Coal-fired flue gas denitration and desulfurization method combined with urea wet method

A coal-fired flue gas, desulfurization and denitrification technology, applied in separation methods, chemical instruments and methods, air quality improvement, etc., can solve the problem of low oxidation degree, achieve the effects of no secondary pollution, convenient transportation, and good technical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

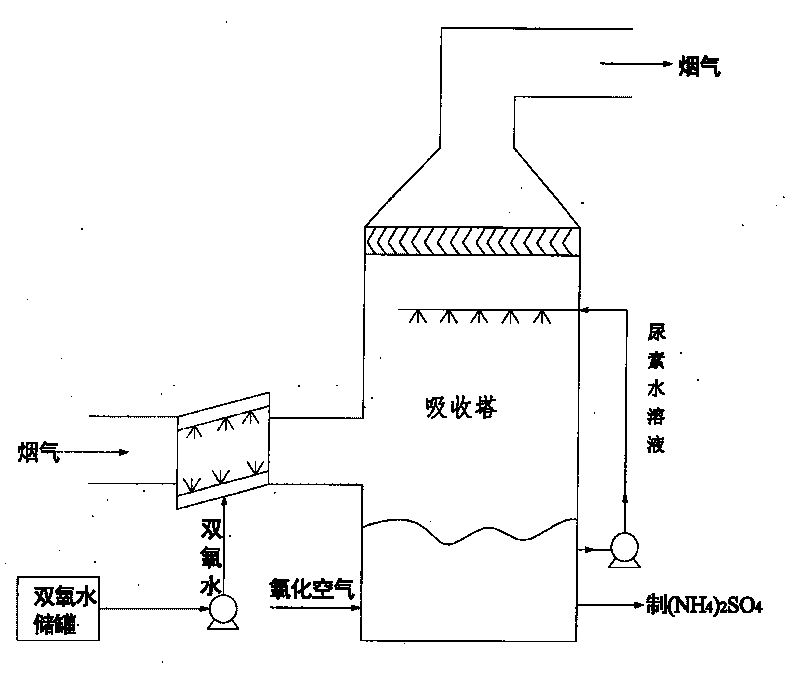

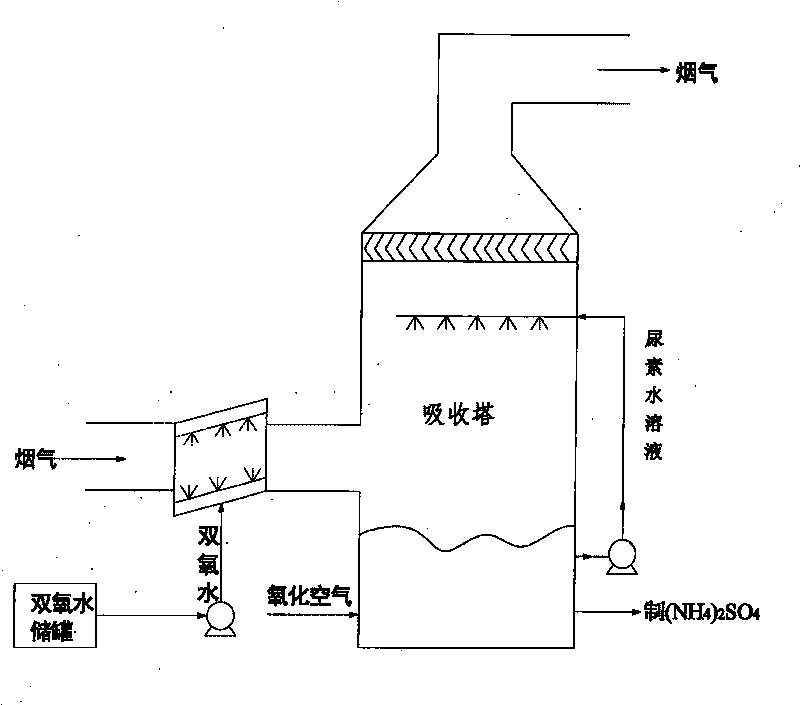

Image

Examples

Embodiment 1

[0029] Embodiment 1, spray into the hydrogen peroxide (H 2 o 2 ), keep H 2 o 2 / NO molar ratio 2~3, oxidize NO in coal-fired flue gas to NO 2 , so that NO X The oxidation degree is increased to 60%, and then the urea aqueous solution in the absorption tower is used for simultaneous desulfurization and denitrification. The concentration of urea aqueous solution is kept at 10%-20% (mass percentage), and the liquid-gas ratio is 9-12L / m 3 , The temperature is controlled at 80-90°C, and the pH value is controlled at 6.5-7. Its desulfurization efficiency can reach more than 90%, and its denitrification efficiency can reach about 50%.

Embodiment 2

[0030] Embodiment 2 is basically the same as Embodiment 1, the difference is: make NO X The degree of oxidation is increased to 50%.

Embodiment 3

[0031] Embodiment 3 is basically the same as Embodiment 1, the difference is: make NO X The degree of oxidation is increased to 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com