Comperssor nozzle

A technology of compressors and nozzles, which is applied in the direction of injection devices, mechanical equipment, injection devices, etc., can solve the problems of large space occupation, low production efficiency, complex piping system, etc., to increase the gas-liquid heat exchange area, improve the cooling effect, The effect of prolonging the heat exchange time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

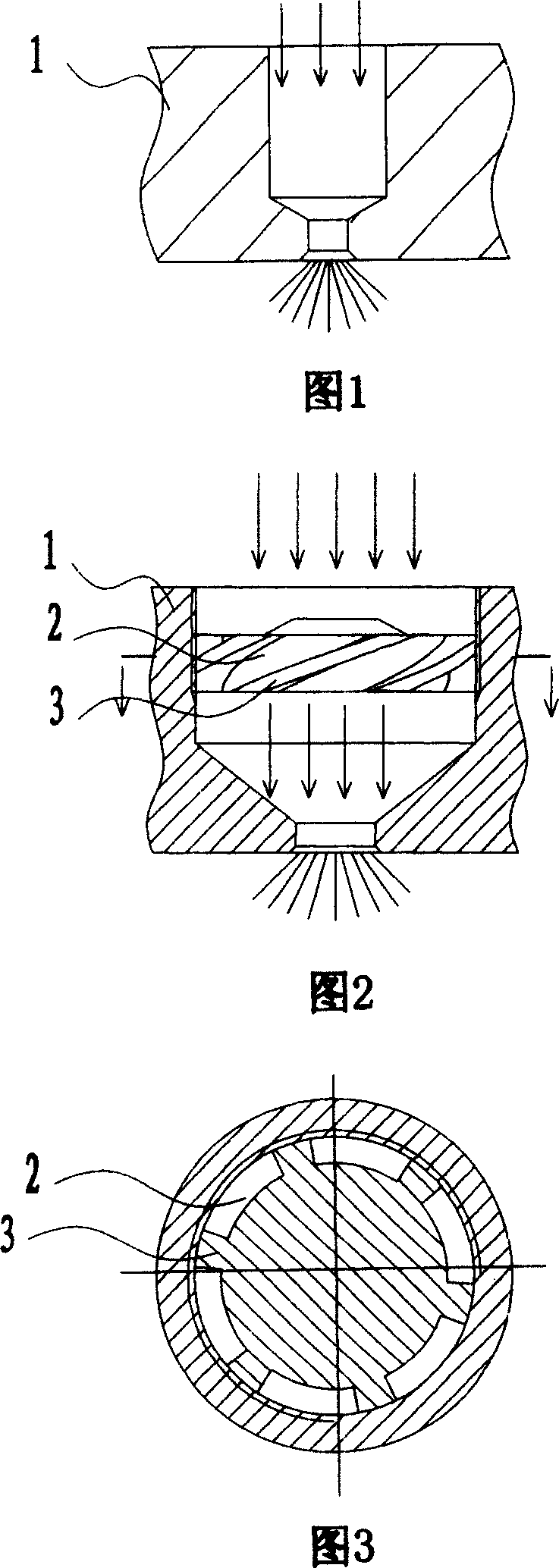

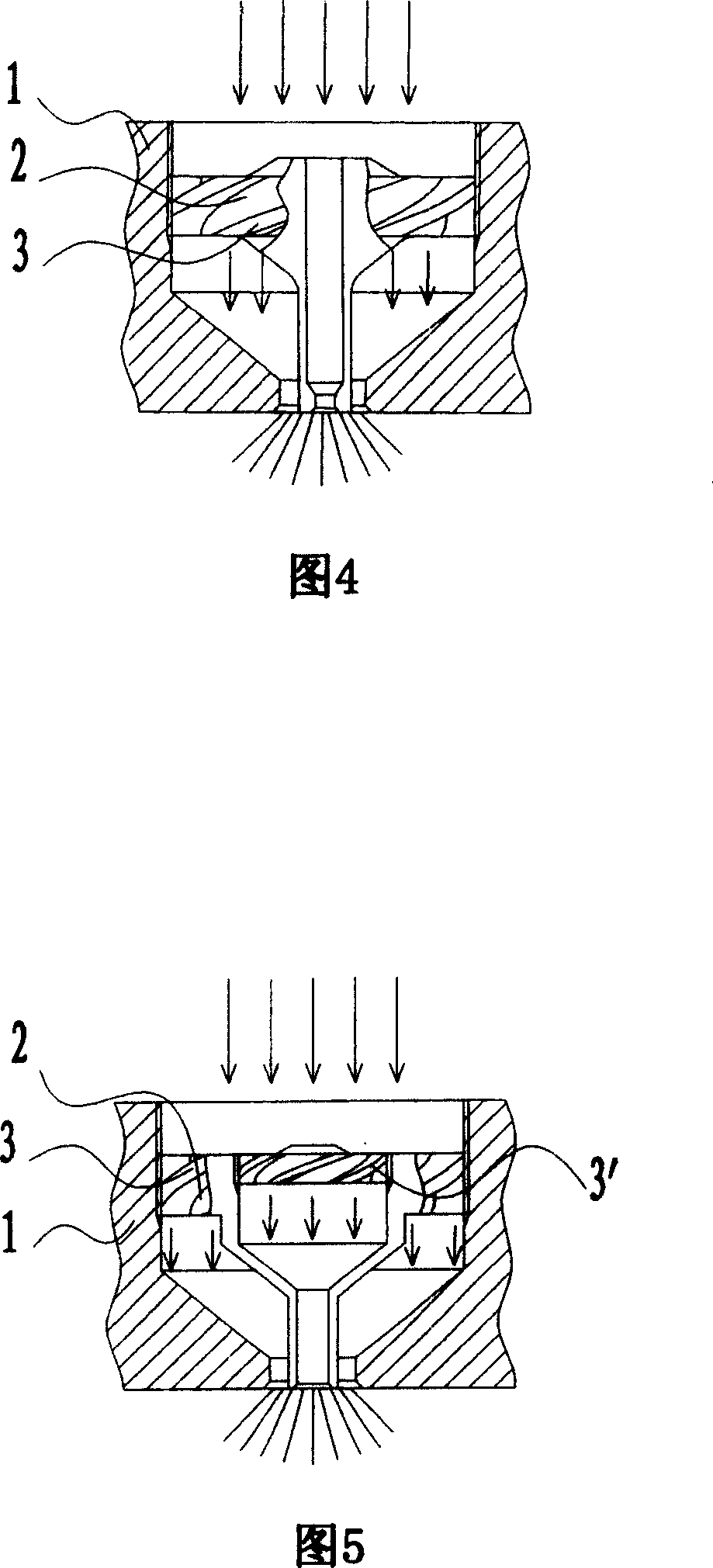

[0016] The compressor nozzle of the present invention will be further described in detail with reference to the accompanying drawings.

[0017] Fig. 2 and Fig. 3 are the structure shown in the embodiment (1) of the compressor nozzle, the compressor nozzle 3 is connected in the cylindrical cavity of the compressor housing 1 through threads, and one end of the cylindrical cavity is a tapered throttling The orifice communicates with the working chamber of the compressor. The substrate of the nozzle 3 is a screw, and there are several spiral grooves or inclined grooves 2 on the outer circle. The number of spiral grooves or inclined grooves 2 and the cross-sectional area of the grooves depend on the amount of spray liquid required by compressors of different specifications. When the cross-section of the grooves 2 is square, the pressure loss is small and the atomization effect is better. Of course, the bottom of the groove can be designed in a circular arc shape, and the effect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com