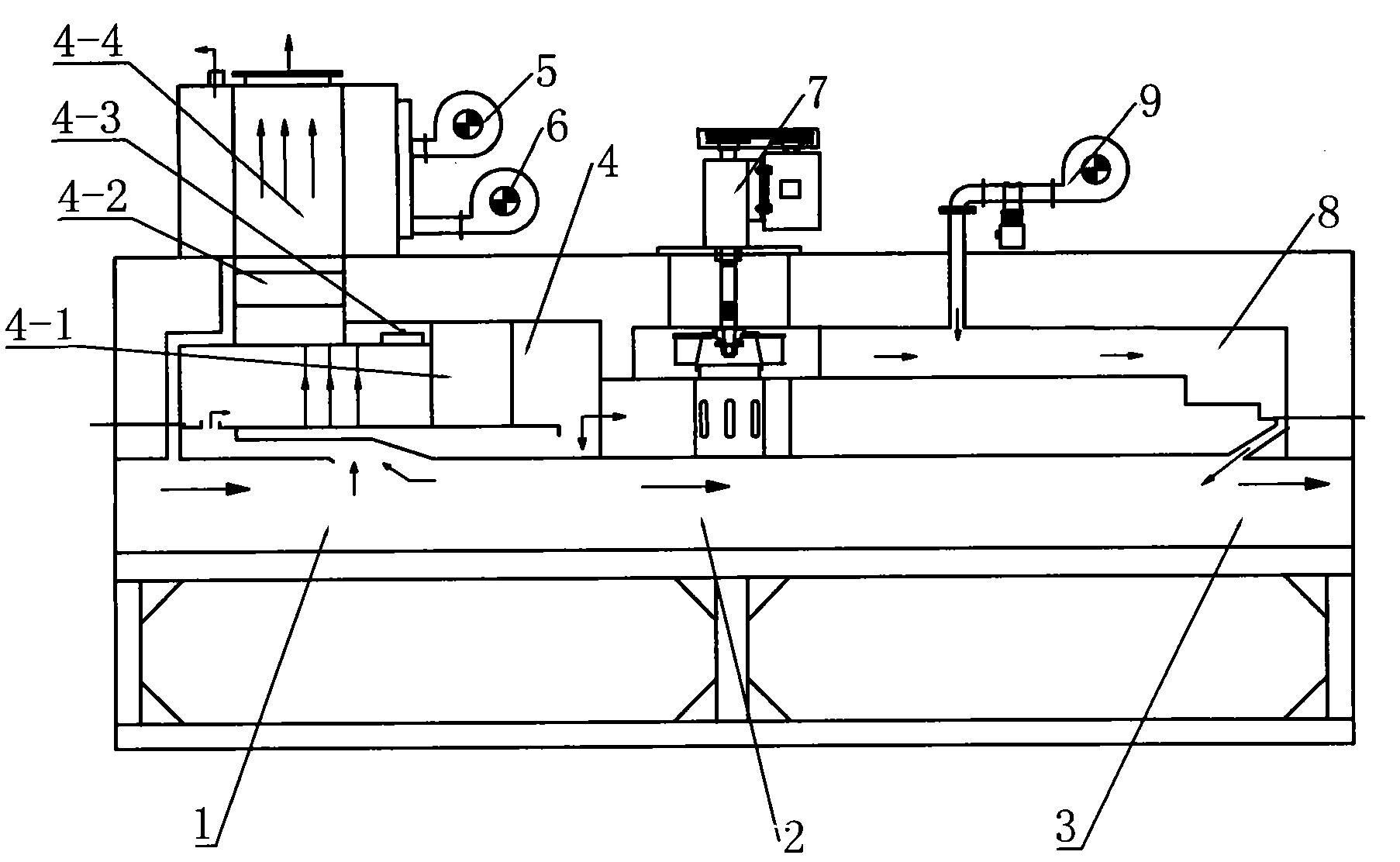

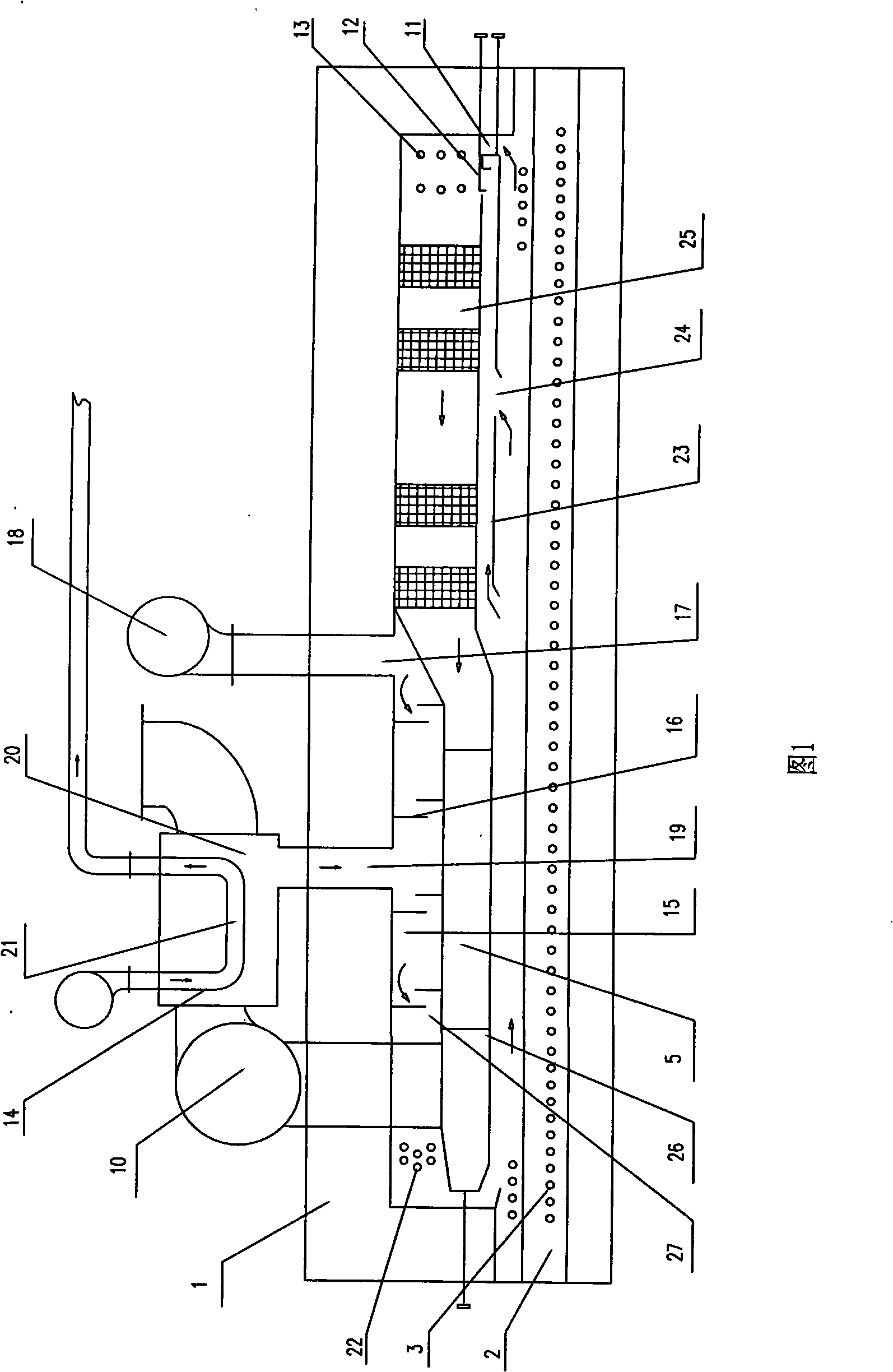

Horizontal enameling machine oven with ultra-wide combustion chamber

InactiveCN101403560AReduce the difficulty of operationMany headsDrying solid materials with heatDrying gas arrangementsCombustion chamberCombustor

The invention discloses a horizontal enameling machine drying oven with a superwide furnace which comprises furnace and heat irradiation equipment arranged in the furnace, wherein, the upper part of the furnace is provided with a catalytic combustor and a catalytic post suction and discharge room which are communicated. Two ends of the catalytic combustor are provided with an air inlet and an air outlet, a heat exchange room is arranged on the periphery of the catalytic post suction and discharge room, and the furnace is separated from a solvent suction and discharge area in the middle. The horizontal enameling machine drying oven is characterized in that more than two air inlets are arranged in the solvent suction and discharge area and the air inlet of the catalytic combustor is respectively communicated with the air inlets at the ends of the furnace and in the solvent suction and discharge area. A multi-channel air-flow distribution device is arranged in the catalytic post suction and discharge room and comprises a solvent distillation channel, the left and right sides and the back end of the channel are all provided with stream inlets, and the middle part thereof is provided with an air flow demarcation strip; and a pump line provided with an exhaust fan is arranged on the periphery of the air flow demarcation strip and communicated with the solvent distillation channel. The horizontal enameling machine drying oven has reasonable structure, uniform airflow direction and temperature, energy conservation and environmental protection, and good popularization value.

Owner:林兆欣 +1

Method for water treatment through ozone oxidation catalyzed by hydroxyl iron oxide

InactiveCN107777768AMeet the process requirementsImprove removal efficiencyWater contaminantsWater/sewage treatment by oxidationChemical oxygen demandSewage

The invention belongs to the technical field of water treatment and discloses an ozone oxidation water treatment method with high-specific-area hydroxyl iron oxide as a catalyst. The method includes:(1) continuously feeding ozone into sewage; (2) feeding the sewage treated in the step (1) into a fixed bed reactor filled with hydroxyl iron oxide. The method for water treatment through ozone oxidation catalyzed by hydroxyl iron oxide has advantages that by feeding the sewage continuously fed with ozone into the fixed bed reactor filled with hydroxyl iron oxide, organic pollutant components andozone in water can be completely contacted with the catalyst while a step of catalyst separation is saved, so that COD (chemical oxygen demand) removal efficiency can be improved while treatment procedures are simplified, and large-scale continuous water treatment requirements can be met.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Treatment method of cotton pulp wastewater

