Recovering method for vanadium catalyst in pigment wastewater

A recovery method and catalyst technology, applied in chemical instruments and methods, water/sewage treatment, improvement of process efficiency, etc., can solve the problems of difficult recovery of vanadium, environmental pollution, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with specific embodiment the present invention is described in further detail:

[0029] The embodiment of the present application is used to treat inorganic ceramic pigment wastewater and recover the vanadium catalyst in it. The effluent meets the national discharge requirements and can be discharged directly, and the recovered vanadium can be reused in the production of ceramic pigments.

[0030] Embodiment 1~6 is the test that preparation simulates vanadium-containing waste water and carries out precipitation operation, and its process is:

[0031] Add 20 g of sodium metavanadate to 2 L of tap water, and add liquid caustic soda to adjust the pH to 12.18. The vanadium content is 3875mg / L, and it precipitates for 2 hours after adding the precipitating agent.

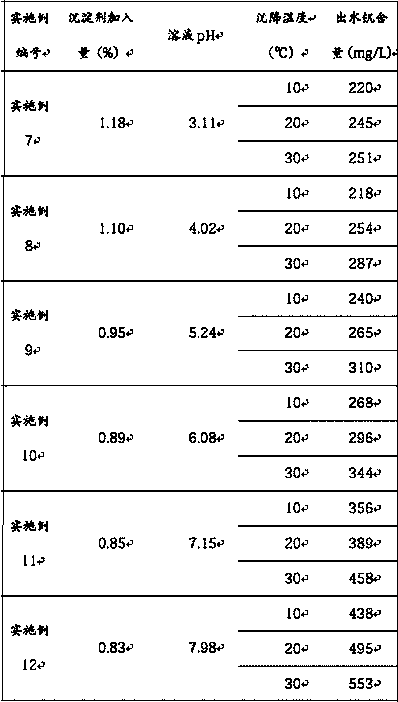

[0032] Table 1 is the test parameter involved in embodiment 1~6

[0033] Table 1 The test parameters involved in embodiments 1 to 6

[0034]

[0035] From the data in Table 1, it can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com