High-speed high-pressure spiral nozzle

A spiral nozzle, high-pressure technology, applied in the direction of injection devices, injection devices, etc., can solve the problems of easy blockage, complex design structure, high energy consumption, etc., and achieve the effect of not easy to block.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

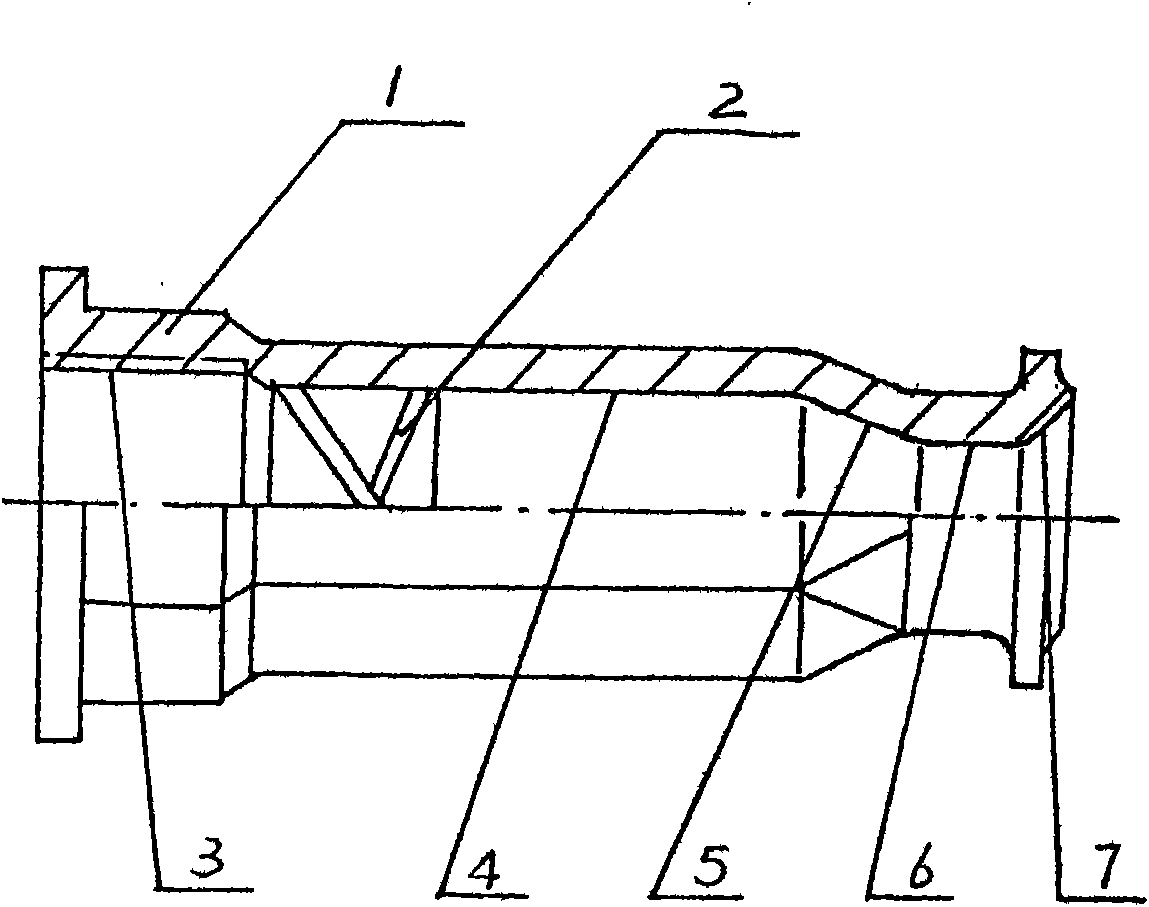

[0009] The high-speed and high-pressure spiral nozzle of the present invention is realized in this way, which will be described in detail below in conjunction with the accompanying drawings. See figure 1 The high-speed and high-pressure spiral nozzle of the present invention is composed of a shell 1 and a core 2. The shell 1 is in the shape of a water cup, and the outer contour is an octagonal polygon, which can increase the rigidity of the shell. The whole is divided into a threaded section 3 and a transition section 4. , contraction section 5, throat 6 and diffusion section 7; the large end in the cup hole has an internal thread as the threaded section 3, which is connected with the liquid delivery pipe joint through threads; the surface of the mating section 4 is a round hole and a core The outer circles of 2 are matched to ensure that the shell 1 and the core 2 are coaxial, and are made of stainless steel casting; The liquid flow generated by the rotation is continuously ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com