Buffering guide method by reciprocating impact reactive force and vibration isolation mining machine

A reaction force and excavator technology, applied in the direction of earth drilling, cutting machinery, slitting machinery, etc., can solve problems such as loosening, mining machine hazards, and travel gear damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

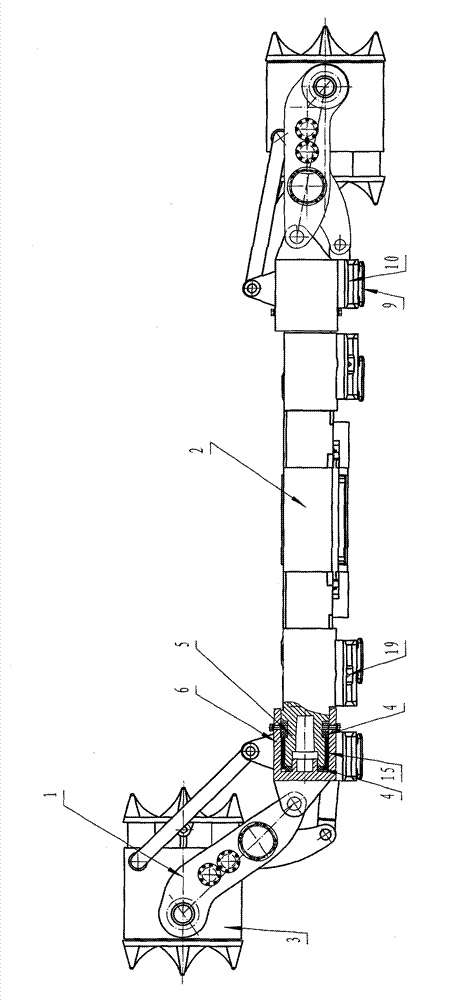

[0079] like figure 1 As shown, a vibration-isolation mining machine includes a lifting part 1, a reciprocating impact part 3, a fuselage 2, and a running part 19. A buffer device is provided between the lifting part 1 and the fuselage 2, and the buffer device includes a direction guide 15, Buffer 4, the fuselage 2 includes a buffer guide 5 and a buffer guide sleeve 6, the buffer 4 is arranged between the buffer guide 5 and the buffer guide 6 of the fuselage 2, and the direction guide 15 is arranged on the buffer guide 5 With the buffer guide sleeve 6, the impact reaction force is exerted on the buffer guide sleeve 6 and the buffer guide member 5, the buffer member 4 deforms to absorb the impact reaction force, and the direction guide member 15 controls the buffer direction as a reciprocating linear buffer to prevent the buffer member 4 from having no direction Separate the lifting part 1 or the fuselage 2, the direction guide 15 is separated from the buffer guide 5 and the buf...

Embodiment 2

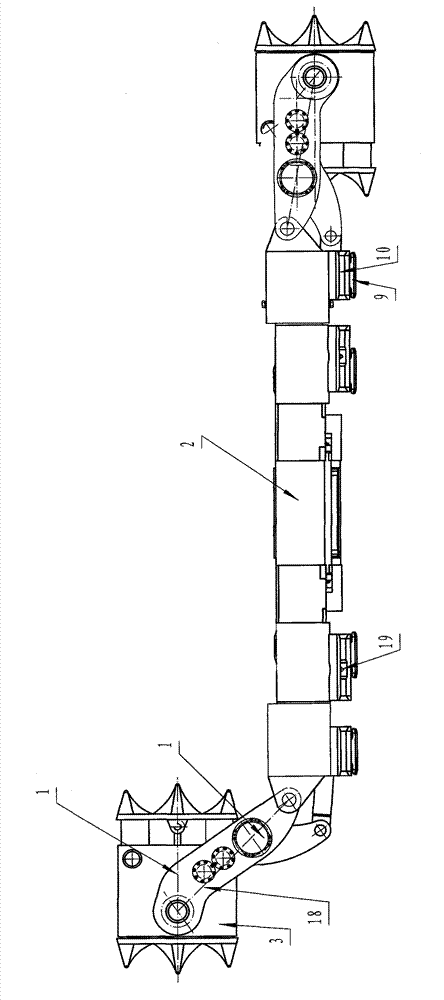

[0081] like Figure 2 to Figure 3 As shown, a vibration isolation mining machine implementing the method includes a lifting part 1, a reciprocating impact part 3, a fuselage 2, and a walking part 19. The lifting part 1 includes a rocker arm 18, and the rocker arm 18 is provided with a buffer device. The device includes a direction guide 15, a buffer 4, and the lifting part 1 includes a fixed support 16 and a buffer support 17. The buffer 4 is arranged between the fixed support 16 and the buffer support 17, and the direction guide 15 is arranged on a fixed On the support member 16 and the buffer support member 17, the impact reaction force is applied on the buffer support member 17 and the fixed support member 16, the buffer member 4 deforms to absorb the impact reaction force, and the direction guide 15 controls the buffer direction as a reciprocating linear buffer, preventing the buffer member 4 Non-directional swing. Separate the lifting part 1 or the fuselage 2. The directi...

Embodiment 3

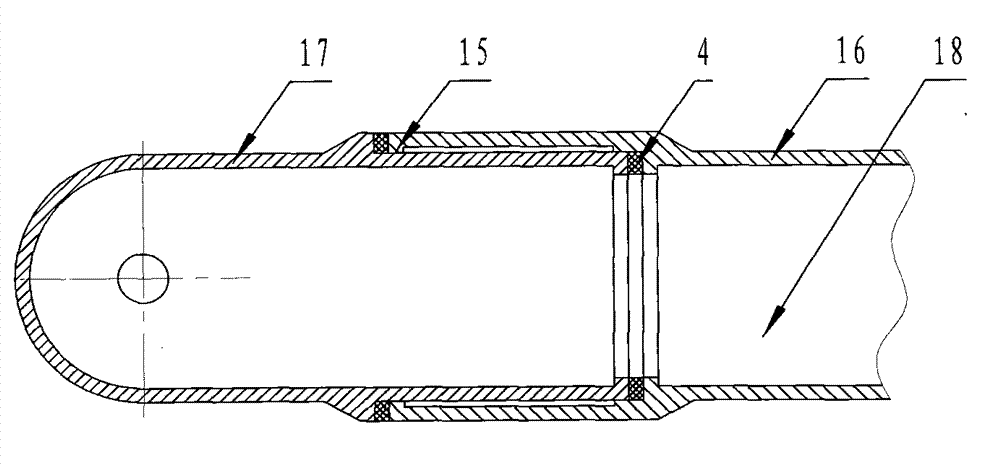

[0083] like Figure 4As shown, a vibration-isolation mining machine includes a lifting part 1, a reciprocating impact part 3, a fuselage 2, and a running part 19. A buffer device is provided between the lifting part 1 and the fuselage 2, and the buffer device includes a direction guide 15, Buffer 4, the fuselage 2 includes a buffer guide 5, a buffer guide sleeve 6, the buffer guide 5 is separated from the fuselage 2 or integrated with the fuselage 2, the buffer guide 5 includes a guide boss 20, and the buffer guide sleeve 6 is fastened with the buffer guide 5, and the buffer guide sleeve is set outside the guide boss 20, and the two sides of the raised part of the guide boss 20 are provided with buffer members 4, and the buffer guide sleeve 6 slides reciprocatingly along the buffer guide 5 in a straight line, and the buffer guide 5. The buffer member 4 and the buffer guide sleeve 6 cooperate to form a two-way guiding structure buffer device 21. The lifting part 1 is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com