A re-repair method for combined transmission generator housing

A technology of combined transmission and repair method is applied in the field of re-repair of combined transmission generator casing, which can solve the problems affecting the mutual positional relationship of assembly parts inside the casing, the change of the shape and position error of the casing assembly size, and the high requirements of the shape and position tolerance. , to achieve the effect of improving equipment support ability, speeding up movement speed, and eliminating stubborn stains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

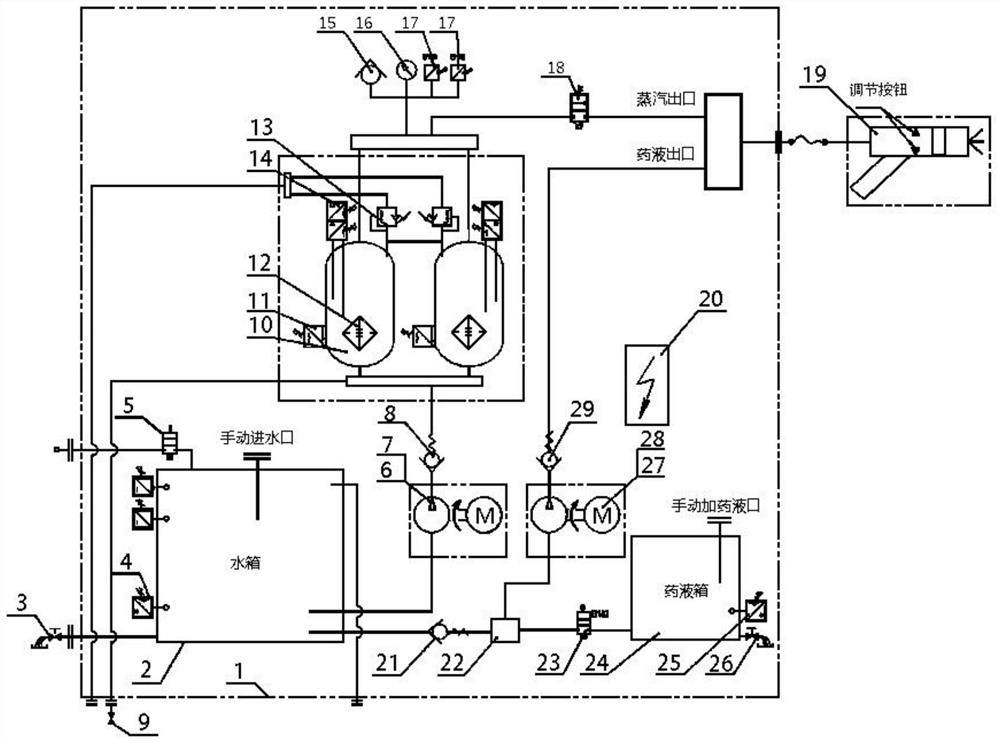

[0034] Such as figure 1 As shown, a method for repairing the shell of the combined transmission generator, the specific steps are as follows:

[0035] (1) Shot blasting and paint removal: compressed air is used to drive iron shot through special tools to achieve paint removal at high speed;

[0036] (2) Parts degreasing: degreasing with special degreasing agent;

[0037] (3) Saturated steam cleaning:

[0038] a: Add water and liquid medicine to the steam cleaner;

[0039] b: Turn on the power switch and start using when the steam pressure reaches the specified value;

[0040] c: Use the spray gun to aim at the part to be cleaned and rinse repeatedly;

[0041] d: After cleaning, place it in a cool place to cool naturally;

[0042] (4) Heating: The heating temperature of the parts i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com