Gas turbine engine dry-type low-NOx combustion adjustment method

A gas turbine and combustion adjustment technology, which is applied to engine components, turbine/propulsion fuel delivery systems, fuel control of turbine/propulsion devices, etc., and can solve problems such as unstable combustion of large gas turbines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings.

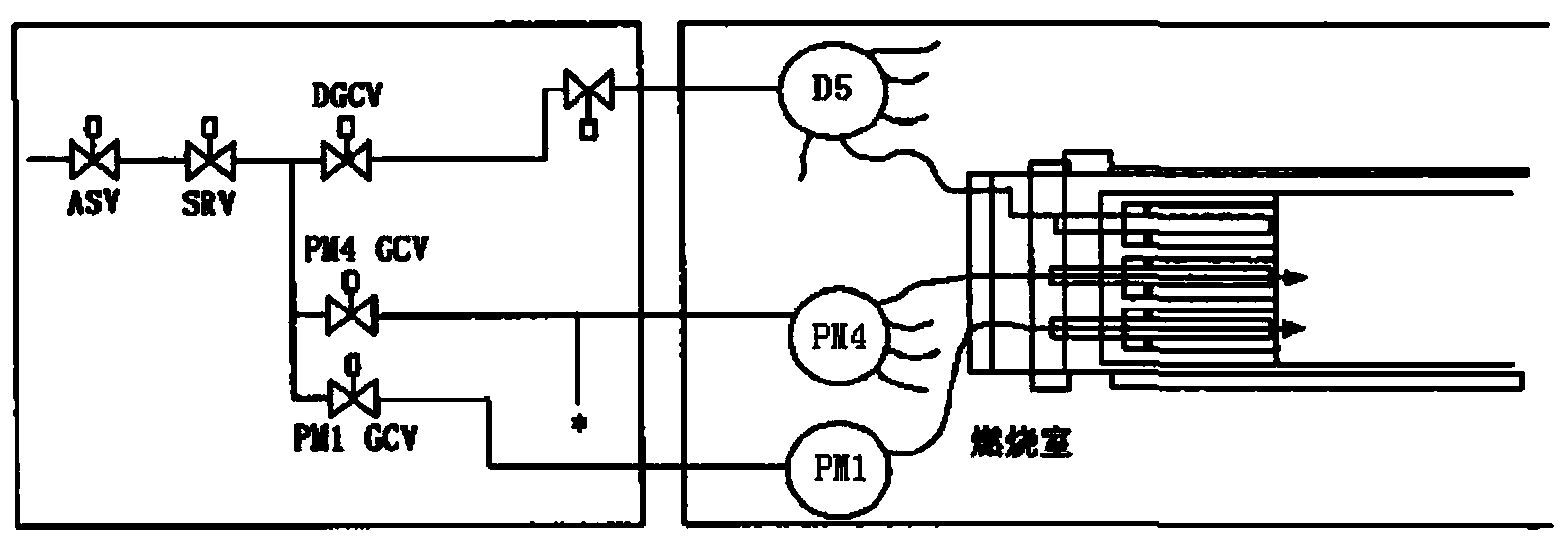

[0026] See figure 1 , Which shows the existing gas turbine DLN-2+ gas fuel system. The gas fuel system consists of auxiliary shutoff valve (ASV), speed ratio valve (SRV), diffusion combustion gas control valve (DGCV), PM4 premixed gas control valve (PM4GCV), PM1 premixed gas control valve (PM1GCV), etc. The DGCV control valve regulates the amount of fuel entering the D5 fuel nozzle, the PM4GCV control valve regulates the flow into the PM4 fuel nozzle, and the PM1GCV control valve regulates the flow into the PM1 fuel nozzle.

[0027] The system uses dry low NO x Combustion technology, in the combustion process, its combustion conditions are easily affected by fuel and environmental parameters and become unstable, and combustion oscillation occurs,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com