Ultra-fine coaxial cable extrusion production line and production method thereof

A production line and cable extrusion technology, applied in the manufacture of coaxial cables, cable/conductor manufacturing, conductor/cable insulation, etc., can solve the problems of poor cooling effect, poor quality of extrusion layer molding, lack of step-by-step cooling steps, etc. problems, to achieve the effect of stable production conditions and good extrusion quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

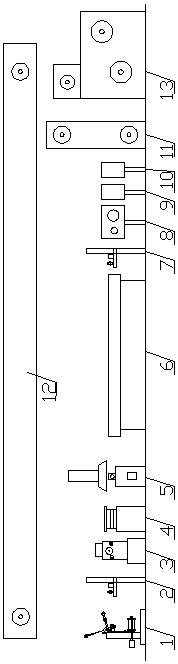

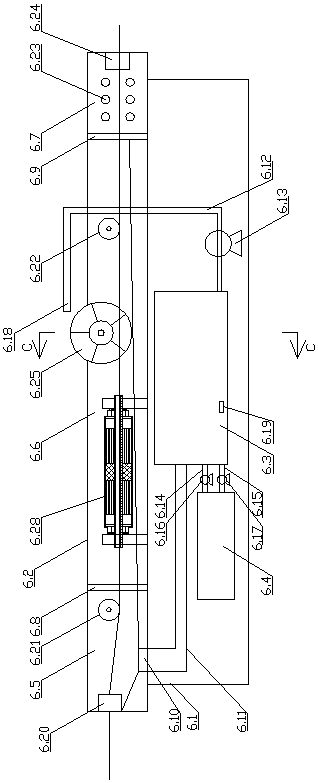

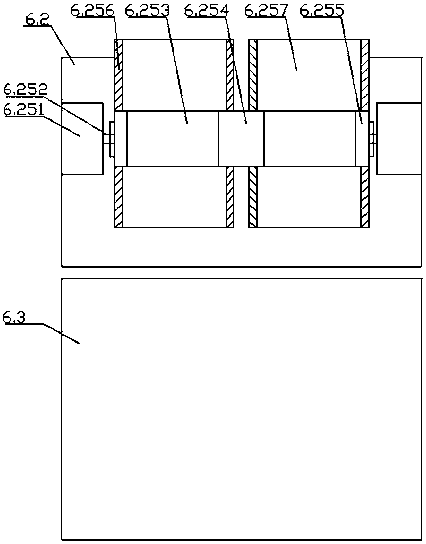

[0031] see Figure 1~Figure 4 , the present invention relates to a production line for extrusion molding of ultra-thin coaxial cables, which successively includes a pay-off device 1, a first diameter measuring instrument 2, a first tension meter 3, a preheater 4, and an extruder from left to right 5. Cooling device 6, second diameter measuring instrument 7, second tension meter 8, electric spark detector 9, concave-convex meter 10, vertical wire storage device 11 and wire take-up device 13, the wire releasing device 1, the first Caliper 2, first tensiometer 3, preheater 4, extruder 5, cooling device 6, second caliper 7, second tensiometer 8, electric spark detector 9, concave-convex meter 10, vertical Above the wire storage device 11 and the wire take-up device 13, a horizontal wire storage device 12 arranged horizontally is arranged.

[0032] After the copper wire is unwound from the pay-off device 1, it passes through the first diameter gauge 2, the first tension gauge 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com