Method for preparing methyl alcohol by continuous methane liquid phase oxidation

A technology for producing methanol and methane, which is applied in the field of continuous liquid-phase oxidation of methane to produce methanol, and can solve problems such as inability to adjust, retention, and high pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

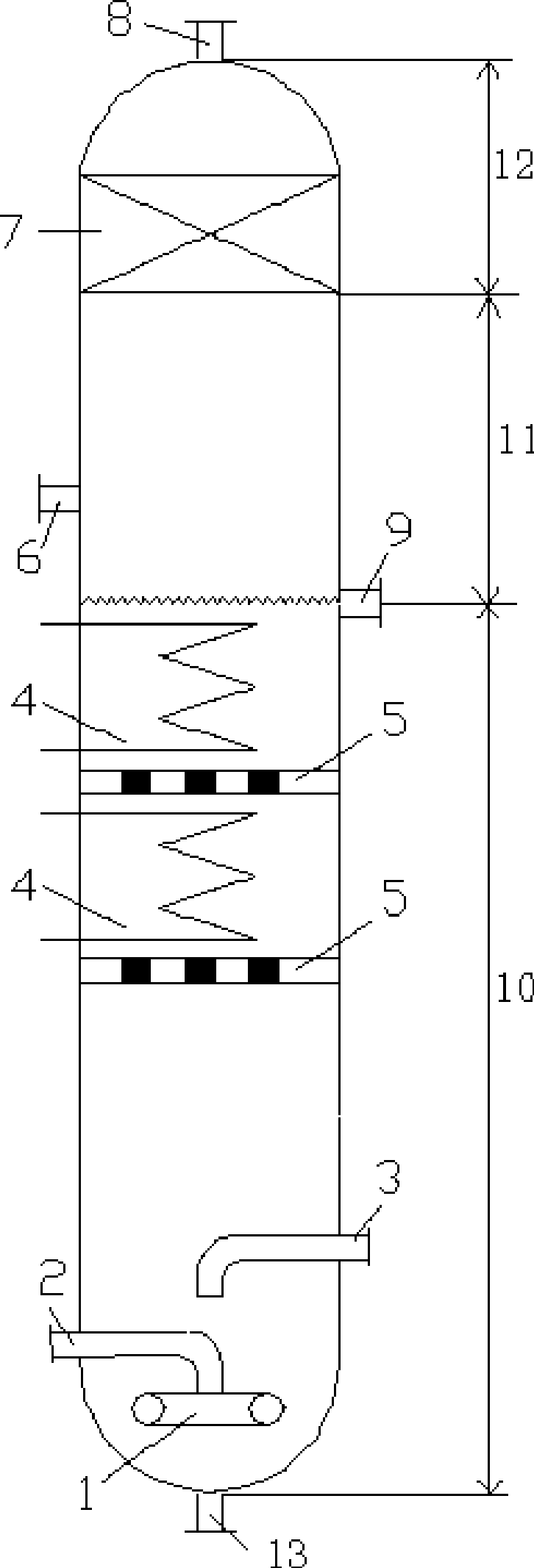

Method used

Image

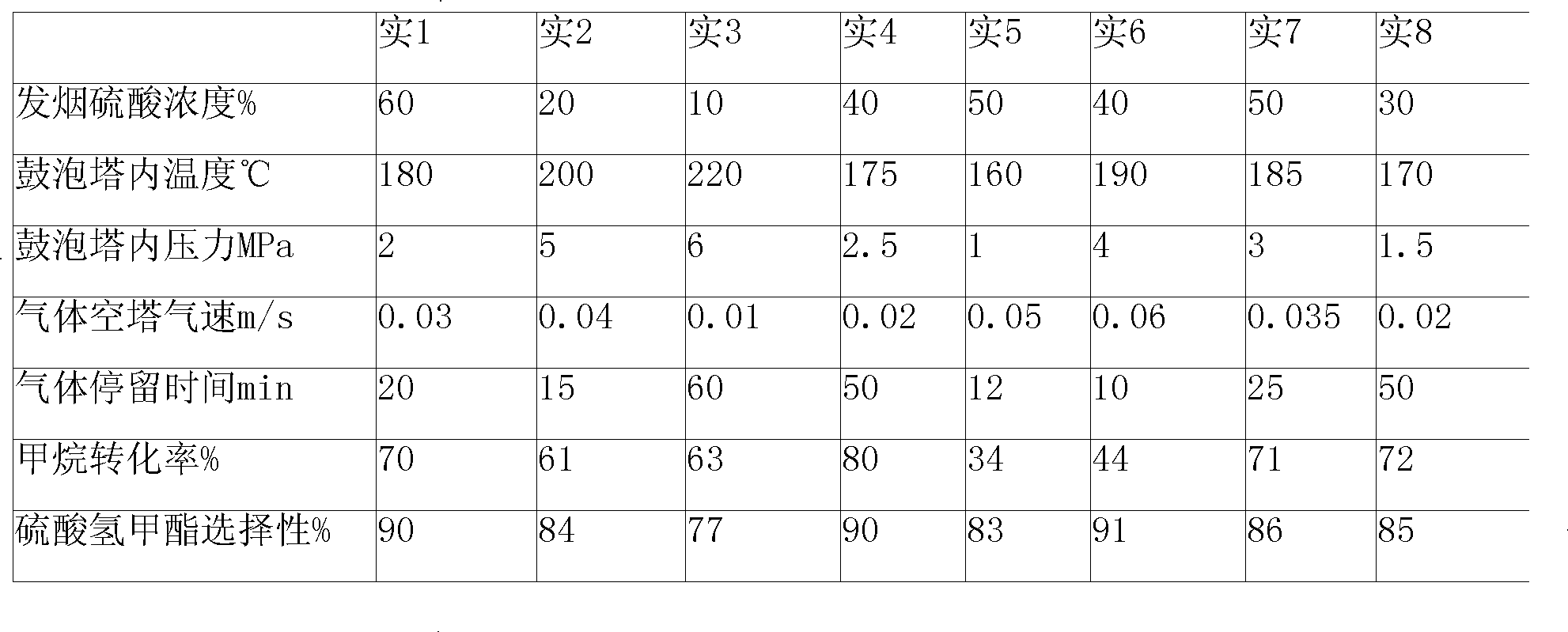

Examples

Embodiment 1

[0021] The concentration of oleum in the present embodiment is 60%, and the iodine concentration in oleum is 1g / 100ml. In order to facilitate the determination of the conversion rate of methane, argon was used as the internal standard gas, and the reaction gas contained 5% argon by volume.

[0022] ①First replace the air in the reaction system with nitrogen, and then use a metering pump to send the oleum dissolved in the catalyst into the sulfuric acid preheater. The oleum in the sulfuric acid preheater is heated to 180°C before entering the The bubble tower is added until it flows out from the overflow port 9 on the top of the bubble tower. Due to the heat dissipation effect of the bubble tower, the temperature of the oleum in the bubble tower will decrease. It is necessary to use heat transfer oil to heat the sulfuric acid in the bubble tower to the set reaction temperature of 180°C, and the reaction will be carried out through the back pressure valve. The pressure is adjus...

Embodiment 4

[0028] The catalyst that embodiment 4 uses is hydrogen iodide, and the consumption of hydrogen iodide in the oleum is calculated as iodine: 1g / 100ml;

Embodiment 5

[0029] The catalyst that embodiment 5 uses is methyl iodide, and the consumption of methyl iodide in the oleum is calculated as iodine: 1g / 100ml;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com