High-water-containing domestic garbage rapid resource cleaning treatment method and system

A technology for domestic waste and cleaning treatment, applied in combustion methods, incinerators, carbon preparation/purification, etc., can solve the problems of polluted groundwater, homologous pollution, large investment, etc., and achieve a small system footprint and easy installation Flexible, highly integrated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

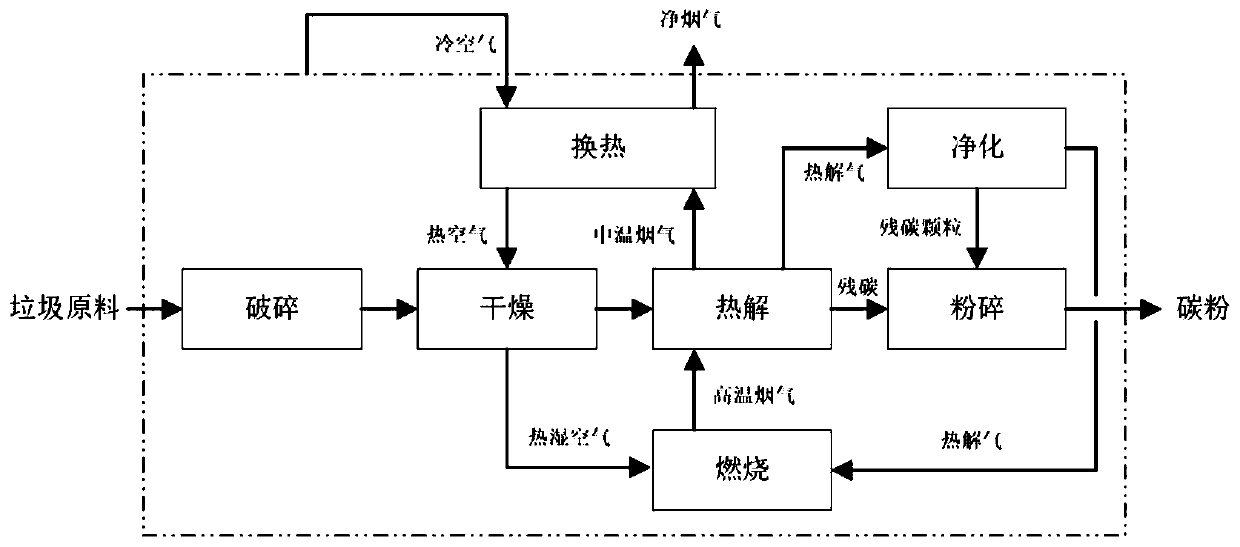

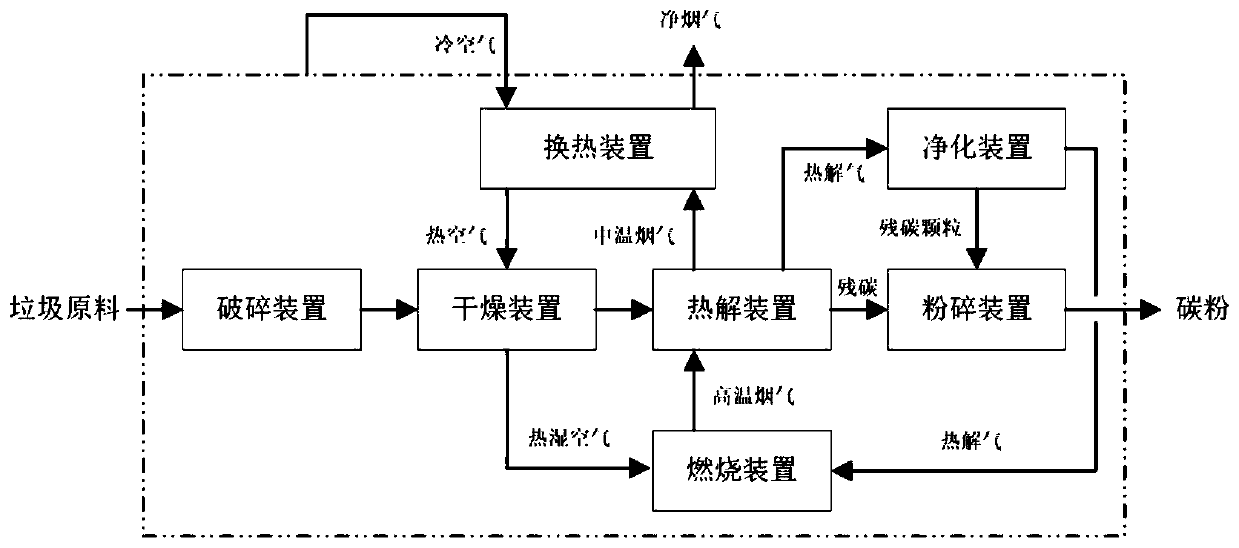

Method used

Image

Examples

Embodiment 1

[0036] 1 ton of kitchen waste with a water content of 60% is crushed until the garbage particles are smaller than 50mm, then sent to the drying equipment, mixed with hot air at 300°C, contacted for heat exchange and dried, and stayed for 30 minutes to heat the garbage to 100°C. The moisture is reduced to 30%, so that the hot air is transformed into hot and humid air at 150°C; the dried garbage is in contact with the high-temperature flue gas at 750°C, and the garbage is heated to 550°C for pyrolysis, staying for 40 minutes, generating residual carbon and pyrolyzing at 250°C High-temperature flue gas is transformed into 320°C medium-temperature flue gas after heating; 250°C pyrolysis gas is subjected to high-temperature dust removal and desulfurization in sequence to obtain residual carbon particles and gas, and then the gas is mixed with hot and humid air for adiabatic and low-nitrogen combustion. After the carbon is mixed and pulverized, 110kg of carbon powder is obtained; the...

Embodiment 2

