MCC extremely fine coaxial cable production line and production method thereof

An ultra-thin coaxial and production line technology, which is applied in the manufacture of coaxial cables, cable/conductor manufacturing, circuits, etc., can solve the problems of poor cooling effect, poor extrusion layer molding quality, and inability to adapt to real-time working environments, etc., to achieve extrusion The effect of good plastic quality and stable production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

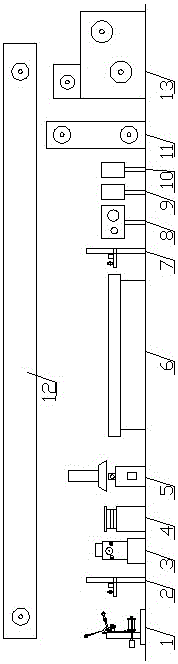

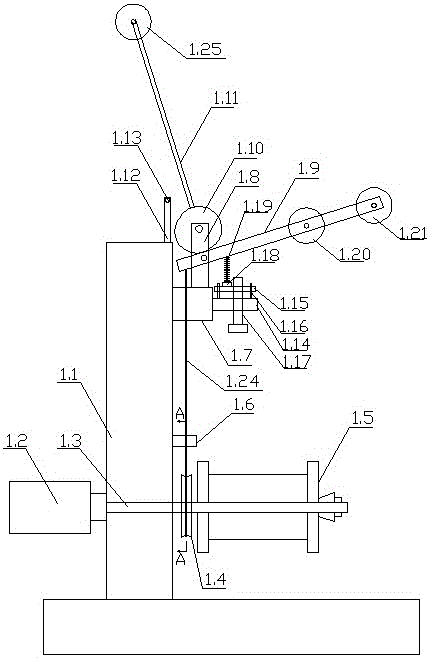

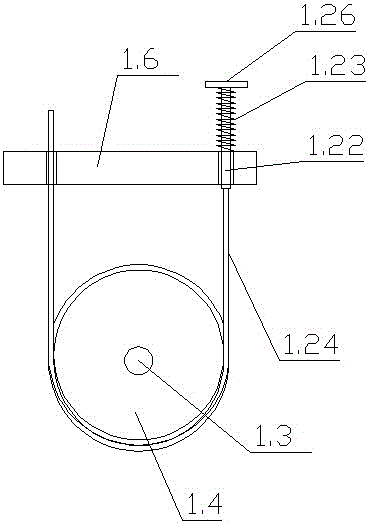

[0043] see Figure 1~Figure 7 , a kind of MCC ultra-thin coaxial cable production line that the present invention relates to, it comprises pay-off device 1, the first caliper 2, the first tensiometer 3, preheater 4, extruder 5, Cooling device 6, second caliper 7, second tension meter 8, electric spark detector 9, concave-convex meter 10, vertical wire storage device 11 and wire take-up device 13, the wire pay-off device 1, the first caliper Instrument 2, first tensiometer 3, preheater 4, extruder 5, cooling device 6, second diameter measuring instrument 7, second tensiometer 8, electric spark detector 9, concave-convex instrument 10, vertical storage line Above the device 11 and the wire take-up device 13, a horizontal wire storage device 12 arranged laterally is arranged.

[0044] After the copper wire is unwound from the pay-off device 1, it passes through the first diameter gauge 2, the first tension gauge 3, and the preheater 4 in order to be extruded and coated at the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com