Patents

Literature

37results about How to "Fully roasted" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing large-size black bricks

The invention relates to a method for manufacturing black bricks, in particular to a method for manufacturing large-size black bricks, which solves the problem that the traditional baking process of black bricks in conventional sizes cannot manufacture large-size black bricks. Each large-size black brick respectively has the length, the width, and the height of 4.2 m, 2 m and 1 m, and the large-size black brick is made from the following raw materials in percentage by weight: 90 percent of clay, 0.5 percent of coal gangue powder, 7.5 percent of coal powder, 1 percent of coal slime, 0.5 percent of iron powder and 0.5 percent of glass powder. The manufacture process comprises the working procedures of kneading mud, making blanks, drying, loading the blanks into a kiln and roasting. During making the blanks, two fine iron wire nets are put among the brick blanks at intervals; during loading the blanks into the kiln, black bricks in the conventional sizes are palletized and clamped on the peripheries and the upper parts of the large-size black bricks; and during roasting, the brick blanks are roasted twice according to a roasting method of the black bricks in the conventional sizes. The large-size black bricks manufactured by the method have higher strength and no cracks and breakages and fully meet the requirement of brick carving.

Owner:王锁贵

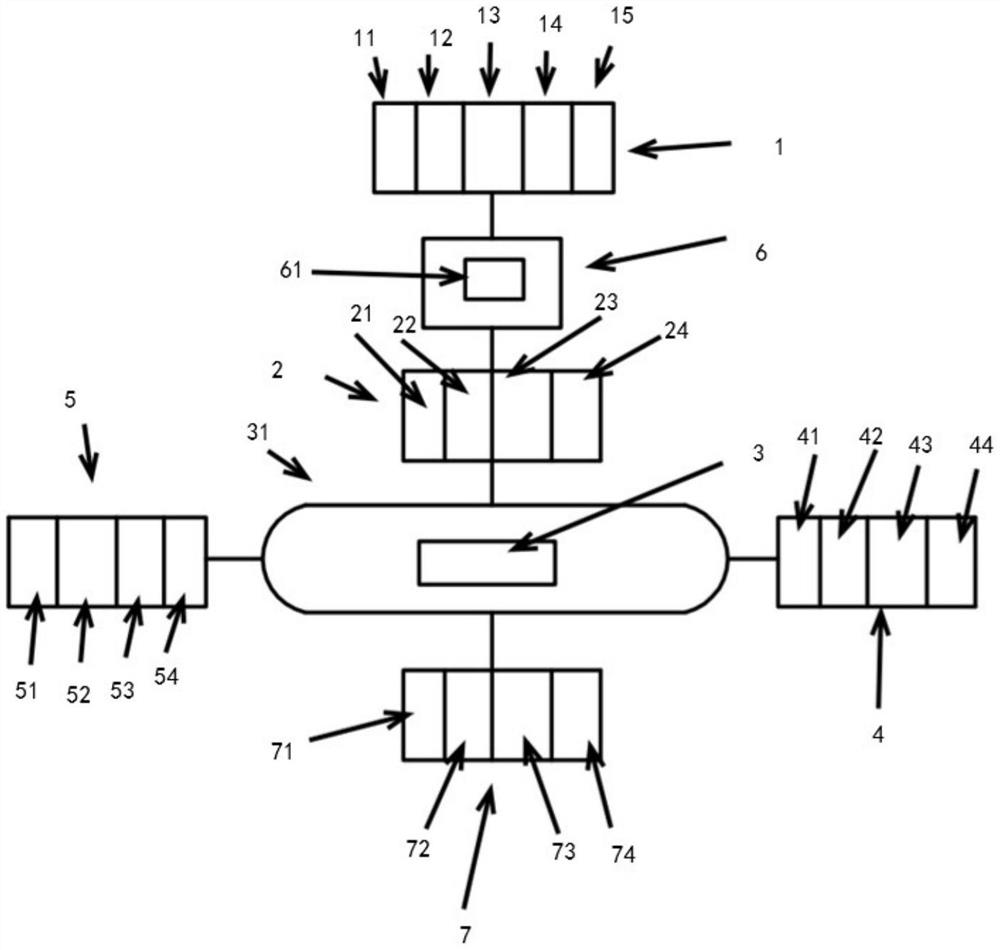

Chain grate-tandem rotary kiln whole-particle fraction magnetic roasting process for refractory low-grade iron ore

The invention provides a chain grate-tandem rotary kiln whole-particle fraction magnetic roasting process for refractory low-grade iron ore. The process mainly comprises the following steps: (1) particle size grading of the iron ore: a step of selecting iron ore respectively with particle sizes of 5 to 15 mm, 3 to 5 mm, 1 to 3 mm and 0 to 1 mm from iron ore with particle sizes of 0 to 15 mm; (2) heating and oxidizing in a chain grate: a step of drying, preheating and oxidizing the iron ore with particle sizes of 5 to 15 mm in the chain grate; (3) roasting in a primary magnetizing rotary kiln: a step of subjecting the oxidized iron ore discharged from the chain grate, the iron ore with particle sizes of 3 to 5 mm and the iron ore with particle sizes of 1 to 3 mm to magnetic roasting in the primary rotary kiln; (4) roasting in a secondary magnetizing rotary kiln: a step of allowing the premagnetized iron ore discharged from the primary rotary kiln and the iron ore with particle sizes of 0 to 1 mm to undergo a reduction reaction with reductive carbon in the secondary rotary kiln in virtue of waste heat of the iron ore; and (5) grinding and magnetic separation of the roasted ore.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Method for preparing mixed rare earth chloride from Bayan Obo rare earth ore concentrates

InactiveCN109097559AReduce energy consumptionSave resourcesPolycrystalline material growthRare earth metal chloridesDecompositionRare earth

The invention discloses a method for preparing mixed rare earth chloride from Bayan Obo rare earth ore concentrates. The method comprises the following steps: mixing the Bayan Obo rare earth ore concentrates with concentrated sulfuric acid at a mass ratio ranging from 1:0.7 to 1:1.5, and carrying out three-section roasting on the mixture to obtain roasted rare earth ores; carrying out leaching andpurification on the obtained roasted rare earth ores, carrying out filtering and deslagging on the leached and purified ores, and carrying out extraction transformation on a filtrate obtained throughthe filtering to obtain a raffinate and a loaded organic phase; and carrying out back extraction on the loaded organic phase through hydrochloric acid to obtain a mixed rare earth chloride solution.The method provided by the invention has the advantages that through the low-temperature external-heating roasting and countercurrent movements of a heat source and materials, energy consumption can be effectively reduced; through the three-section roasting method, sufficient decomposition of the rare earth ore concentrates can be further promoted, so that the materials can be prevented from adhering to a kiln, and can be more sufficiently roasted to effectively reduce exhaust emissions; and through the continuous leaching and the countercurrent purification, the rare earth ore concentrate recovery rate can be effectively improved.