[0038]Mix 0.5 tons of kitchen waste with a water content of 70% and 0.5 tons of waste paper waste with a water content of 10% and crush them. After being crushed, they are sent to the drying equipment, mixed with hot air at 250°C, and dried by contact with heat exchange. Stay for 30 minutes to raise the temperature of the waste to 90°C, the moisture is reduced to 20%, so that the hot air is transformed into hot and humid air at 150°C; the dried garbage is in contact with the high-temperature flue gas at 750°C, and the garbage is heated to 500°C for pyrolysis, resulting in residual carbon and pyrolysis at 200°C Gas, stay for 30 minutes, the high-temperature flue gas is heated and transformed into 340°C medium-temperature flue gas; 200°C pyrolysis gas is subjected to high-temperature dust removal and desulfurization in sequence to obtain residual carbon particles and gas, and then the gas is mixed with hot and humid air for adiabatic and low-nitrogen Combustion, the residual carb...

Embodiment 3

[0040] Mix 0.3 tons of kitchen waste with a water content of 70% and 0.7 tons of waste paper waste with a water content of 10% and crush them. After being crushed, they are sent to the drying equipment, mixed with hot air at 200°C, and dried by contact with heat exchange. Stay for 25 minutes to heat up the waste to 80°C, the moisture is reduced to 10%, so that the hot air is transformed into hot and humid air at 170°C; the dried garbage is in contact with the high-temperature flue gas at 700°C, and the garbage is heated to 450°C for pyrolysis, resulting in residual carbon and pyrolysis at 180°C Gas, stay for 20 minutes, the high-temperature flue gas is heated and transformed into 350°C medium-temperature flue gas; 180°C pyrolysis gas is subjected to high-temperature dust removal and desulfurization in sequence to obtain residual carbon particles and gas, and then the gas is mixed with hot and humid air for adiabatic and low-nitrogen After burning, the residual carbon is crushed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com