Process of producing monocholo benzen anhydride by continuous liquid phase oxydation

A technology of monochlorinated phthalic anhydride and chlorinated o-xylene, which is applied in the field of liquid phase continuous oxidation to produce monochlorophthalic anhydride, can solve the problems of unstable production index, lack of stirring function, uneven air distribution, etc., and achieve effective increase Production time, avoiding fatigue damage, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

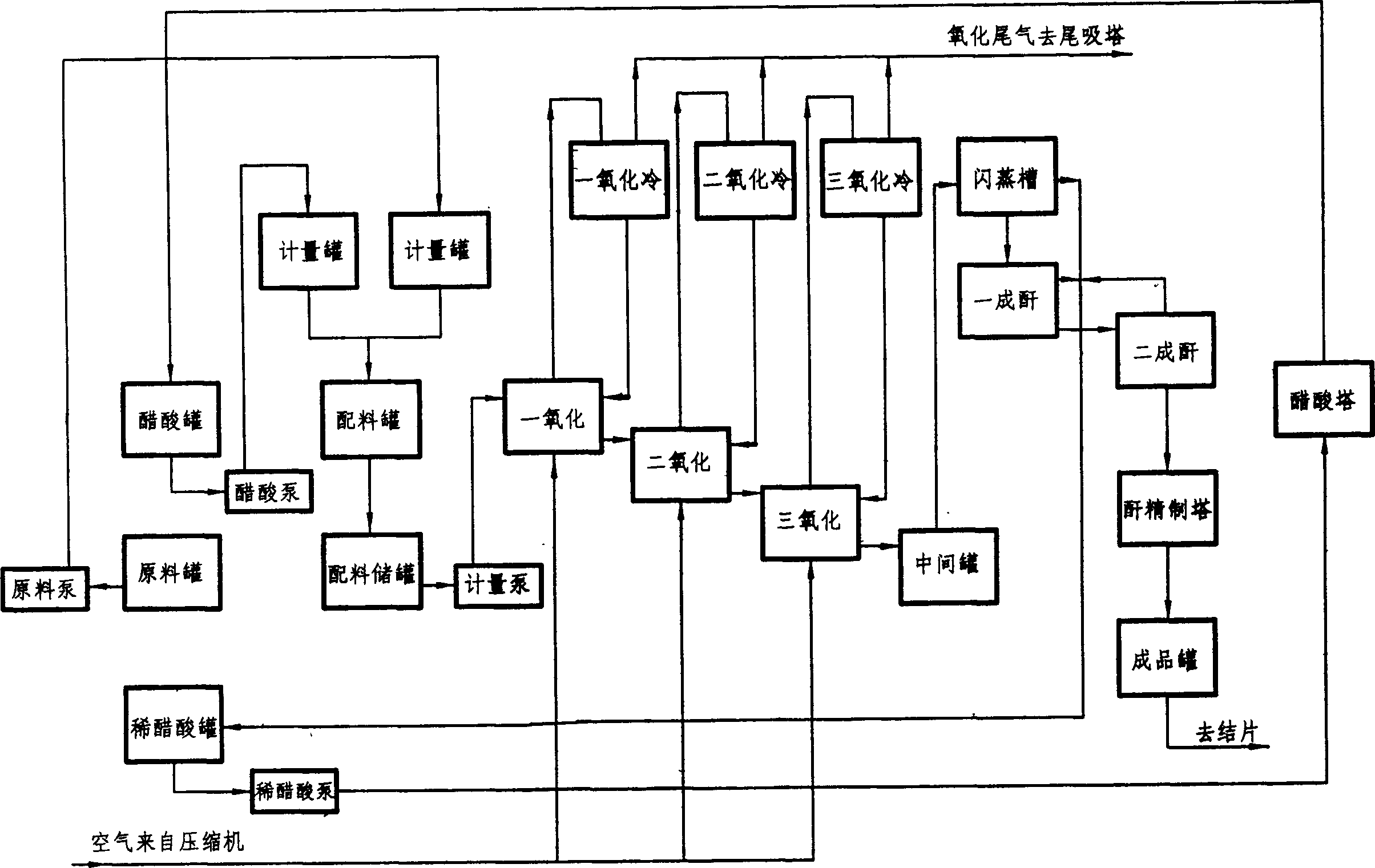

[0023] 1000 kg of monochlorinated o-xylene (wherein the ratio of 3-monochlorinated o-xylene and 4-monochlorinated o-xylene is about 1:1) is pumped into the metering tank. Pump 5000 kg of raw material concentrated acetic acid into another metering tank. Then it is metered and transported to the batching tank with stirring and heating jacket for mixing and dissolving, and then enters the storage tank for storage, and is pumped into the three-stage series oxidation reaction kettle with stirring by a metering pump. 5.2 kg of catalyst cobalt acetate, 5.2 kg of manganese acetate, and 5.2 kg of accelerator tetrabromoethane are added from the mixing batching tank to mix and dissolve evenly with the raw materials, and then enter the oxidation reaction kettle. Compressed air is fed into the three-stage oxidation reactor in parallel, and the flow distribution thereof is controlled separately. For example, if the total amount is 1.0, the ratio of the three stages is controlled to be 0.5 >...

Embodiment 2

[0025] 1000 kg of monochlorinated o-xylene (wherein the ratio of 3-monochlorinated o-xylene and 4-monochlorinated o-xylene is about 1:1) is pumped into the metering tank. Pump 4000-6000 kg raw concentrated acetic acid into another metering tank. Then it is metered and transported to the batching tank with stirring belt and heating jacket, and the mixed solution is then stored in the storage tank, and pumped into the three- or four-stage oxidation reaction kettle in series with a metering pump. The catalyst cobalt acetate is 1-49 kg, the manganese acetate is 1-49 kg, the accelerator tetrabromoethane or hydrogen bromide is 1-49 kg, and the raw materials are evenly mixed and dissolved from the mixing batching tank, and then enter the oxidation reaction kettle. The compressed air is fed into the three or four oxidation reactors in parallel, and the flow distribution is controlled respectively. The oxidation reaction is carried out at a pressure of 0.5 to 4 Mpa (table) and a tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com