Owner:西安西骏新材料有限公司

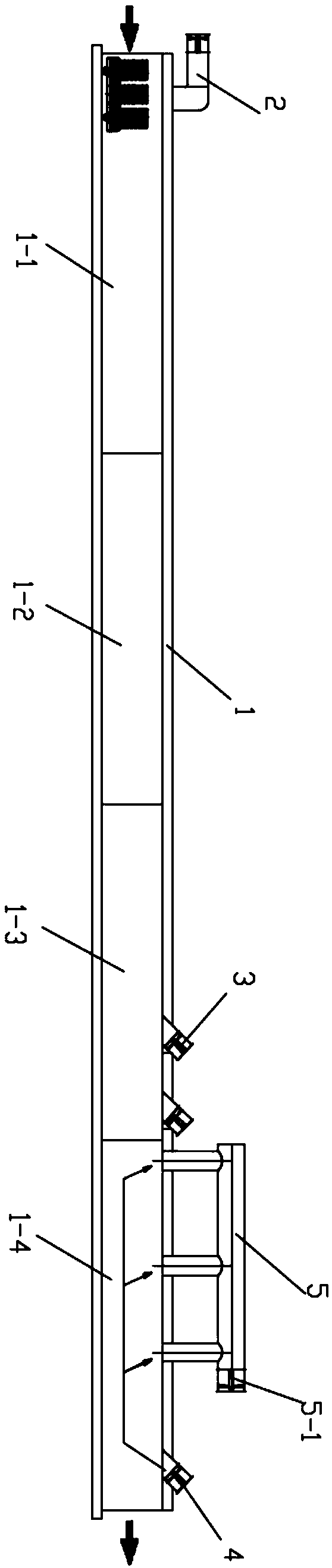

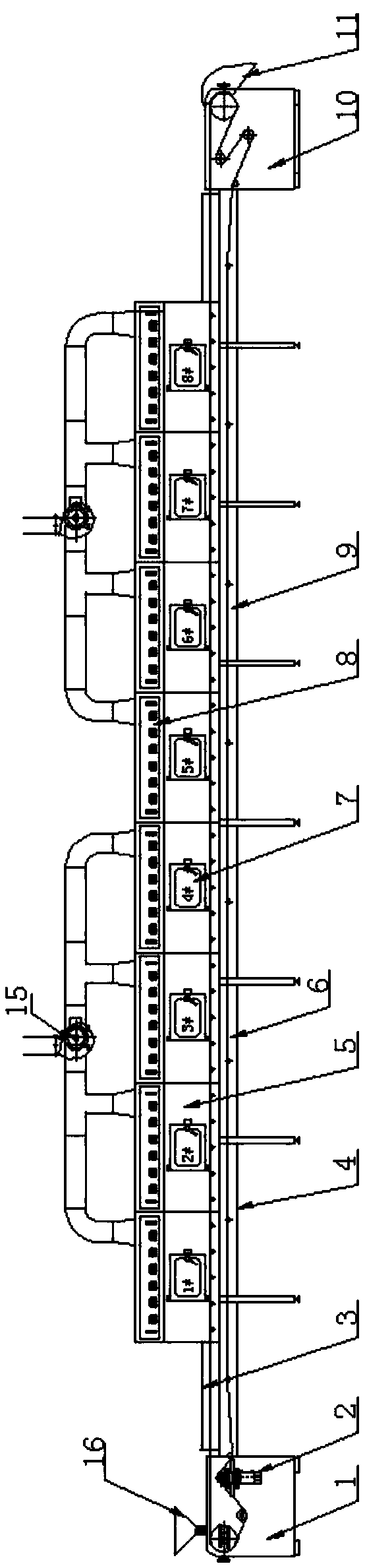

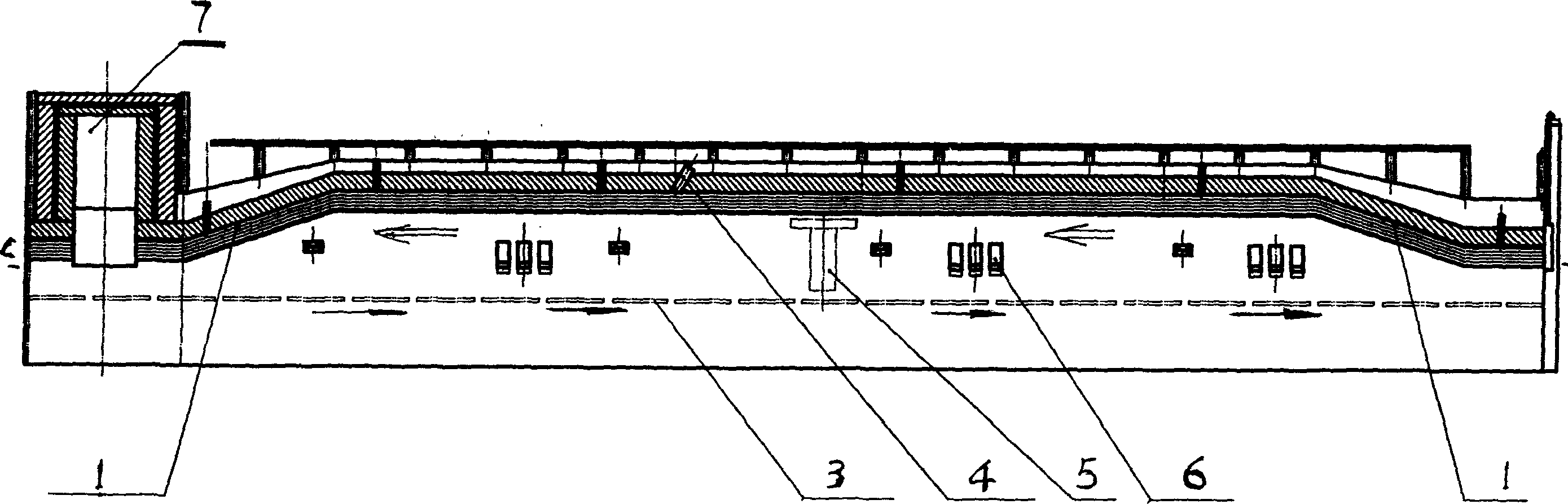

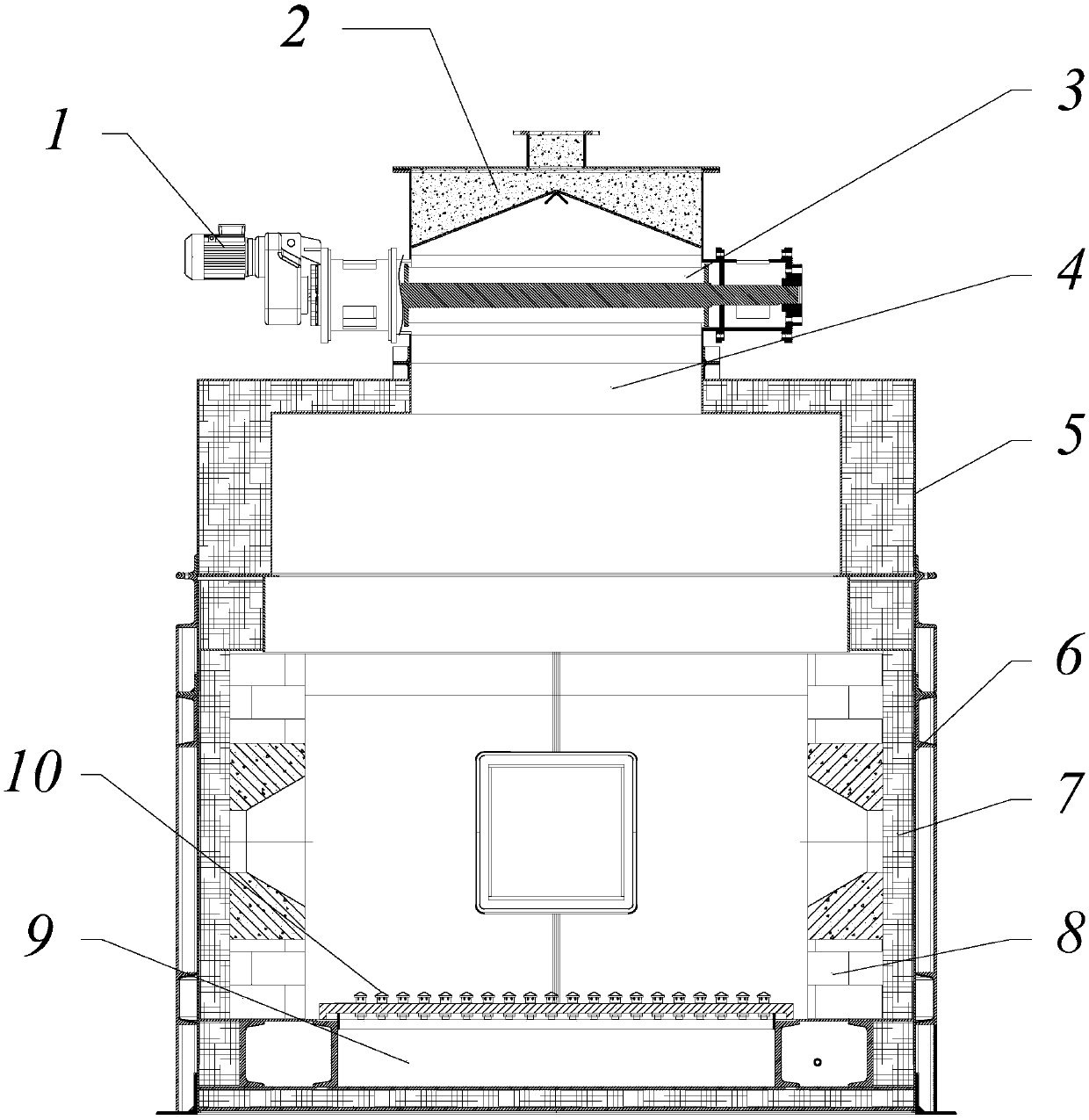

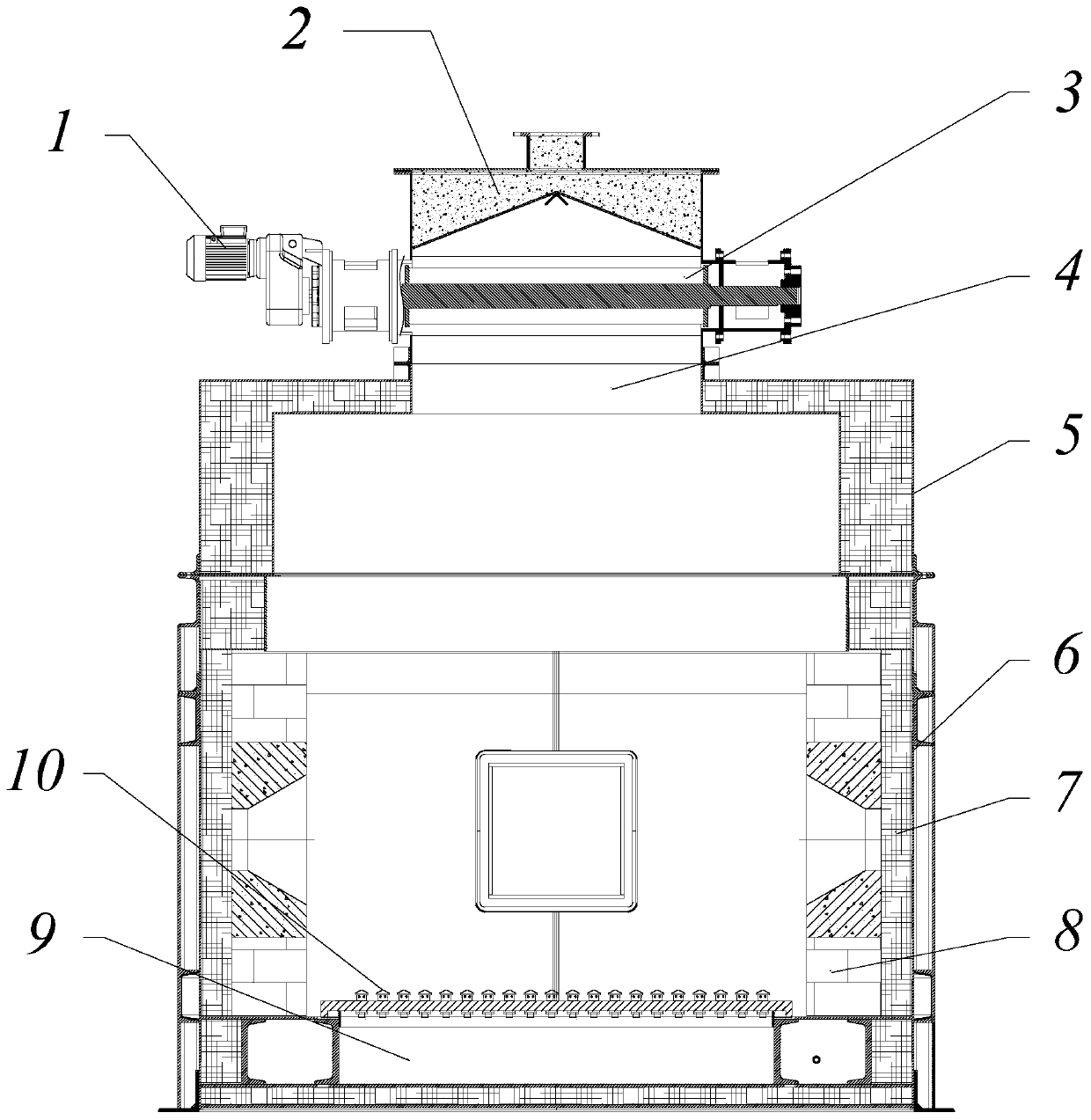

Energy-saving and environment-friendly brick burning tunnel kiln for achieving complete separation of smoke and waste heat

InactiveCN109237939AFully roastedPrevent insufficient anoxic roastingFurnace typesCeramic materials productionEngineeringTunnel kiln

The invention relates to an energy-saving and environment-friendly brick burning tunnel kiln for achieving complete separation of smoke and waste heat. The tunnel kiln comprises a tunnel kiln body, acart entrance and a cart exit for a brick cart to enter and exit from are formed in the left and right ends of the tunnel kiln body respectively, and the tunnel kiln body is divided into a brick blankpreheating warming band area, a high-temperature roasting band area, a heat preservation band area and a cooling band area from left to right in sequence; a smoke desulphurization device is connectedto the top of the brick blank preheating warming band area, supply fans are arranged at the top of the heat preservation band area, and air exhausters are installed on the side walls of the two sidesof the rightmost end of the cooling band area; an air exhaust pipe is connected to the top of the cooling band area and communicated with a drying kiln, and a first fan is installed in the air exhaust pipe. The energy-saving and environment-friendly brick burning tunnel kiln has the advantages of being simple in structure, easy to manufacture, practical and efficient.

Owner:CHANGZHOU GUICHENG BUILDING MATERIALS CO LTD

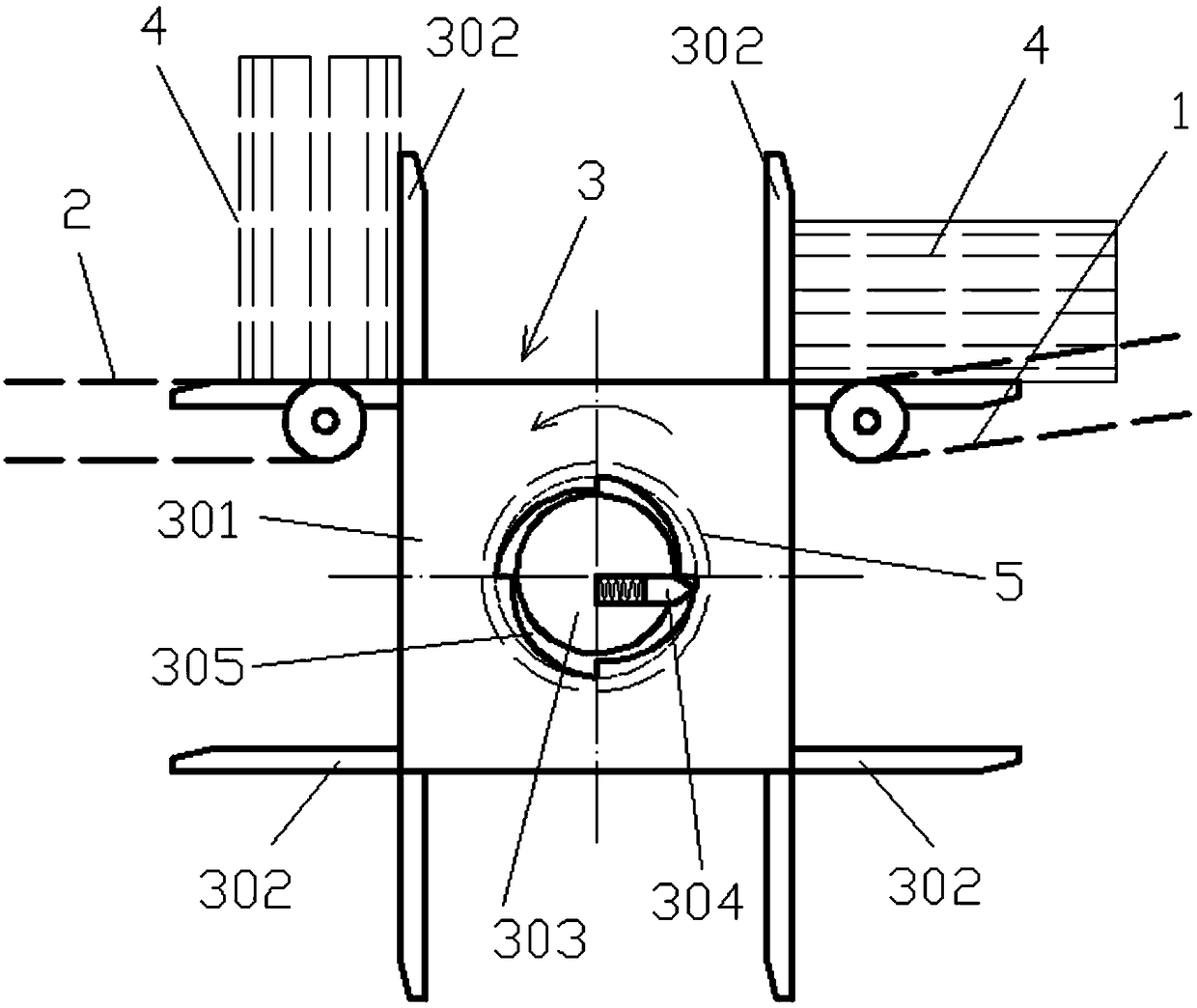

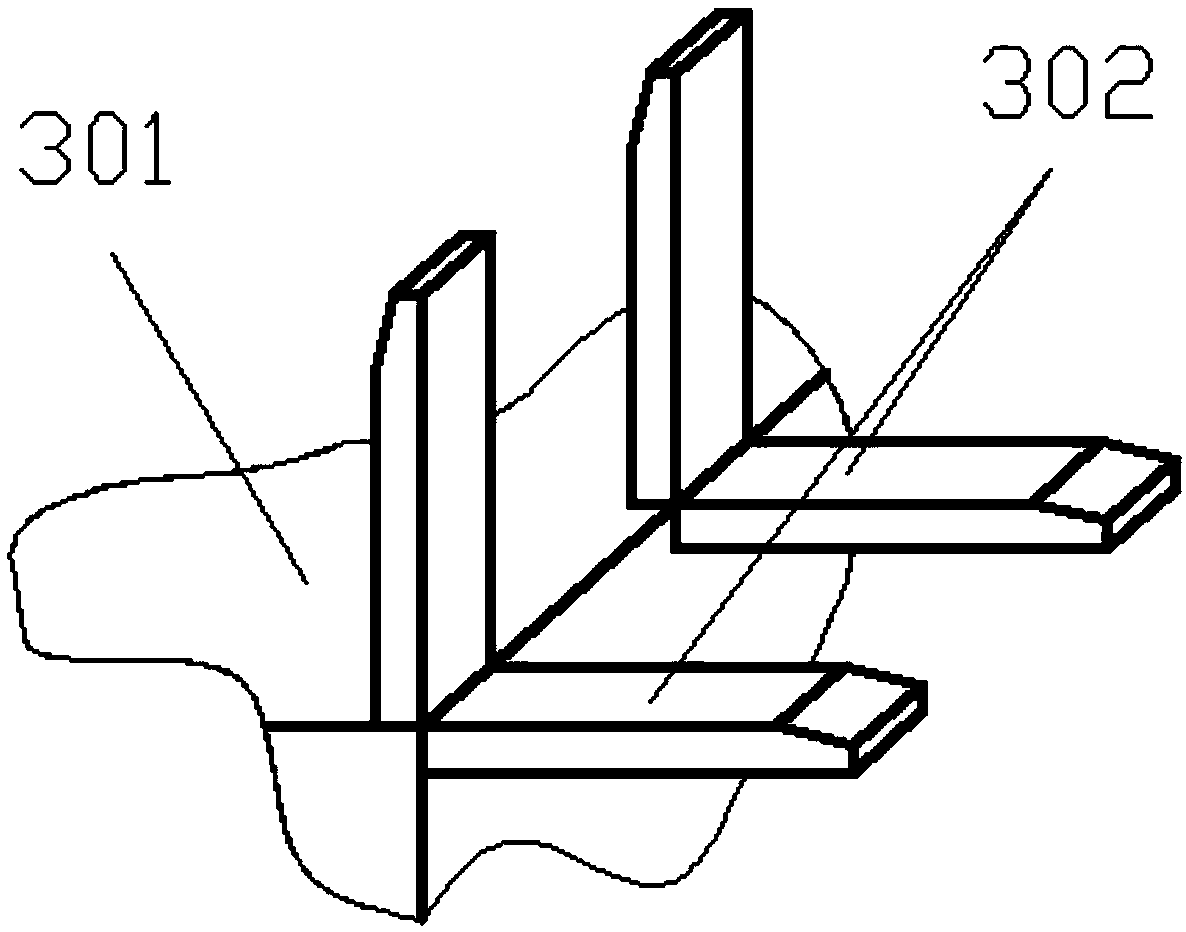

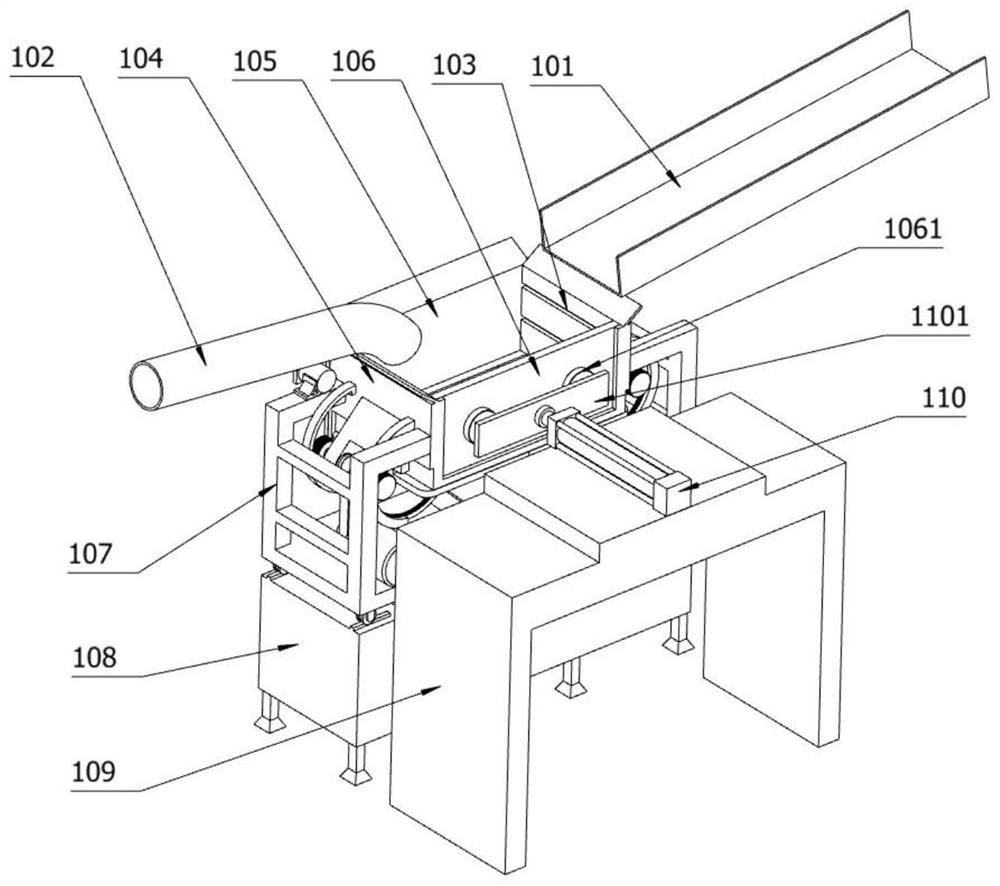

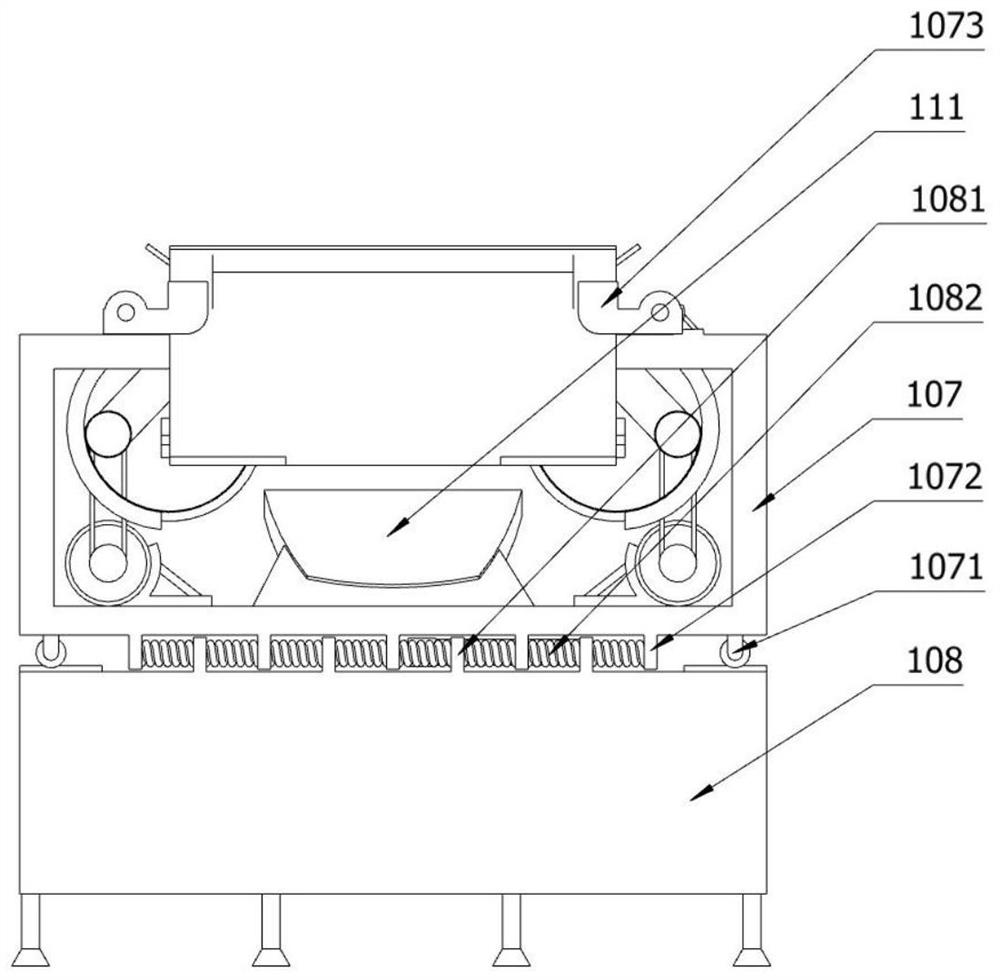

Automatic blank overturning device of blank stacking machine

PendingCN108773654ASimple structureEfficient automatic blank turningConveyorsConveyor partsInertia forceEngineering

The invention provides an automatic blank overturning device of a blank stacking machine. The device comprises a front end conveying device, a back end conveying device and a passive overturning bracket roller; a roller of the passive overturning bracket roller realizes passive fixed-axis 90-degree intermittent revolving movement through a pure mechanical ratchet mechanism; L-shaped bracket platforms poked by inertia force and overturned along with a roller body are fixedly mounted at the northeast, northwest, southwest and southeast angles of the roller are fixedly mounted in a manner of central symmetry; when the bracket platforms are intermittently overturned and deflected by 90 degrees, adobes are driven to overturn by 90 degrees in the brick hole directions; and after the adobes are rotated along with the bracket platforms from one side of the roller to the other side, the overturned adobes are conveyed and transferred by the back end conveying device. The device is simple in structure, economical, practical and efficient in blank overturning, saves the manpower, the time and the power, and is more suitable for popularization and application.