ActiveCN103304058AQuick responseImprove the bactericidal effectMultistage water/sewage treatmentChemical oxygen demandChlorine dioxide

The invention provides a treatment method of cotton pulp wastewater. The treatment method comprises the following steps of: a) providing flocculated cotton pulp; and b) mixing the cotton pulp obtained in step a) with chlorine dioxide for decolorizing treatment. According to the treatment method, a decolorizing agent adopted in the decolorizing treatment is chlorine dioxide which has great discoloring effect on the cotton pulp wastewater, is fast to react, and has relatively high sterilizing effect so that the discharged water which is subjected to discolored by chlorine dioxide has good purification effect on the water quality in the downstream, and has environment-friendly effect; in addition, during discoloring, the chlorine dioxide also can reduce the COD (Chemical Oxygen Demand) of the wastewater, and reduces the comprehensive treatment cost. The chlorine dioxide is fast in discoloring speed and great in discoloring effect, so that a Fenton reactor and a reaction tank are not need to be added in the discoloring process, and as a result, the cost of facility instrument is greatly decreased.

Owner:ANHUI SNOW DRAGON FIBER TECH

Water-based transparent polyurethane, water-based UV curing gloss oil, water-based UV curing ink and preparation method thereof

InactiveCN111607057AHigh glossImprove stabilityInksPolyurea/polyurethane coatingsIsophoronePrepolymer

The invention provides water-based transparent polyurethane, water-based UV curing gloss oil, water-based UV curing ink and a preparation method thereof. The water-based transparent polyurethane is prepared from the following raw materials in parts by weight: 30-50 parts of isophorone or diisopropylketone, 5-20 parts of diisocyanate, 80-120 parts of polyester polyol, 1-3 parts of 2, 2-dimethylolpropionic acid, 10-30 parts of neopentyl glycol and 5-30 parts of C7-C22 alkanediol. Isophorone and diisopropylketone not only can be used as reaction monomers, but also can be used as solvents, have high dissolvability to diisocyanate, and are miscible with water, so that the generated prepolymer can form a uniform dispersion in water. 2, 2-dimethylolpropionic acid not only can be used as a chain extender, but also can enable polyurethane to obtain a self-emulsifying property, so that the self-emulsifying water-based polyurethane with excellent stability can be prepared in an internal emulsification manner. Under the action of isophorone, diisopropylketone, neopentyl glycol and alkanediol, a polyurethane aqueous dispersion which is uniformly dispersed can be generated, and the polyurethaneaqueous dispersion has high refractive index and aqueous solution stability.

