A kind of method for producing ferronickel by adding nickel sulfide concentrate to laterite ore

A technology of nickel sulfide and laterite ore, which is applied in the field of ferroalloy production, can solve the problems of low nickel recovery rate, high production cost, and high energy consumption, and achieve the effects of reducing nickel ore consumption per ton, reducing procurement pressure, and broadening development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] 1. Pre-roasting the nickel sulfide concentrate to remove more than 90% of S and 30% of As in the nickel sulfide concentrate. The ingredients before and after roasting pretreatment are shown in Table 1:

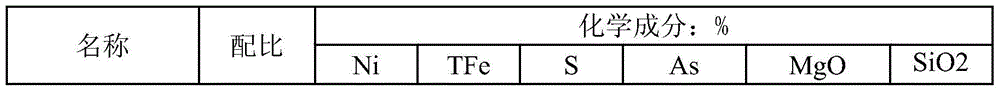

[0026] Table 1 Composition changes of nickel sulfide concentrate before and after roasting pretreatment

[0027] Element%

[0028] 2. Pre-reduction of ore blending and roasting. The ore blending of laterite ore and nickel sulfide concentrate is shown in Table 2. The amount of reducing coal blended is 69kg / ton of dry base ore, of which, the blended amount of bituminous coal is 37kg, and the blended amount of anthracite is 32kg.

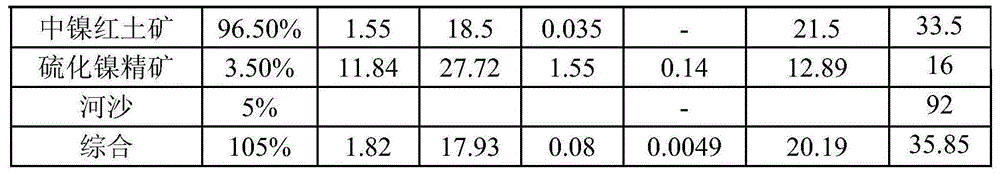

[0029] Table 2 Mixing of laterite ore and nickel sulfide concentrate

[0030]

[0031]

[0032] 3. The calcination temperature of the rotary kiln is 650°C, and the high-temperature calcine of 650°C is sent to the submerged arc furnace for smelting to obtain ferronickel products. The products and slag are shown in Table 3 and Ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com