Treatment method of cotton pulp wastewater

A treatment method and technology for cotton pulp wastewater, applied in the textile field, can solve problems such as ineffective chroma removal, effluent chroma that does not meet discharge requirements, and high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

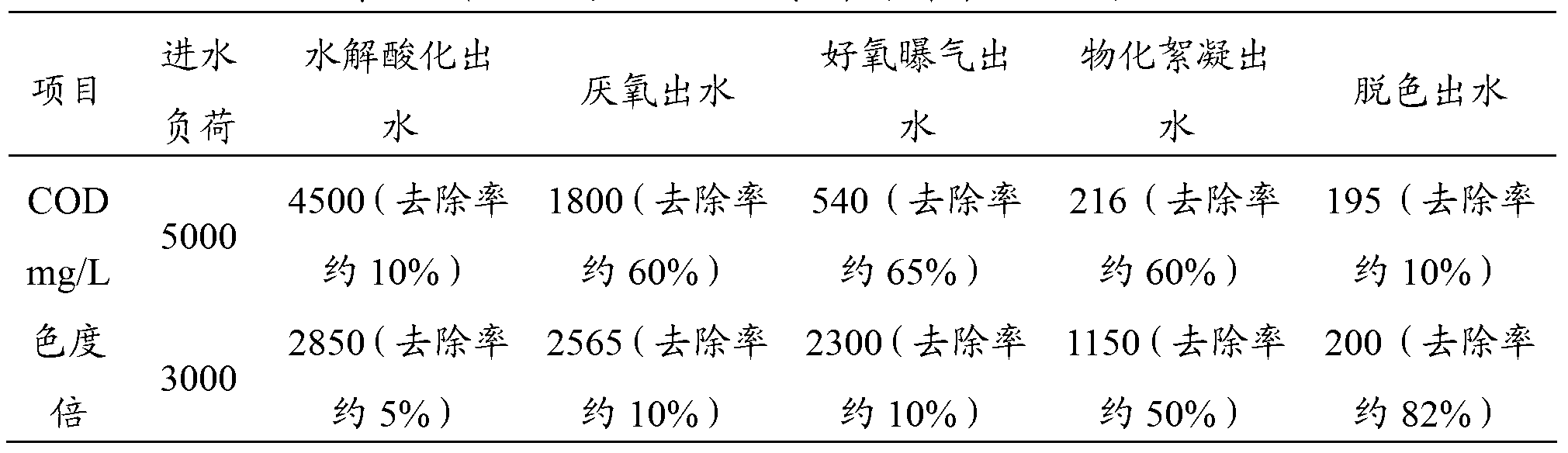

Embodiment 1

[0070] The cotton pulp wastewater with a COD concentration of 5000mg / L and a chroma of 3000 times passes through the black liquor filter, hydrolysis acidification tank, anaerobic reactor, aerobic aeration tank, secondary sedimentation tank, dosing reaction tank and decolorization reaction in sequence pool, and pump the obtained sedimentation sludge and aerobic residual sludge into the sludge thickening tank for thickening and pressure filtration treatment. In the present embodiment, the hydraulic retention time of the hydrolytic acidification treatment is 6 hours, the hydraulic retention time of the anaerobic treatment is 16 hours, the hydraulic retention time of the aerobic aeration treatment is 20 hours, and the hydraulic retention time of the sedimentation treatment is 8 hours. In the process of flocculation, the dosage of aluminum sulfate is 3‰, and the hydraulic retention time is 8 hours; in the dehydration treatment, the dosage of chlorine dioxide is 0.1‰, and the hydraul...

