A graphite fine processing equipment

A processing equipment and refining technology, applied in the direction of graphite, grain processing, chemical instruments and methods, etc., can solve the problems of low graphite processing efficiency, avoid ineffective processing, improve refining efficiency, and improve processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

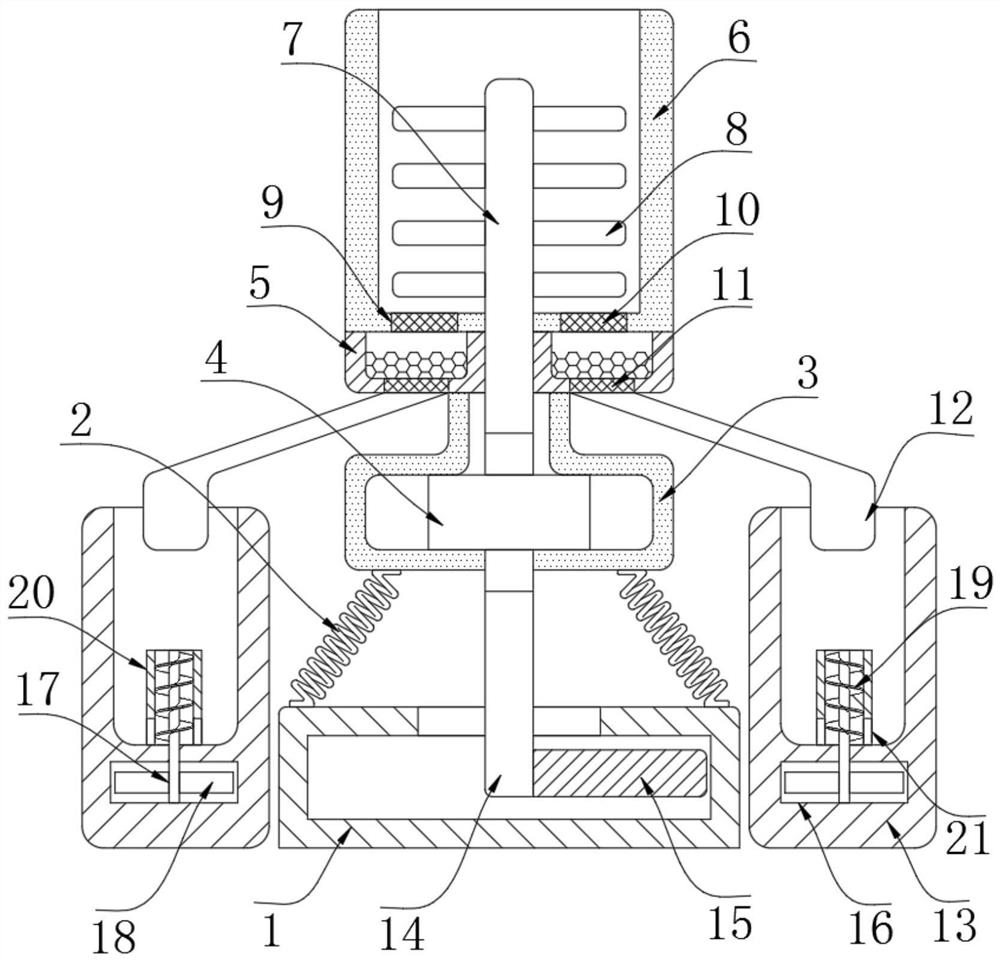

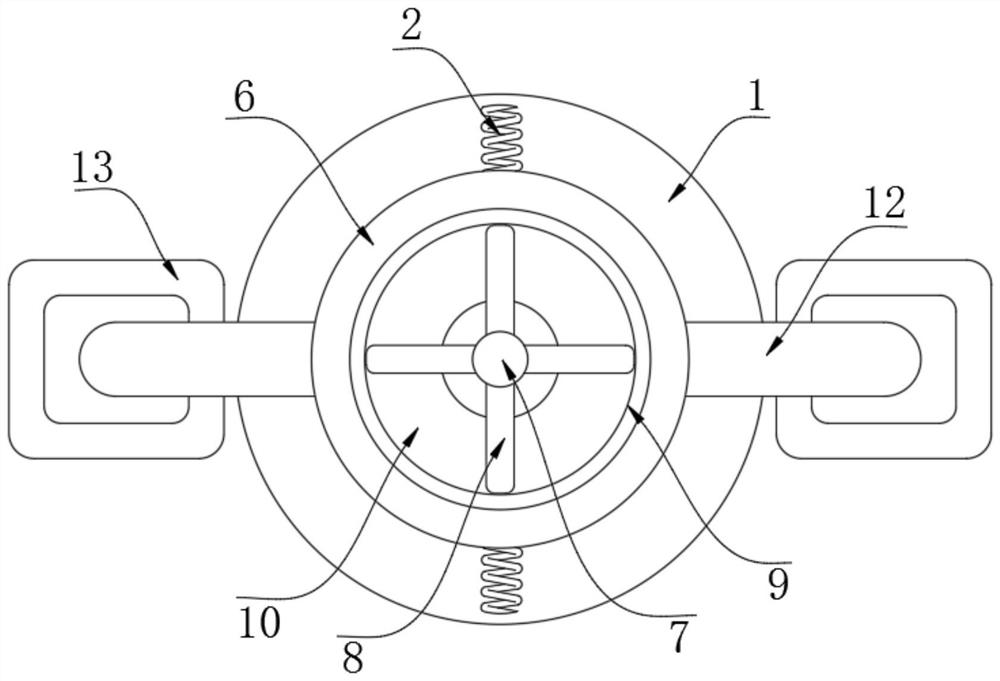

[0018] refer to Figure 1-2 , a graphite refinement processing equipment, comprising a base 1 and two collection boxes 13, the upper end of the base 1 is connected to an organic case 3 through a plurality of buffer springs 2, the upper end of the case 3 is fixed with a refinement box 5, the refinement box The upper end of 5 is fixed with a crushing box 6, and the inside of the cabinet 3 is fixed with a motor 4, which is a double-headed motor. A plurality of stirring blades 8 are fixed on the circumferential side wall of a section inside the crushing box 6, and a blanking chute 9 is provided through the bottom of the crushing box 6, and a blanking net 10 is fixed on the inner wall of the blanking chute 9, and a blanking net 10 is fixed on the inner wall of the crushing box 5. Two collection nets 11 are inserted through the bottom, and the bottom of the thinning box 5 is fixed with a collection pipe 12 corresponding to the two collection nets 11. The two collection pipes 12 comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com