Method and system for analyzing thermal runaway gas production of lithium ion battery containing hydrofluoric acid

A lithium-ion battery and analysis method technology, which is applied in the field of thermal runaway gas production analysis of lithium-ion batteries, can solve the problems of large sample gas consumption, achieve the effects of reducing usage, improving convenience, and improving data stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment one: the thermal runaway gas production analysis method of a lithium ion battery containing hydrofluoric acid, comprising the following steps:

[0028] Step 1: Put the battery into an explosion-proof tank and seal it, and heat-insulate the outside. The heat-insulation treatment can be done by setting up a heat-insulation layer to trigger the battery’s thermal runaway. After the battery’s thermal runaway, a large amount of gas will be generated, and the pressure of the explosion-proof tank will rise. After the pressure stabilizes, record the air pressure and temperature inside the tank at this time, remove the heat insulation layer outside the explosion-proof tank, and quickly cool the explosion-proof tank and the sample gas inside; the battery triggers thermal runaway in the explosion-proof tank to avoid gas leakage And reduce potential safety hazards, insulate the explosion-proof tank to reduce heat loss, ensure that the battery continues to run out of contro...

Embodiment 2

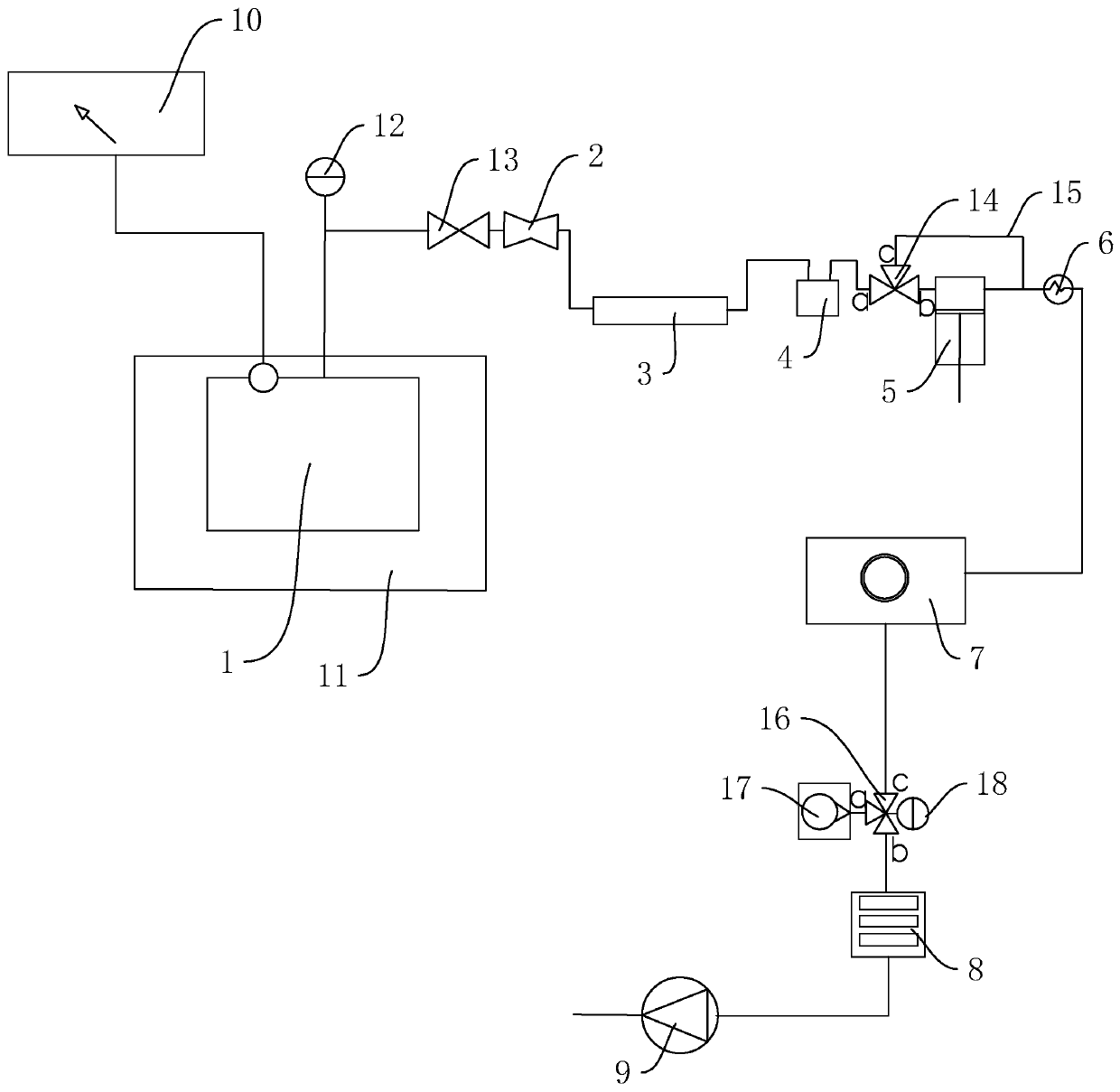

[0041] Embodiment two: the thermal runaway gas production analysis system of lithium-ion batteries containing hydrofluoric acid, such as figure 1 As shown, it includes an explosion-proof tank 1, a venturi tube 2, a corrosion-resistant dust collector 3, a cold trap 4, a diaphragm pump 5, a heat exchanger 6, a detection gas pool 7, an exhaust gas treatment device 8, and an induced draft fan 9 connected by pipelines in sequence. The internal circuit of the tank 1 is connected with a battery testing system 10. The explosion-proof tank 1 is wrapped with a detachable heat insulation layer 11. The explosion-proof tank 1 is provided with a barometer A12. A valve A13 is provided between the explosion-proof tank 1 and the Venturi tube 2. 4 and the diaphragm pump 5 are provided with a three-way valve B14, the three-way valve B14 is externally connected to an independent pipeline 15, the independent pipeline 15 is connected to the heat exchanger 6, and a three-way valve is provided between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com