Owner:陕西新兴建材机械制造有限公司

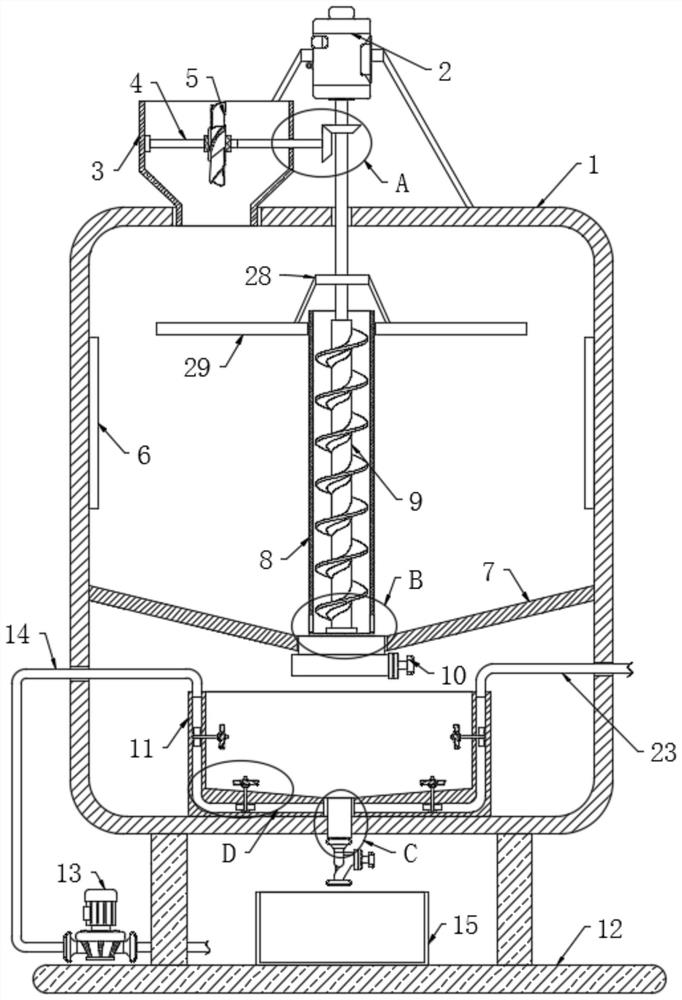

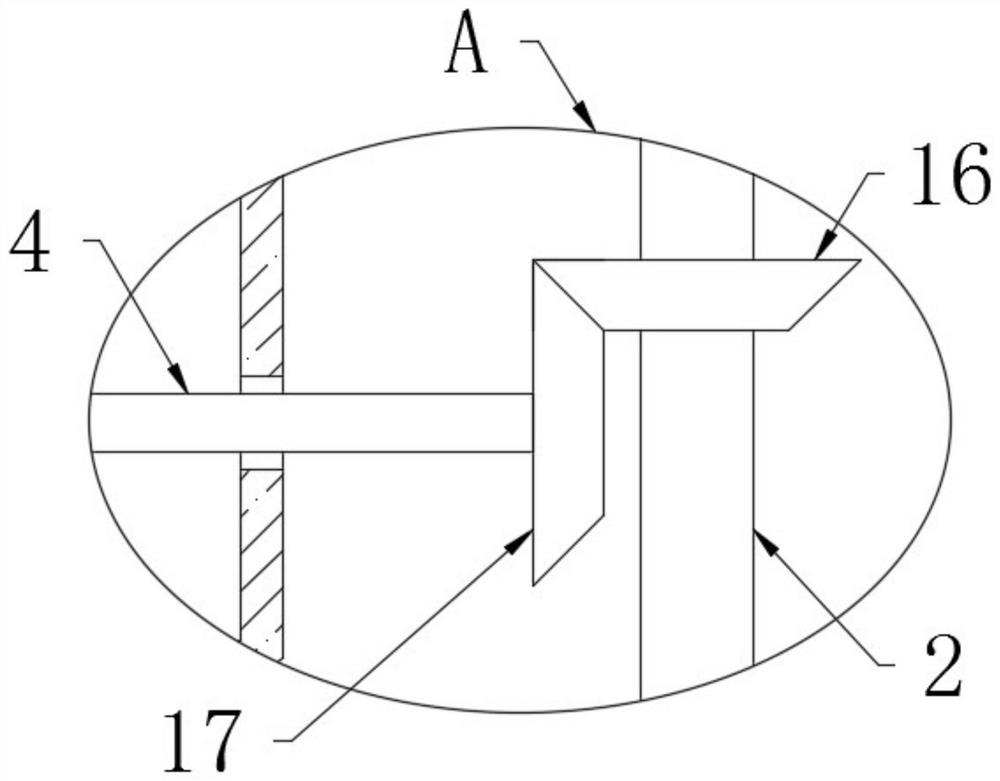

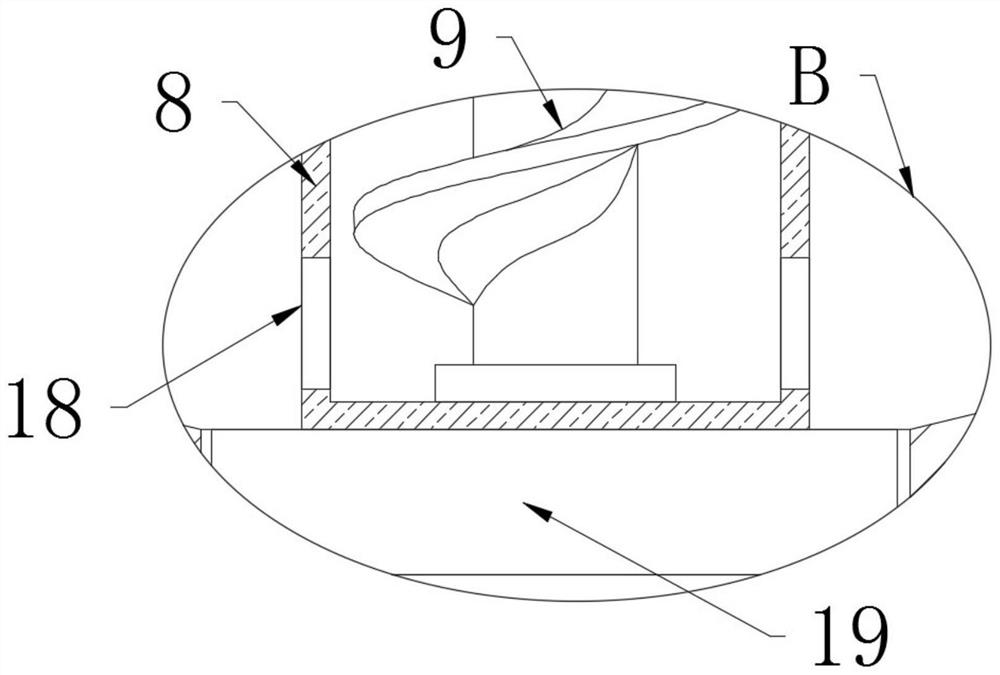

Molecular sieve activated powder production equipment and molecular sieve activated powder production method

InactiveCN112694096AAvoid accumulationShorten the timeDomestic cooling apparatusMolecular-sieve and base-exchange compoundsMolecular sieveElectric machine

The invention discloses molecular sieve activated powder production equipment and a molecular sieve activated powder production method, the molecular sieve activated powder production equipment comprises a processing tank and an electric baking plate, the outer side wall of the processing tank is fixedly connected with a driving motor, the outer side wall of the processing tank is fixedly connected with a feeding pipe, and the inner side wall of the feeding pipe is rotatably connected with a transmission rod, dredging blades are fixedly connected to the outer side wall of the transmission rod, the tail end of the transmission rod penetrates through the outer side wall of the feeding pipe, a second bevel gear is fixedly connected to the tail end of the transmission rod, a first bevel gear is fixedly connected to the outer side wall of an output shaft of the driving motor, and a supporting plate is fixedly connected to the inner side wall of the processing tank, temperature in materials is transmitted through water flow, cooling of the molecular sieve activated powder is achieved in the process, stirring blades begin to rotate in the water flow flowing process, materials can be fully cooled, the cooling time of the molecular sieve activated powder is greatly shortened, and the processing rate of the whole device is increased.

