Curing forming device for civil sludge treatment

A municipal sludge, solidification and molding technology, applied in sludge treatment, fixed/solidified sludge treatment, water/sludge/sewage treatment, etc., can solve the problem of low anaerobic digestion efficiency, difficult to support combustion, and low gas production rate and other problems, to achieve the effect of high work efficiency, improved effect, and improved dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

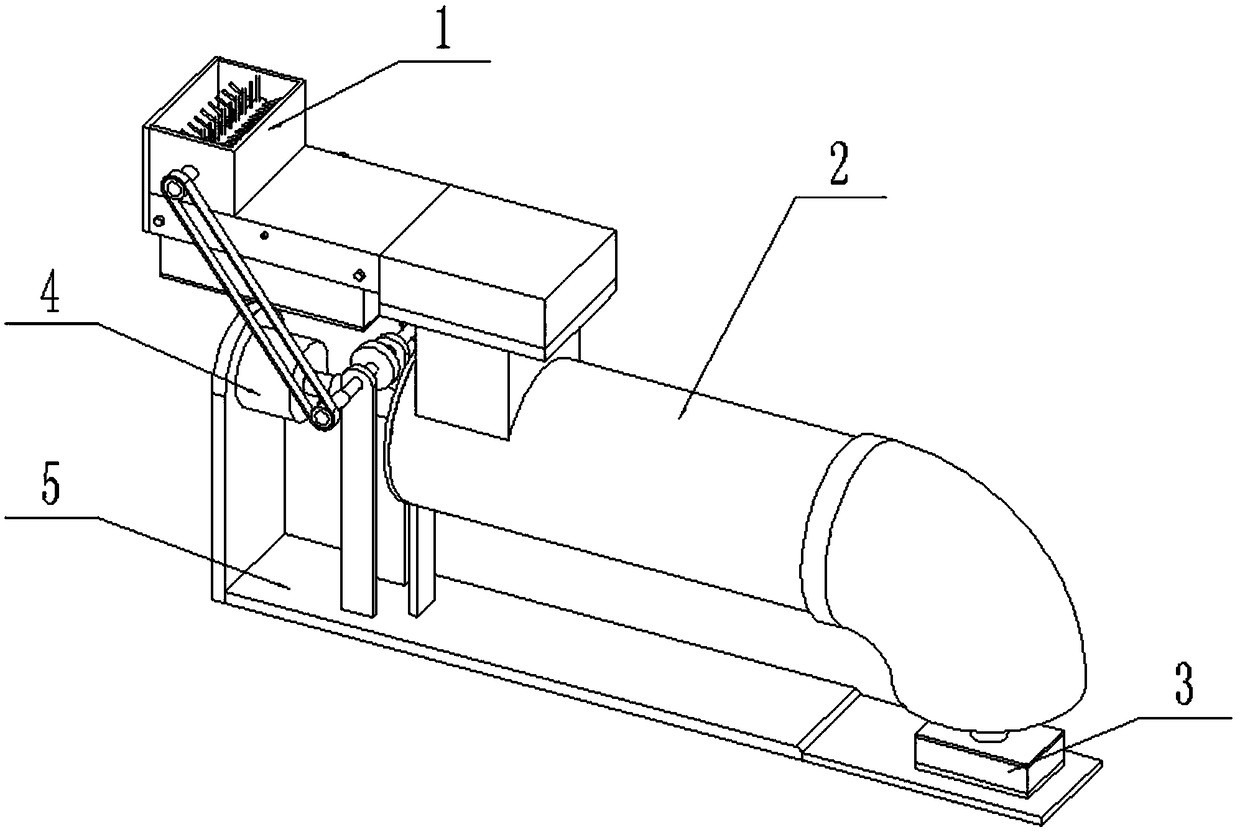

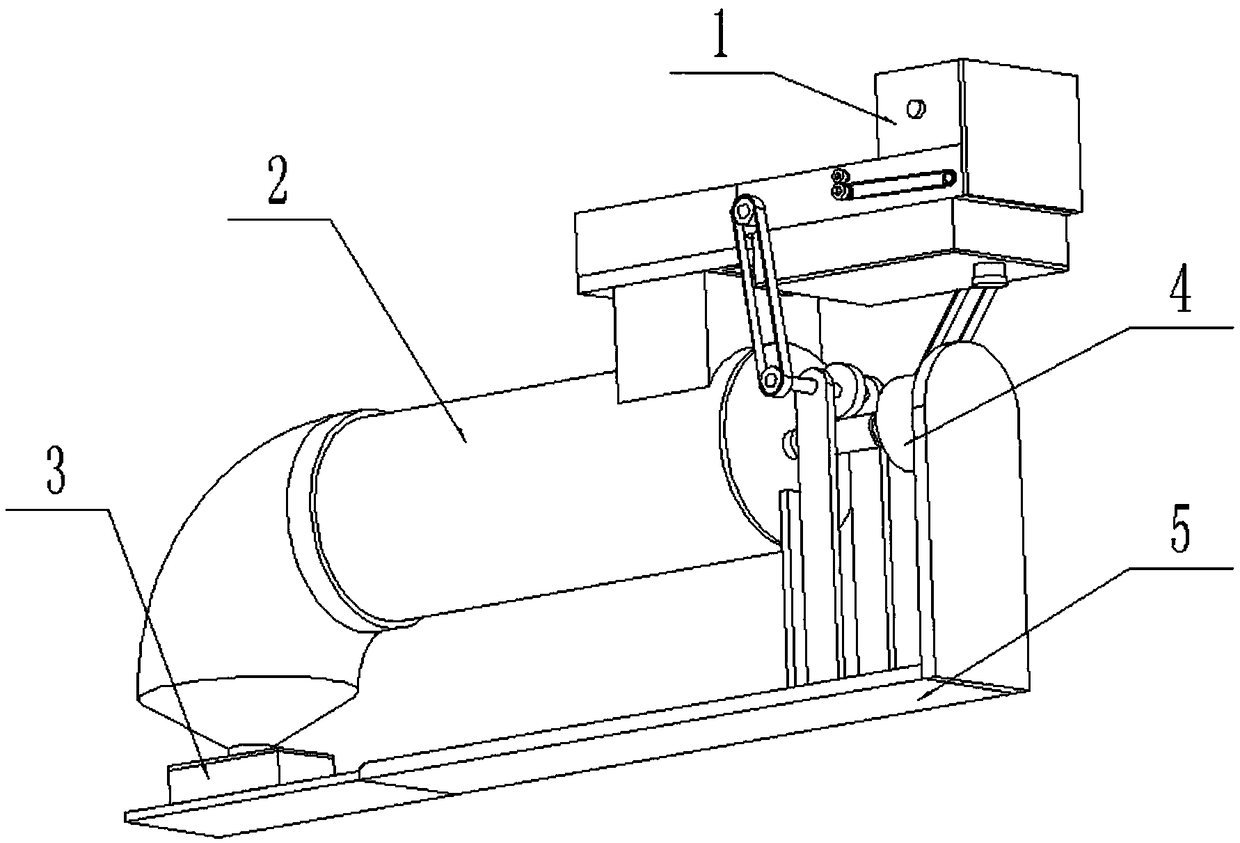

[0028] Such as Figure 1-11 As shown, the solidification molding device for municipal sludge treatment includes a mud feeding device 1, a crushing treatment device 2, a molding die 3, a drive control device 4 and a base plate 5, and the lower end of the mud feeding device 1 is fixedly connected and connected. Crushing treatment device 2; the lower end of the crushing treatment device 2 is fixedly connected and communicated with the forming mold 3; the drive control device 4 is fixedly connected to the base plate 5, and the crushing treatment device 2 and the forming mold 3 are both fixedly connected to the base plate 5 Above; the drive control device 4 is connected to the mud feeding conveying device 1 and the crushing processing device 2 through transmission. The solidification molding device for municipal sludge treatment of the present invention, when in use, after the drive control device 4 is connected to the power supply and turned on by the control switch, the drive con...

specific Embodiment approach 2

[0029] Such as Figure 1-11As shown, the drive control device 4 includes a drive motor 4-1, a motor base 4-2, a worm 4-3, a worm wheel 4-4, a wheel shaft 4-5, a shaft frame plate 4-6, a first transmission wheel 4- 7 and the second transmission wheel 4-8; the drive motor 4-1 is fixedly connected to the motor base 4-2, and the motor base 4-2 is fixedly connected to the base plate 5; the output end of the drive motor 4-1 The worm 4-3 is connected through a coupling; the worm gear 4-4 is meshed with the worm 4-3; the worm gear 4-4 is fixedly connected to the middle end of the wheel shaft 4-5, and the wheel shaft 4-5 is rotatably connected through a bearing with seat On the axle frame plate 4-6, the axle frame plate 4-6 is fixedly connected on the base plate 5; the left and right ends of the axle 4-5 are respectively fixedly connected to the first transmission wheel 4-7 and the second transmission wheel 4- 8. The worm 4-3 is connected to the crushing device 2, and the first transm...