Owner:东莞市神乐高分子科技有限公司

Asphalt mixing plant tail gas white smoke eliminating treatment apparatus

PendingCN110180314AReduce the temperatureAbatement of sulfur dioxide gasGas treatmentDispersed particle separationFlue gasProcess engineering

The invention discloses an asphalt mixing plant tail gas white smoke eliminating treatment apparatus, and belongs to the technical field of flue gas treatment. The asphalt mixing plant tail gas whitesmoke eliminating treatment apparatus comprises an installing frame, a flue gas heat exchange assembly, a spraying assembly, a circulating water supply assembly, a steam-water separation assembly, anautomatic feeding assembly, a flue gas mixing assembly and a flue gas discharge assembly, wherein the flue gas heat exchange assembly is arranged on the side of the spraying assembly, the circulatingwater supply assembly is arranged on the side of the spraying assembly, the steam-water separation assembly is arranged on the installing frame, the automatic feeding assembly is arranged on the top portion of the installing frame, and is further positioned on the steam-water separation assembly, the flue gas mixing assembly is arranged on the top portion of the installing frame, and the flue gasdischarge assembly is arranged on the side of the installing frame. According to the present invention, the flue gas treated by the flue gas heat exchange assembly, the spraying assembly, the circulating water supply assembly, the steam-water separation assembly, the automatic feeding assembly and the flue gas mixing assembly cannot present the white color during the externally being discharged, such that the unnecessary misunderstanding cannot be caused due to the colorlessness of the discharged flue gas.

Owner:JIANGSU MODERN ROAD & BRIDGE

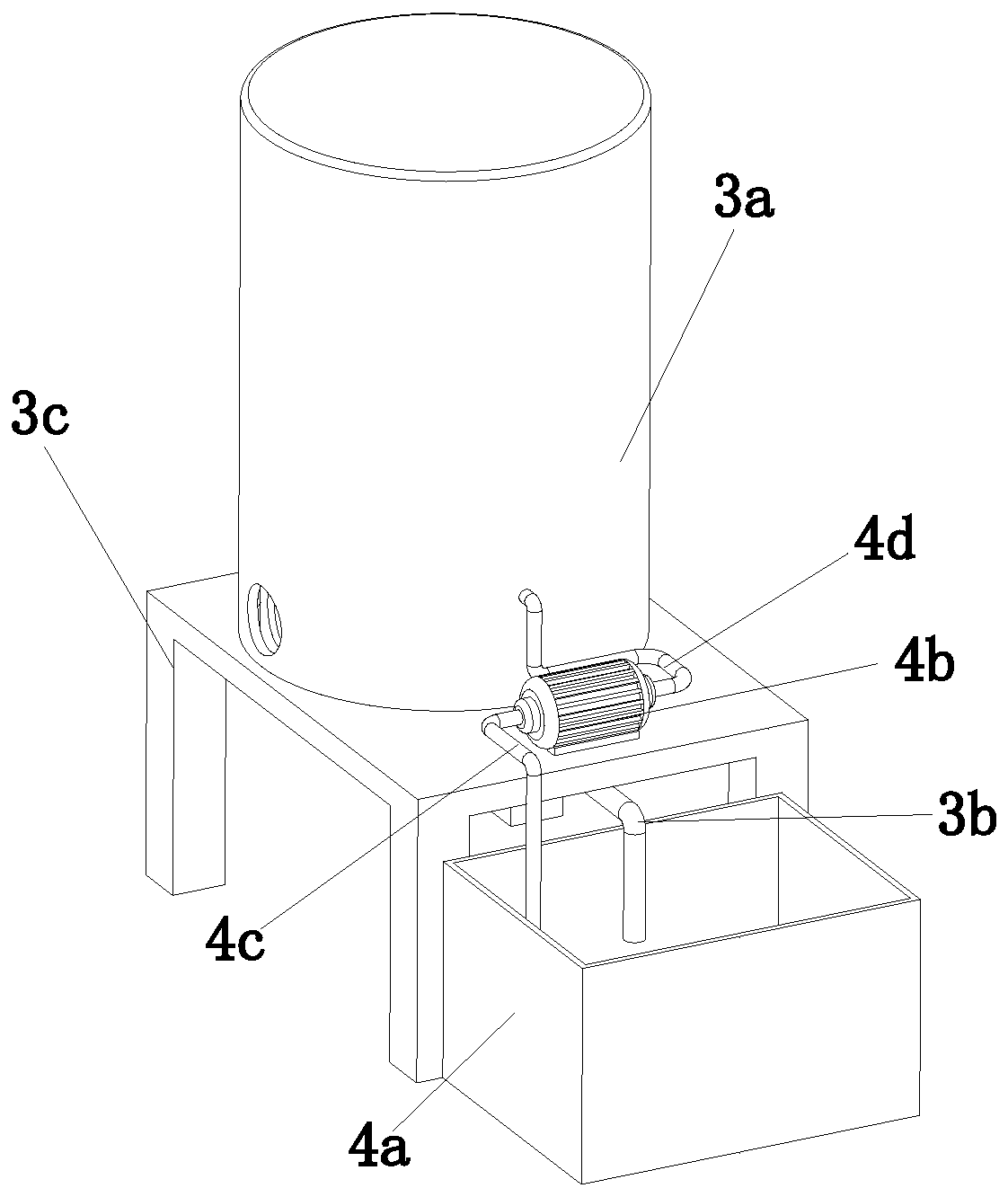

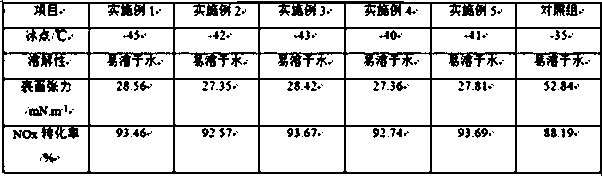

Urea solution for vehicle and preparation method thereof

InactiveCN108993137ALowering the freezing pointReduce distortionDispersed particle separationCarboxylic saltCocamidopropyl betaine

The invention relates to a urea solution for a vehicle and a preparation method thereof, belonging to the technical field of treatment of automobile exhaust. The urea solution for the vehicle comprises, by weight, 30-40 parts of urea, 60-80 parts of high-purity water, 12-18 parts of cocamidopropyl betaine, 15-20 parts of an amido carboxylate type gemini surfactant, 3-4 parts of polyvinylpyrrolidone, 1-3 parts of an alcohol derivative of phenols and 5-8 parts of polyepoxysuccinic acid. The preparation method comprises the following steps: (1) mixing urea with high-purity water under stirring soas to obtain a mixed solution, allowing the mixed solution to pass through a filter so as to remove impurities, and then removing metal ions in the mixed solution through an ion exchange resin columnso as to obtain a urea solution; and (2) mixing the urea solution prepared in the step (1), cocamidopropyl betaine, the amido carboxylate type gemini surfactant, polyvinylpyrrolidone, the alcohol derivative of phenols and polyepoxysuccinic acid under stirring and then carrying out filtering so as to obtain the urea solution for the vehicle.

