MCC very-fine coaxial cable cooling device and cooling method thereof

A cooling device, ultra-thin coaxial technology, applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of poor cooling effect, poor quality of extrusion layer molding, lack of step-by-step cooling steps, etc., to achieve extrusion The effect of good quality and stable production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

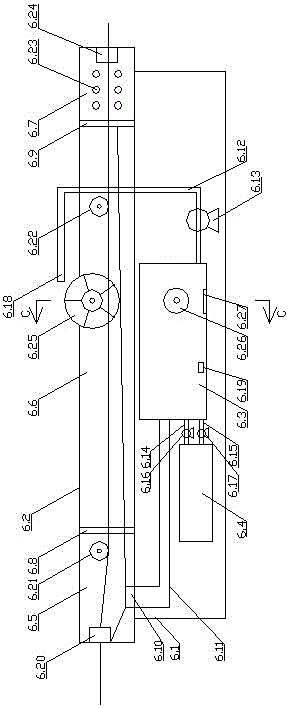

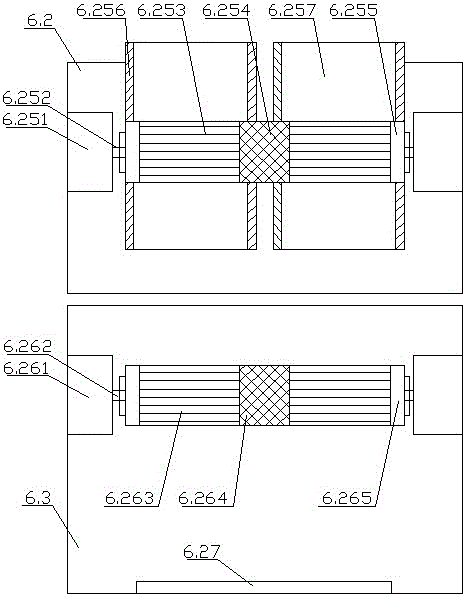

[0026] see Figure 1~Figure 2 , a kind of MCC superfine coaxial cable cooling device that the present invention relates to, it comprises cooling device frame 6.1, and the upper half section of cooling device frame 6.1 is provided with horizontal cooling groove 6.2, and the lower half section of cooling device frame 6.1 A water storage tank 6.3 and a refrigerator 6.4 are provided, and the cooling tank 6.2 includes a feed zone 6.5 at the left end, a cooling zone 6.6 at the middle section, and a drying zone 6.7 at the right end, and a vertical filter is passed between the feed zone 6.5 and the cooling zone 6.6 The plate 6.8 is separated, the cooling area 6.6 and the drying area 6.7 are separated by a vertical partition 6.9, the cooling water between the feeding area 6.5 and the cooling area 6.6 can circulate, and the lowest part of the feeding area 6.5 is provided with Drain outlet 6.10, the outlet 6.10 is connected to the water inlet of the water storage tank 6.3 through the dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com