Combined template mechanism for mold spraying

A combined formwork technology, which is applied in the shaft lining, tunnel lining, underground chamber, etc., can solve the problems of reducing the rebound rate of concrete, concrete leakage, and aggravating concrete leakage, so as to increase the amount of concrete spraying, improve efficiency, The effect of increasing the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

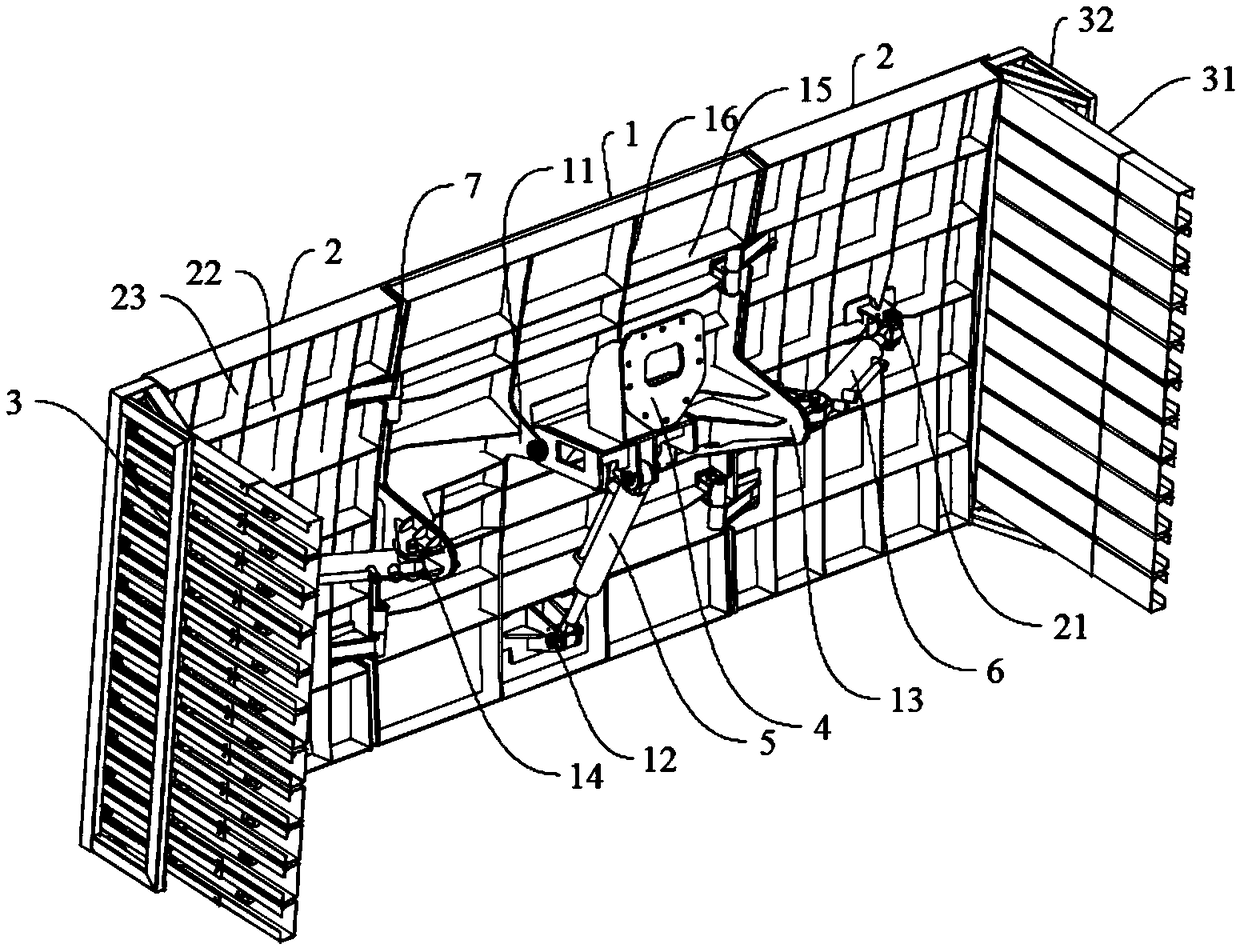

[0034] The combined template mechanism for mold spraying includes a template group, which is formed by connecting more than two single templates in a horizontal and / or vertical direction; the whole formed after the template group is unfolded Type formwork, which can cooperate with the excavated rock surface to form at least one mold cavity; the formwork group is connected to the frame / carrier, and an opening and closing control mechanism is provided between the single formwork of the formwork group.

[0035] Further, the formwork group is composed of more than two single formworks that can be folded / folded in the lateral direction, and adjacent single formworks are hinged to each other and connected by an opening and closing control mechanism, and the opening and closing control mechanism The opening and closing between adjacent single templates can be adjusted. The opening and closing control mechanism is set as a lateral oil cylinder 6, and the cylinder body and the piston r...