Owner:罗永平

Rapid shaping method of carbon fiber preform

PendingCN113372128ACompliance with emission requirementsWill not be affected by the weaving structurePolymer chemistryAir drying

In order to reduce the high cost generated in the shaping process of preparing a carbon fiber reinforced high-temperature composite material by adopting a chemical vapor deposition process, the invention provides a rapid shaping method of a carbon fiber preform. The method comprises the steps of S1, impregnating the carbon fiber preform in a resin impregnation liquid for the first time; S2, carrying out air-drying shaping on the resin-impregnated carbon fiber preform for the first time; S3, carrying out second-time impregnation on the carbon fiber preform subjected to the first-time shaping in the resin liquid; and S4, carrying out secondary air-drying shaping on the carbon fiber preform subjected to secondary impregnation.

Owner:陕西金承烯新材料科技有限公司

Method and system for analyzing thermal runaway gas production of lithium ion battery containing hydrofluoric acid

PendingCN111289468AReduce usageAvoid differentSecondary cellsColor/spectral properties measurementsHydrofluoric acidPhysical chemistry

The invention discloses a method and system for analyzing thermal runaway gas production of hydrofluoric acid-containing lithium ion battery, relates to a lithium ion battery, and aims to solve the problem that a large amount of sample gas needs to be consumed in the process that a special gas absorption cell needs to be filled with gas and air in the gas absorption cell needs to be completely exhausted in a spectral absorption test. According to the method for analyzing the thermal runaway gas production of the lithium ion battery containing the hydrofluoric acid, the sample gas is transferred by adopting a two-step method, so compared with the prior art, the use amount of the sample gas is effectively reduced, and a gas production analysis result is prevented from being interfered. According to the invention, the gas sampling, detection and tail gas treatment are continuously carried out, and the convenience and safety of sample gas transfer are improved.

Owner:ZHEJIANG UNIV

Magnesium alloy desilicon flux and production method

Besides magnesium chloride 15-30%, potassium chloride 15-30%, calcium fluoride 10-20%, barium chloride 8-12% and magnesium fluoride 10-25% etc. the chemical constituent of fusing agent has titanium compound 10-20% and carbonate 1-10% being added. Magnesium chloride and potassium chloride etc. is added into the warmed up crucible. With the magnesium chloride etc. being melted, calcium fluoride and magnesium fluoride is added to the crucible. The fusing agent is made through procedures of heating up, stirring and pouring in bulk, then the procedures of crushing, milling and sifting out as well as with titanium compound and carbonate being added. The invented magnesium alloy provides the advantages of remarkable effect of removal of silica and excellent deslagging performance as well as improving mechanical property and corrosion-resisting properties.

Owner:SHANGHAI JIAOTONG UNIV

Coal-fired flue gas denitration and desulfurization method combined with urea wet method

ActiveCN101708419BIncrease the degree of oxidationGood chemical stabilityLighting and heating apparatusDispersed particle separationFlue gasEconomic benefits

The invention discloses a coal-fired flue gas denitration and desulfurization method combined with the urea wet method. The method comprises the following steps: spraying 50wt% of hydrogen peroxide at the coal-fired flue gas inlet of a absorption tower while keeping the molar ratio of H2O2 to NO to be 2-3, so as to oxidize NO in the coal-fired flue gas to NO2 and increase the oxidization degree of NOX; and perform denitration and desulfurization simultaneously by using the urea aqueous solution in the absorption tower. The method of the invention increases the denitration rate of the coal-fired flue gas denitration and desulfurization combination technology by increasing the oxidization degree of NOX and the temperature of the absorption solution. The method has simple technology, convenient operation and management, no secondary pollution and good environmental and economic benefits.

Owner:GUODIAN ENVIRONMENTAL PROTECTION RES INST CO LTD +1

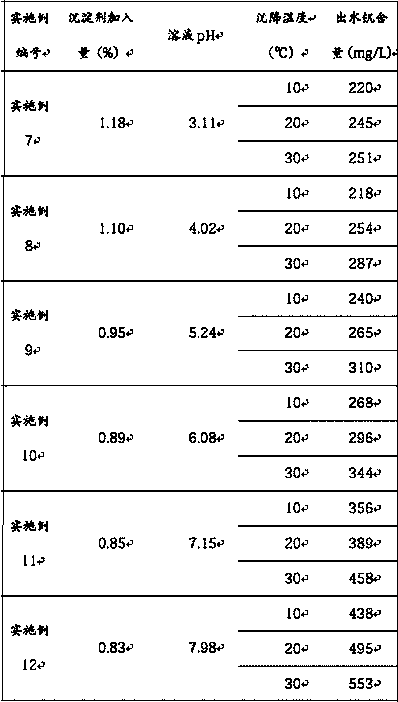

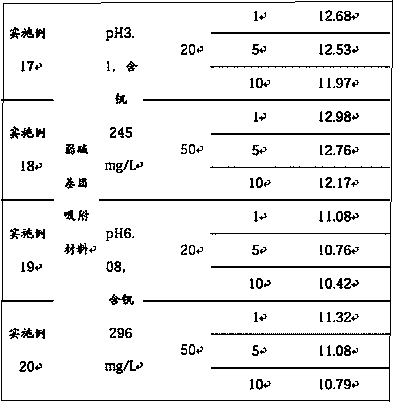

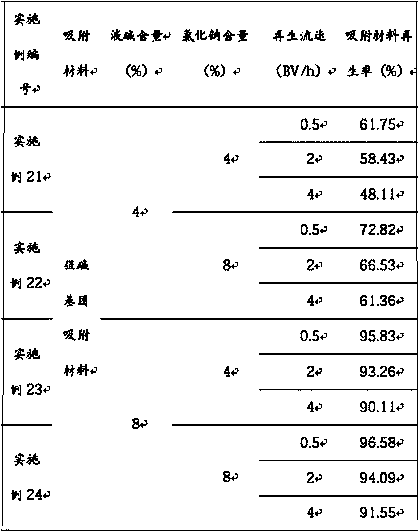

Recovering method for vanadium catalyst in pigment wastewater

InactiveCN109081465ACompliance with emission requirementsMultistage water/sewage treatmentProcess efficiency improvementRecovery methodPhysical chemistry

The invention discloses a recovering method for a vanadium catalyst in pigment wastewater, and belongs to the technical field of the vanadium catalyst recovery. The method comprises the following steps: (1) pre-processing: adding a precipitant to the pigment wastewater containing the vanadium catalyst and generating a precipitate and supernatant fluid, wherein the precipitant is inorganic acid; and (2) adsorption-processing: after adsorbing through feeding the supernatant fluid into an adsorption device, to obtain effluent, wherein the adsorption device is internally provided with an adsorption material. The method is used for processing the inorganic ceramic pigment wastewater and recovering the vanadium catalyst in the wastewater, the effluent is in comply with requirements of national standard emission, and can be directly discharged, and recovered vanadium can be reused for ceramic pigment production.

