Flow control screen pipe for oil well

A technology of flow screen and base pipe, which is applied in the fields of production fluids, wellbore/well components, earth-moving drilling and mining, etc., can solve the problems of high cost, long working hours, manpower and material resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

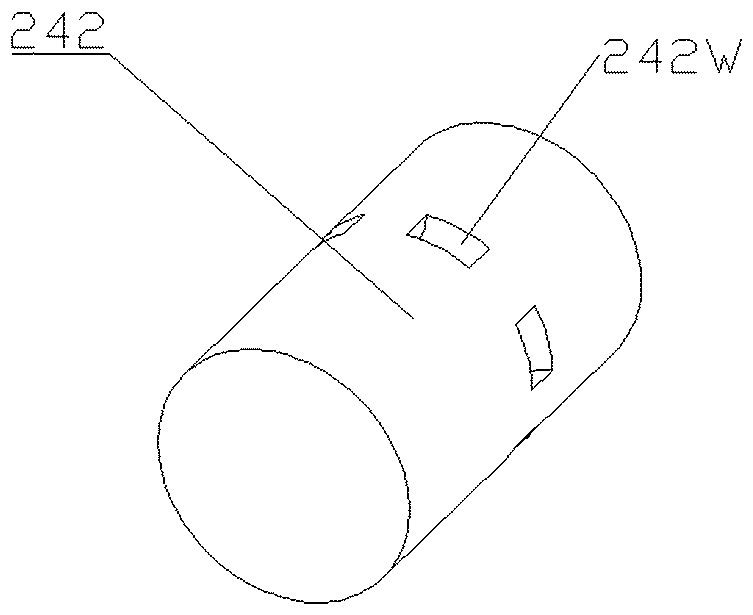

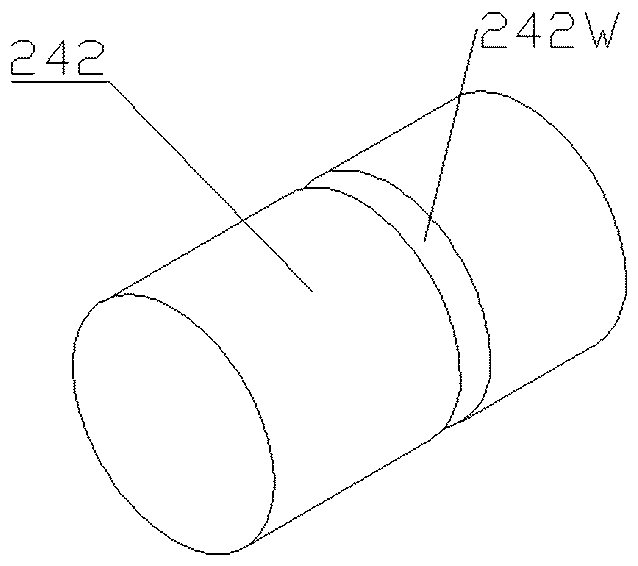

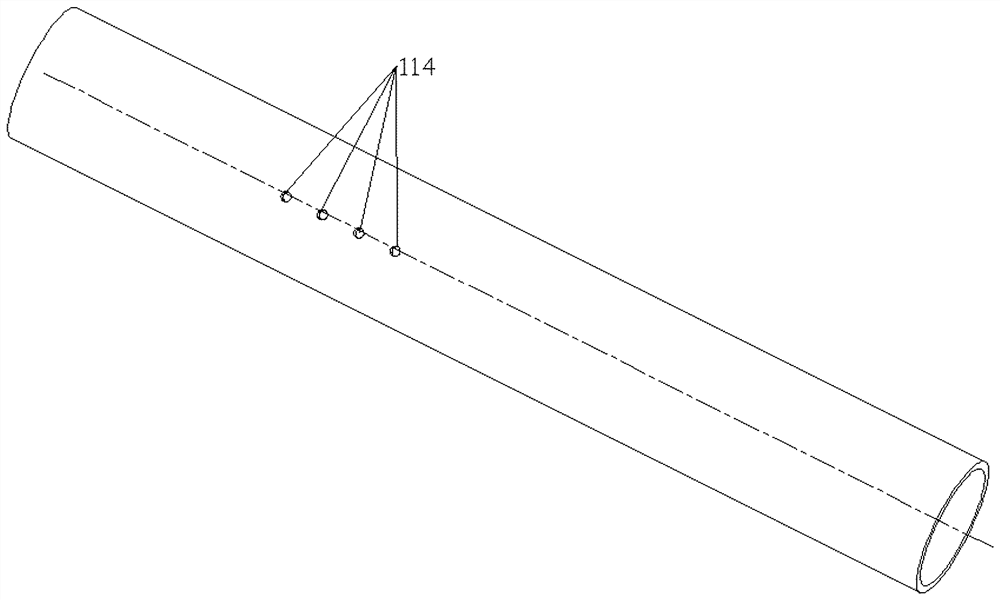

Method used

Image

Examples

Embodiment 1

[0100] There is a new well in an offshore oil field. The viscosity of the oil layer in this well is 142 cps, the viscosity of the formation water is 0.9 cps, the oil-water viscosity ratio is 158, the diameter of the horizontal section is 6 inches, and the length of the horizontal section is 1000 meters. A well structure according to the present invention was run, comprising 100 flow control screens according to the present invention, each flow control screen comprising three fluid valves with predetermined opening thresholds of 5 MPa, 12 MPa and 17 MPa, respectively. Thus, the entire oil well structure includes 100 fluid valves with a predetermined opening threshold of 5 MPa, 100 fluid valves with a predetermined opening threshold of 12 MPa, and 100 fluid valves with a predetermined opening threshold of 17 MPa.

[0101] After the well is opened, the daily fluid production is 176 cubic meters per day, the daily oil production is 172 cubic meters per day, the water content is 2.3...

Embodiment 2

[0109] An old well in an oil field has an 8.5-inch hole with a horizontal section of 400 meters. In the initial stage, a 5.5-inch screen was installed for simple sand control completion. After 90 days of anhydrous oil production period, low fluid volume, high water cut, and high production pressure drop occurred. The daily fluid production was 80 cubic meters per day, and the water cut quickly rose to 96%. The well was shut in and stopped production.

[0110] According to comprehensive analysis, the main reasons for the shutdown of the well are local water production and blockage of the original screen, and water control and sand control should be implemented to increase oil production.

[0111] Perforating the original screen, that is, forming multiple radial channels, makes the screen lose its ability to control flow. Then, 40 flow control screens according to the present invention are arranged in series in the original screen, so that the inner cavities of the base pipes o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com