Owner:JINZHONG UNIV

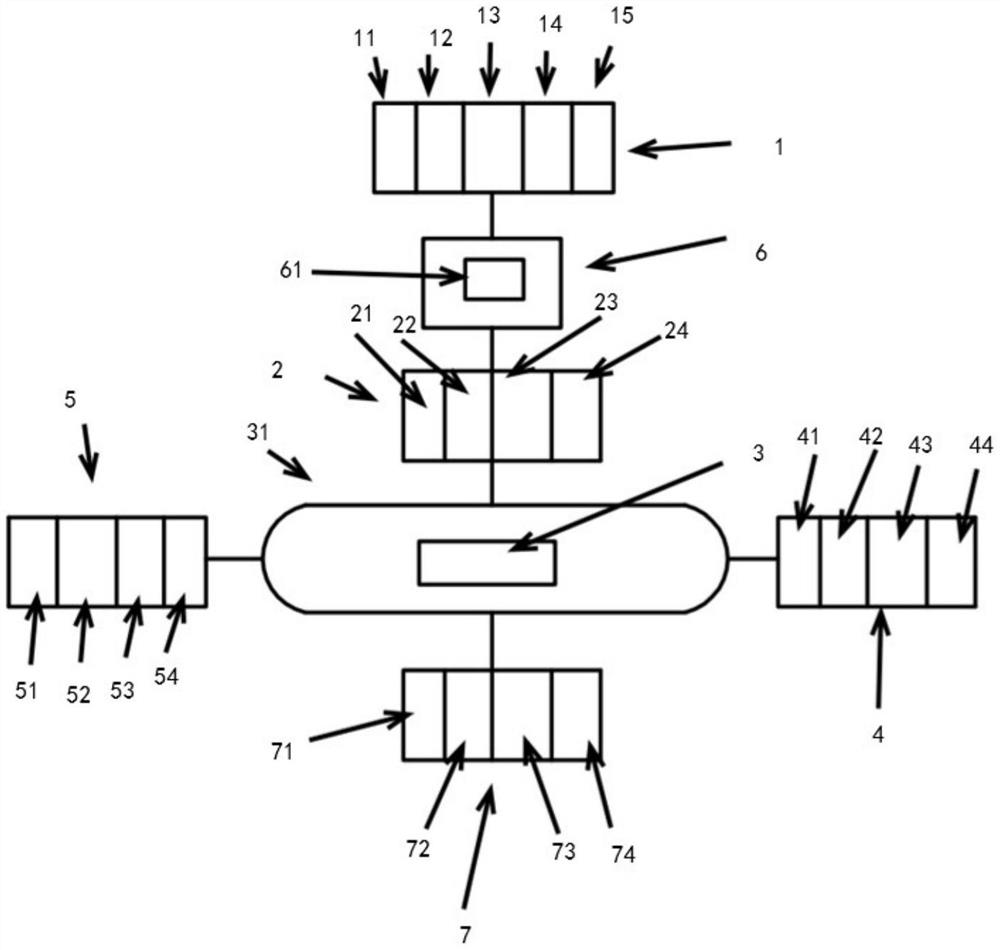

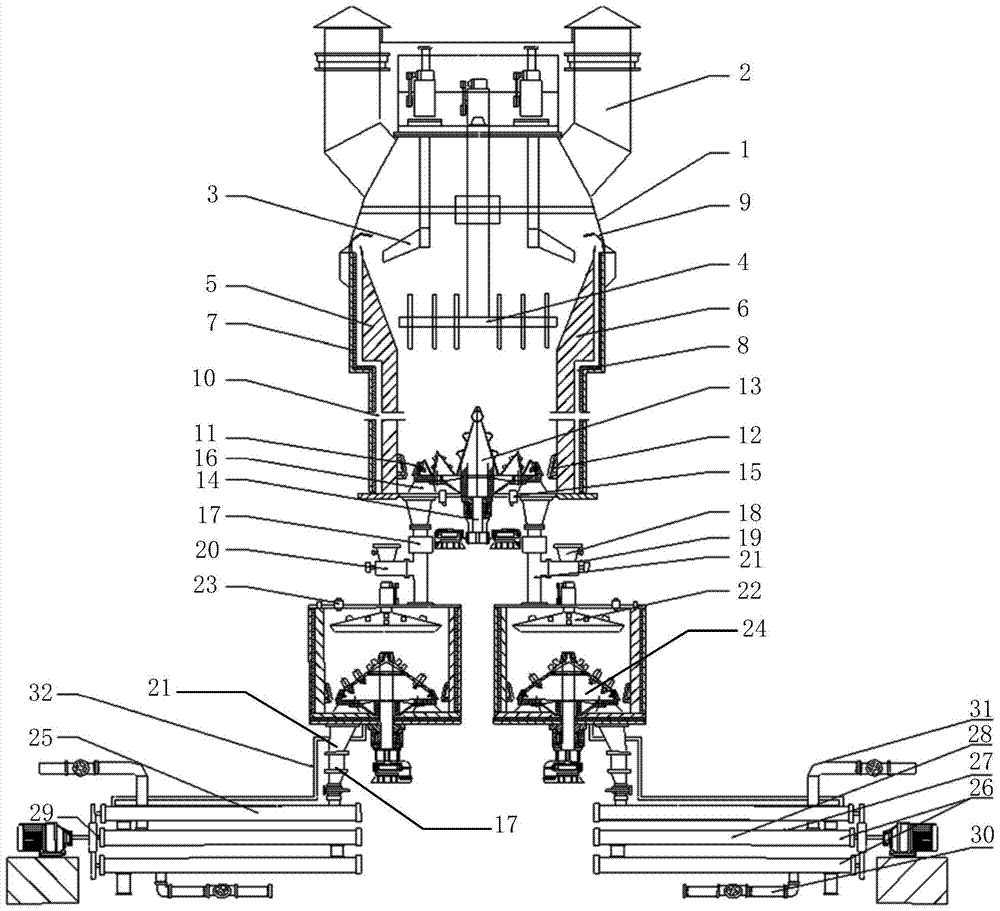

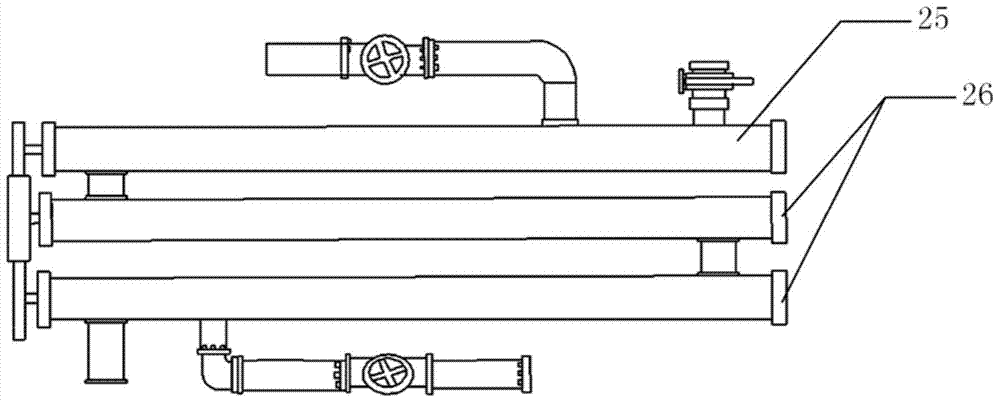

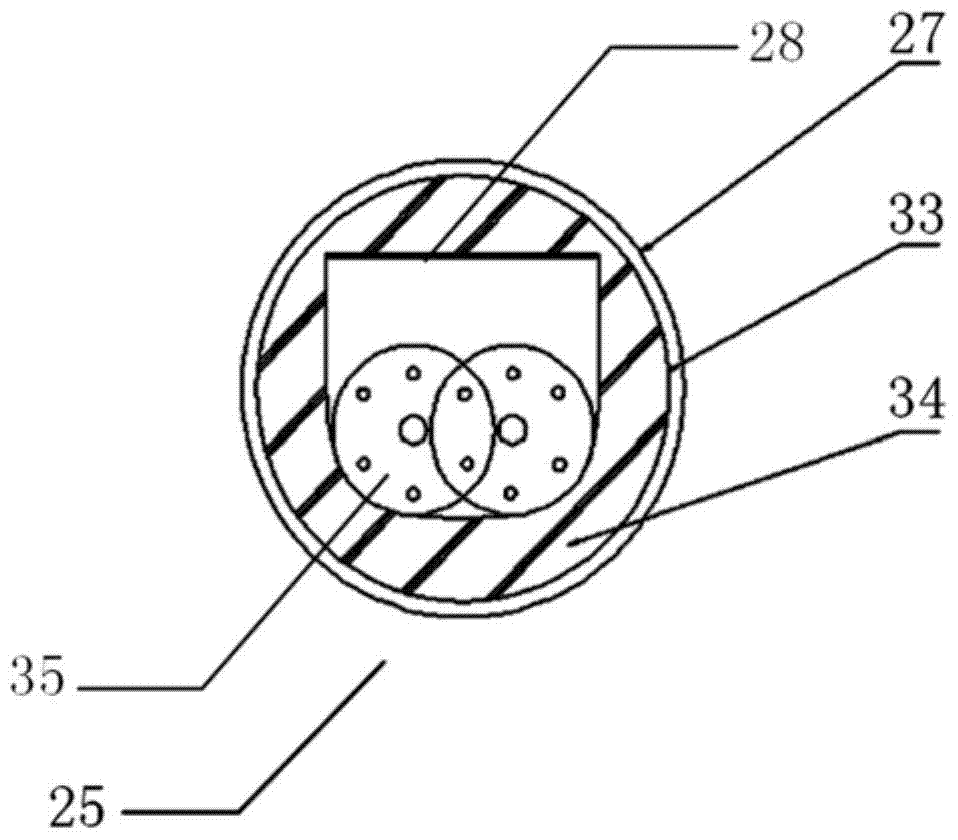

Preprocessing device for neodymium, iron and boron waste materials before roasting

PendingCN111607695AFully roastedImprove roasting efficiencyProcess efficiency improvementEngineeringReamer

The invention discloses a preprocessing device for neodymium, iron and boron waste materials before roasting, and mainly solves the problem that existing neodymium, iron and boron waste materials cannot be fully roasted and roasting efficiency is affected. The preprocessing device comprises a washing device, a breaking device, a centering device and a roasting device, wherein the washing device is provided with a left baffle plate, a right baffle plate, a front plate, a rear plate and a bottom plate; the right baffle plate is arranged on the right of the left baffle plate; the front plate isarranged in front of the left baffle plate and the right baffle plate; the rear plate is arranged behind the left baffle plate and the right baffle plate; the bottom plate is arranged on the bottom ofthe left baffle plate, the right baffle plate, the front plate and the rear plate; the breaking device is arranged in front of the washing device and is provided with a breaking box and a breaking reamer, wherein the breaking reamer is arranged in the breaking box and is used for breaking neodymium, iron and boron; the centering device is arranged between the breaking device and the washing device and is provided with a material blocking plate; the material blocking plate is arranged between the breaking box and the front plate; and the roasting device is arranged in front of the breaking device. The processing device has the advantages of being sufficient in roasting and high in roasting efficiency.

Owner:XINFENG BAOGANG XINLI RARE EARTH

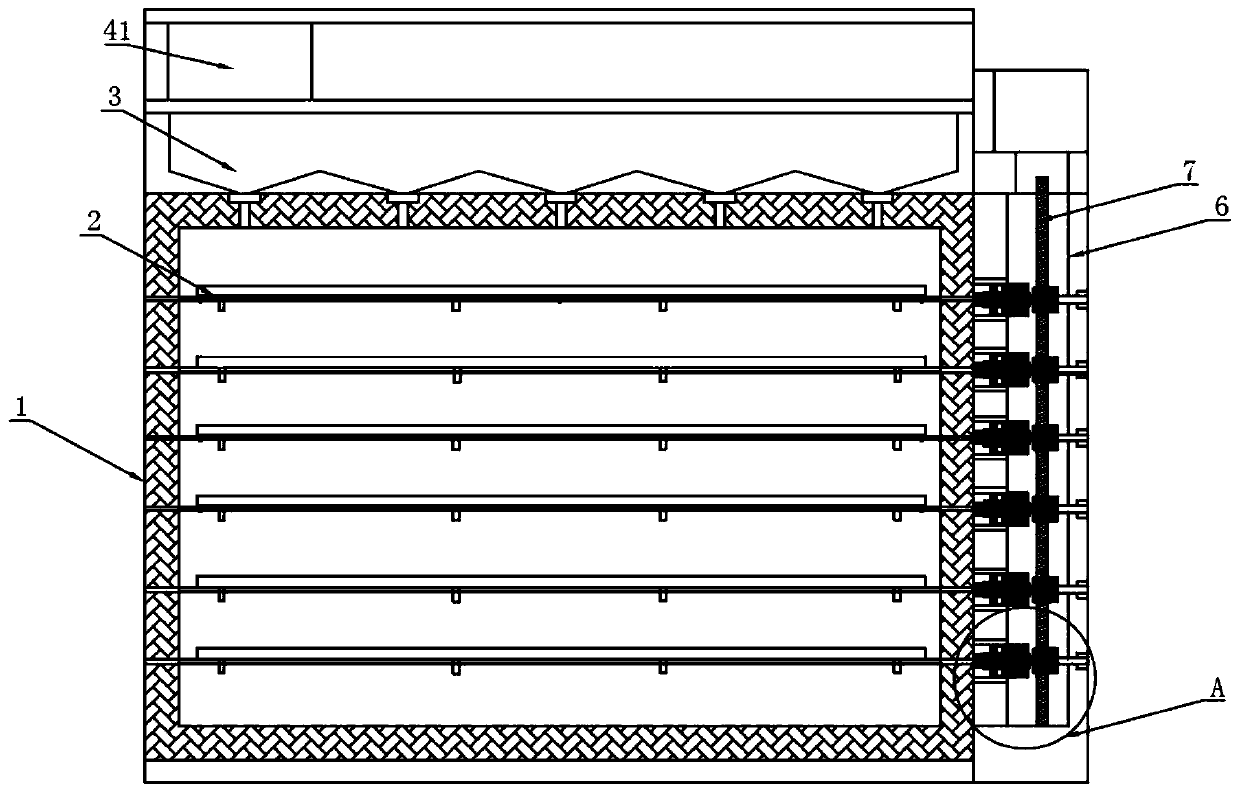

Microwave drying kiln

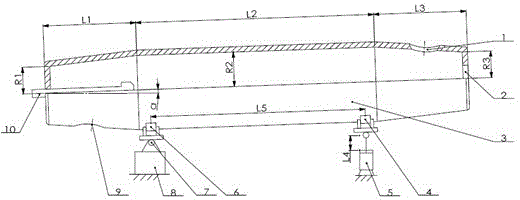

PendingCN108981365AUniform roastingFully roastedDrying solid materials with heatDrying machines with progressive movementsMicrowaveDrive motor

The invention discloses a microwave drying kiln. The microwave drying kiln comprises a bridge body bottom plate, a reversing end frame fixedly installed outside one side of the bridge body bottom plate and a power end frame fixedly installed outside the other side of the bridge body bottom plate. The bridge body is fixedly installed at the top of the bridge body bottom plate, a through groove bodyis formed in the plate surface of the bridge body, a conveying belt is arranged in the through groove body, and one end of the conveying belt is connected with a driving motor in the reversing end frame in a sleeving mode. The other end of the conveyor belt is connected with a driving motor in the power end frame in a sleeving mode, a plurality of microwave heating boxes are fixedly installed ona frame of a bridge body, and the conveyor belt penetrates through the interior of the microwave heating boxes. According to the microwave drying kiln, the residence time of materials in the microwaveheating boxes is controlled by adjusting the moving speed of the conveyor belt, that is, the roasting time of the materials is controlled; in the microwave roasting process of the materials, the phenomenon that the temperature of the surface materials in direct contact with gas is too low is eliminated, so that the materials are roasted uniformly and fully, and the microwave drying kiln is further suitable for microwave heat treatment of other powdery materials, such as drying, sintering and the like.

Owner:苏州苏丰机械科技有限公司

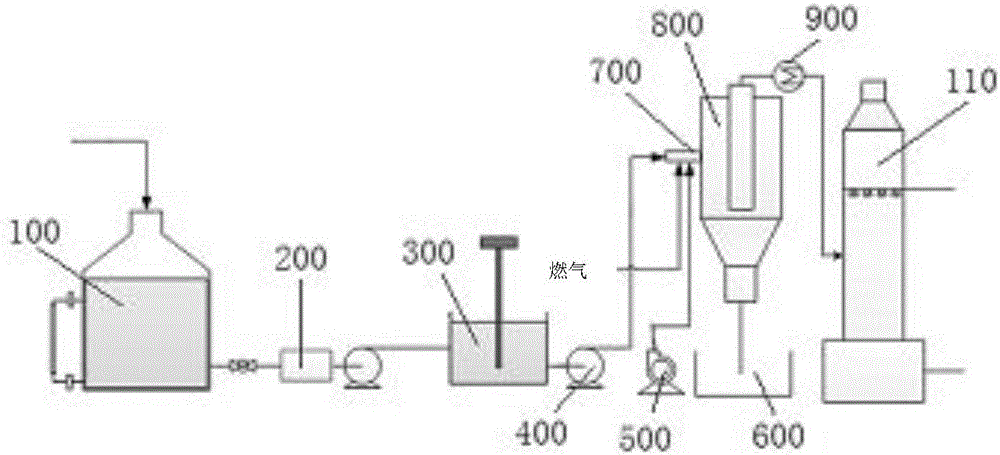

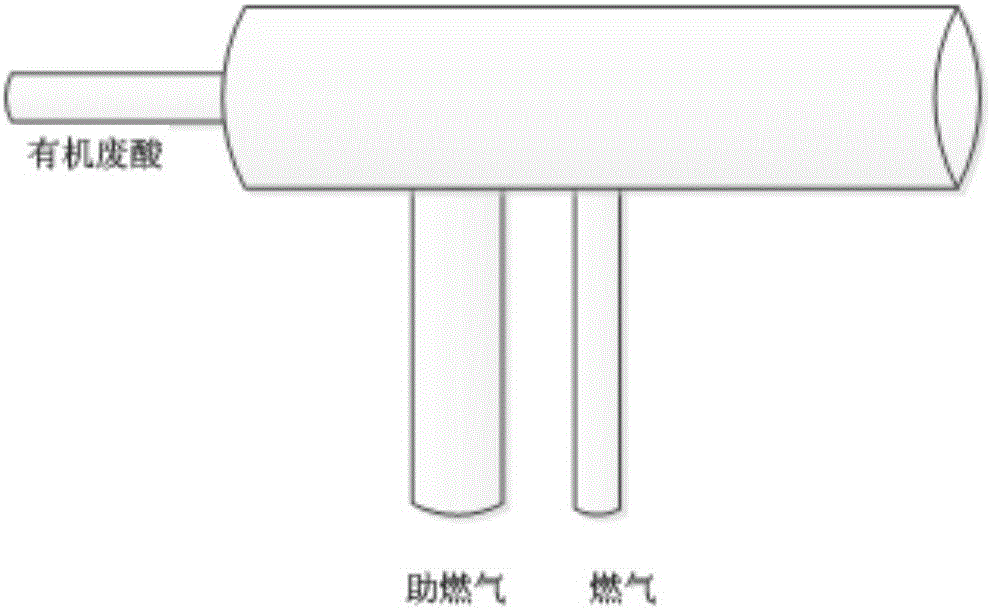

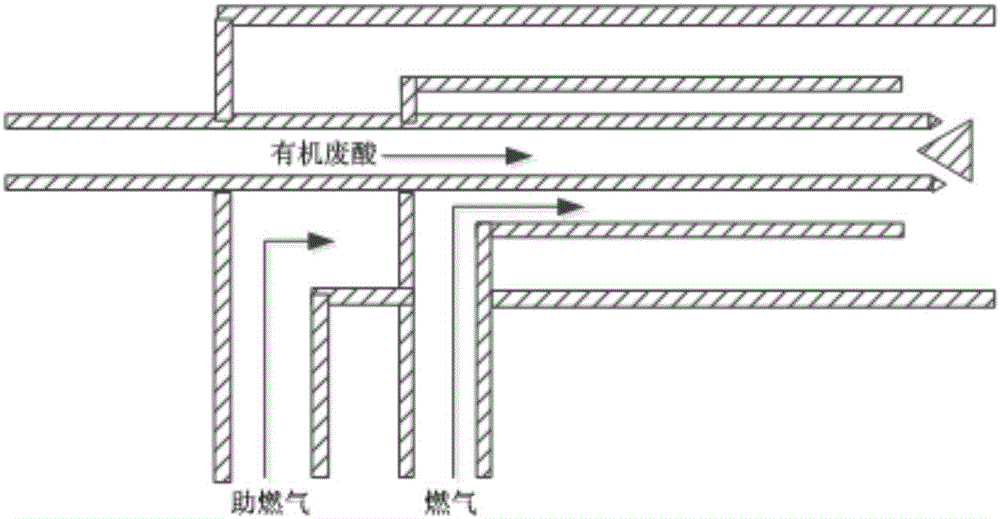

High-temperature roasting device and treatment method thereof

InactiveCN106287752AReduce system power consumptionSave resourcesIncinerator apparatusHigh concentrationPyrolysis

The invention relates to a high-temperature roasting device. The device comprises a waste liquid tank, a high-pressure pump, a cooling tank, a spray combustion system, a combustion fan and a spraying device, wherein the spray combustion system comprises a waste liquid pipeline, a combustion gas pipeline, a combustion-supporting gas pipeline, a spray combustion device, an atomization roasting furnace and a mist pipeline. The high-temperature roasting device has the advantages and the benefits as follows: 1, through filtration and ultrasonic dispersion of a waste liquid, a uniform slurry system is obtained, and the slurry is roasted more sufficiently by means of a special combustion device; 2, in the roasting process, combustible substances such as organic matter and the like are combusted to generate high temperature, compounds difficult to decompose are pyrolysed, the pyrolysis efficiency is high, and recovery is easy to realize; 3, neutralization agents are not required to be added, and new salt components are not introduced; 4, high-concentration organic matters in the waste liquid can be sufficiently utilized and combusted to supply heat, only a little fuel is required to be supplemented, system energy consumption is low, waste heat of high-temperature smoke can be recovered, resources are saved, and the environment is protected; 5, the technological procedure is simple, the system operates stably, the production safety performance is high and the like.

