Industrial production method and apparatus of sulfur coated controlled release fertilizer

A production method and technology for controlled-release fertilizers, which are applied in fertilization devices, agriculture, fertilizer mixtures, etc., can solve the problem of increasing the intermediate transmission process of sulfur-packaged and controlled-release fertilizers, the rupture of sulfur films of sulfur-packaged and controlled-release fertilizers, and the inapplicability of large-scale production, etc. problems, to achieve the effect of improving the effective production time, being conducive to environmental protection, and reducing the intermediate transmission process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

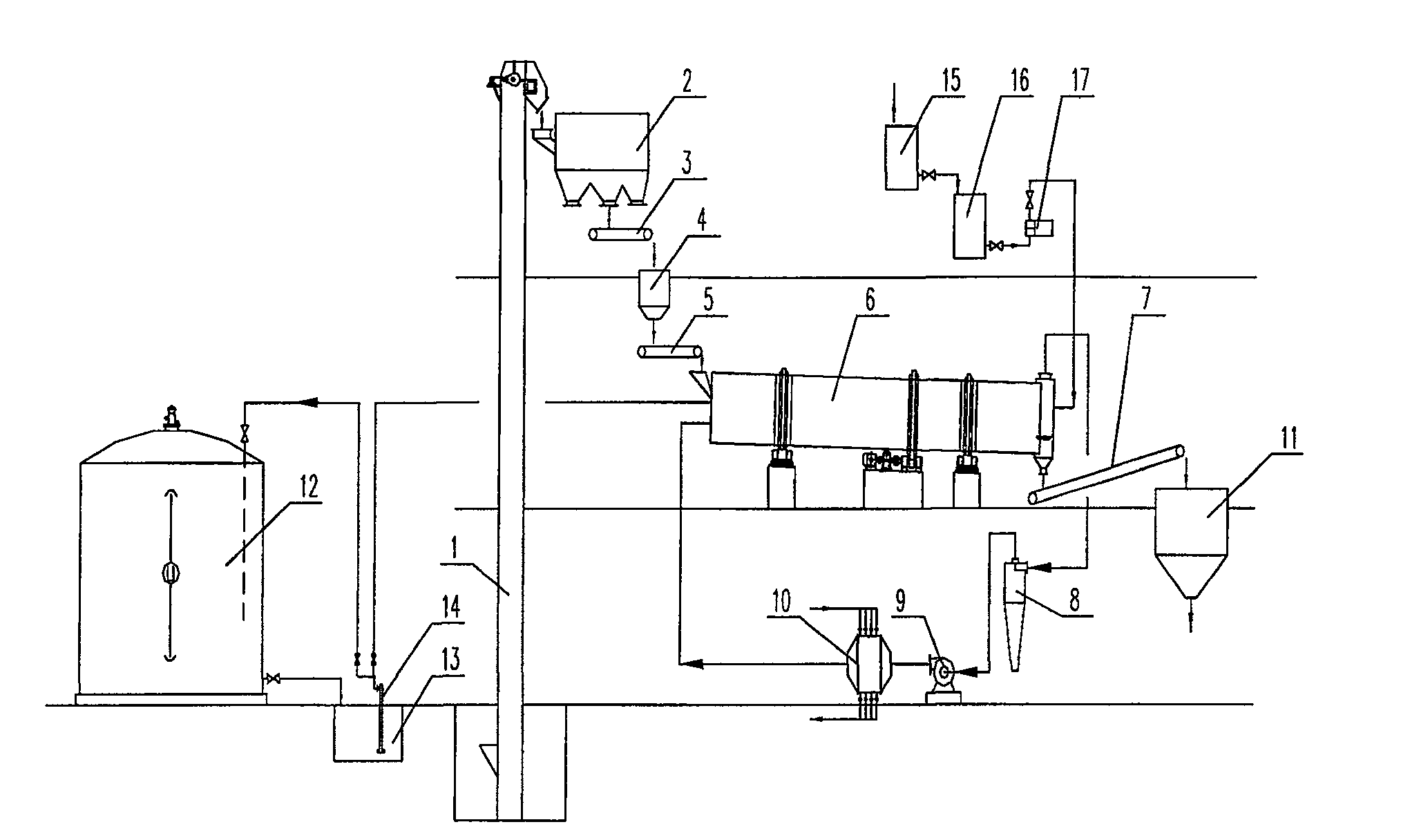

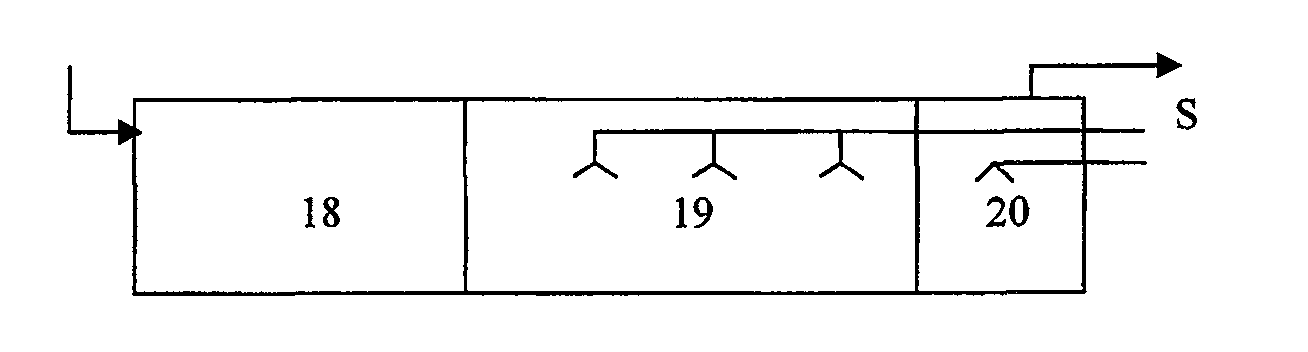

[0026] The industrialized production device of sulfur-containing controlled-release fertilizer, the structure of which is as follows figure 1 , 2 As shown, it includes bucket elevator 1, screening machine 2, raw material belt conveyor 3, raw material silo 4, quantitative feeding scale 5, drum 6, dust collector 8, induced draft fan 9, preheater 10, liquid sulfur storage tank 12. Liquid sulfur underground tank 13, liquid sulfur pump 14, sealing agent dissolving tank 15, sealing agent storage tank 16, sealing agent metering pump 17, finished product belt conveyor 7 and finished product silo 11, the bucket elevator 1 passed through the screening machine 2, the raw material belt conveyor 3, the raw material silo 4 and the quantitative feeding scale 5 are connected with the granular fertilizer inlet of the drum 6, and the tail gas outlet of the drum 6 is connected with the dust collector 8, the induced draft fan 9, the preheater 10 and the The preheated air inlet of the drum 6 is c...

Embodiment 2

[0029] Utilize the device described in embodiment 1 to carry out the industrialized production of bag sulfur controlled release fertilizer, and step is as follows:

