Asphalt mixing plant tail gas white smoke eliminating treatment apparatus

A treatment device and asphalt mixing station technology, applied in gas treatment, dispersed particle separation, membrane technology, etc., can solve the problems of non-energy-saving and environmental protection of asphalt flue gas, ineffective treatment effect, single asphalt flue gas treatment method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

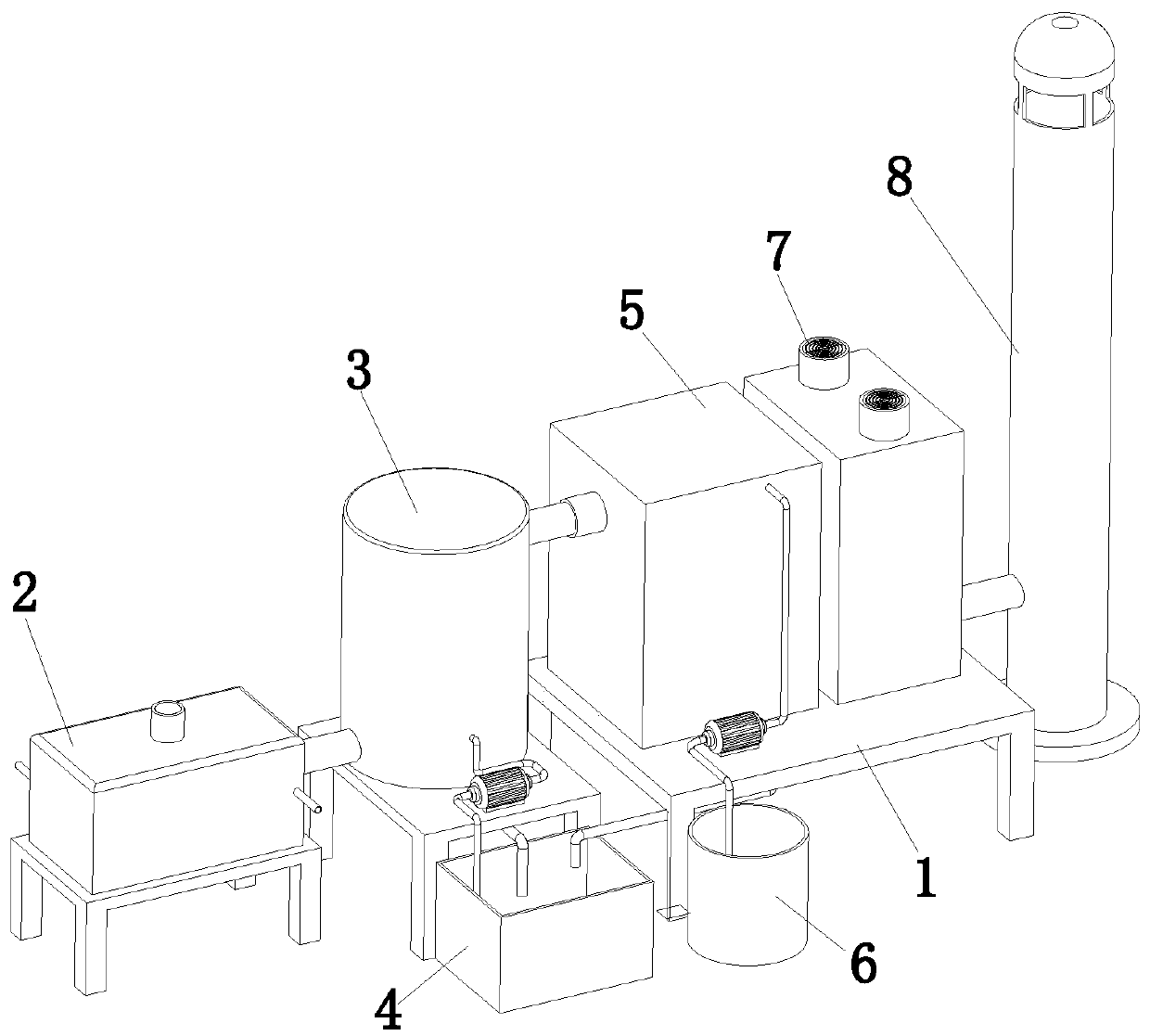

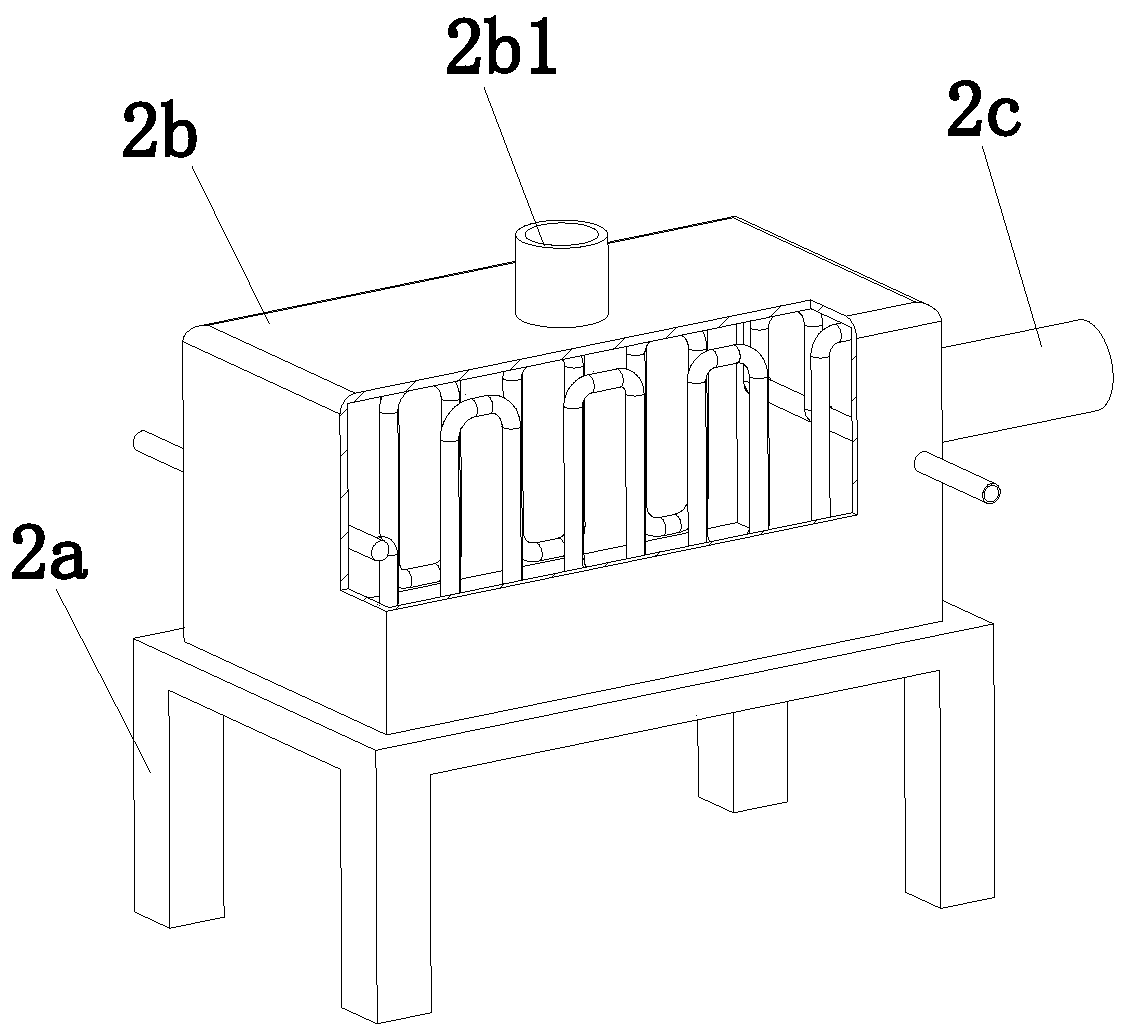

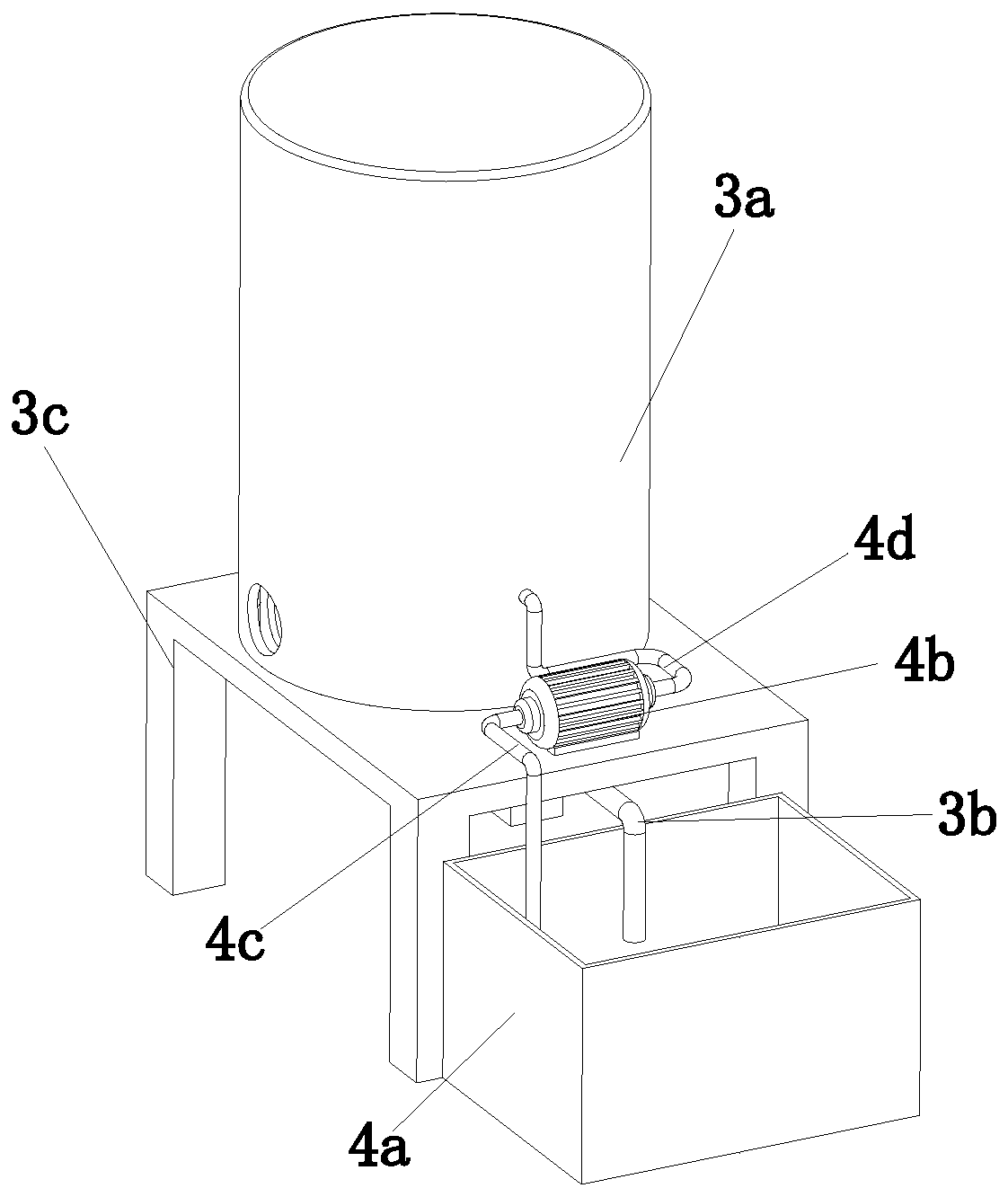

[0040] Embodiment one: combine below Figure 1 to Figure 7 As shown, the embodiment of the present invention provides a whitening treatment device for the tail gas of a drip mixing station, including a mounting frame 1, a flue gas heat exchange assembly 2, a spray assembly 3, a circulating water supply assembly 