Owner:北京煜境科技有限公司

A manganese ore roasting rotary kiln system

Owner:内蒙古景蕾实业有限公司

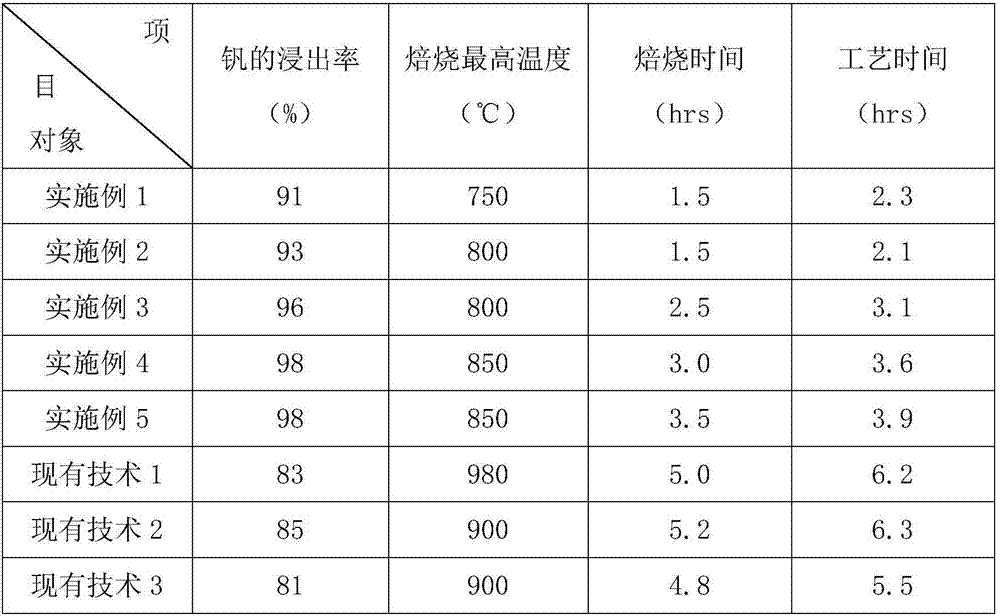

Composite additive used for roasting vanadium extracting and use method of additive

ActiveCN107287410AIncrease conversion rateEasy to extract vanadiumHazardous substanceMixed materials

The invention relates to the technical field of metallurgy, and provides a composite additive used for roasting vanadium extracting. The additive is formed through the step that four materials including, by mass part, 35 parts to 55 parts of sodium materials, 15 parts to 25 parts of calcium materials, 0.5 part to 1 part of vanadium materials and 1 part to 5 parts of titanium materials are mixed and ground to 80 meshes to 100 meshes; the invention further provides a use method of the composite additive used for roasting vanadium extracting. The use method comprises following steps: A, mixing, wherein screened vanadium containing raw materials are selected, and a mixed material with the evenly-mixed composite additive is added; B, roasting, wherein the mixed material is subject to two-time roasting. According to the composite additive and the use method of the additive, the vanadium-contained ore is not likely to generate a liquid phase in the roasting process, the phenomenon of equipment bonding is avoided, toxic and harmful substances are not likely to be generated, the conversion rate and the purity of vanadium can be effectively improved, the roasting time is shortened, the roasting process is simplified, production cost is reduced, and process efficiency is improved.

Owner:CHONGQING KOOPPER CHEM IND

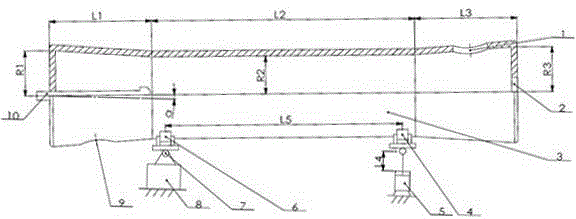

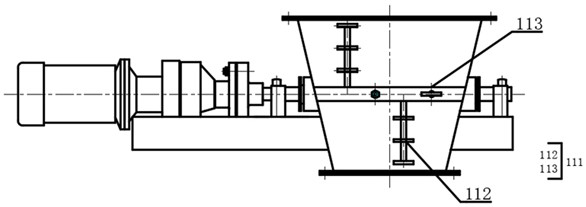

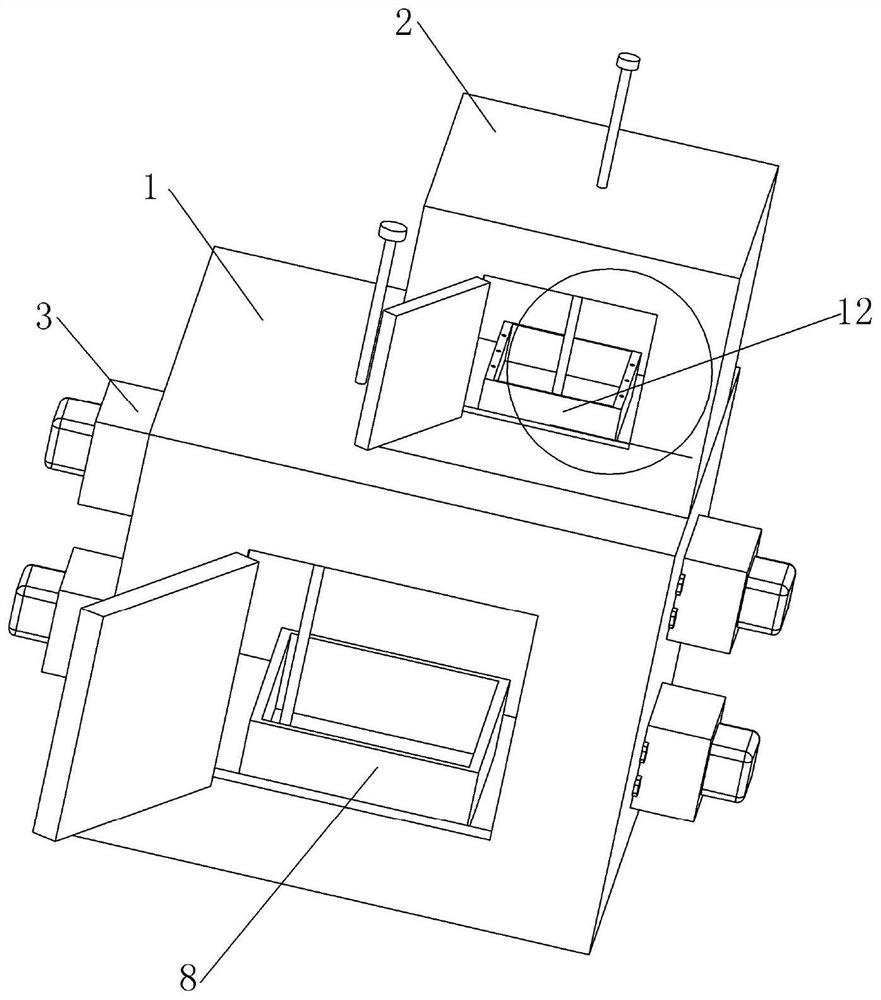

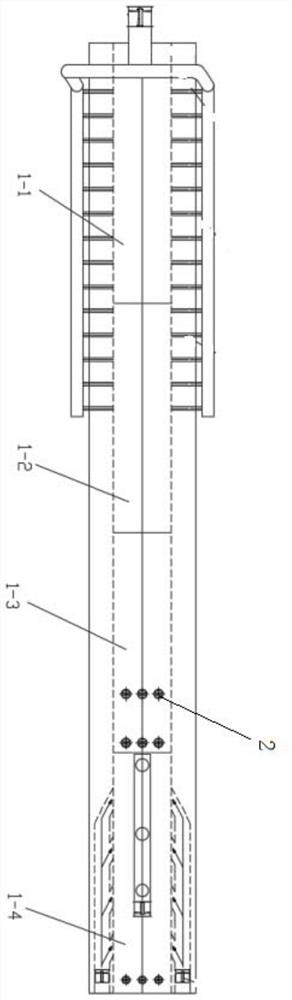

Flaring-type rotary kiln for vanadium extraction of stone coal

ActiveCN103557692AControl the time of roastingEasy to unloadRotary drum furnacesHydraulic cylinderEngineering

The invention relates to a flaring-type rotary kiln for vanadium extraction of stone coal. The technical scheme adopted by the invention is as follows: a left flaring-section kiln body, a straight barrel-section kiln body and a right flaring-section kiln body of a kiln body (3) are of an overall structure; a material outlet (9) is formed at a position adjacent to the left end of the kiln body (3), and a material inlet (1) is formed at a position adjacent to the right end of the kiln body (3); the left end of the interior of the kiln body (3) is coaxially and fixedly provided with a sleeve-type burner (10), and the center of the end face of the right end of the kiln body (3) is provided with a fume outlet (2); the excircle of the straight barrel-section kiln body is provided with a first jockey pulley group (6) and a second jockey pulley group (4); the first jockey pulley group (6) is mounted on a foundation platform (8) by virtue of a rotation pair (7); a bracket of the second jockey pulley group (4) is articulated with a piston rod of a hydraulic cylinder (5). The flaring-type rotary kiln has the characteristics of regulating the inclination angle of the central line of the rotary kiln, improving the preheating capability and heating capability of the rotary kiln, enabling the temperature distribution of the burning zone of the rotary kiln to be uniform and achieving high low-price vanadium conversion rate.

