Arsenic-containing waste acid low-cost harmless treatment method

A harmless treatment, low-cost technology, applied in metallurgical wastewater treatment, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve the problems of low efficiency, high cost, difficult treatment, etc., and achieve simple process and low cost Low, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

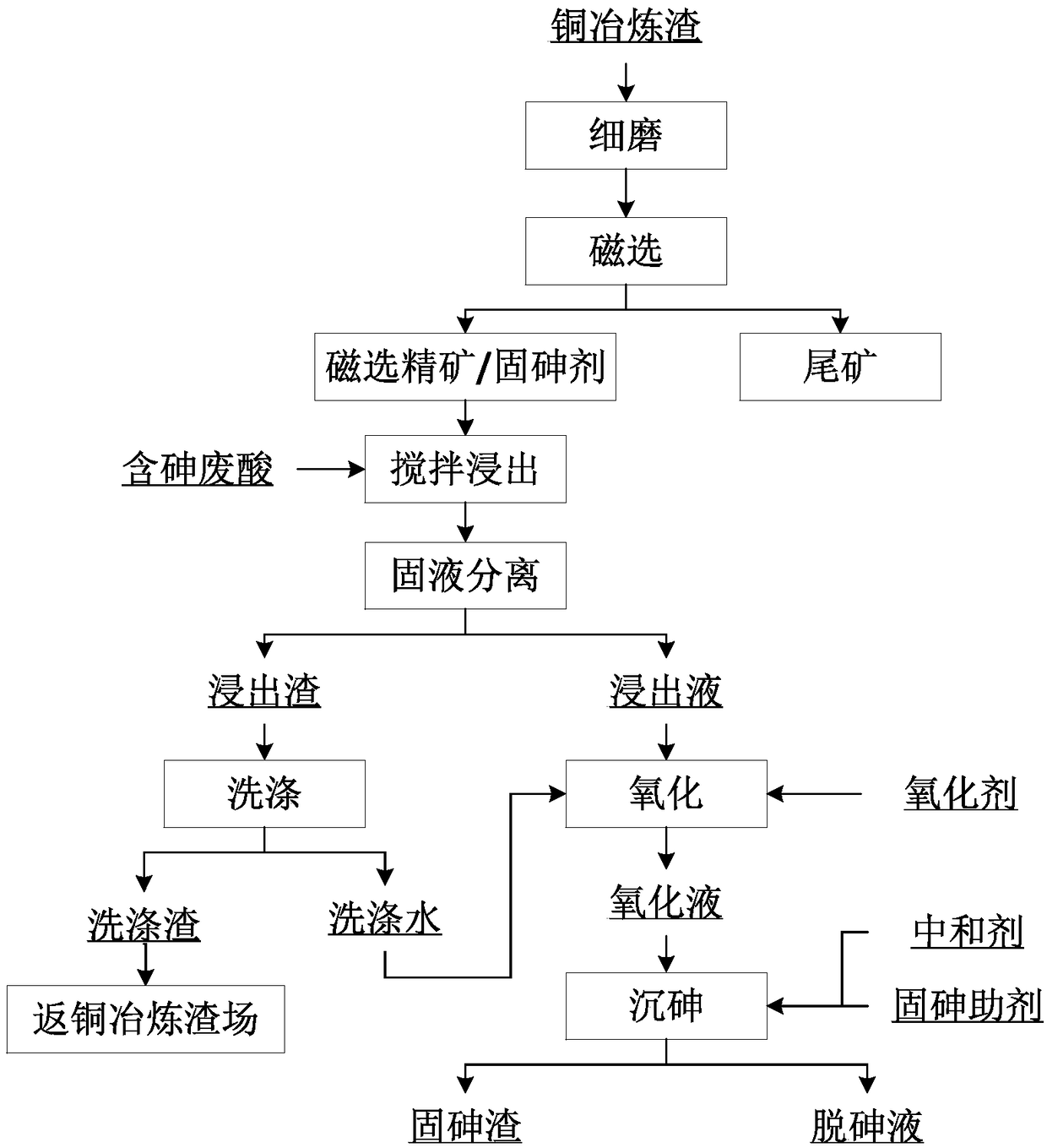

Method used

Image

Examples

Embodiment 1

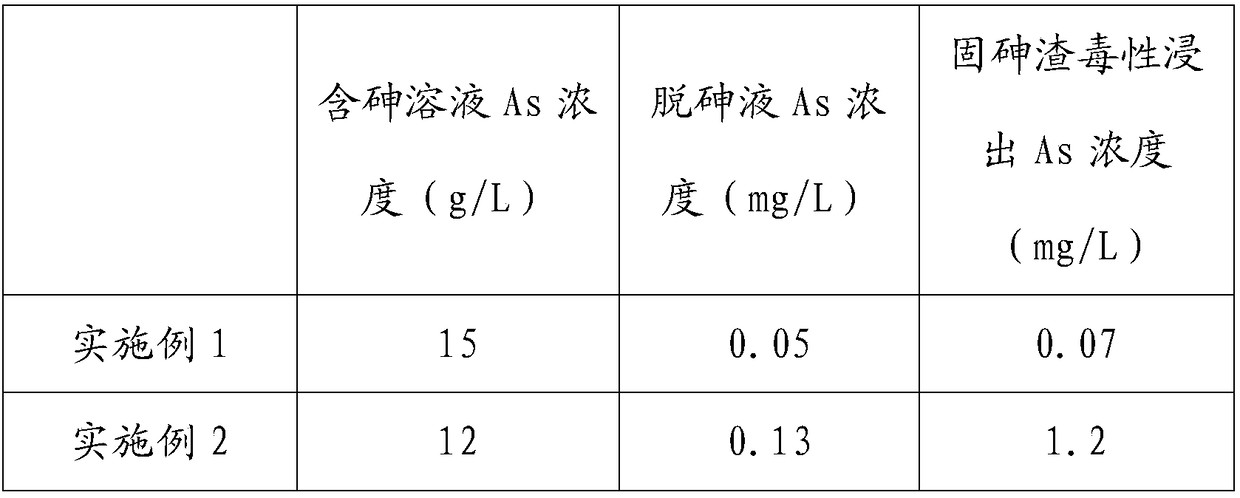

[0038] Finely grind copper smelting slag to 325 mesh P 70 , After magnetic separation by a 120mT magnetic separator, the magnetic separation concentrate is obtained. Add the magnetic separation concentrate to the arsenic-containing waste acid with a sulfuric acid concentration of 70g / L and arsenic content of 15g / L. The liquid-solid ratio (L / g) is 8:1. The liquid is separated to obtain leaching residue and leaching liquid. After mixing the leaching residue with industrial water at a ratio of 1:1, filter and wash repeatedly for 4 times, and obtain the washing residue and washing water after solid-liquid separation. Wash water is pumped into the leaching solution. Add 10g / L hydrogen peroxide to the leaching solution mixed with washing water for oxidation, then add arsenic-fixing additive polymeric ferric sulfate, the initial iron-arsenic mass concentration ratio is 1.5, and add neutralizing agent calcium hydroxide at 90°C The arsenic precipitation is carried out by stirring, t...

Embodiment 2

[0040] Finely grind copper smelting slag to 200 mesh P 85 , after magnetic separation by 100mT magnetic separator, the magnetic separation concentrate is obtained. Add the magnetic separation concentrate to the arsenic-containing waste acid with a sulfuric acid concentration of 80g / L and arsenic content of 12g / L. The liquid-solid ratio (L / g) is 7:1. separate. After the leaching residue is mixed with industrial water at a ratio of 1:1, it is filtered and washed 4 times repeatedly, the solid and liquid are separated, and the washing water is pumped into the leaching liquid for treatment. Add 9g / L hydrogen peroxide to the leachate mixed with washing water for oxidation, then add arsenic-fixing additive polymerized ferric chloride sulfate, the initial iron-arsenic mass concentration ratio is 1.5, and add calcium oxide to stir at 90°C Arsenic precipitation, the arsenic precipitation time is 2 hours, the end point pH is 8, and the arsenic-removing liquid and arsenic-fixed residue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com