4, a steam-water separation assembly 5, an automatic adding medicine component 6, flue gas mixing component 7 and flue gas discharge component 8, the flue gas heat exchange component 2 is arranged on the side of the spray component 3, and the flue gas heat exchange component 2 communicates with the spray component 3, The circulating water supply assembly 4 is arranged on the side of the spray assembly 3, the circulating water supply assembly 4 communicates with the spray assembly 3, the steam-water separation assembly 5 is arranged on the installation frame 1, and the steam-water separation assembly 5 is connected to the spray assembly 3. The spray assembly 3 is connect...

Embodiment 2

[0057] Embodiment 2: With the continuous improvement of environmental protection requirements and the company's own emphasis on environmental protection, in order to completely solve the phenomenon of white smoke from the exhaust pipe, when the temperature is low in winter, there will still be a little white smoke with the above-mentioned treatment method. The adopted process is: adding a flue gas reheater after the above-mentioned treatment process.

[0058] The whitening mechanism of flue gas condensation reheating technology is as follows: Figure 9 As shown, the initial state of wet flue gas is at point A. After cooling down, it is condensed according to AD, then heated along DE, and then blended along EC and cooled to the ambient state point C. The change process of EC does not intersect with the saturated humidity curve, so there is no white smoke. The mechanism of white smoke removal shows that ambient humidity and ambient temperature have a great influence on the form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com