Washing device

A cleaning device and technology to be cleaned are applied in the directions of cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., which can solve the problem that the substrate polishing liquid cannot be thoroughly cleaned, and the substrate yield is reduced. The use of organic electroluminescent devices effect and other issues, to avoid the deterioration of the use effect, facilitate wide application, and improve the convenience of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

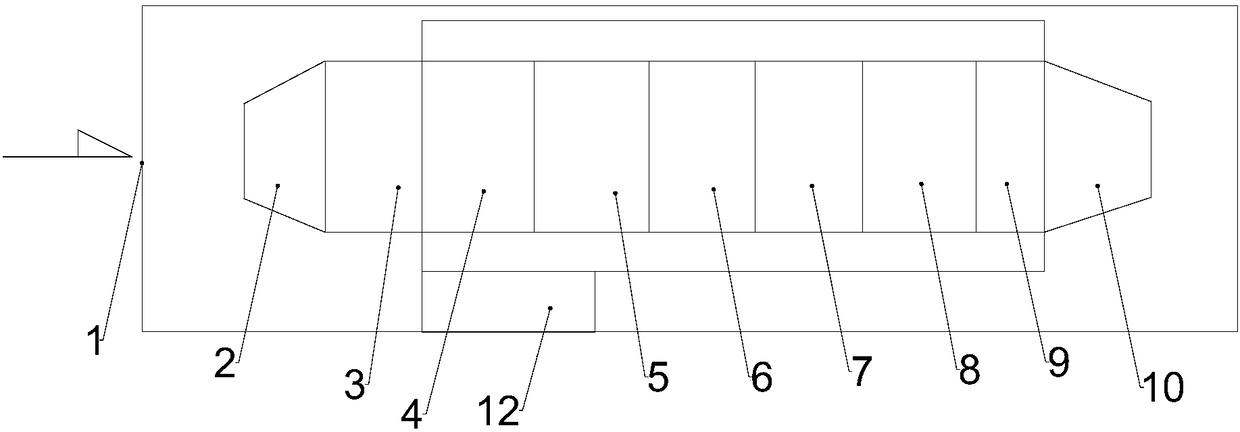

[0047] An embodiment of the present invention provides a cleaning device, which is mainly used for cleaning a polished substrate. like Figure 1-2 As shown, it includes a transport mechanism 1 and an ultrasonic cleaning unit 4 , a liquid medicine cleaning unit 6 , a two-fluid cleaning unit 7 , a pure water cleaning unit 8 and a drying unit 9 arranged in sequence along the first direction.

[0048] The conveying mechanism 1 is used for conveying the substrate to be cleaned along a first direction. Among them, the first direction refers to the figure 1 The direction of the pipeline of the cleaning device.