Owner:WUHAN UNIV OF SCI & TECH

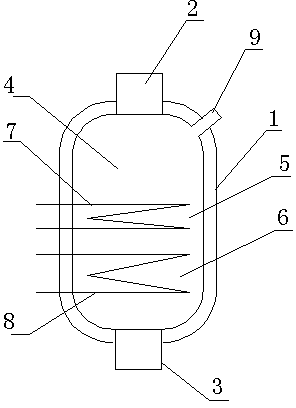

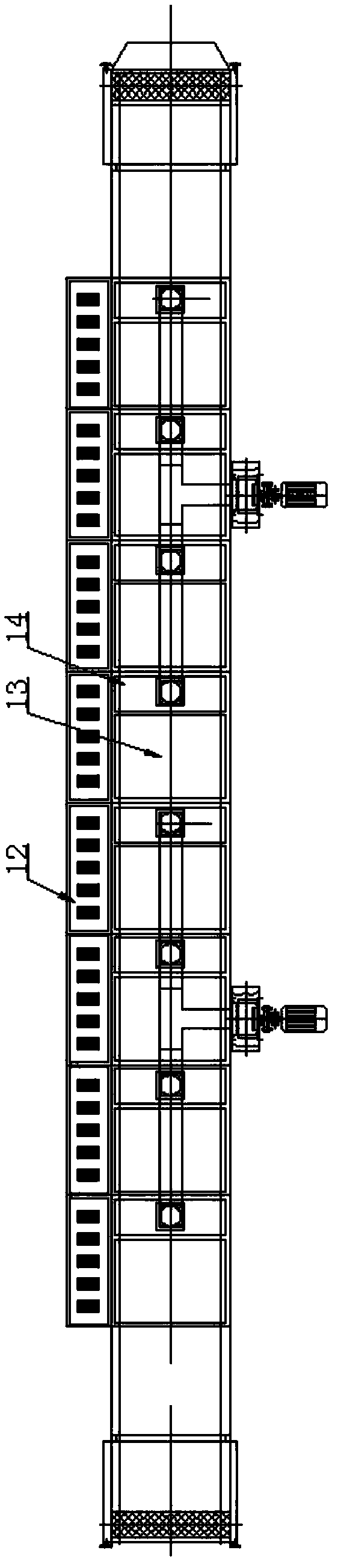

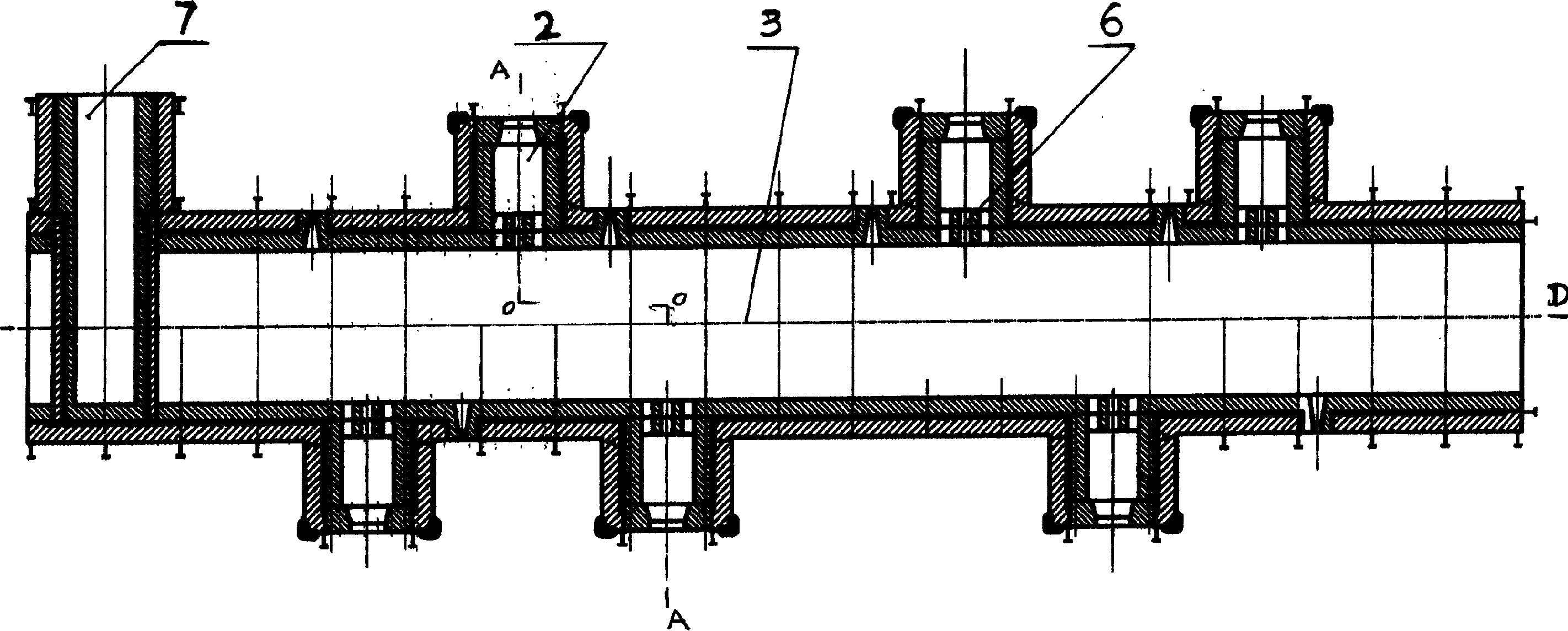

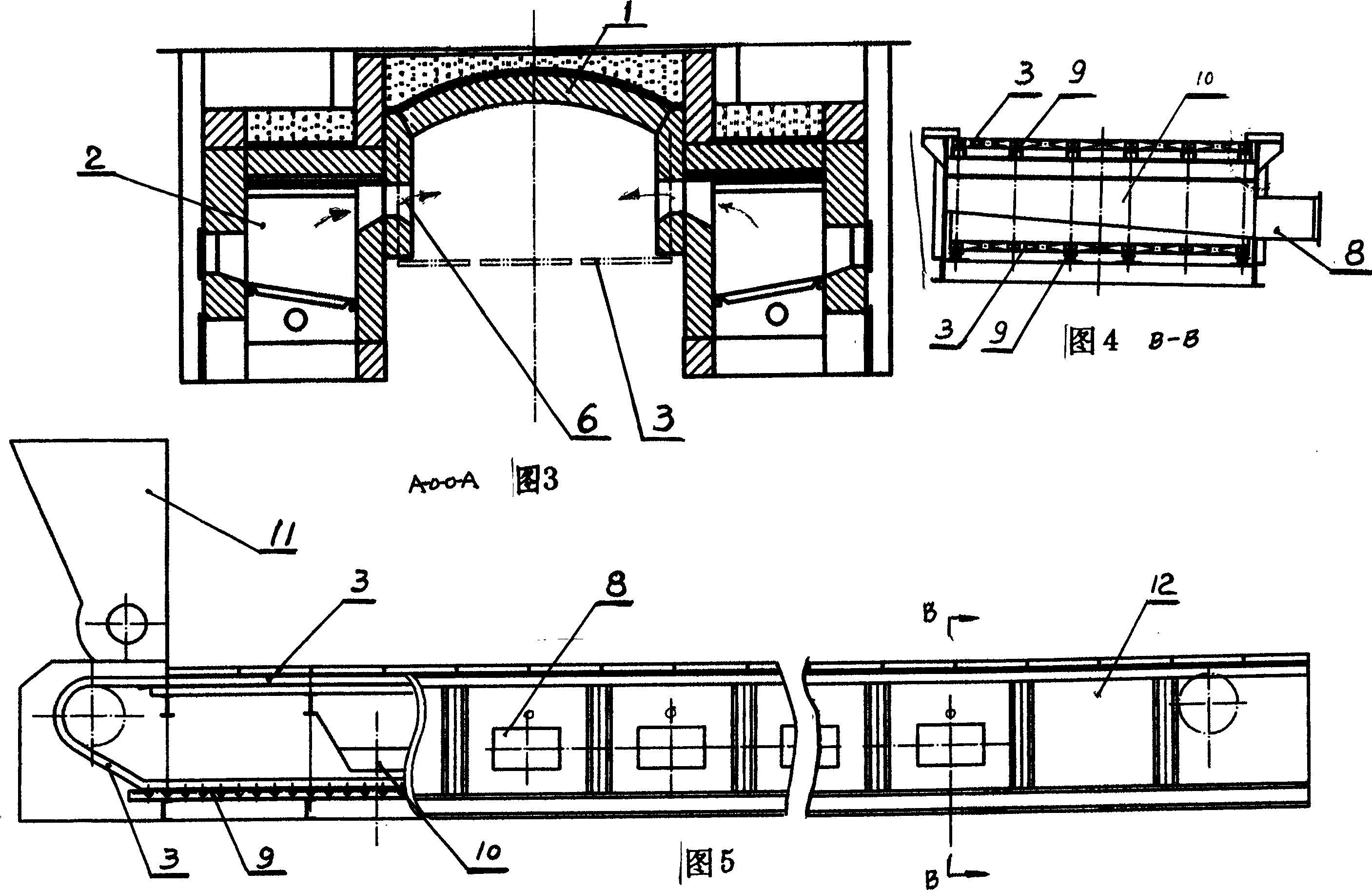

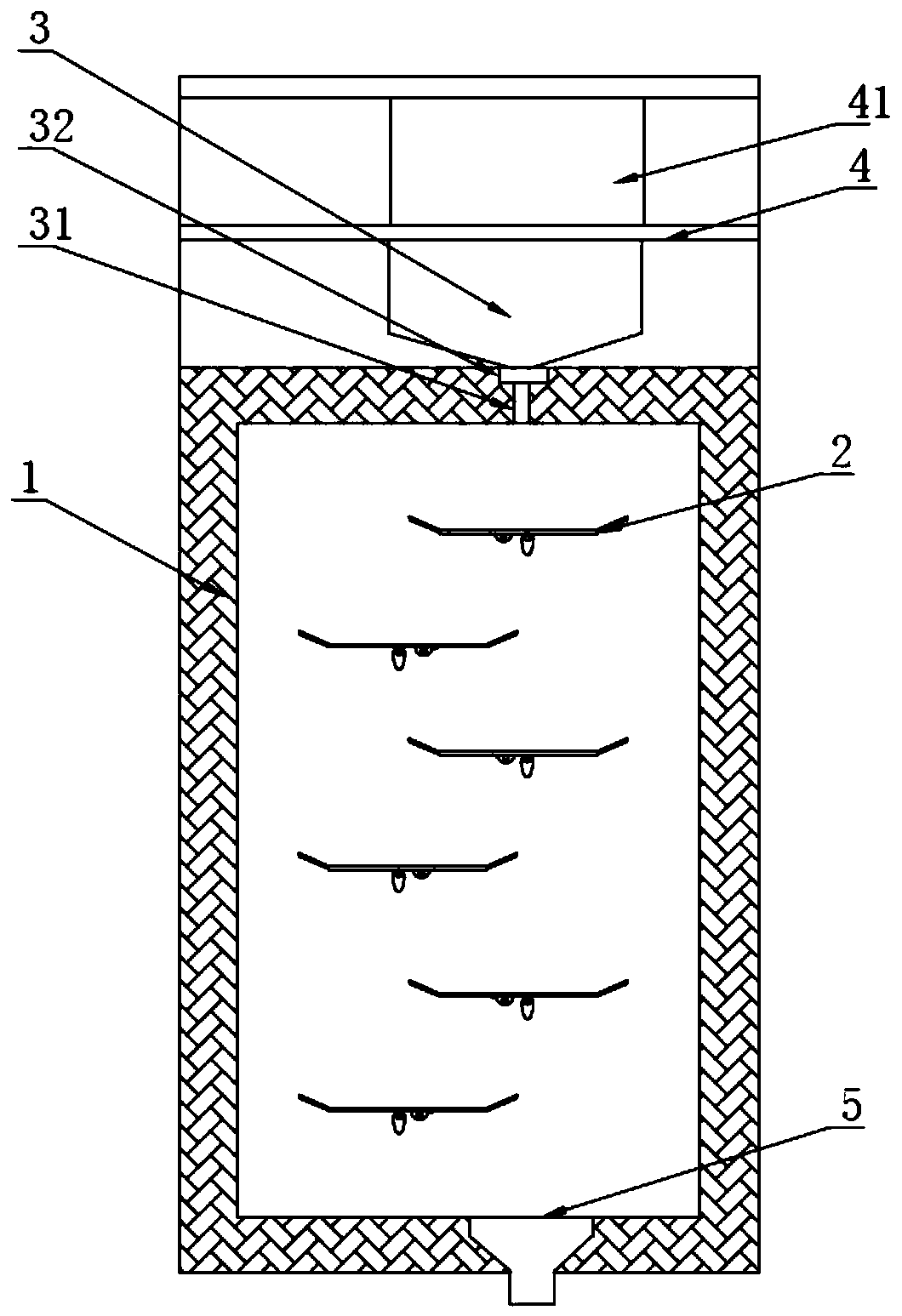

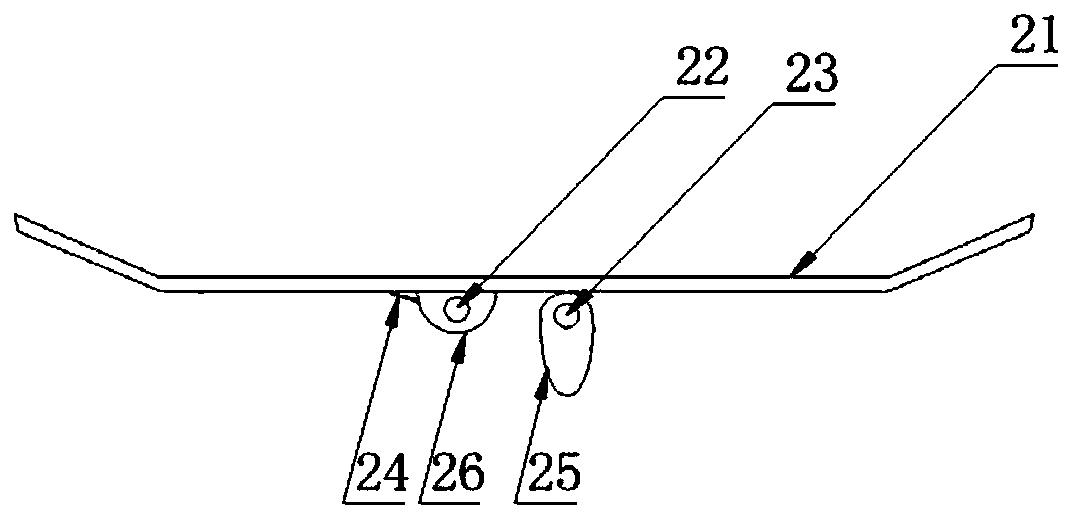

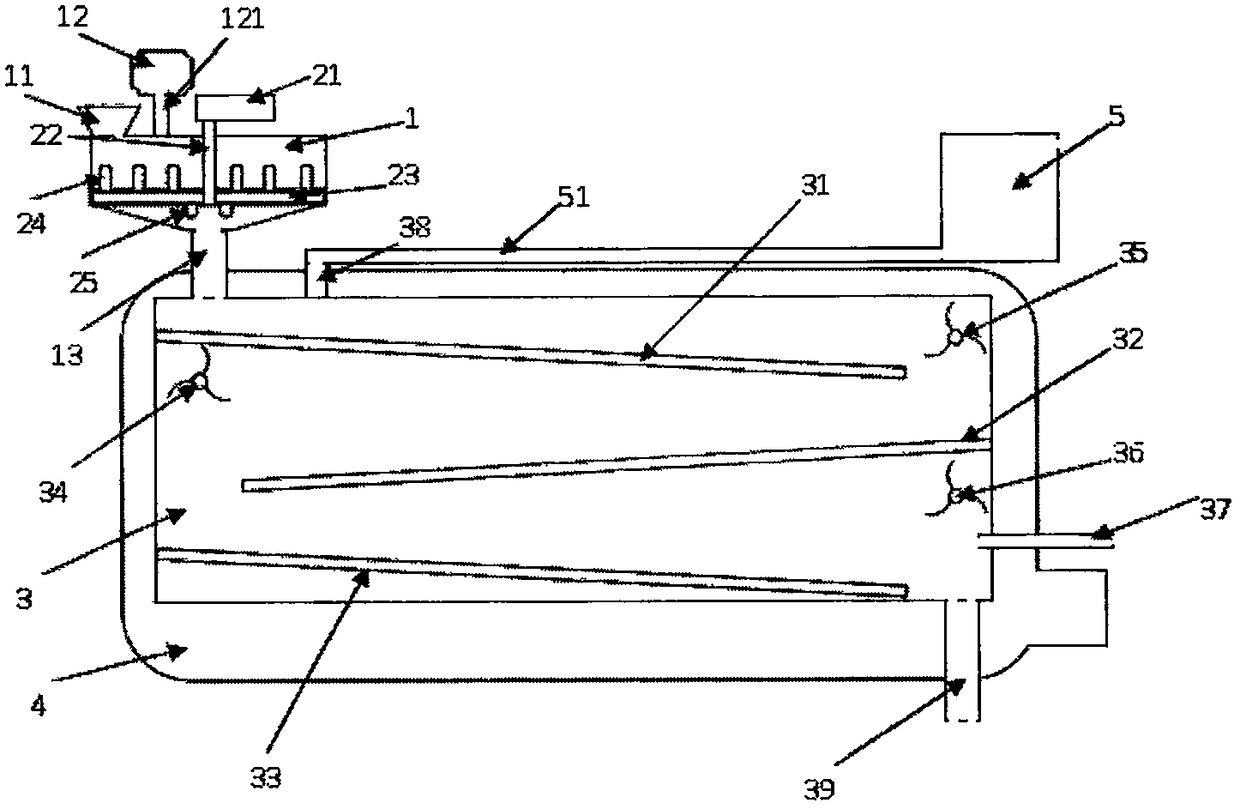

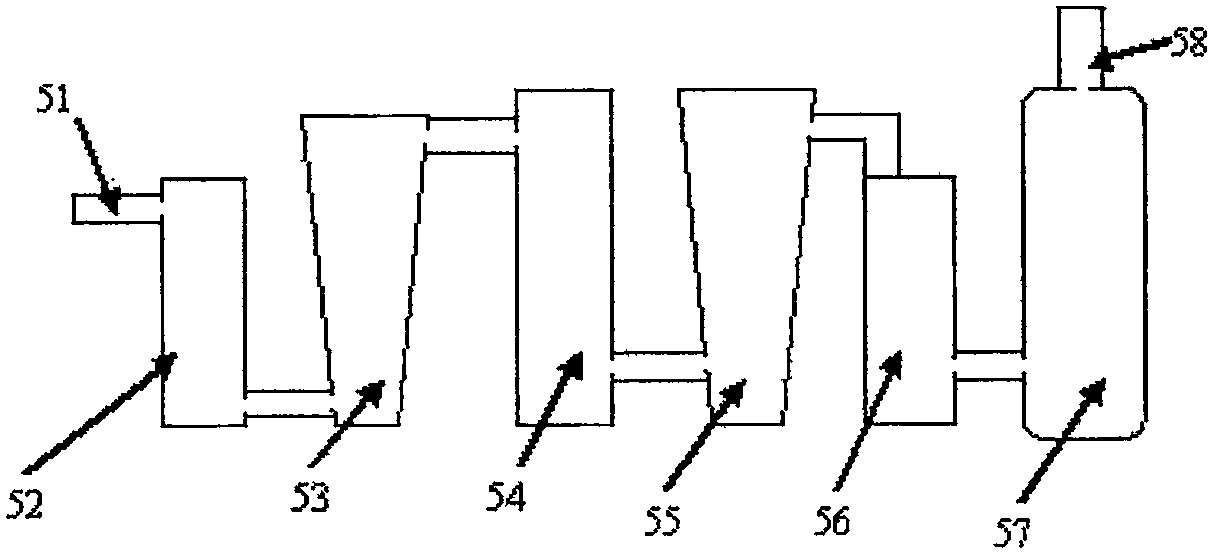

Continuous roasting furnace for vanadium pentoxide

InactiveCN1844819AFully roastedImprove roasting efficiencyFurnace typesAutomatic controlNonferrous metal

The invention discloses an ore continuous bake furnace, which can solve the defects of hearth-furnace and revolution furnace that short bake time and lower weight when continuously baking colorful metallic ore, as vanadic anhydride. Wherein, the hearth comprises a material feeder 12; two sides of bake furnace are distributed with burning furnace 2; the middle of bake furnace is mounted with a material mixer 5; the arc top of furnace 1 has an incline oxygen ejector 4. The invention can realize bath and automatic production, with high baking efficiency, while it can bake vanadic anhydride and other metallic ores.

Owner:胡熙友 +1

Method for recycling waste foundry sand through compound roasting device

ActiveCN109654882AImprove heat transfer effectReduce heat lossMould handling/dressing devicesFluidised-bed furnacesFoundryCold air

The invention discloses a method for recycling waste foundry sand through a compound roasting device. The method for recycling the waste foundry sand through the compound roasting device comprises thefollowing steps that S1, materials enter a receiving tank through a material uniformizing plate, then enter a feeding protection device through an impeller and finally enter a horizontal combustion chamber; S2, the materials are blown and boiled through hot air from the bottom of the combustion chamber to flow from one end of the combustion chamber to the other end of the combustion chamber, andthree-stage roasting is conducted in the flowing process of the materials, wherein the temperature for the first stage of roasting is 300-400 DEG C, and the time for the first stage of roasting is 10-20 s; the temperature for the second stage of roasting is 600-800 DEG C, and the time for the second stage of roasting is 180-240 s; and the temperature for the third stage of roasting is 850-900 DEGC, and the time for the third stage of roasting is 10-20s; and S3, the roasted materials enter an air preheating chamber, exchange heat with cold air to be cooled to 200-300 DEG C and then are discharged, and high-temperature waste gas is exhausted after heat exchange. According to the method for recycling the waste foundry sand through the compound roasting device, the discharge temperature is lower than 300 DEG C, and the furnace temperature can be increased rapidly and can be increased to the material roasting temperature within 30 min; and the exhausted waste gas has a low temperature andcontains few hazardous substances.