Owner:绍兴齐英膜科技有限公司

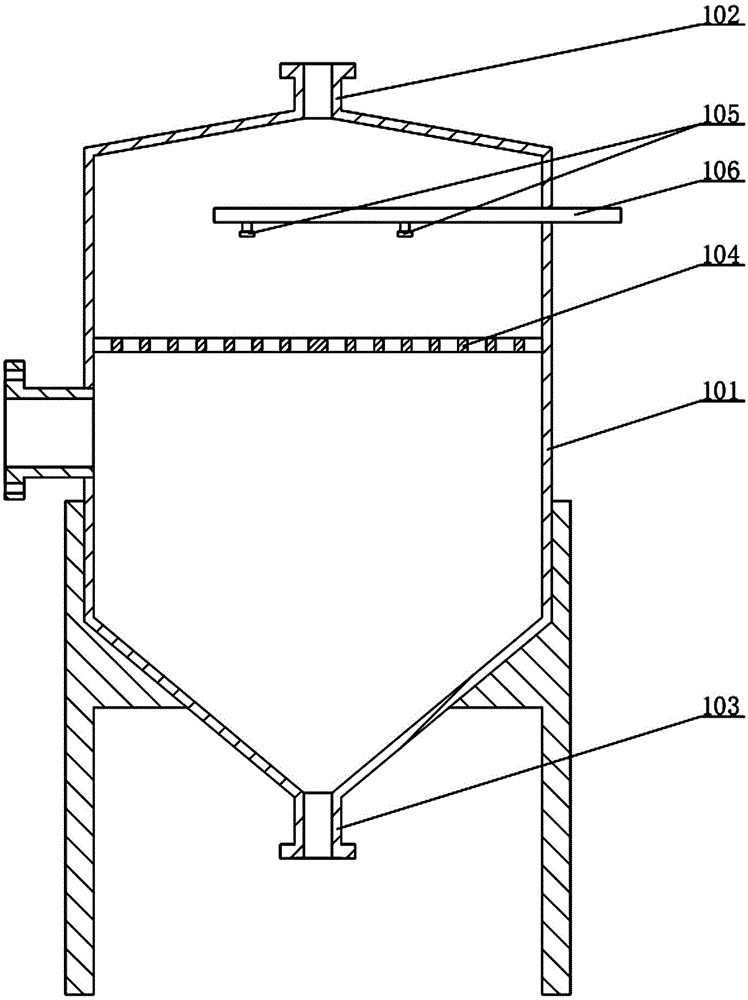

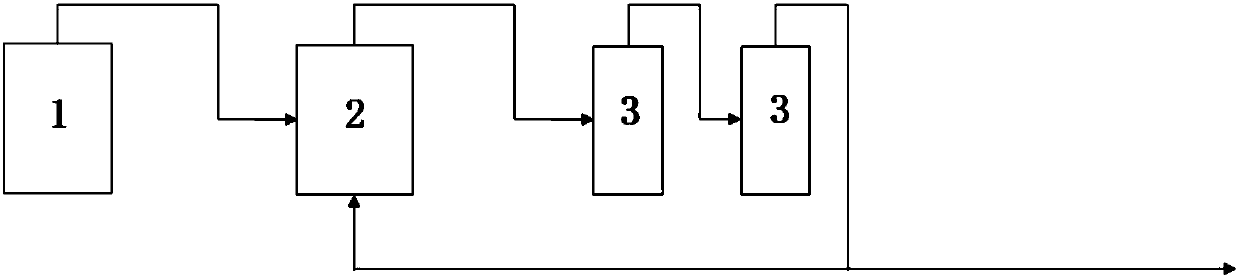

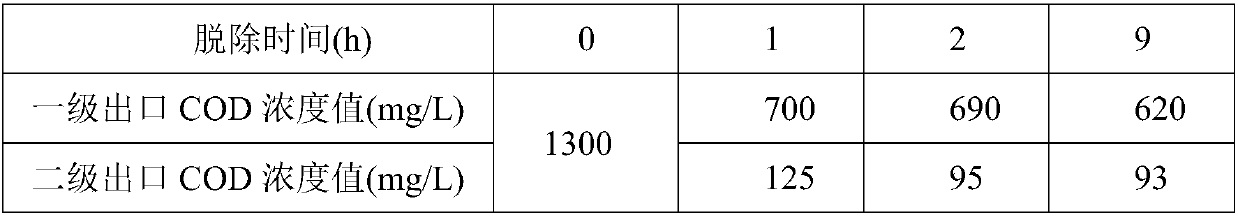

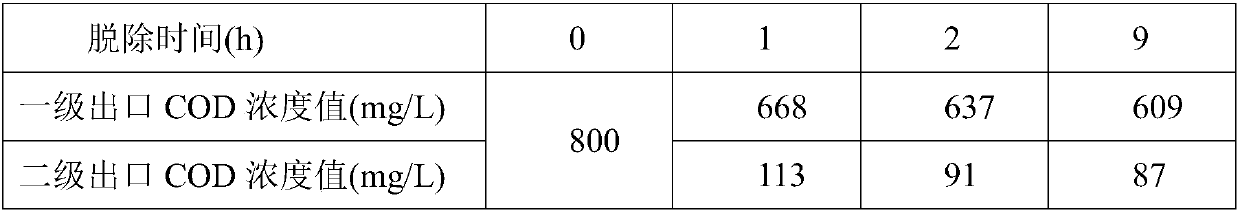

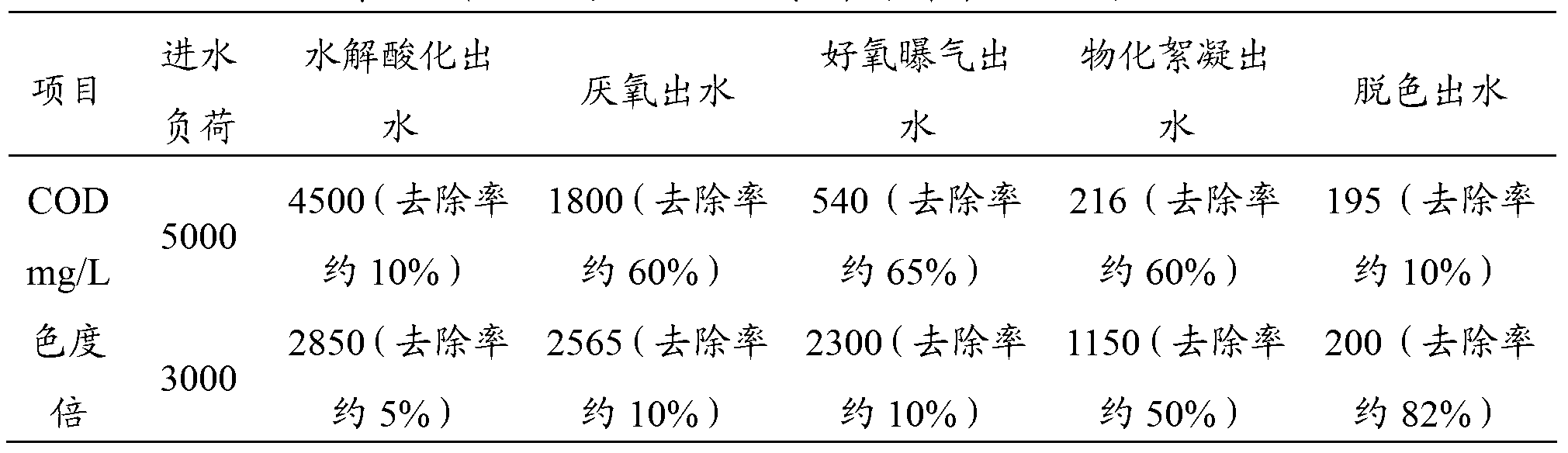

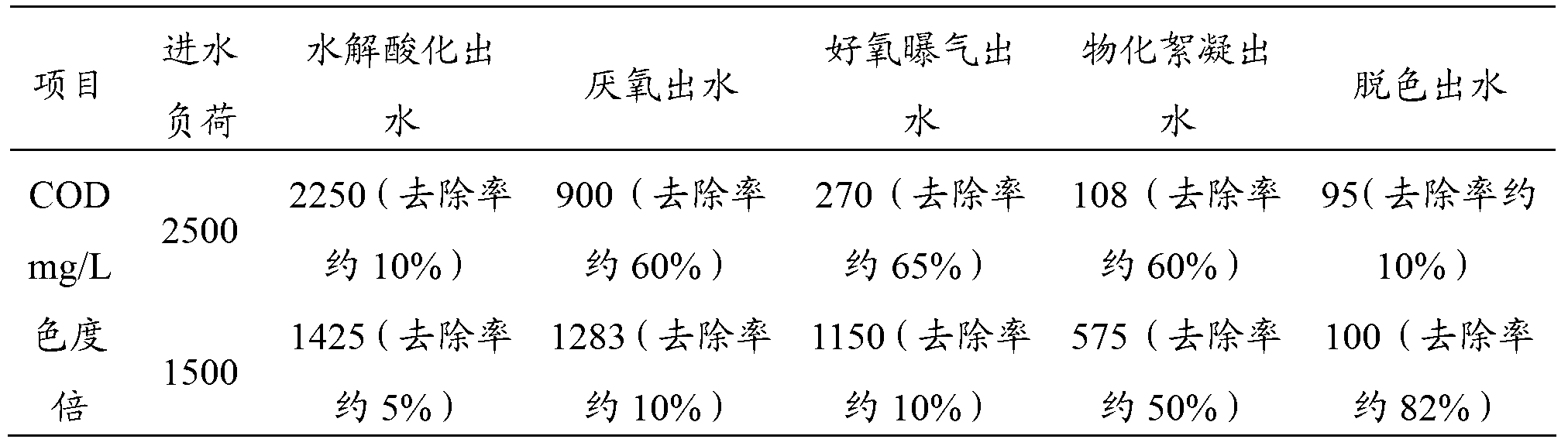

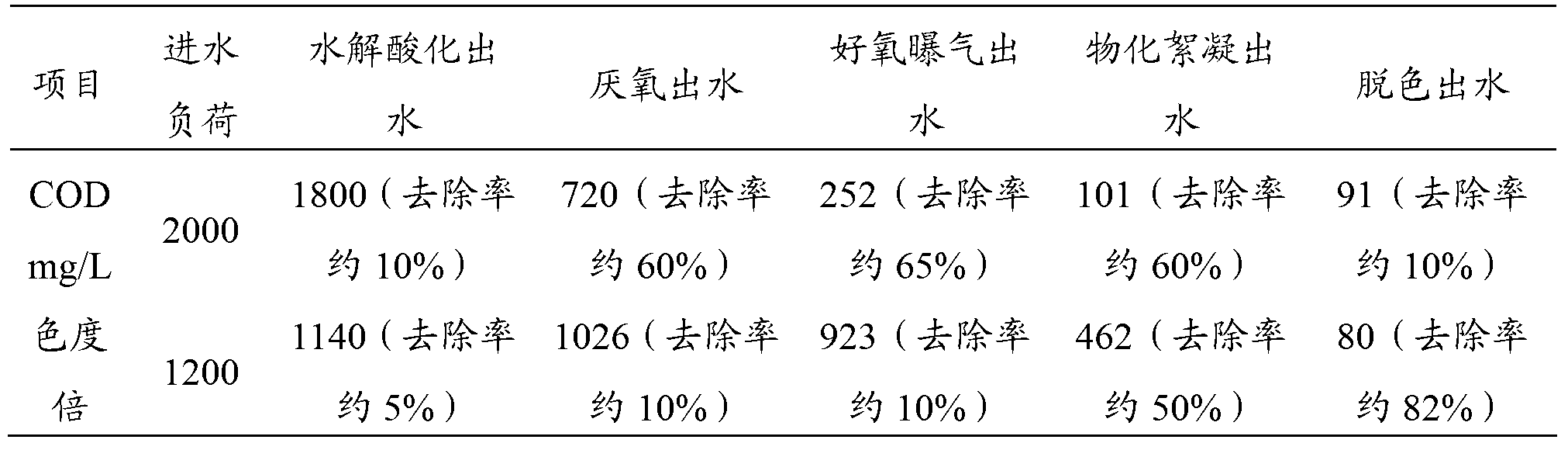

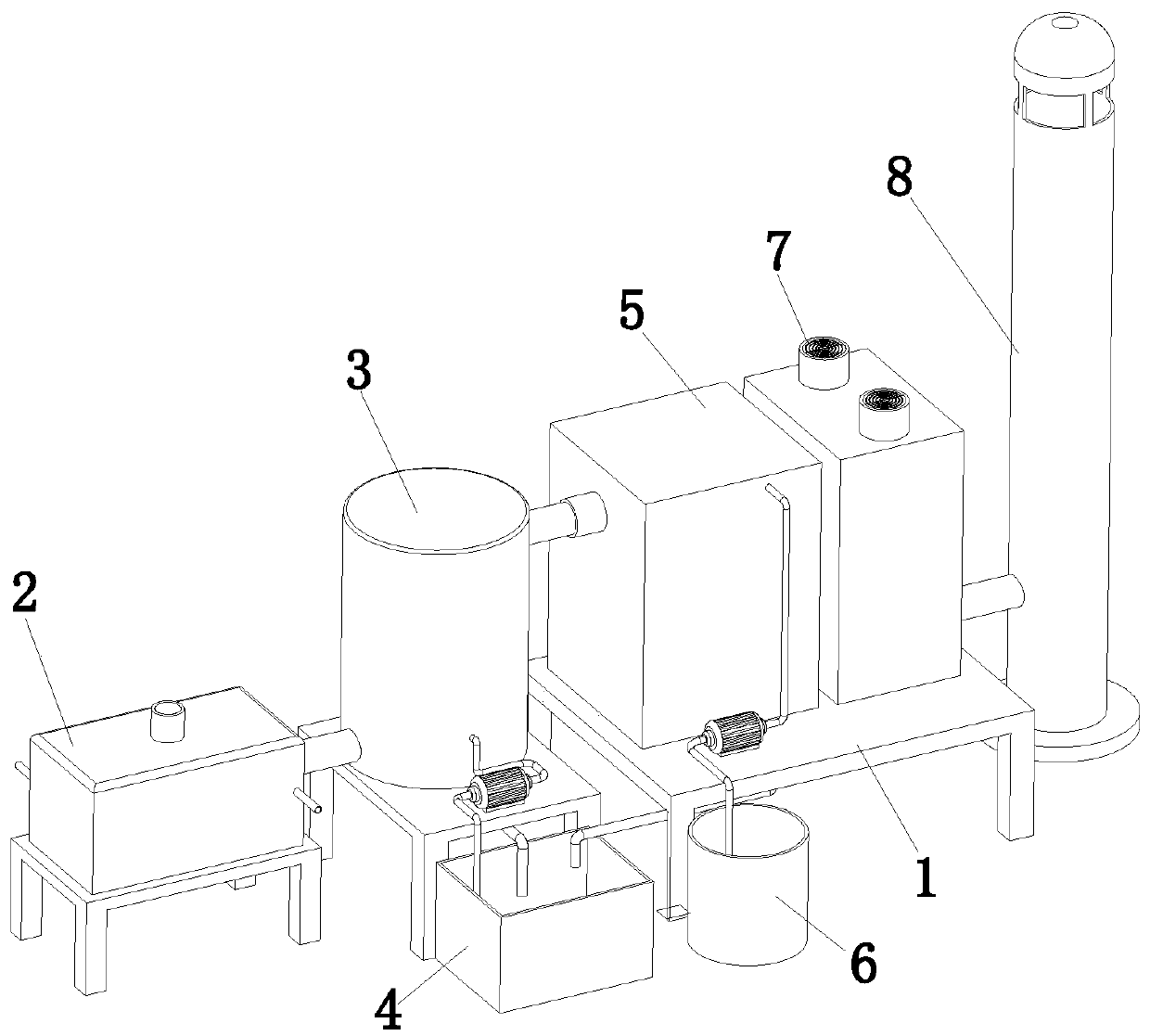

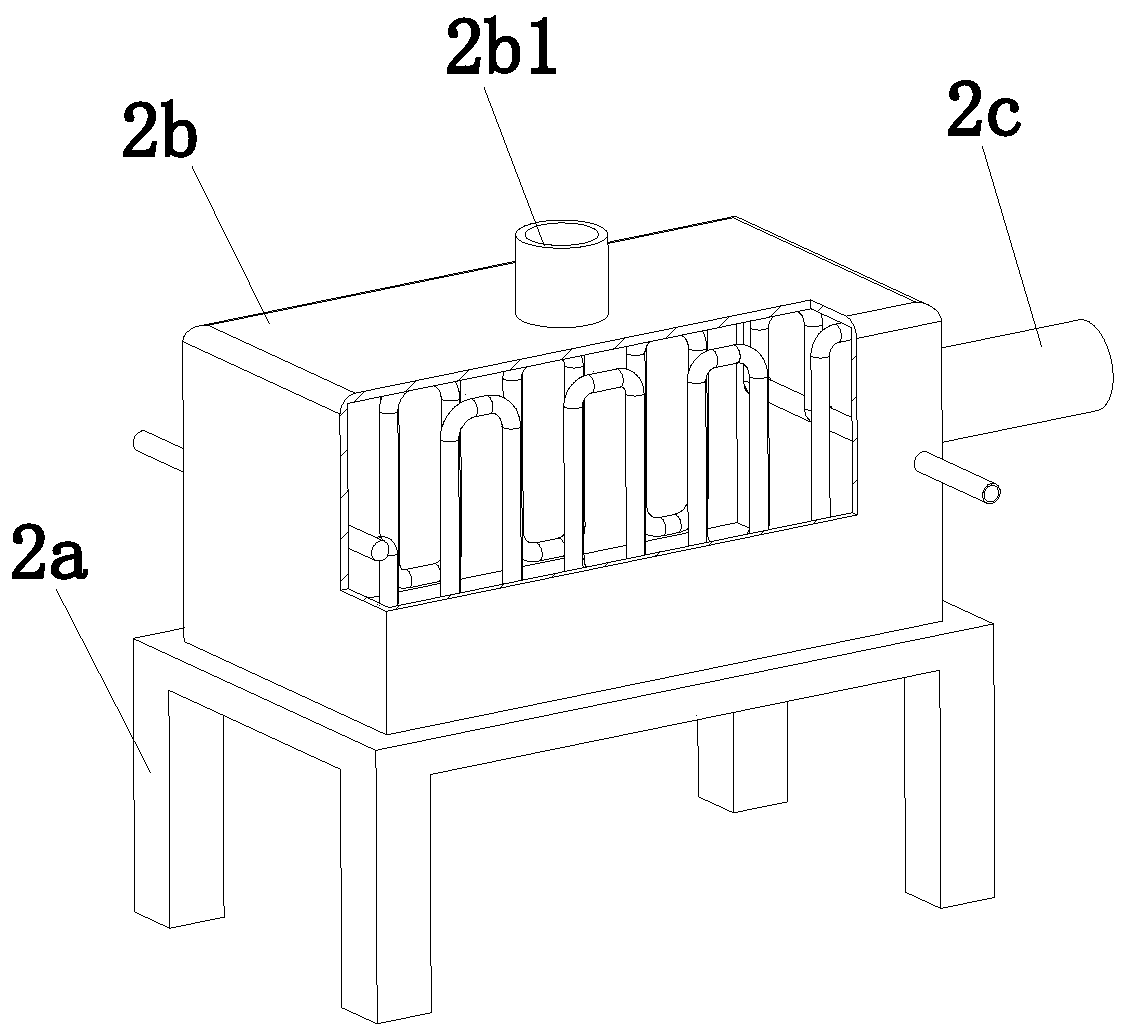

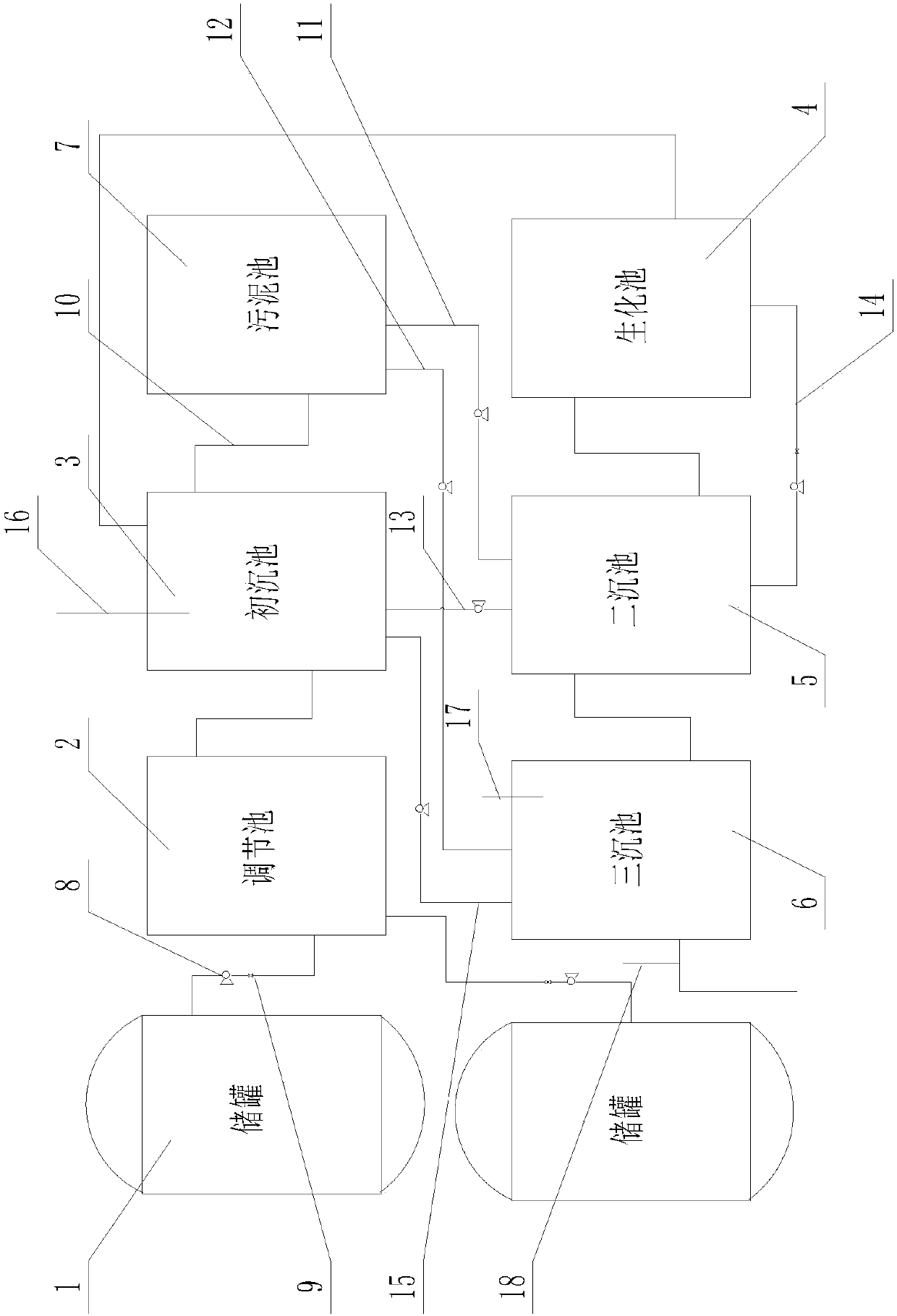

Treatment system and treatment method for distillation mother liquor of CMC wastewater

PendingCN107892445AEfficient use ofMeet environmental protection requirementsWater treatment parameter controlTreatment with aerobic and anaerobic processesSludgeDistillation

