Trolley replacement device

A trolley and driving device technology, which is applied to furnaces, furnace types, lighting and heating equipment, etc., can solve problems such as fluctuations in production conditions, large fluctuations in production conditions, and inability to achieve online replacement, and achieve stable production conditions. The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

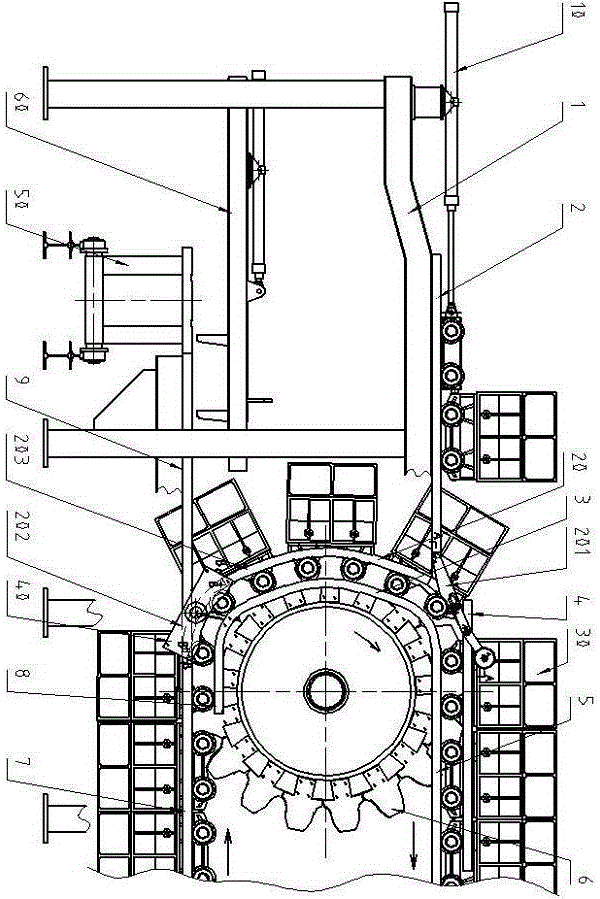

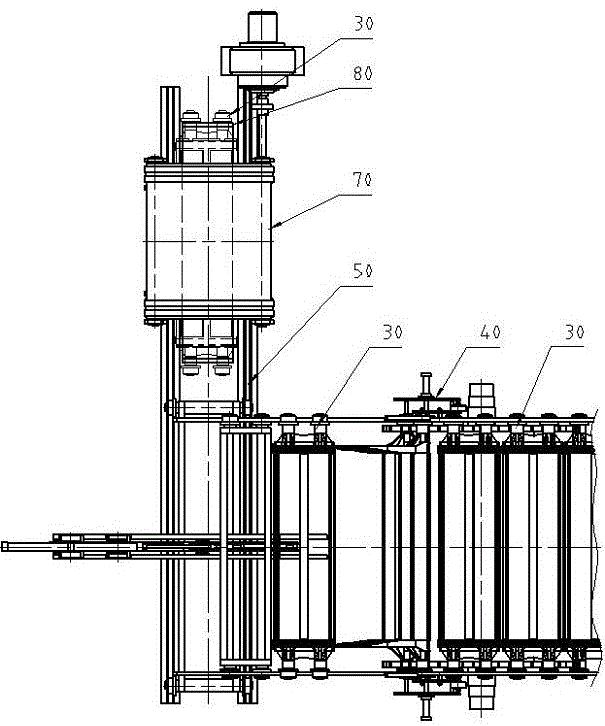

[0066] Example 1, such as Figure 1 to Figure 12 shown.

[0067] The trolley replacement device consists of trolley 30, inner straight rail 5, 8, inner curved rail 3, outer straight rail 4, 7, outer curved rail 20, main drive wheel 6, trolley moving out of rail 9, trolley moving into rail 2 and so on.

[0068] Inner straight rails (5, 8) and inner curved rails (3) form inner guide rails; outer straight rails (4, 7) and outer curved rails (20) form outer guide rails; main drive wheels ( 6), the gear of the main drive wheel (6) is located between the inner guide rail and the outer guide rail;

[0069] Outer curved rail 20 is installed on the both sides of main drive wheel 6, is made up of bottom movable outer curved rail 202, middle part fixed outer curved rail 203, top movable outer curved rail 201 etc.

[0070] The lower movable outer curved rail 202 is a partial ring structure, and two round holes are provided at both ends to cooperate with the guide rod 401. The lower mov...

Embodiment 2

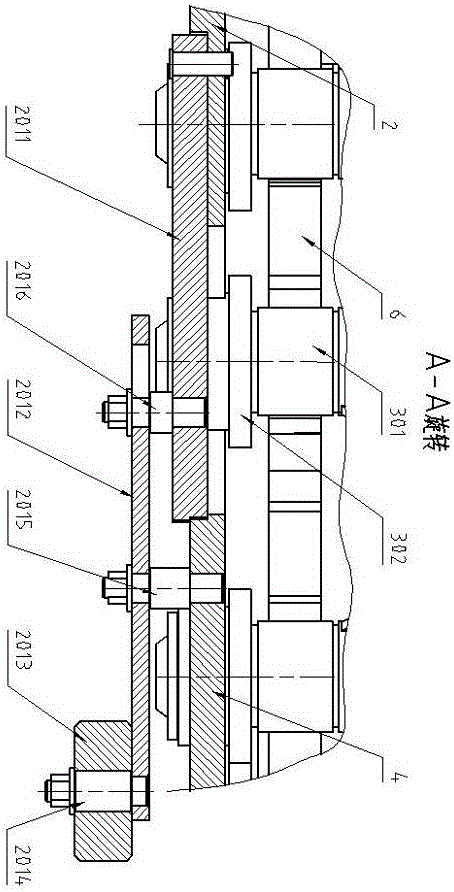

[0074] Example 2, Figure 13 shown.

[0075] This embodiment is a change carried out on the basis of Embodiment 1, the difference is:

[0076] 1. Simplify the upper movable outer curved rail 201 in Embodiment 1, cancel the rail II2012, become a single rail and lengthen the rail I2011, and install the weight 2013 directly on the rail I2011.

[0077] 2. At the lower right corner of the upper movable outer curved rail 201, a circular arc step matching the shape of the inner curved rail 3 is provided.

[0078] For the rest, it is the same as Example 1, and reference may be made to this specification and the relevant descriptions of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com