Embodiment 2

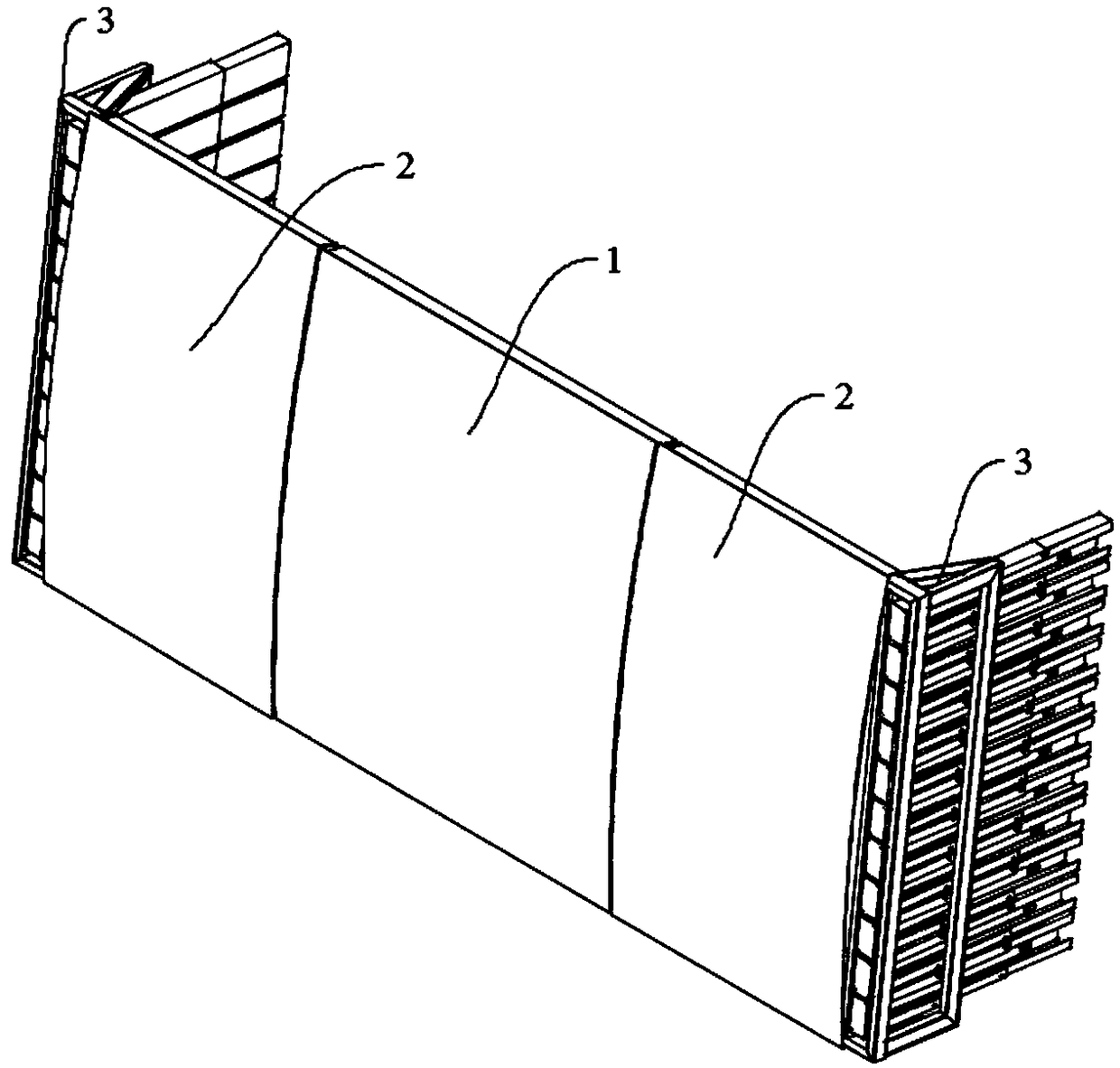

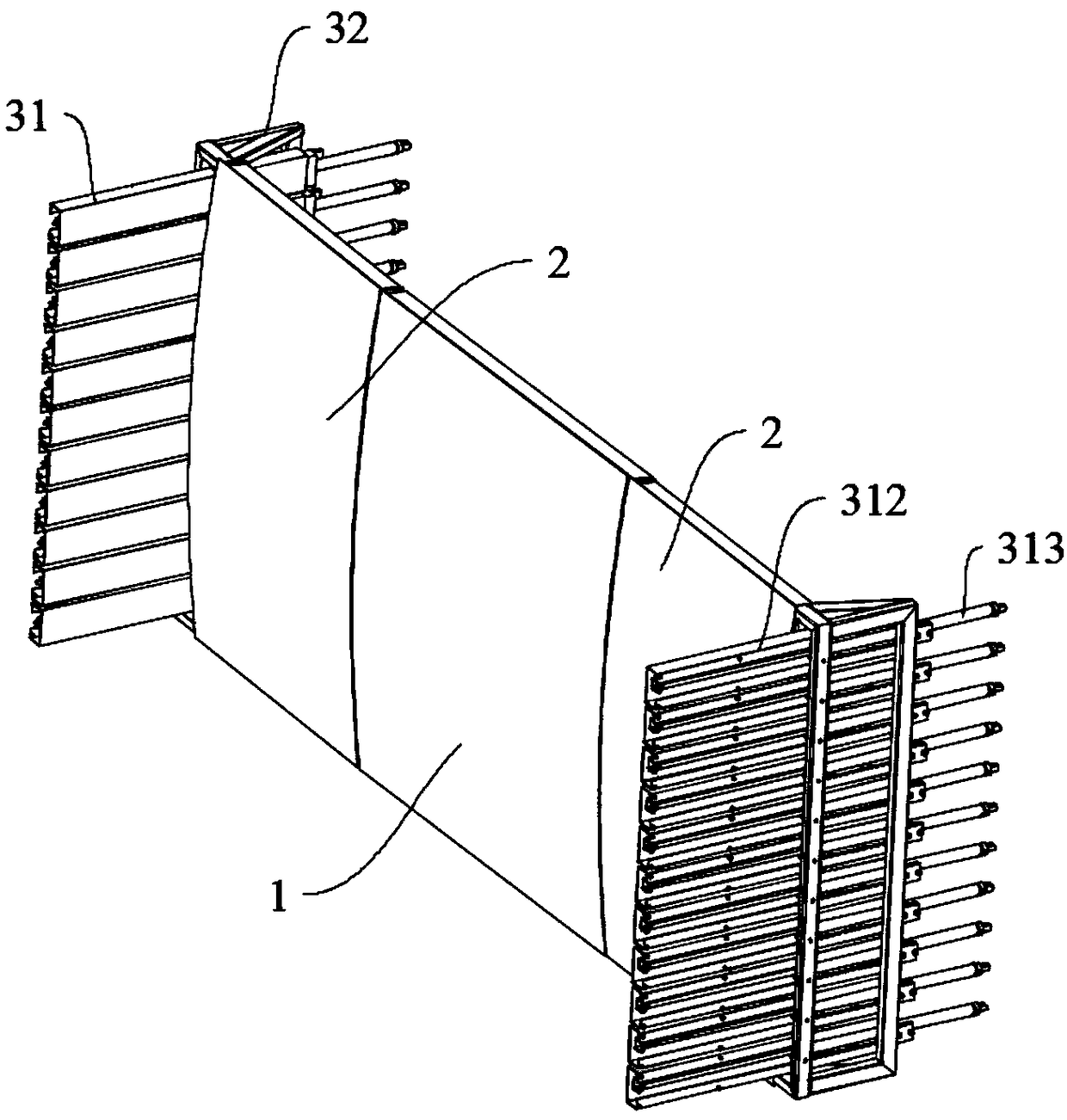

[0039]The formwork group is composed of more than two single formworks, which can be folded / turned in the transverse direction, and the adjacent single formworks are hinged to each other and connected by an opening and closing control mechanism. Opening and closing between adjacent single templates. Side form mechanism 3 is provided at the transverse edge of the single formwork at the two ends of the formwork group, and the side form mechanism 3 includes a side formwork assembly, and the side formwork assembly can move in a direction perpendicular to the connected single formwork. It stretches and sticks to the excavation surface of the tunnel, so that the template group, the excavation rock surface and the side formwork mechanism can cooperate with each other to form a mold cavity.

[0040] The side formwork assembly is composed of several side formwork units 31 arranged in the vertical direction, and each side formwork unit 31 is respectively connected with a telescopic mech...

Embodiment 3

[0044] Combined formwork mechanism for concrete mold spraying, the formwork group includes main formwork 1, auxiliary formwork 2, side formwork assembly 3, formwork support 4, pitch cylinder 5, side cylinder 6 and hinge seat 7, the main formwork 1 Hinged on the formwork support 4, the lateral two sides of the main formwork 1 are respectively hinged to the secondary formwork 2. The lateral oil cylinder 6 is set on the middle formwork 1 as an opening and closing control mechanism, and is respectively connected to and controls the opening and closing of the two auxiliary formworks 2; in this way, the integral formwork group formed by the three formworks cooperates with the excavated rock face to form a 1 one or more mold cavities.

[0045] That is to say, the formwork group is composed of three single formworks, which are foldable / foldable and connected in the transverse direction, and are respectively the main formwork 1 in the middle and the secondary formwork 2 located on both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com