Process for preparing waste water purifying agent

A technology for wastewater treatment and water purifying agent, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc. It can solve the problems that papermaking wastewater tailings cannot be fully recycled and zero-discharged. The effect of improving the ring crush strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

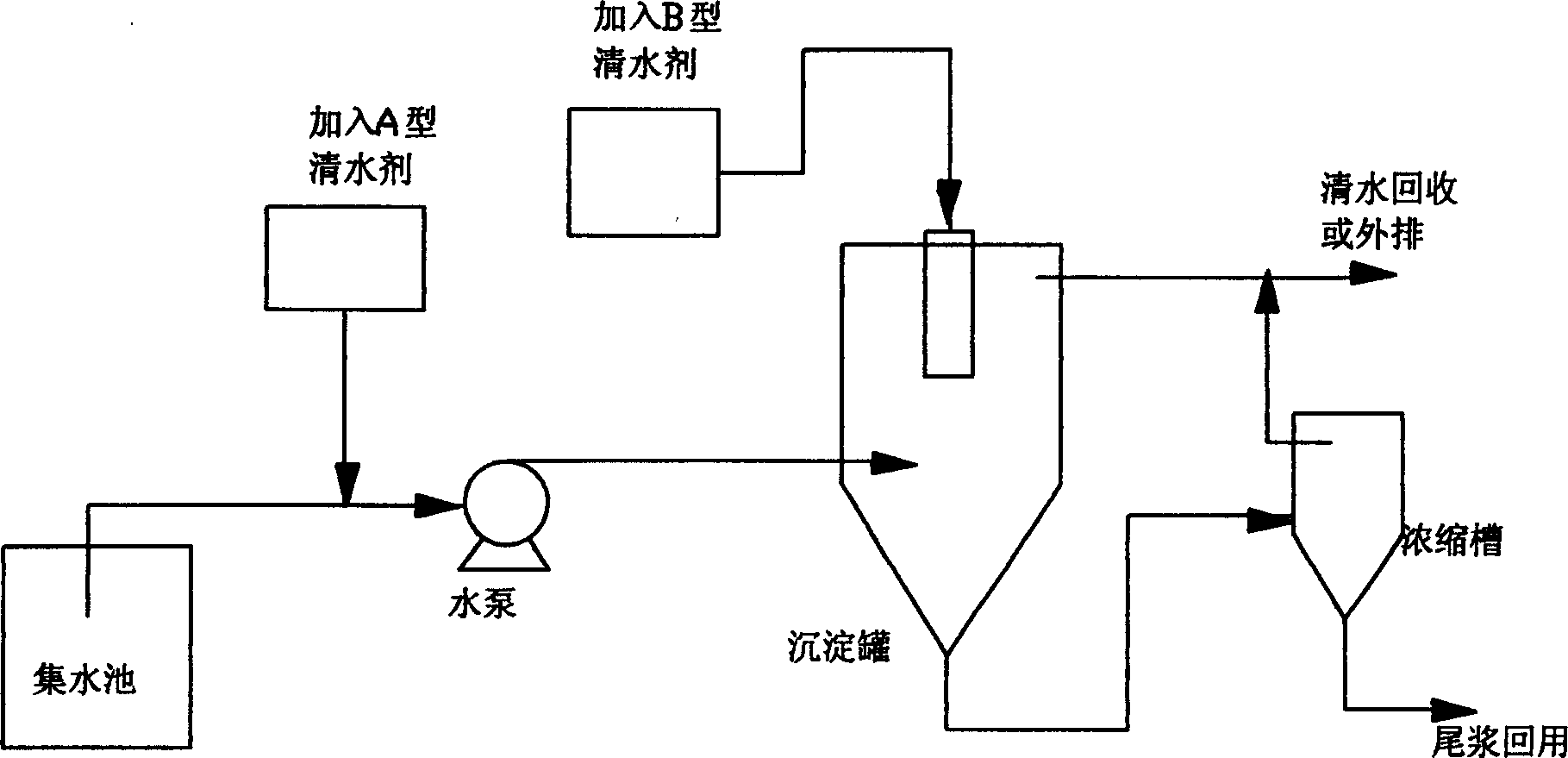

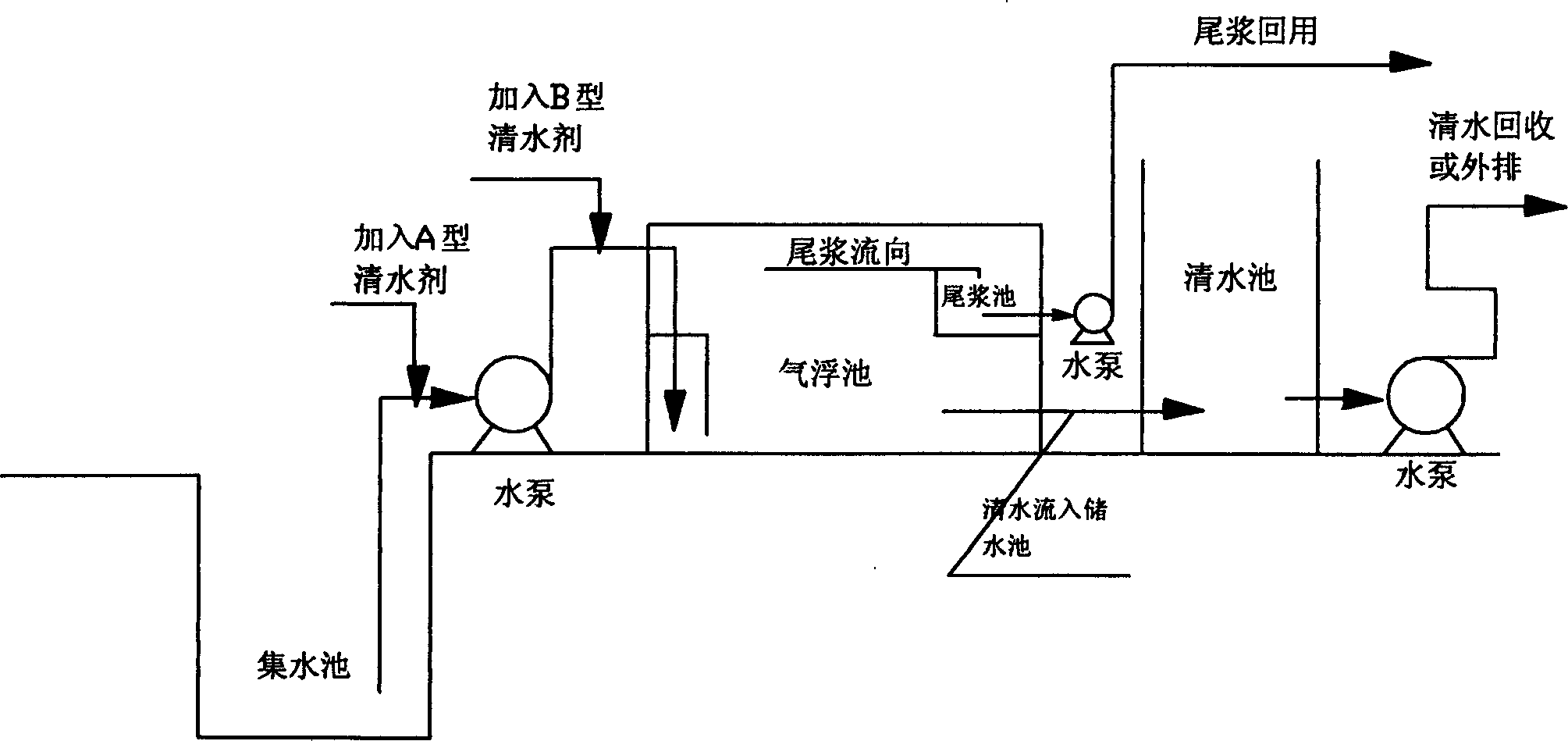

Image

Examples

Embodiment Construction

[0020] The raw material for the preparation of Type A water purifier of the present invention is the by-product ferrous aluminum salt produced by the sulfuric acid method in a chemical plant, and the ferrous aluminum salt is oxidized with sulfuric acid and hydrogen peroxide strong oxidant, and after 5-6 hours of hydrolysis reaction, a certain amount of ferrous aluminum salt is formed after polymerization. Polymerized iron with a high degree of alkalization, on this basis, add phosphate, react at a certain temperature for 30-60 minutes to form a liquid polymer, and after concentration and drying at 60-90°C, a gray-white solid product can be obtained.

[0021] In industrial production, the ferrous aluminum salt is often oxidized with air or oxygen under the action of a catalyst, and in the laboratory, a strong oxidant is often used for direct oxidation.

[0022] The following two reactions will occur when a strong oxidizing agent is added to the ferrous aluminum salt solution:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com