Phenol water treatment technique and device for gas furnace

A technology of treatment device and treatment process, applied in the direction of heating water/sewage treatment, etc., can solve the problems of large energy consumption, heavy burden on enterprises, high treatment costs, etc., and achieve the effect of reducing pollution, lightening load, and effectively treating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

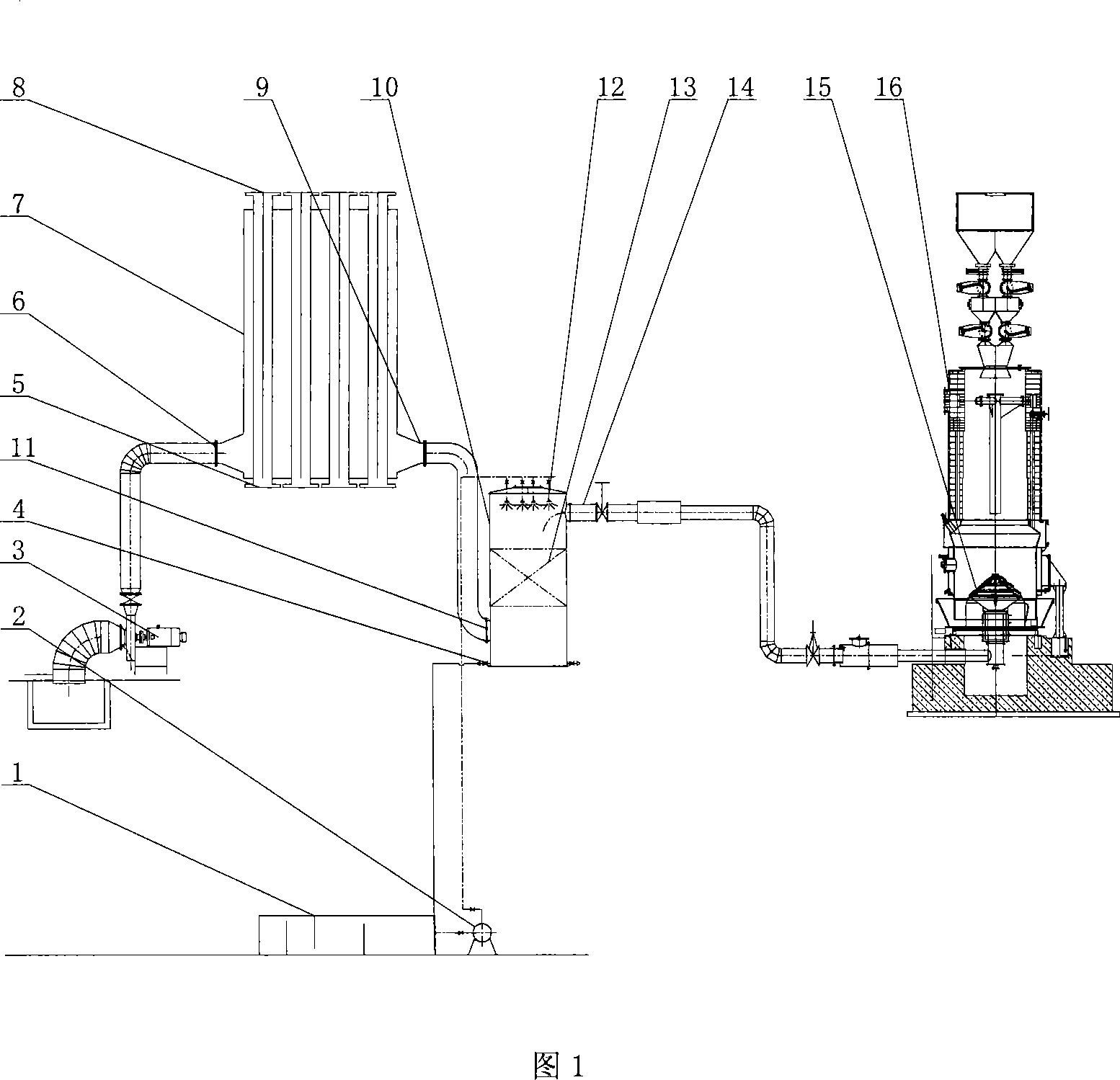

Embodiment 1

[0014] Embodiment 1: As shown in Figure 1: the shell-and-tube heat exchanger 7 is divided into a tube side and a shell side, the tube side is provided with a gas inlet 8 and a gas outlet 5, and the shell side is provided with an air inlet 6 and an air outlet 7 , air inlet 6 is connected with air pump 3 by pipeline, and air outlet 7 is connected with air inlet 11 on the cyclone saturation tower 10 by pipeline, and air inlet 11 is positioned at the bottom of cyclone saturation tower 10 side walls, and cyclone saturation tower 10 The lower part of the side wall is also provided with a sewage outlet 4, and the upper part of the side wall of the cyclone saturation tower 10 is also provided with an air outlet 14. The gas outlet 14 is connected to the combustion layer 15 at the bottom of the two-stage gasifier 16 through a pipeline, and the cyclone saturation tower 10 There is an atomizer on the top, and the phenol water pump 2 is connected to the atomizer and the phenol water pool th...

