Stably-operating adiabatic compressed air storage power generation method and system

A compressed air energy storage and stable operation technology, which is applied to gas turbine devices, machines/engines, liquid variable displacement machinery, etc., can solve problems such as uncontrolled temperature, rise or fall of the temperature of the gas storage chamber, and drop of compressed air temperature , to avoid fatigue damage, stabilize air temperature and improve operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

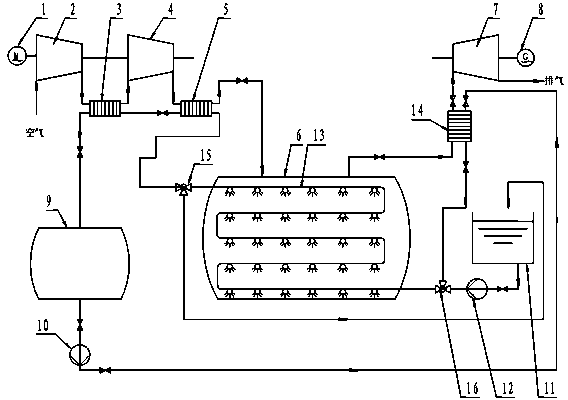

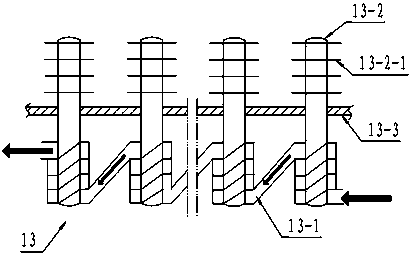

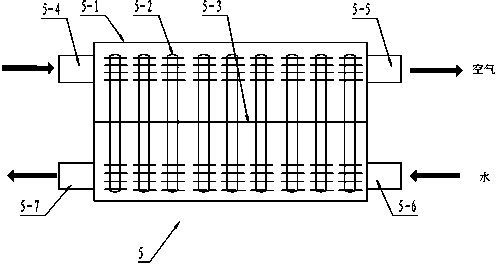

[0019] see figure 1 , the working principle of the present invention is as follows: during the low load period of the power grid, the low-pressure compressor 2 and the high-pressure compressor 4 of the compressed air energy storage power generation system start to work, the compressed air is continuously charged into the air storage chamber 6 through the pipeline, and the air at the outlet of the compressor The temperature, as well as the temperature of the air in the storage chamber, will increase accordingly. At this time, the booster pump 12 starts to work, pumps water out of the reservoir 11, and sends it to the serpentine coil heat pipe heat exchanger 13 through the inlet three-way valve 16 to absorb the heat of compression in the air storage chamber 6; Under the effect of pressure, the final hot water enters the high-pressure countercurrent gas-liquid heat pipe heat exchanger 5 and the low-pressure countercurrent gas-liquid heat pipe heat exchanger 3 through the outlet t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com