Exhaust steam trap and method of use thereof

A trap and steam technology, applied in the field of exhaust steam traps, can solve the problems of steam not being fully and effectively utilized, energy waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

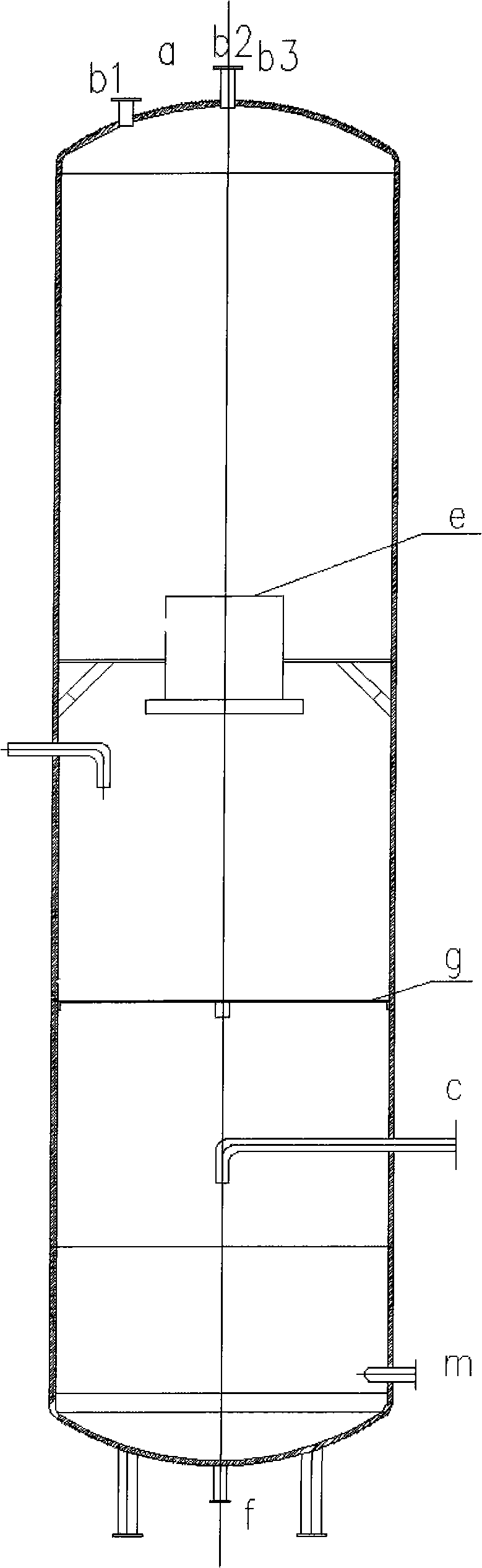

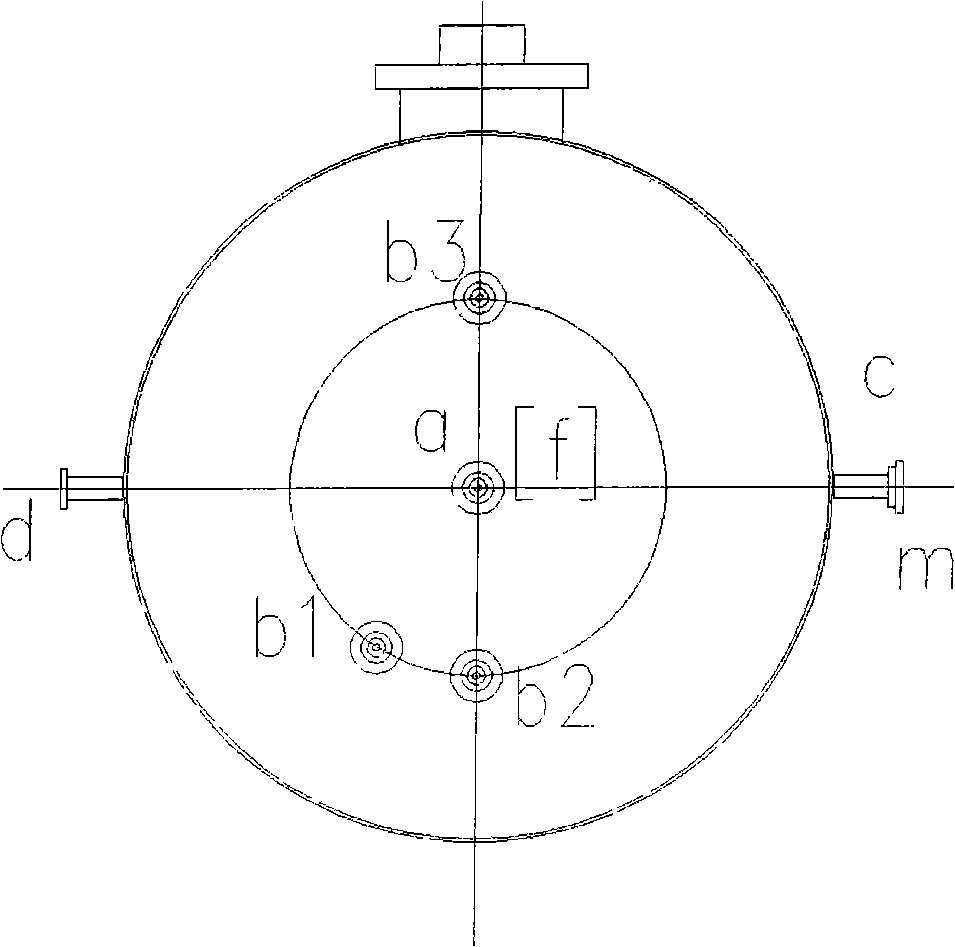

[0028] Embodiment 1: Pour toluene into the oxidation tower, open the saturated boiler steam valve, and use 0.8Mpa saturated boiler steam to heat up the toluene at normal temperature. When the temperature of toluene reaches 120°C, ventilation is started, and the temperature continues to rise to 160°C, and then the saturated boiler steam valve is closed. At this time, the saturated boiler steam used for heating the toluene has become exhausted steam, and all exhausted steam is collected by the exhausted steam trap (referred to as boiling pot) collected. Close the gas outlet b1-3, close the lower water outlet c, open the lower M-water outlet, and transport the condensed water with a temperature of 90-95°C to the coil that was originally heated for toluene in the oxidation tower. The cooling has been 160°C~ For toluene at a temperature of 175°C, adjust the opening of the condensate valve at any time to keep the temperature of the toluene at about 160°C relatively stably.

Embodiment 2

[0029] Embodiment 2: when the steam pressure in the upper half of the exhaust steam trap (abbreviation: boiling pot) reaches 0.2Mpa~0.3Mpa, and the temperature is 133°C~143°C, close the gas outlets (b2), (b3), and close The water outlets c and M are sent to the benzoic acid production system from the b1-steam outlet for the drying process of the tail gas adsorber.

Embodiment 3

[0030] Embodiment 3: In embodiment 2, the steam pressure on the upper part of the exhaust steam trap (abbreviation: boiling pot) reaches 0.2Mpa~0.3Mpa, and the temperature: close the gas outlet (b1), (b3) when the temperature is 133°C~143°C , close the water outlets c and M, and transport them to the refined benzoic acid production system from the b2- steam outlet for use in the drying process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com