A kind of additive preparation method of double-sided panel

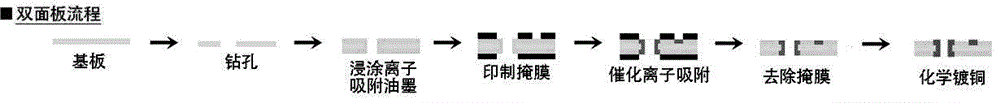

A double-sided, additive technology, applied in the direction of multi-layer circuit manufacturing, etc., can solve the problems of inability to achieve the conductivity of bulk materials, low conductivity of conductive lines, affecting conductivity, etc., so as to reduce purchase pressure, simplify equipment, reduce The effect of the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

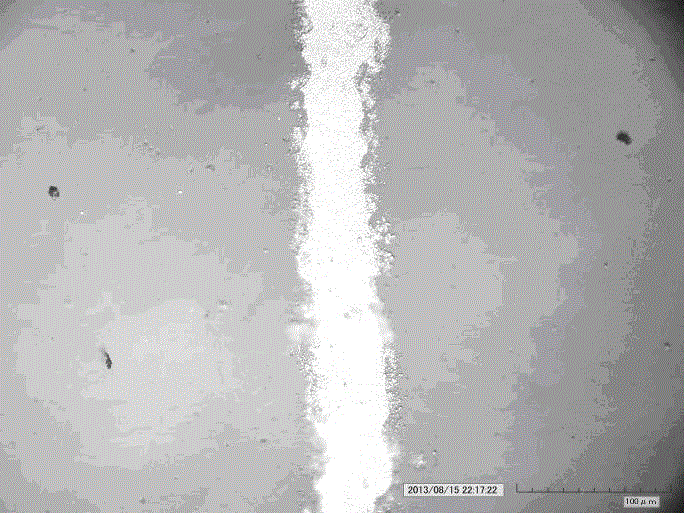

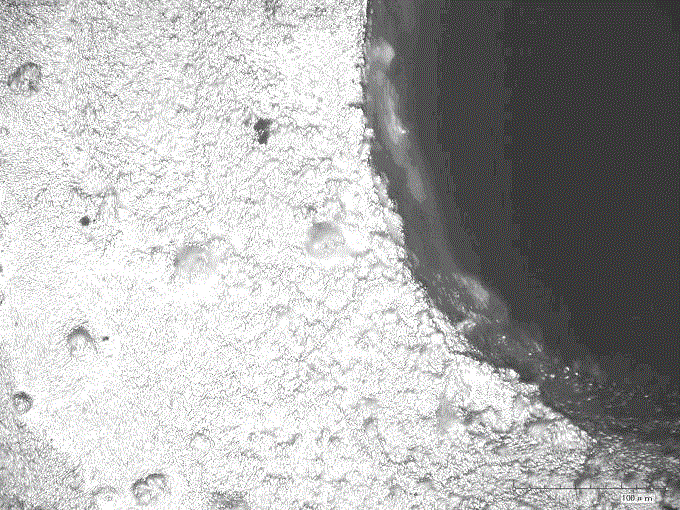

Examples

Embodiment 1

[0034] (1) Use glass fiber cloth epoxy laminate as the substrate, drill holes in the design part, remove flash and burrs, wash with clean water, and dry.

[0035] (2) The substrate after drilling is placed in a container containing 100g / LH 2 SO 4 ,120g / LKMnO 4 Roughen in the coarsening solution at 50 degrees for 30 minutes, take it out, wash it with clean water, and dry it.

[0036] (3) The roughened substrate is immersed in the ion-absorbing ink. The ion-absorbing ink contains 0.1 polyacrylic acid, 0.1 polyvinyl alcohol, and 0.8 water. It is taken out after 30 seconds and placed in an oven for 30 minutes at 70 degrees.

[0037] (4) Use screen printing to print a mask pattern on the substrate after dipping the ion-adsorbing ink to expose the circuit and through hole.

[0038] (5) Place the substrate after printing the mask at 50 degrees 0.05mol / LNa 2 PdCl 4In the aqueous solution for 30 seconds, take it out, wash it with clean water, and dry it.

[0039] (6) The substra...

Embodiment 2

[0045] (1) Select a polyimide flexible substrate, drill holes in the design part, remove flash and burrs, wash with clean water, and dry.

[0046] (2) The substrate after drilling is placed in a 4 Roughen in the coarsening solution at 50 degrees for 30 minutes, take it out, wash it with clean water, and dry it.

[0047] (3) The roughened substrate is immersed in the ion-absorbing ink. The ion-absorbing ink contains 0.05 polyacrylamide, 0.1 polyvinyl butyral, 0.35 water, and 0.5 ethanol. Take it out after 30 seconds, and place it in an oven for 30 minutes at 70 degrees.

[0048] (4) Use laser printing to print a mask pattern on the substrate after dipping the ion-adsorbing ink to expose the circuit and through hole.

[0049] (5) Place the substrate after printing the mask at 50 degrees 0.05mol / LAgNO 3 In the aqueous solution for 30 seconds, take it out, wash it with clean water, and dry it.

[0050] (6) The substrate adsorbing catalytic ions is placed in ethyl acetate to di...

Embodiment 3

[0056] (1) Choose a polyethylene terephthalate flexible substrate, drill holes in the design part, remove flash and burrs, wash with clean water, and dry.

[0057] (2) The substrate after drilling is placed in a roughening solution containing 120g / L NaOH, 60g / L 1,2-propylene glycol to roughen at 50 degrees for 30 minutes, take it out, wash it with clean water, and dry it.

[0058] (3) The roughened substrate is immersed in the ion-absorbing ink. The ion absorbing ink contains 0.05 polyaminosiloxane, 0.05 polybutyl acrylate, 0.05 polyvinyl chloride, 0.25 ethanol, 0.25 butyl acetate, and 0.35 xylene. Take it out after 30 seconds, and put it in the oven for 30 minutes at 70 degrees.

[0059] (4) Use inkjet printing to print a mask pattern on the substrate after dipping the ion-adsorbing ink to expose the circuit and through hole.

[0060] (5) Place the substrate after printing the mask at 50 degrees 0.05mol / LNa 2 PdCl 4 In the aqueous solution for 30 seconds, take it out, was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com