Treatment system and treatment method for distillation mother liquor of CMC wastewater

A treatment method and technology for a treatment system, which are applied to the CMC wastewater distillation mother liquor treatment system and treatment field, can solve problems such as secondary pollution, maximize the recycling rate, and are conducive to full recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

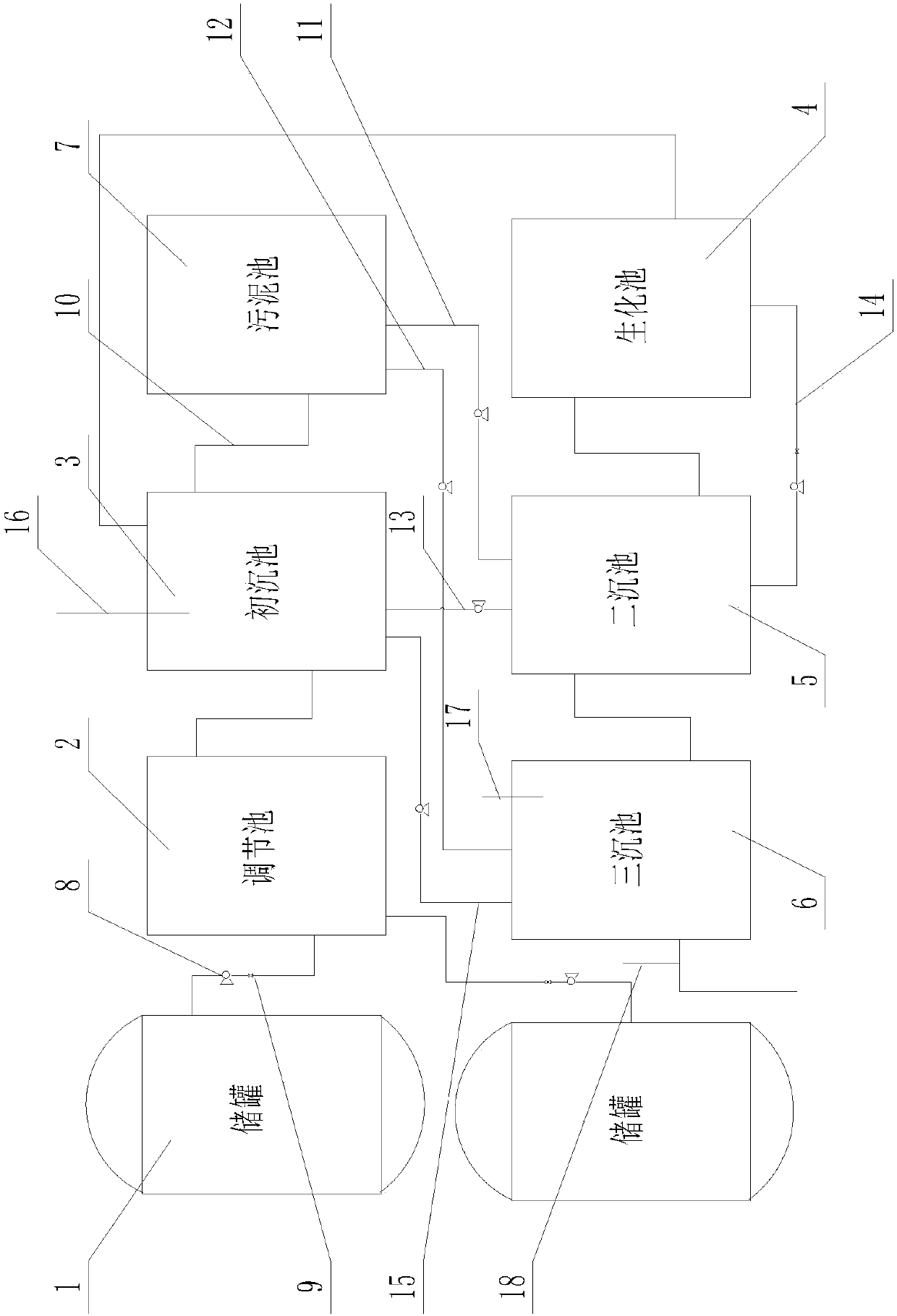

[0032] Such as figure 1 As shown, a CMC waste water distillation mother liquor treatment system includes a storage tank 1, a regulating pond 2, a primary sedimentation pond 3, a biochemical pond 4, a secondary sedimentation pond 5, and a tertiary sedimentation pond 6 according to the flow direction of the CMC waste water distillation mother liquor. The outlet of the tank 1 is connected with the inlet of the regulating tank 2, the outlet of the regulating tank 2 is connected with the inlet of the primary sedimentation tank 3, the outlet of the primary sedimentation tank 3 is connected with the inlet of the biochemical tank 4, and the outlet of the biochemical tank 4 is connected with the secondary sedimentation tank The entrance of the 5 is connected, the outlet of the secondary settling tank 5 is connected with the entrance of the tertiary settling tank 6, the outlet of the tertiary settling tank 6 is connected with the outside world, and a device for controlling CMC waste wat...

Embodiment 2

[0039] The influent flow rate of CMC wastewater distillation mother liquor in regulating tank 2 is 0.8m 3 / h, the COD concentration of the regulating pool 2 is 500mg / L, the CMC waste water distillation mother liquor treatment method and other process parameters of the present embodiment are basically the same as those of the embodiment 1, and will not be repeated here.

Embodiment 3

[0041] The feed flow of CMC wastewater distillation mother liquor in regulating tank 2 is 1.2m 3 / h, the COD concentration of the regulating tank 2 is 550mg / L, the primary sedimentation tank 3PAC flocculant dosing pipeline 16, when the SS value of the suspended matter is greater than 500mg / L, add PAC with a concentration of 10%, and the flow rate is 1.2 T / h, the three sedimentation tank 6 is provided with PAC and PAM primary dosing pipeline 17, when the COD concentration of the effluent chemical oxygen demand of the secondary sedimentation tank 5 is greater than 50mg / L, the primary dosing pipeline 17 first adds a concentration of 10 % PAC, the flow rate is 0.5T / h, then add PAM with a concentration of 0.05%, the flow rate is 0.6T / h, the secondary dosing pipeline 18 of sodium hypochlorite in the three sedimentation tank 6, when the concentration of ammonia nitrogen in the effluent of the three sedimentation tank 6 is above 4.5mg / L , add sodium hypochlorite, flow rate 0.8T / h, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com