The invention discloses a treatment system and treatment method for distillation mother liquor of CMC wastewater. The treatment system comprises a storage tank, a regulating tank, a primary sedimentation tank, a biochemical tank, a secondary sedimentation tank and a ternary sedimentation tank which are successively arranged along the flow direction of the distillation mother liquor of CMC wastewater, wherein the outlet of the storage tank is communicated with the inlet of the regulating tank; the outlet of the regulating tank is communicated with the inlet of the primary sedimentation tank; the outlet of the primary sedimentation tank is communicated with the inlet of the biochemical tank; the outlet of the biochemical tank is communicated with the inlet of the secondary sedimentation tank; the outlet of the secondary sedimentation tank is communicated with the inlet of the ternary sedimentation tank; the outlet of the ternary sedimentation tank is communicated with the outside; and aninfusion pump and a flow meter for controlling the flow of the distillation mother liquor of CMC wastewater are arranged between the storage tank and the regulating tank. The treatment system also comprises a sludge tank which is separately communicated with the primary sedimentation tank, the secondary sedimentation tank and the ternary sedimentation tank; a part of liquid and sludge in the secondary sedimentation tank flow back into the primary sedimentation tank and into the biochemical tank; and a part of liquid and sludge in the ternary sedimentation tank flow back into the primary sedimentation tank. The system overcomes the problem of secondary pollution after the distillation of CMC wastewater and realizes effective usage of the distillation mother liquor of CMC wastewater.

Owner:张家港市清泉水处理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com