Online oil-gas recovery intelligent control system

An intelligent control system, oil and gas technology, applied in special distribution devices, packaging, distribution devices, etc., can solve problems such as high cost, failure to meet standards, and irregular manual inspections, reduce maintenance costs, realize online monitoring, and reduce air pollution. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

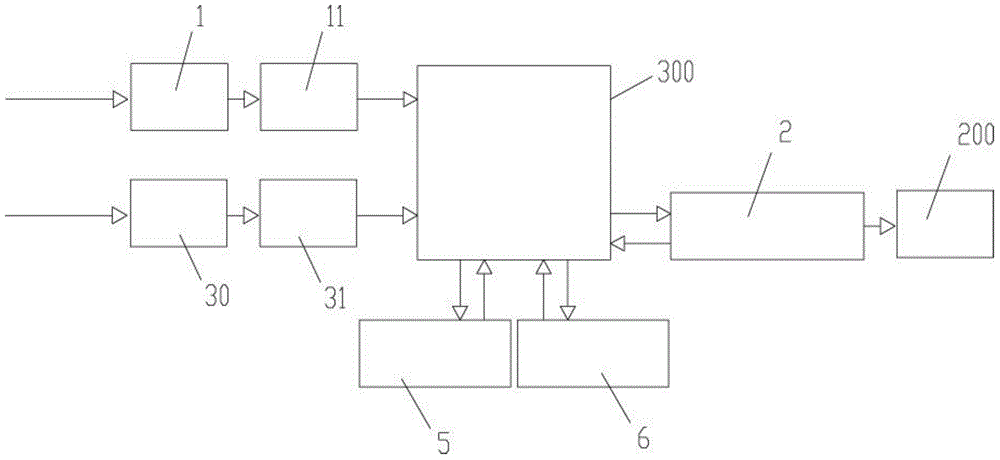

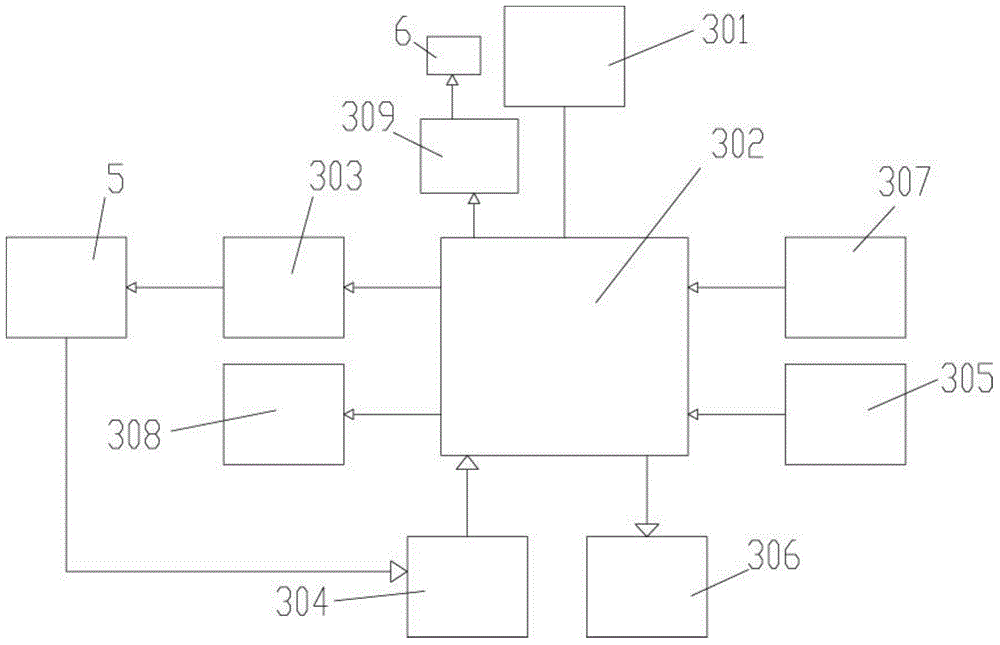

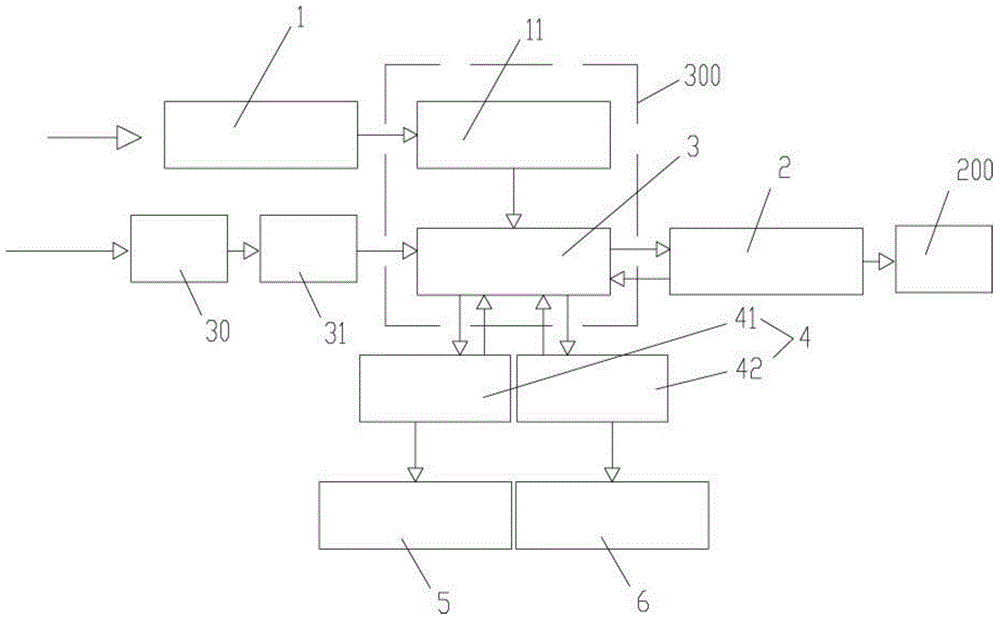

[0036] Example 2, see Figure 3 to Figure 4 As shown, the control main board 300 includes a gas monitoring board 3 and an oil and gas recovery control board 4, the gas monitoring board 3 sends the data received to the monitoring host 2 with the flow data on the gas monitoring board 3, and the monitoring host 2 will receive After comparing and processing the data, the control signal is sent to the gas monitoring board 3, and the gas monitoring board 3 sends the processed signal to the oil and gas recovery control board 4, and the oil and gas recovery control board 4 controls the oil and gas recovery pump 5 after processing the received signal The speed or the gas flow rate of the oil and gas recovery solenoid valve 6, the oil and gas recovery control board 4 sends the controlled signal to the gas monitoring board 3, and the gas monitoring board 3 sends the processing information of the oil and gas recovery control board 4 to the monitoring host 2 for storage , the monitoring ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com