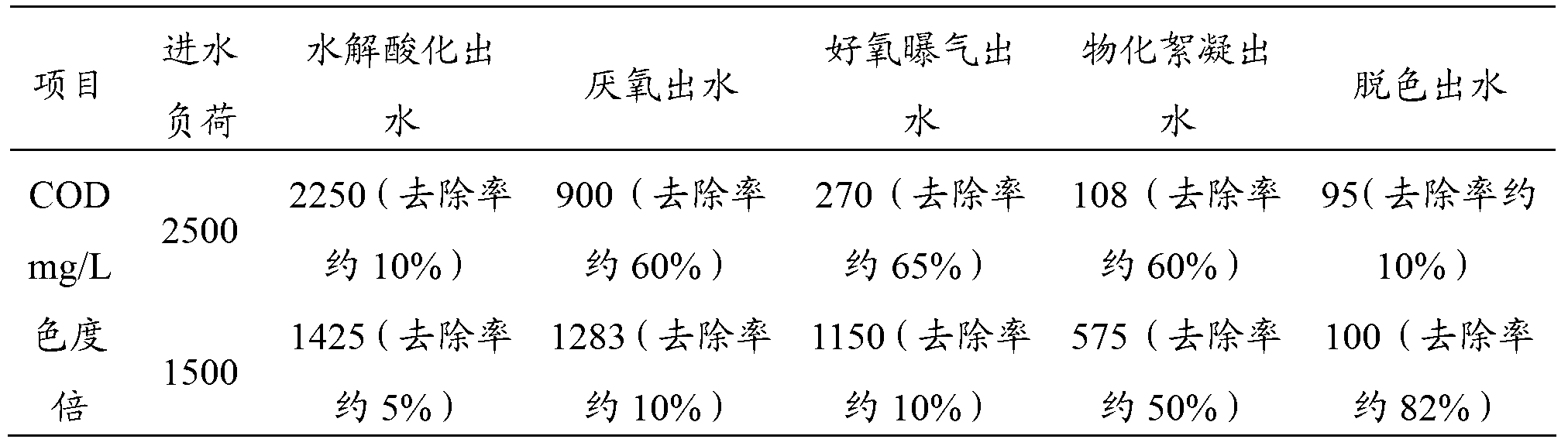

Embodiment 2

[0076] The cotton pulp wastewater with a COD concentration of 2500mg / L and a chroma of 1500 times passes through the black liquor filter, hydrolysis acidification tank, anaerobic reactor, aerobic aeration tank, secondary sedimentation tank, dosing reaction tank and decolorization reaction tank in sequence , and the obtained sedimentation sludge and aerobic residual sludge are pumped into the sludge thickening tank for thickening and pressure filtration treatment. In the present embodiment, the hydraulic retention time of hydrolytic acidification treatment is 10 hours, the hydraulic retention time of anaerobic treatment is 20 hours, the hydraulic retention time of aerobic aeration treatment is 24 hours, and the hydraulic retention time of sedimentation treatment is 12 hours. During the flocculation treatment, the dosing amount of aluminum sulfate is 5‰, and the hydraulic retention time is 12 hours. In the dehydration treatment, the addition amount of chlorine dioxide is 0.2‰, an...

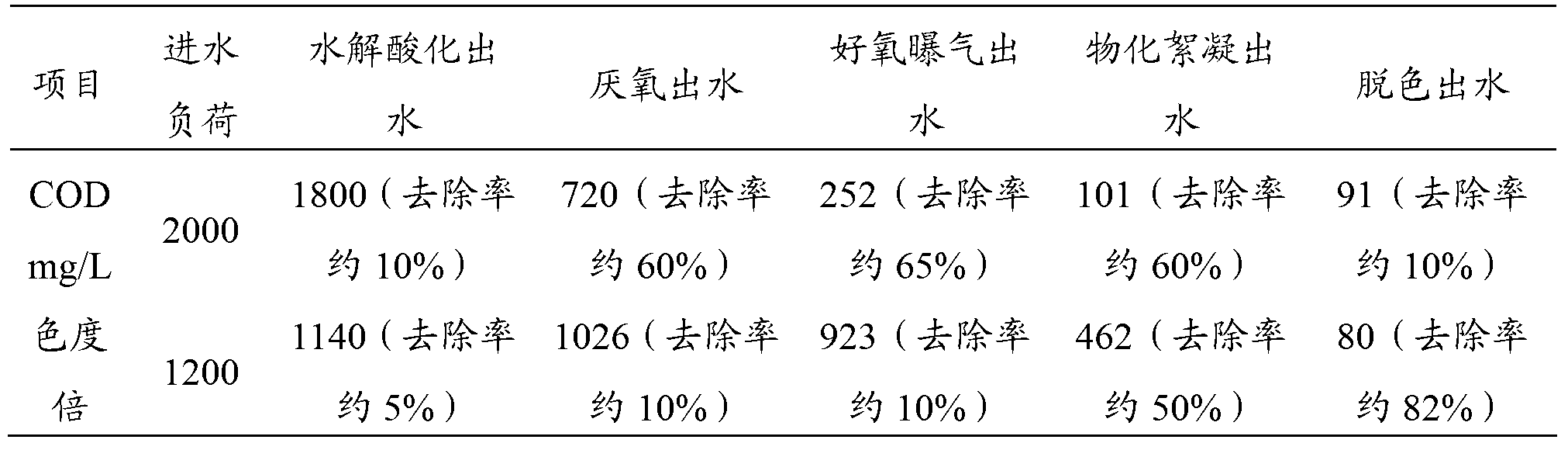

Embodiment 3

[0082] The cotton pulp wastewater with a COD concentration of 2000mg / L and a chroma of 1200 times passes through the black liquor filter, hydrolysis acidification tank, anaerobic reactor, aerobic aeration tank, secondary sedimentation tank, dosing reaction tank and decolorization reaction in sequence pool, and pump the obtained sedimentation sludge and aerobic residual sludge into the sludge thickening tank for thickening and pressure filtration treatment. In the present embodiment, the hydraulic retention time of hydrolytic acidification treatment is 8 hours, the hydraulic retention time of anaerobic treatment is 18 hours, the hydraulic retention time of aerobic aeration treatment is 22 hours, and the hydraulic retention time of sedimentation treatment is 7 hours. In the process of flocculation, the dosage of aluminum sulfate is 4‰, and the hydraulic retention time is 10 hours. In the dehydration treatment, the dosage of chlorine dioxide is 0.15‰, and the hydraulic retention t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com