Owner:广西兰科资源再生利用有限公司

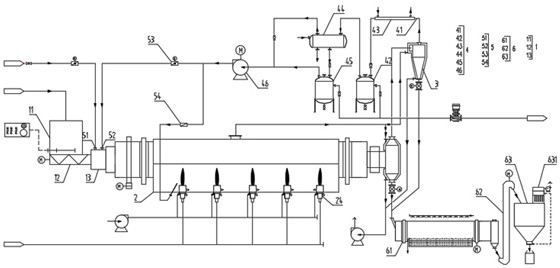

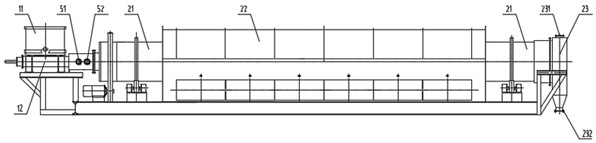

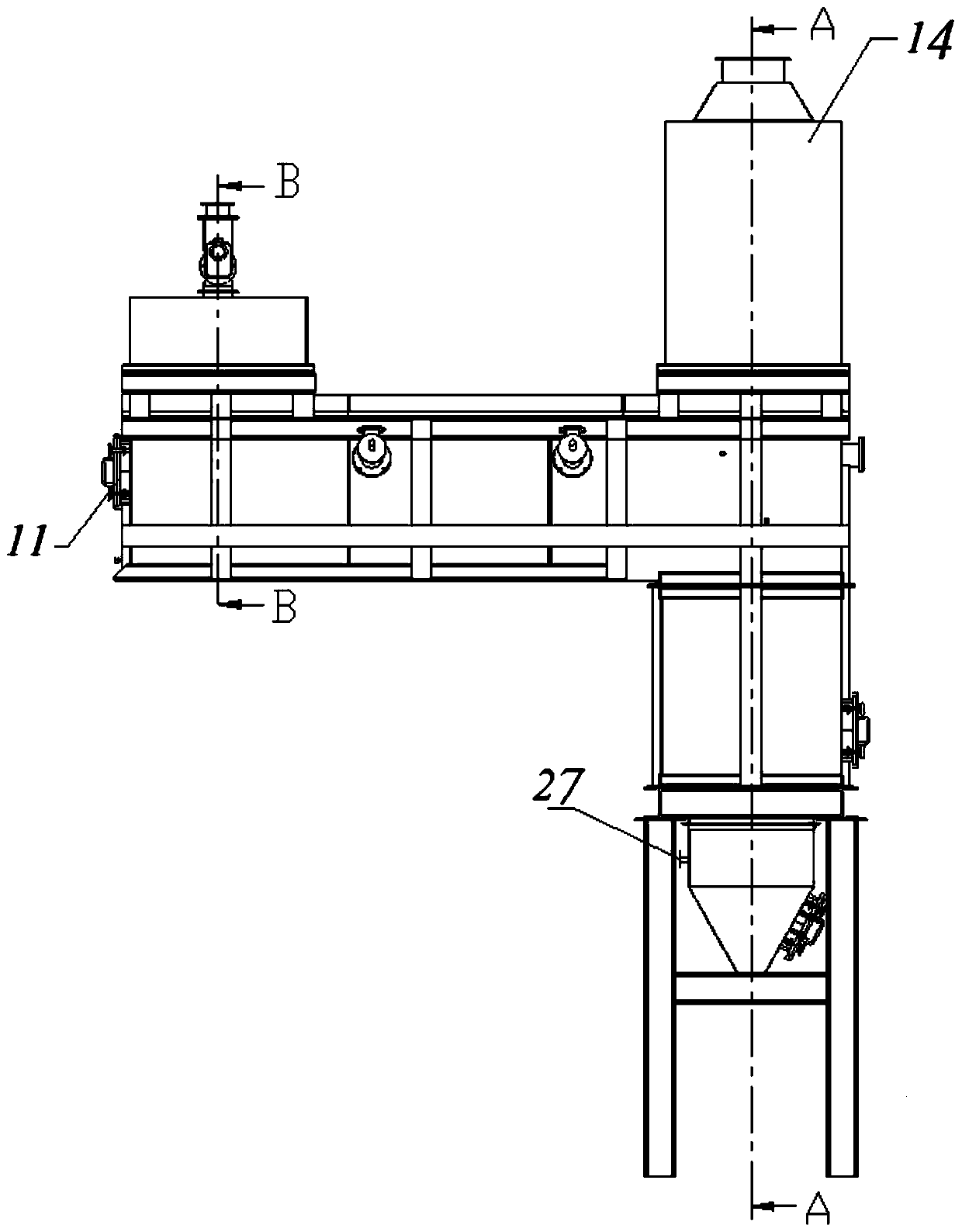

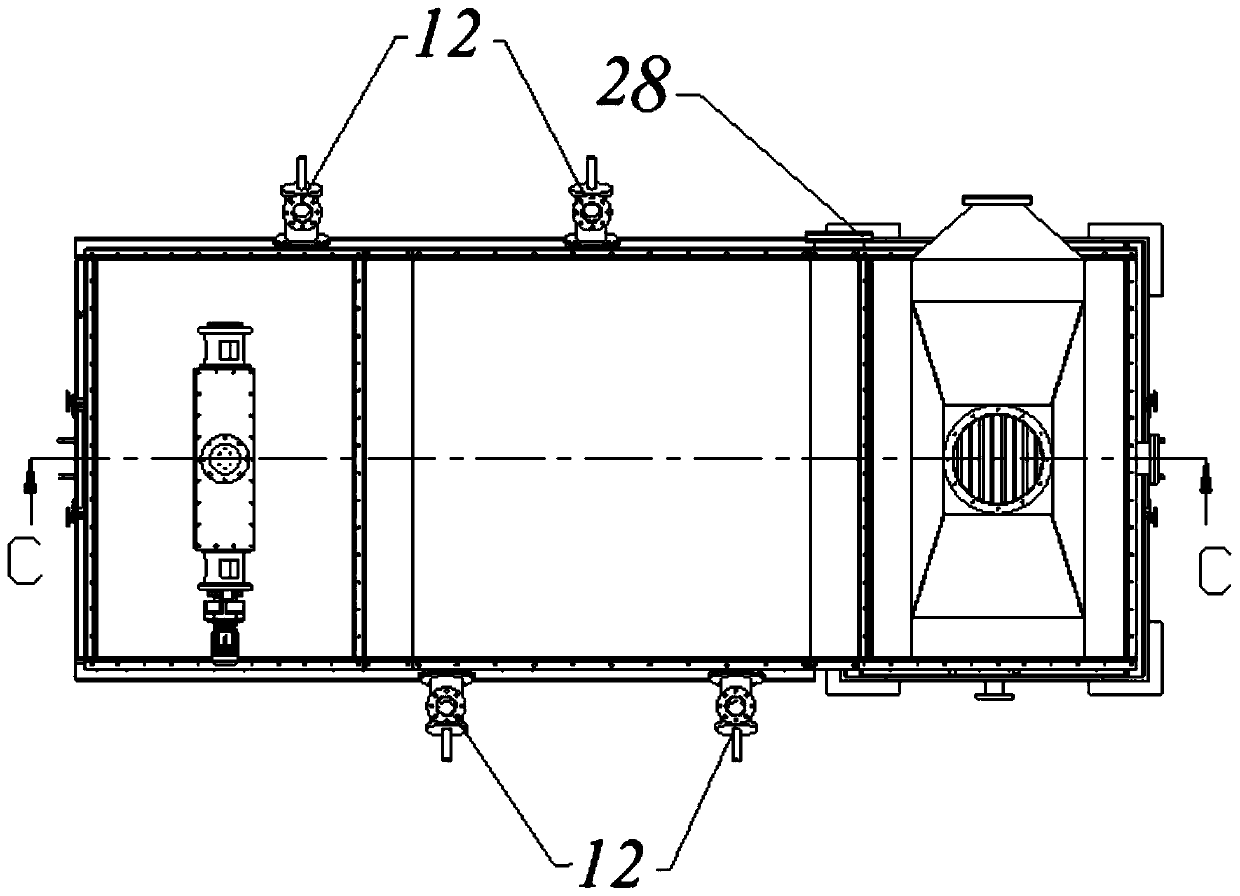

Manganese ore roasting rotary kiln system

The invention relates to a manganese ore roasting rotary kiln system, comprising a batching system, a feeding system, a rotary kiln, a tail gas dust removal system and a gas burner. The batching system comprises a batching belt weigher; the batching belt weigher is provided with a quality inspection device; the feeding system comprises a disc feeder and a feeding chute; the tail gas dust removal system comprises a cooler, a cloth bag type dust remover, an induced draft fan and a chimney; the gas burner comprises a gas burner nozzle and a control valve set; the cooler is provided with a kiln-out tail gas detection device; the kiln-out tail gas detection device detects the content of various smoke in kiln-out tail gas; and the quality inspection device inspects the quality of manganese ore to be batched. When the smoke content in the kiln-out tail gas exceeds a preset value, it is indicated that the roasting reaction in the rotary kiln is insufficient; and the rotary kiln is fed by adjusting the disc feeder and the feeding chute to increase the quality of the manganese ore in the rotary kiln, so that the roasting reaction in the rotary kiln is more sufficient, the emission of smoke is reduced, the cost and resources are saved, and the environmental pollution is reduced.

Owner:内蒙古景蕾实业有限公司

A kind of method for producing mixed rare earth chloride from Baiyun Obo rare earth concentrate

InactiveCN109097559BReduce energy consumptionSave resourcesPolycrystalline material growthRare earth metal chloridesFiltrationWater chlorination

The invention discloses a method for preparing mixed rare earth chloride from Baiyan Obo rare earth concentrate, comprising: mixing Baiyan Obo rare earth concentrate with concentrated sulfuric acid at a mass ratio of 1:(0.7-1.5) and performing three-stage roasting to obtain rare earth roasting ore; after leaching and removing impurities, the obtained rare earth roasted ore is filtered and slag removed, and the filtered filtrate is extracted and transformed to obtain raffinate and loaded organic phase; the loaded organic phase is back-extracted with hydrochloric acid to obtain mixed rare earth chloride solution. The invention adopts low-temperature external heat roasting and the heat source and materials move countercurrently, effectively reducing energy consumption; the three-stage roasting method can further promote the full decomposition of rare earth concentrates, avoid materials sticking to the kiln, and at the same time make the materials roast more fully and effectively reduce tail gas discharge; continuous leaching and countercurrent impurity removal can effectively improve the recovery rate of rare earth concentrate.

Owner:西安西骏新材料有限公司

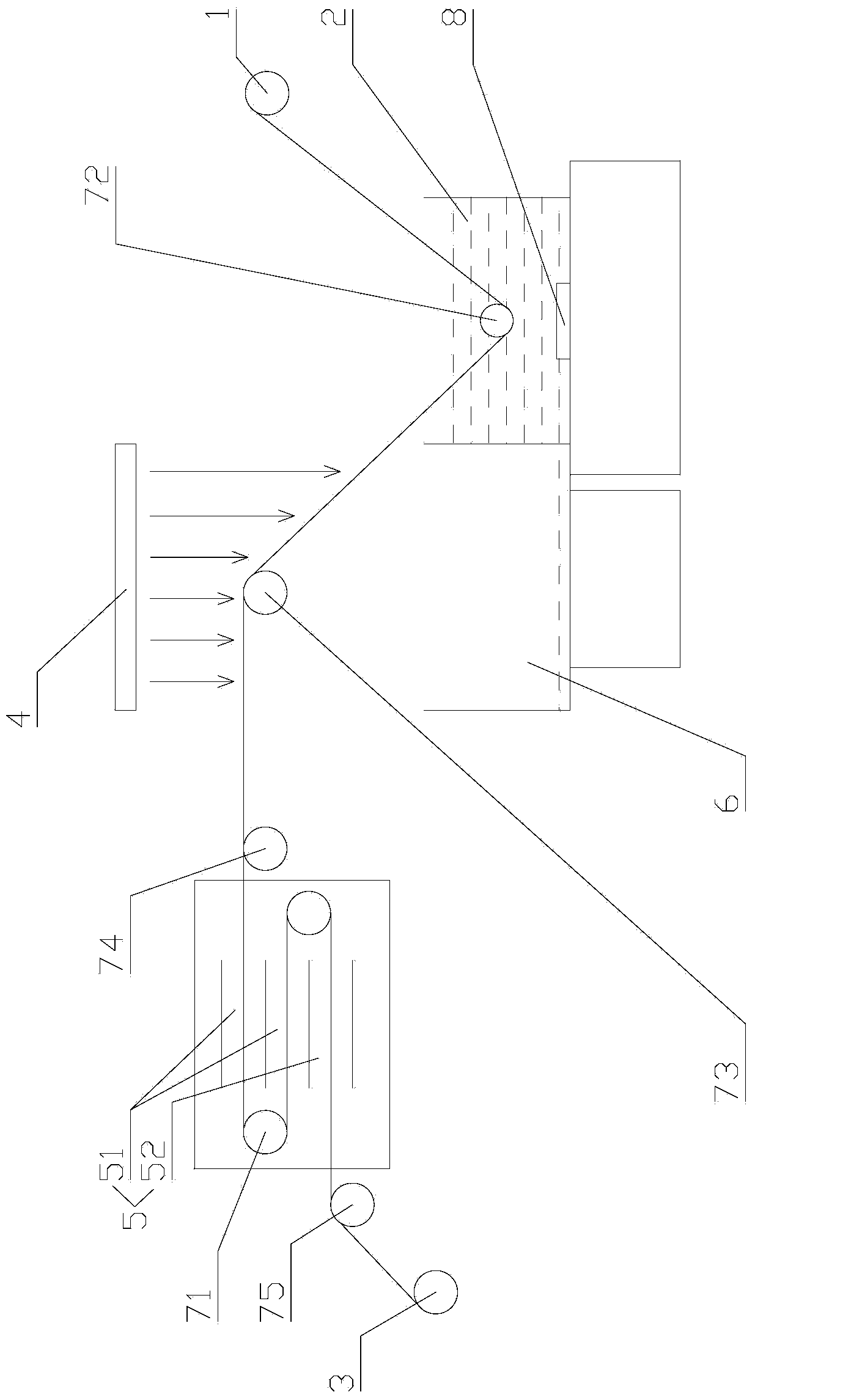

Coating apparatus for active coating on carrier in exhaust particulate trap

ActiveCN103817044AConsistent thicknessSimple structurePretreated surfacesCoatingsParticulatesTunnel kiln

The invention discloses a coating apparatus for an active coating on a carrier in an exhaust particulate trap. The coating apparatus is equipped with a unreeling shaft, a coating tank, a rapid drier, a tunnel kiln and a reeling shaft in sequence along a conveying direction of the carrier, wherein the tunnel kiln comprises M (M is an integer and is larger than or equal to 2) isolation areas which are arranged from up to down; the carrier passing through the former isolation area enters into the following isolation area through a steering shaft; N isolation areas (N is an integer and N is smaller than M but larger than or equal to 1) disposed at the upper part are roasting areas, each roasting area being connected to a first control unit for adjusting temperature and hot wind power; the temperature at a following roasting area is higher than that of the former roasting area; and M-N isolation areas disposed at the lower part are cooling areas, each cooling area being connected to a second control unit for adjusting cold wind volume and measuring the temperature of the cooling area. The coating apparatus realizes integrated operation from coating, drying, roasting and winding and shaping. The coating apparatus is simple in structure and low in cost, is simple and convenient for operation, saves labor and is uniform in coating.

