Method for water treatment through ozone oxidation catalyzed by hydroxyl iron oxide

A technology of iron oxyhydroxide and ozone oxidation, applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of insufficient contact between solid catalyst and sewage, and achieve full and thorough catalysis Effects of oxidation, prolongation of time, and increased chance of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

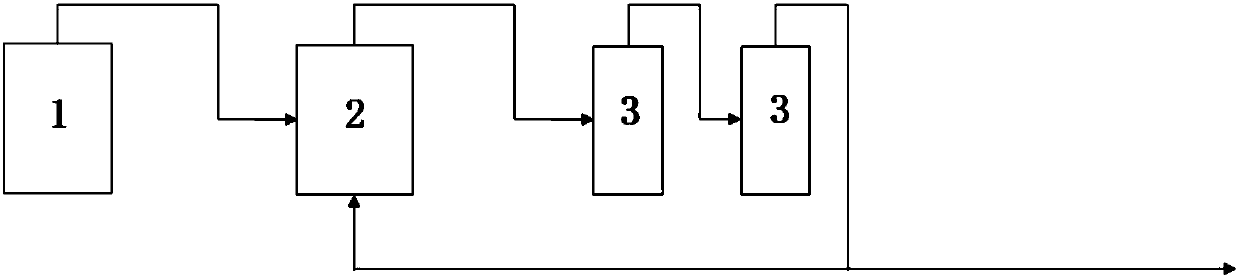

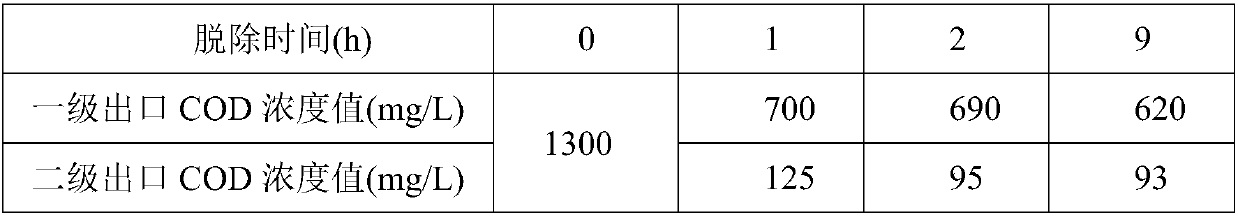

[0035] The specific surface area is 226m 2 / g, the iron oxyhydroxide with particle diameter of Φ2mm is filled in two fixed-bed reactors connected in series with a height-to-diameter ratio of 8:1, such as figure 1 As shown, ozone is continuously introduced into the sewage to be treated with a COD concentration value of 1300mg / L. Ozone is generated by oxygen through an ozone generator, and the ozone flow rate is 60mL / min; Pass it into the aforementioned fixed-bed reactor, and monitor the COD concentration values at the outlets of the two fixed-beds when reacting for 1h, 2h, and 9h. The monitoring results are shown in Table 1.

[0036] Table 1

[0037]

[0038] It can be seen from the above table 1 that after two stages of fixed beds, the COD concentration of sewage is greatly reduced, and after 2 hours, it is lower than 100mg / L, which can reach the discharge standard.

Embodiment 2

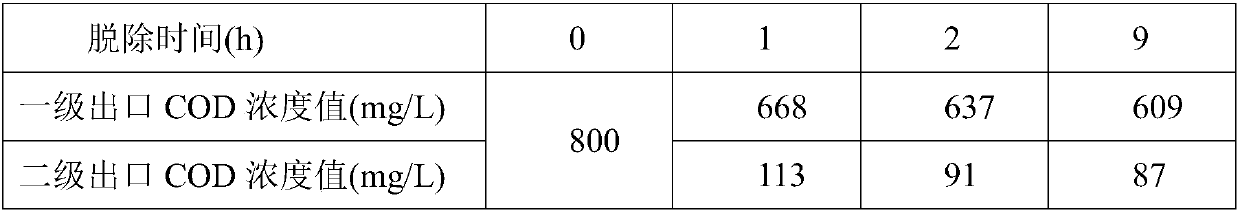

[0040] The specific surface area is 180m 2 / g, the iron oxyhydroxide particle size of Φ1mm is packed in two fixed-bed reactors connected in series with a height-to-diameter ratio of 6:1, such as figure 1 As shown, ozone is continuously introduced into the sewage to be treated with a COD concentration value of 800mg / L. Ozone is generated by oxygen through an ozone generator, and the ozone flow rate is 30mL / min; Pass it into the aforementioned fixed-bed reactor, and monitor the COD concentration values at the outlets of the two fixed-beds when reacting for 1h, 2h, and 9h. The monitoring results are shown in Table 2.

[0041] Table 2

[0042]

[0043] It can be seen from the above table 2 that after two stages of fixed beds, the COD concentration of sewage is greatly reduced, and after 2 hours, it is lower than 100mg / L, which can meet the discharge standard.

Embodiment 3

[0045] The specific surface area is 239m 2 / g, particle size of Φ3mm ferric oxyhydroxide is filled in two fixed-bed reactors connected in series with a height-to-diameter ratio of 7:1, such as figure 1As shown, ozone is continuously introduced into the sewage to be treated with a COD concentration value of 1000mg / L. Ozone is generated by oxygen through an ozone generator, and the ozone flow rate is 45mL / min; Pass it into the aforementioned fixed-bed reactor, and monitor the COD concentration values at the outlets of the two fixed-beds when reacting for 1h, 2h, and 9h. The monitoring results are shown in Table 3.

[0046] table 3

[0047]

[0048] It can be seen from the above table 3 that after two stages of fixed bed, the COD concentration of sewage is greatly reduced, and after 2 hours, it is lower than 100mg / L, which can reach the discharge standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com