Method for decolorizing solvent oil and extracting durene

A technology of mesitylene and solvent oil, used in chemical instruments and methods, purification/separation of hydrocarbons, organic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

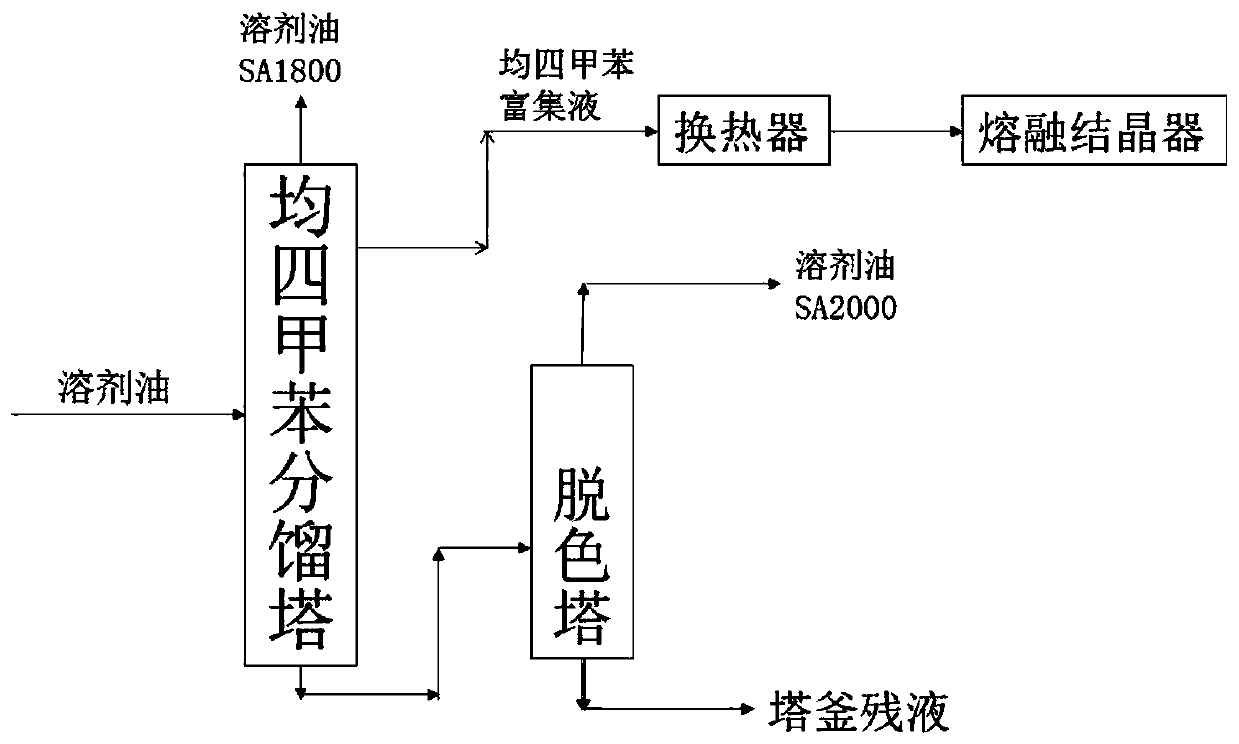

[0031] The solvent oil raw material enters the durene fractionation tower, the mass fraction of the solvent oil raw material durene is 12%, the pressure of the fractionation tower is a negative pressure of 30KPa, the temperature of the tower top is 120°C, the temperature of the side stream is 140°C, and the temperature of the tower bottom is 160°C ℃. Solvent oil SA1800 is obtained at the top of the tower, and the durene enriched liquid with a mass fraction of 45% is obtained from the side line extraction. The durene enriched liquid is passed into a heat exchanger, and high-pressure hot water is used to condense the durene. The tetramethylbenzene enrichment liquid is sent to a multi-stage melting crystallizer for crystallization.

[0032] The melting crystallizer is cooled to 70°C at 4°C / h, the uncrystallized mother liquor is discharged, and the crystal is sweated. The sweating temperature is 77°C, and the constant temperature is sweated for 0.5h. The product tank obtains dure...

Embodiment 2

[0035] The solvent oil raw material enters the durene fractionation tower, the mass fraction of the solvent oil raw material durene is 14%, the pressure of the fractionation tower is a negative pressure of 30KPa, the temperature of the side stream is 120°C, the temperature of the tower top is 140°C, and the temperature of the tower bottom is 160°C ℃. Solvent oil SA1800 is obtained at the top of the tower, and the durene enriched liquid with a mass fraction of 48% is obtained from the side line extraction. The durene enriched liquid is passed into a heat exchanger, and high-pressure hot water is used to condense durene. The tetramethylbenzene enrichment liquid is sent to a multi-stage melting crystallizer for crystallization.

[0036] The melting crystallizer cools down to 72°C at 3°C / h, discharges the uncrystallized mother liquor, sweats the crystal, the sweating temperature is 78°C, sweats at a constant temperature for 1 hour, discharges the sweating mother liquor, heats the ...

Embodiment 3

[0039] The solvent oil raw material enters the durene fractionation tower, the mass fraction of the solvent oil raw material durene is 12%, the pressure of the fractionation tower is a negative pressure of 50KPa, the temperature of the side stream is 170°C, the temperature of the tower top is 150°C, and the temperature of the tower bottom is 200 ℃. Solvent oil SA1800 is obtained at the top of the tower, and the durene enriched liquid with a mass fraction of 50% is obtained from the side line extraction. The durene enriched liquid is passed into a heat exchanger, and high-pressure hot water is used to condense durene. The tetramethylbenzene enrichment liquid is sent to a multi-stage melting crystallizer for crystallization.

[0040] The melting crystallizer cools down to 73°C at 2°C / h, discharges the uncrystallized mother liquor, sweats the crystal, the sweating temperature is 78.5°C, sweats at a constant temperature for 1 hour, discharges the sweating mother liquor, heats the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com