specific Embodiment approach 3

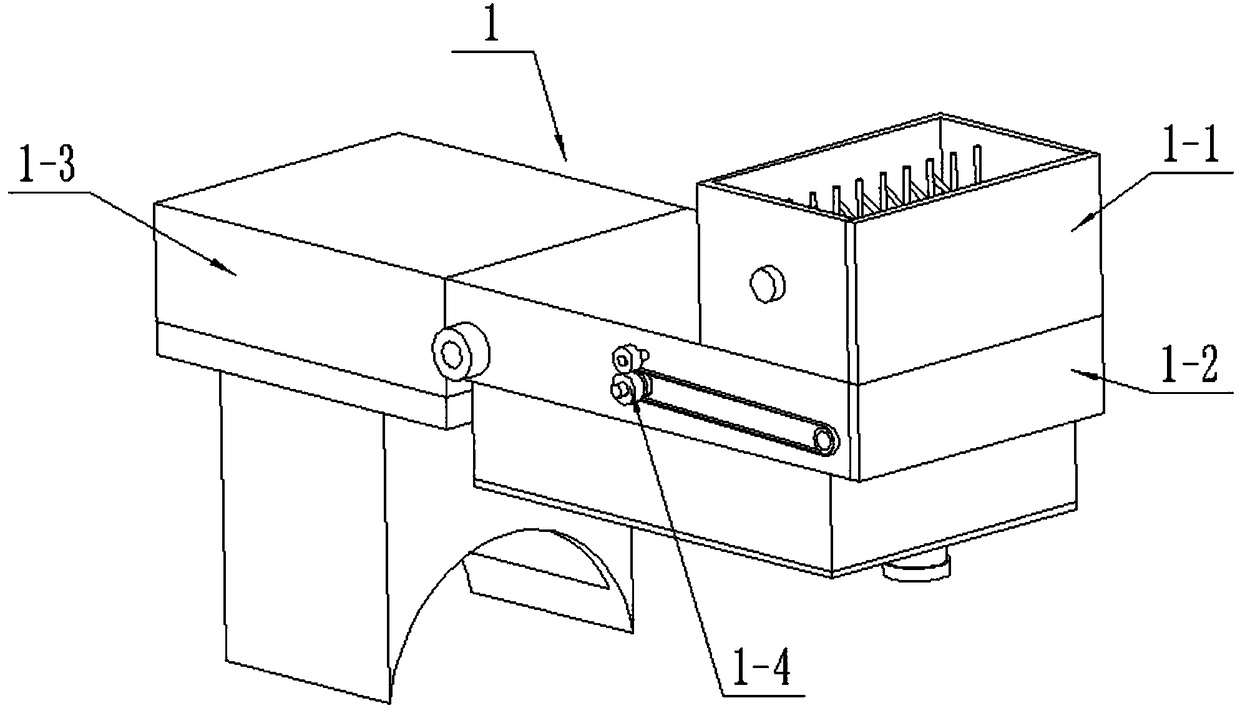

[0030] Such as Figure 1-11 As shown, the mud feeding conveying device 1 includes a mud feeding box assembly 1-1, a mud feeding box assembly 1-2, a mud dropping box assembly 1-3 and a sludge conveyor belt assembly 1-4; the mud feeding box assembly The lower end of 1-1 is fixedly connected to and communicated with the mud delivery box assembly 1-2, and the front end of the mud delivery box assembly 1-2 is fixedly connected to and communicated with the mud drop box assembly 1-3; the sludge conveyor belt assembly 1-4 is connected to The inside of the mud delivery box assembly 1-2; the mud inlet box assembly 1-1 is connected to the second transmission wheel 4-8 through a belt; the sludge conveyor belt assembly 1-4 is connected to the first transmission wheel 4-7 through a belt ; The lower end of the mud drop box assembly 1-3 is fixedly connected and communicated with the crushing treatment device 2 . When the mud feeding conveying device 1 is in use, the first transmission wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com