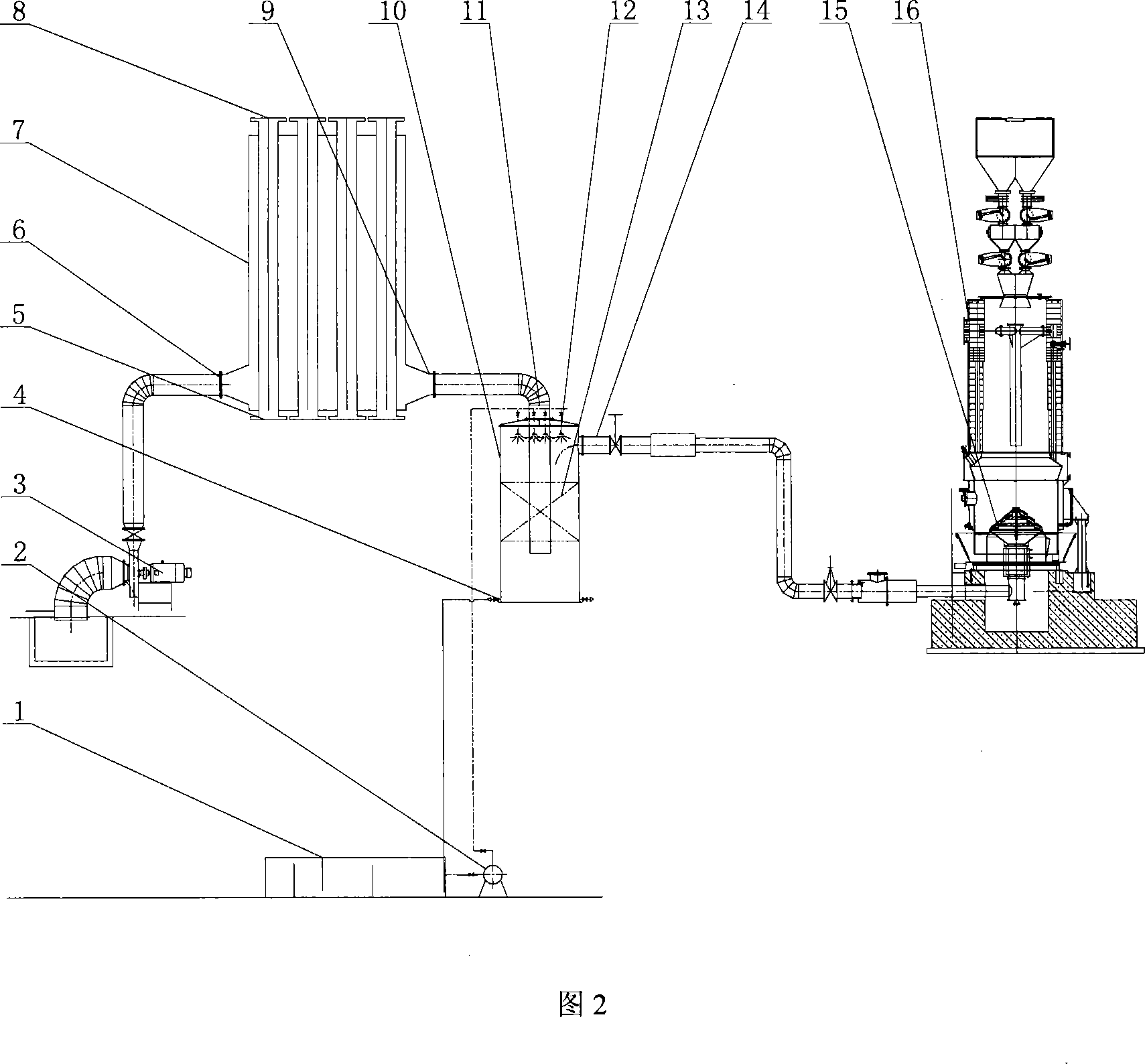

Embodiment 2

[0017] As shown in Figure 2: the air inlet 11 is located at the top of the cyclone saturation tower, and the air inlet extends downward in the cyclone saturation tower to near the bottom of the tower, and the others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com