[0030] (1) After the granular fertilizer is lifted by the bucket elevator 1 to the screening machine 2 for screening, it is sent to the raw material bin 4 through the raw material belt conveyor 3, and then is metered into the drum 6 by the quantitative feeding scale 5;

[0031] (2) The liquid sulfur in the liquid sulfur storage tank 12 enters the liquid sulfur underground tank 13, is pressurized to 0.6-6.0 MPa by the liquid sulfur pump 14, and enters the rotating drum 6 through liquid sulfur flow meter metering;

[0032] (3) Put the sealing agent into the sealing agent dissolving tank 15, heat and dissolve it, put it into the sealing agent storage tank 16, and then meter it into the drum 6 through the sealing agent metering pump 17;

[0033] (4) In the drum 6, the granular fertilizer is preheated to 70-80°C in the...

experiment example 2

[0042] Experimental example 2: Production of 13-13-13-18S sulfur-coated compound fertilizer

[0043] (1) The 17-17-17 compound fertilizer granules are screened and meet the requirements of 2.5-4.2mm particles into the feed bin, and then fed into the drum 6 at a rate of 10 tons / hour through quantitative feeding.

[0044] (2) The liquid sulfur in the liquid sulfur storage tank 12 enters the liquid sulfur underground tank 13, is pressurized to 1 MPa by the liquid sulfur pump 14, and enters the drum 6 at 2.4 tons / hour through the liquid sulfur flow meter.

[0045] (3) Add the sealing agent containing 30% polyethylene and 70% heavy oil into the sealing agent dissolving tank 15 and heat it at 60-70° C. to dissolve, then meter the sealing agent metering pump 17 into the drum 6 at 280 kg / hour.

[0046] (4) In the drum 6, the compound fertilizer is preheated to 70-80°C in the preheating zone of the machine head, and then atomized and sprayed liquid sulfur at 145-155°C and a pressure of 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com