Spray tower and electrostatic dust-removing, desulfurizing and denitrating device

A technology for desulfurization, denitrification, and electrostatic dust removal, which is applied in the direction of combined devices, separation of dispersed particles, chemical instruments and methods, etc., and can solve problems such as large floor area, high energy consumption, and large one-time investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

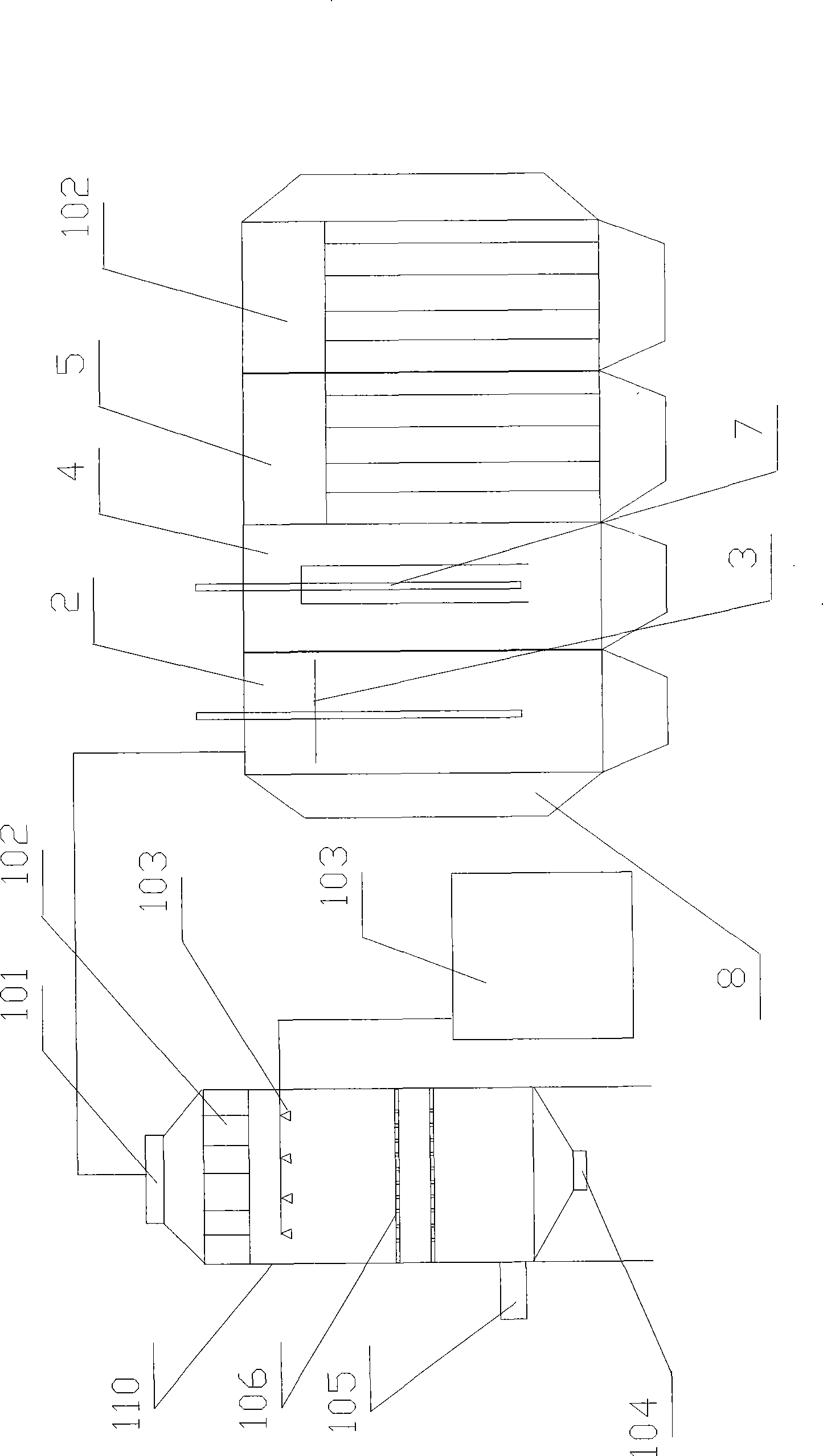

[0007] see figure 1 , the present invention comprises spray tower 100, temperature increasing and cooling device, activation device, ammonium salt collecting device and is made up of, and wherein is divided into two parts on the shell, and a part is spray tower and supporting equipment thereof (for example liquid storage tank 107 and pump), The other part is mainly related to static electricity. In the same shell, along the airflow direction, there are humidification and temperature regulation zone 2 of humidity control and temperature control device, ammoniation activation zone 4 of ammoniation activation device, oxidation synthesis zone 5 of oxidation synthesis device and ammonium The ammonium salt collection area 6 of the salt collection device; the humidification and temperature adjustment area includes the atomized water nozzle 3 arranged on the top of the casing, the sewage pump and the water pond arranged at the bottom of the casing, and the temperature sensor arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com