Bridgman-method single crystal production device with integrated environment maintenance

A crucible descending method and a technology for a production device, which are applied in the directions of single crystal growth, crystal growth, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

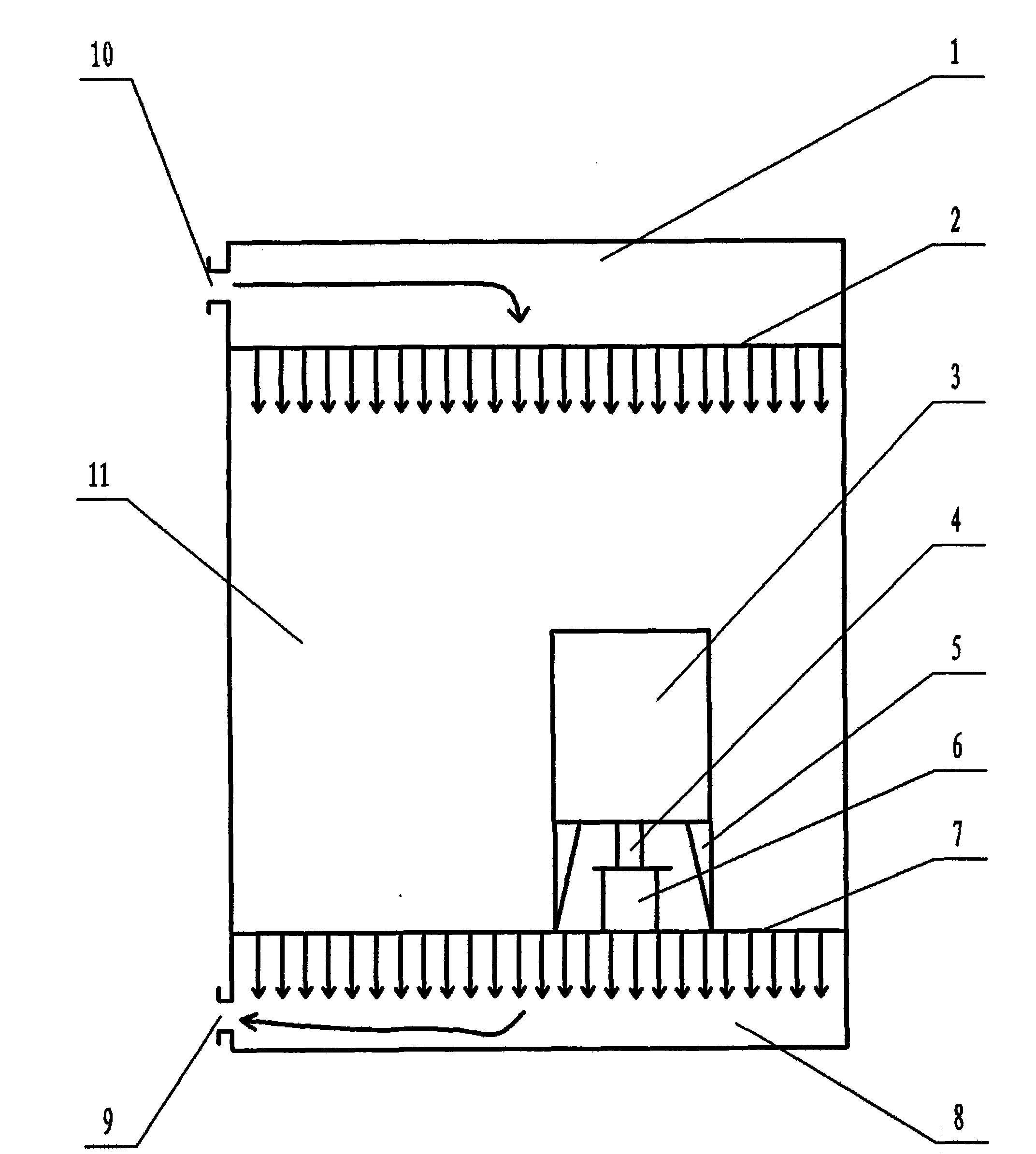

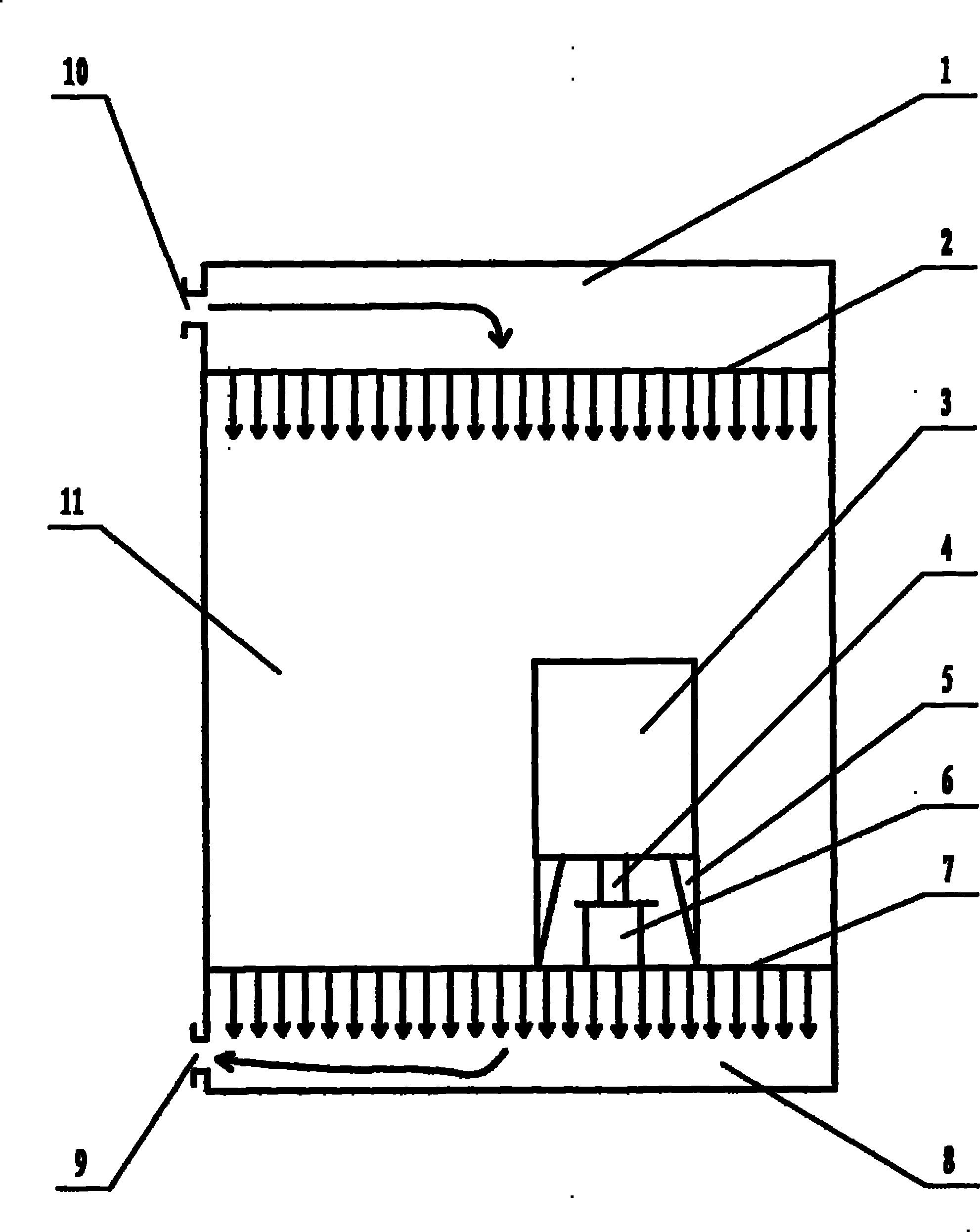

[0026] figure 1 The partial morphology of the embodiment of this case and the air renewal operation of the single crystal incubator after the device is started are shown. The structure of the device in this example includes the air distribution chamber 1 and the single crystal incubator 11, and the set that are arranged adjacently from top to bottom. The air silo 8, the air distribution silo 1 is a silo-shaped object with a cavity for uniformly distributing fresh air from the outside of the single crystal incubation silo 11, and the bottom side panel 2 of the air distribution silo 1 is evenly distributed with many holes The side or top of the air distribution bin 1 is equipped with an air inlet port 10, and the air collection bin 8 is a bin-shaped object with a cavity for uniformly collecting toxic polluted air from the inside of the single crystal incubation bin 11, There are many holes evenly distributed on the upper side panel 7 of the air bin 8. The side or bottom of the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com