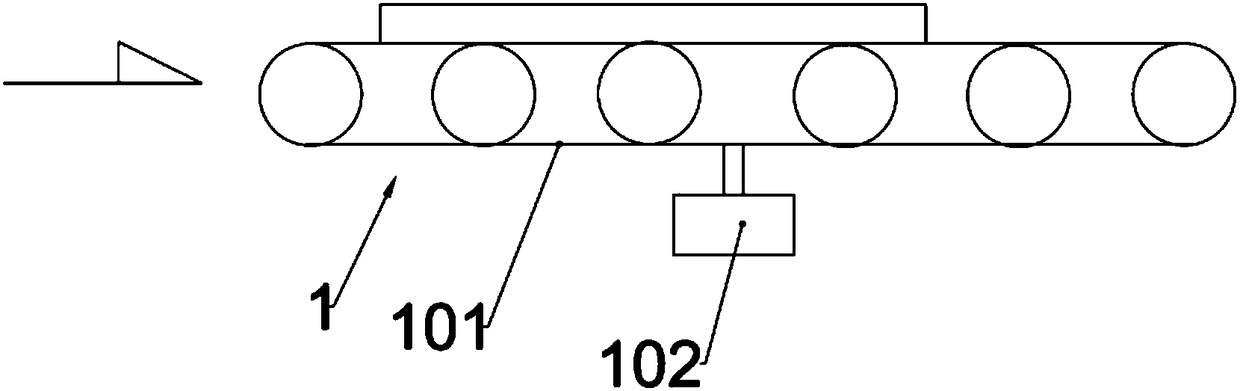

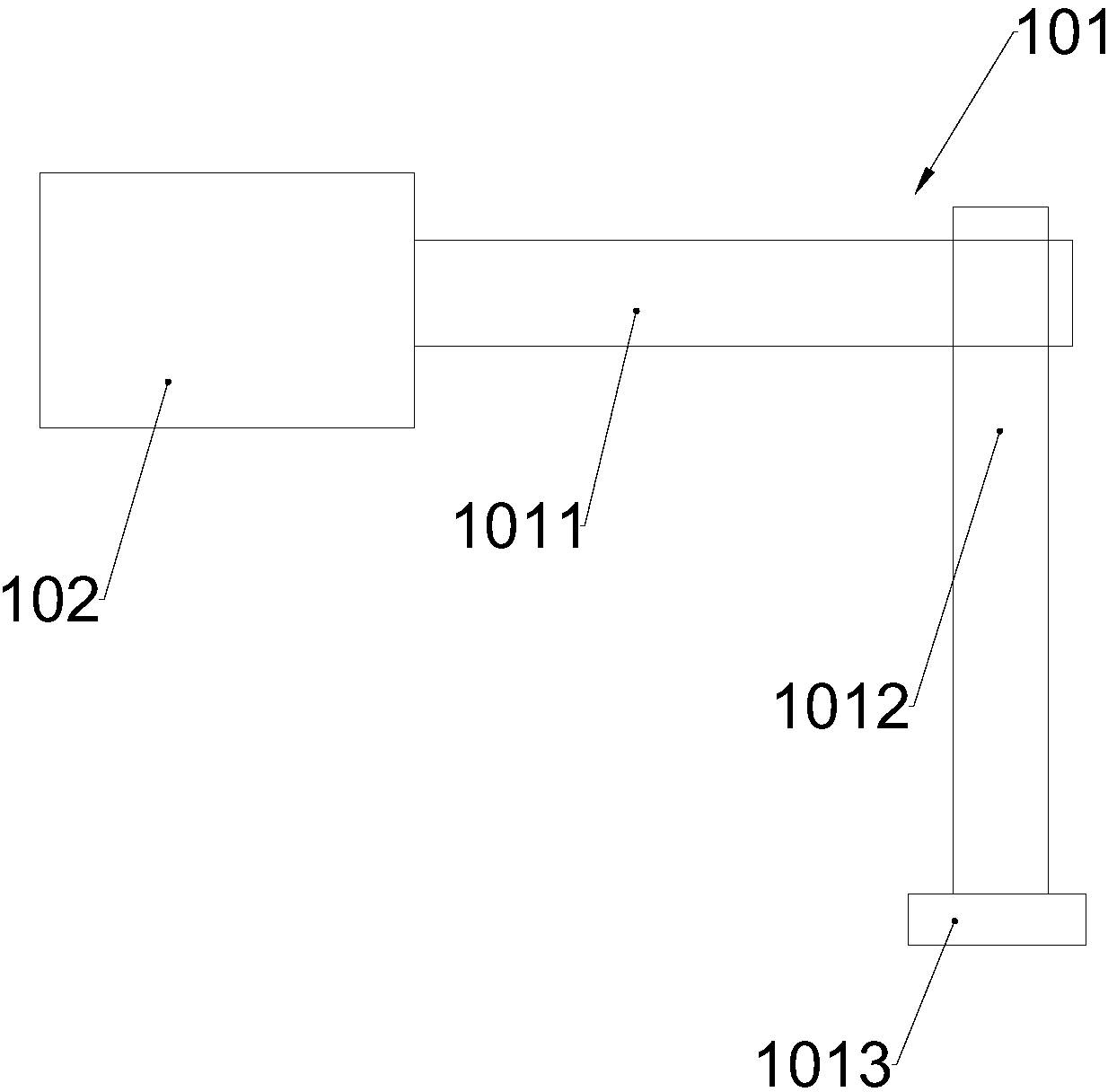

[0049] As a preferred embodiment, such as figure 2 As shown, the conveying mechanism 1 includes a conveying member 101 and a driving member 102 . in,

[0050]The transport member 101 is used to place the substrate to be cleaned. In this embodiment, the conveying member 101 may include conveying rollers arranged at intervals along the first direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com