Owner:ZHEJIANG DA FENG AUTOMOBILE TECH

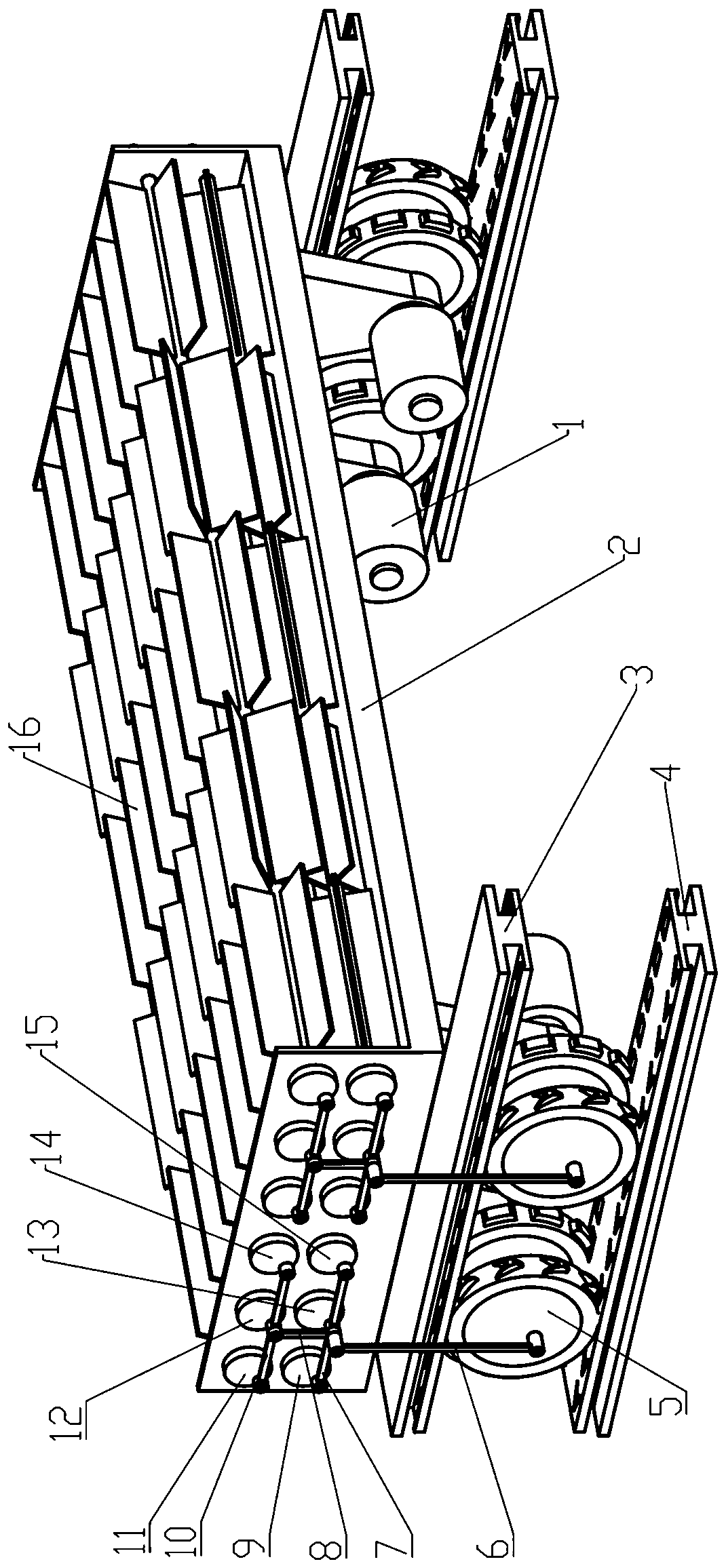

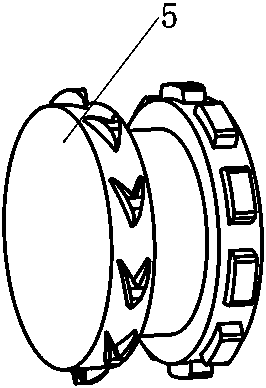

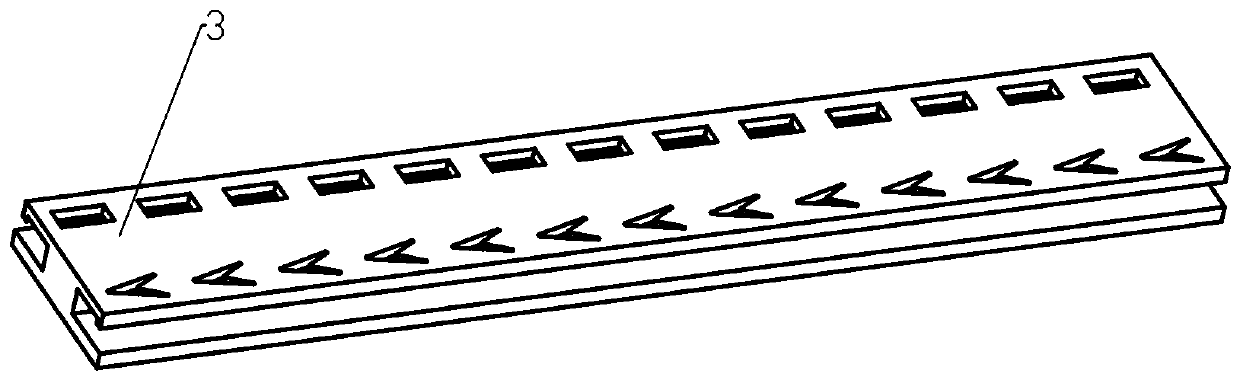

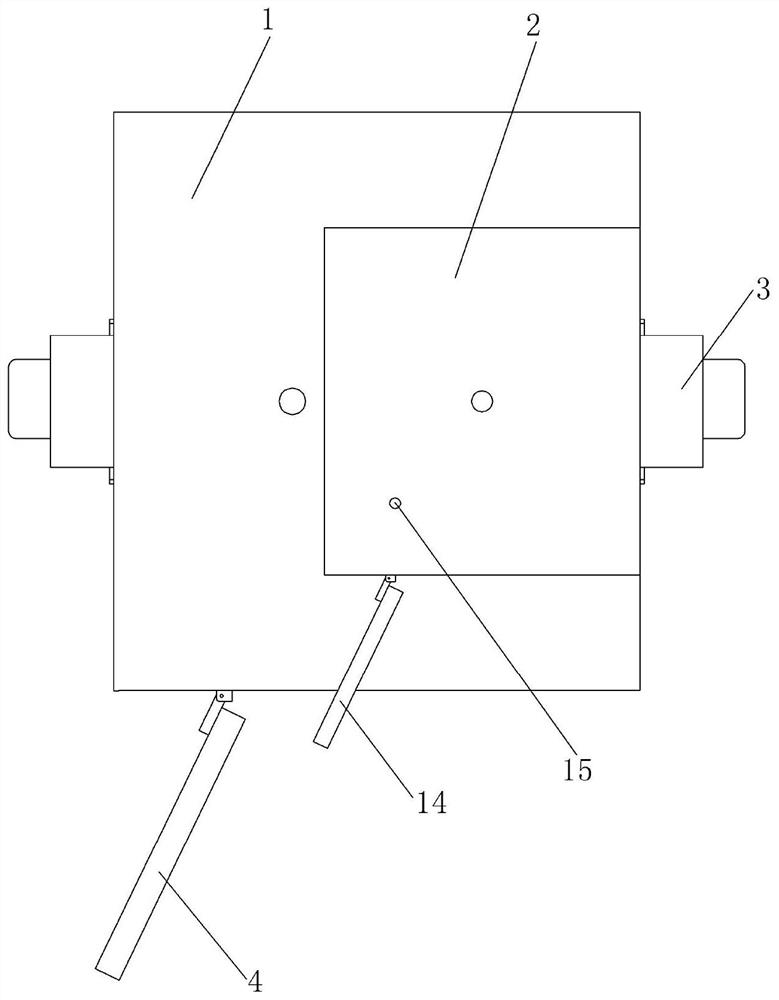

Device for fully roasting pellets in belt type roasting machine

In order to solve the problem of influence on the quality of pellets due to inconsistent raw material roasting of the belt type roasting machine, the invention provides a device for fully roasting pellets in the belt type roasting machine. The device comprises a power system and a transmission system, wherein the power system is mainly composed of double gear wheels, a guide rail, a rolling wheeland a power connecting rod, and the transmission system is composed of a mixing rod group and a connecting rod mechanism. The problem of influence on the quality of the pellets due to inconsistent rawmaterial roasting in a bogie can be effectively prevented.

Owner:江苏宏大特种钢机械厂有限公司

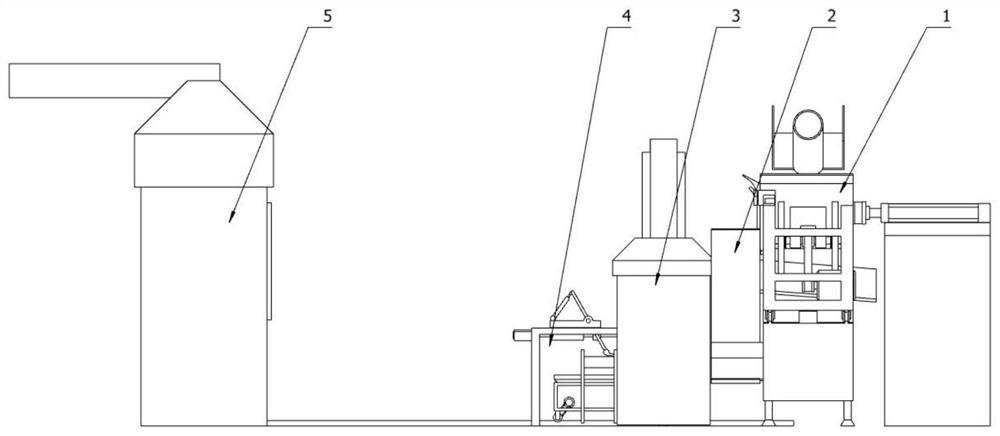

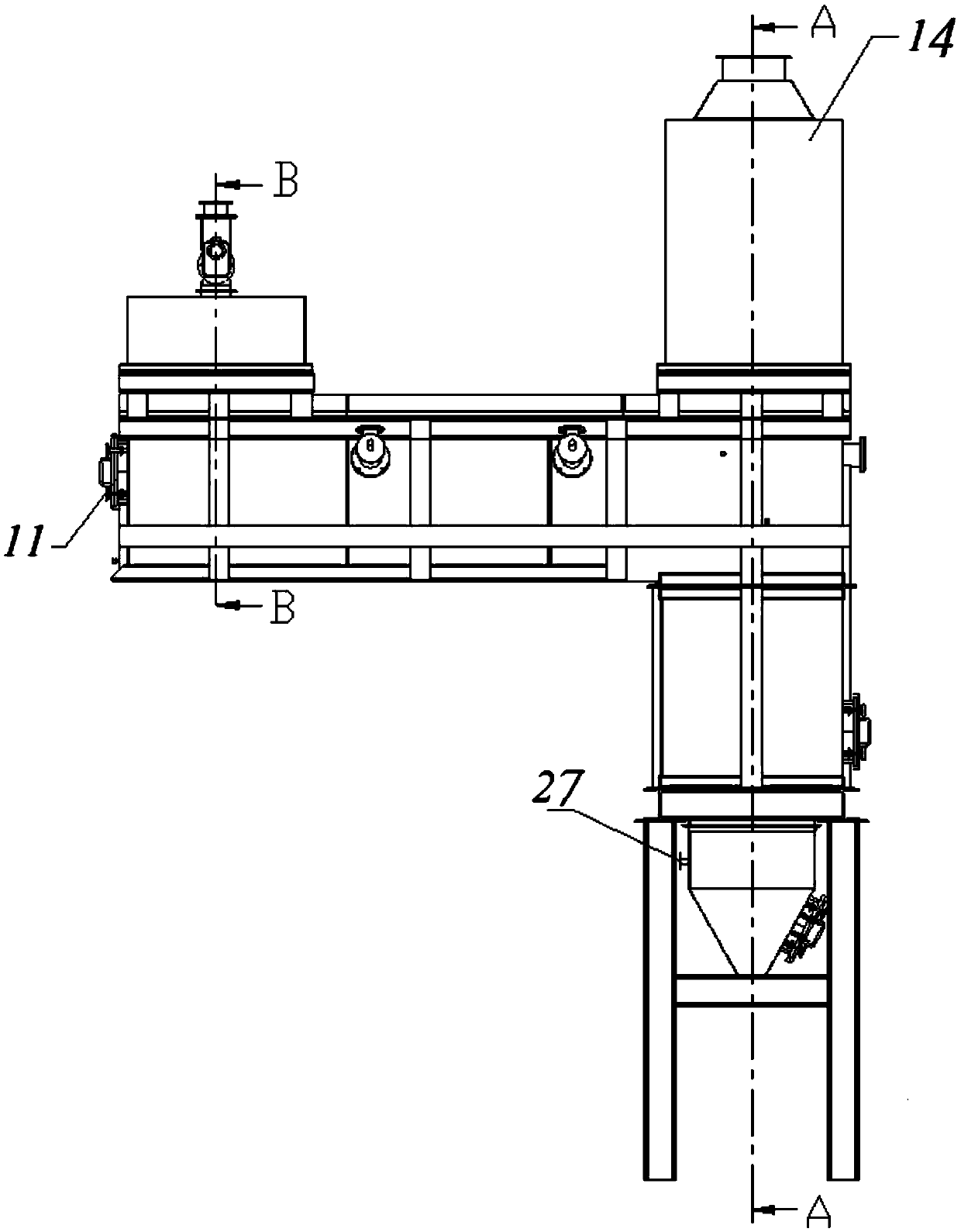

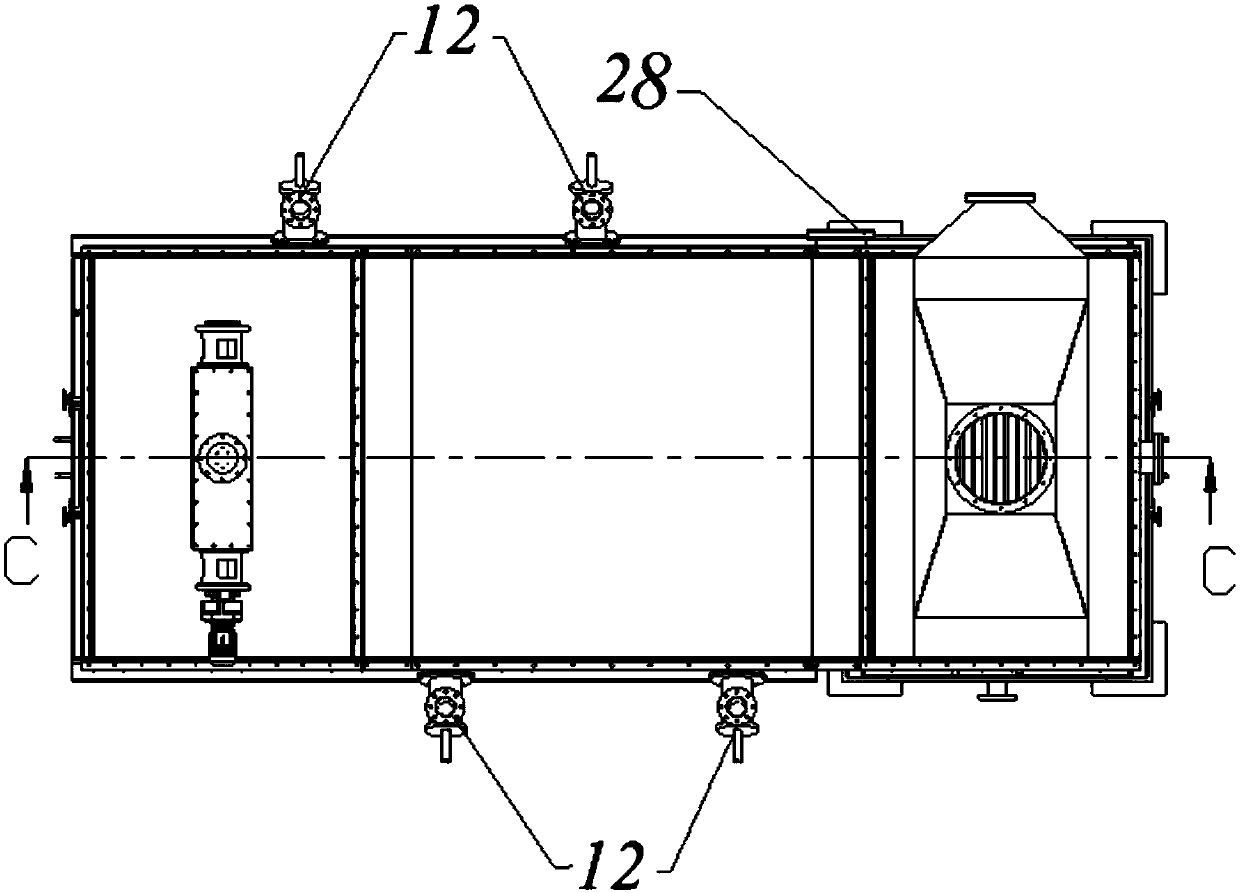

Closed-loop circulation roasting oil extraction system and process

PendingCN111996067AReduce dosageReduce consumptionFatty-oils/fats refiningFatty-oils/fats productionThermodynamicsProcess engineering

The invention provides a closed-loop circulation roasting oil extraction system and process. The system comprises a conveying and feeding device, a rotary roasting device, a gas-dust separation device, a fractional condensation device, a closed circulation and non-condensable gas treatment device and a material treatment device. With the closed-loop circulation roasting oil extraction system adopted, the problems of low safety, high possibility of the blockage of an oil-gas outlet pipeline, insufficient roasting, and low actual oil yield of an open system in the prior art can be effectively solved. According to the system and process of the invention, nitrogen is introduced into the system for closed circulation, the oxygen content in the system is strictly controlled to be within 10%, sothat explosion danger is eradicated, and meanwhile the nitrogen consumption and energy consumption are reduced. A downstream process is adopted to prevent an oil-gas outlet pipeline from being blocked, materials are fully roasted, and the oil yield is high. Continuous and efficient production of the whole system is achieved through effective connection of all devices and efficient utilization of energy.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

A method for recycling foundry waste sand based on compound roasting equipment

ActiveCN109654882BImprove heat transfer effectReduce heat lossMould handling/dressing devicesFluidised-bed furnacesFoundryCold air

The invention discloses a method for recycling waste foundry sand through a compound roasting device. The method for recycling the waste foundry sand through the compound roasting device comprises thefollowing steps that S1, materials enter a receiving tank through a material uniformizing plate, then enter a feeding protection device through an impeller and finally enter a horizontal combustion chamber; S2, the materials are blown and boiled through hot air from the bottom of the combustion chamber to flow from one end of the combustion chamber to the other end of the combustion chamber, andthree-stage roasting is conducted in the flowing process of the materials, wherein the temperature for the first stage of roasting is 300-400 DEG C, and the time for the first stage of roasting is 10-20 s; the temperature for the second stage of roasting is 600-800 DEG C, and the time for the second stage of roasting is 180-240 s; and the temperature for the third stage of roasting is 850-900 DEGC, and the time for the third stage of roasting is 10-20s; and S3, the roasted materials enter an air preheating chamber, exchange heat with cold air to be cooled to 200-300 DEG C and then are discharged, and high-temperature waste gas is exhausted after heat exchange. According to the method for recycling the waste foundry sand through the compound roasting device, the discharge temperature is lower than 300 DEG C, and the furnace temperature can be increased rapidly and can be increased to the material roasting temperature within 30 min; and the exhausted waste gas has a low temperature andcontains few hazardous substances.

Owner:广西兰科资源再生利用有限公司

A continuous and rapid roasting equipment for powder or granular materials

The invention provides continuous quick roasting equipment for powder or particle materials, and the equipment is suitable for the field of lithium batteries. In the equipment, the to-be-roasted materials fall into roasting discs on the top from distribution hoppers, rotary shafts below the current roasting discs are controlled to rotate after roasting is carried out for a period of time, the materials in the discs are poured into roasting discs on the lower layer and continue to be roasted, similarly, the materials in the roasting discs on the second layer continue to be poured into roastingdiscs on the third layer, the operation is conducted repeatedly till the materials in roasting discs on the lowermost layer are poured out, finally the materials fall out of discharge hoppers at the bottom, and the process is carried out repeatedly; and if the current roasting discs contain the materials, only after the materials in the discs are poured to the roasting discs on the lower layer canthe roasting discs receive the materials from the roasting discs on the upper layer. As the materials scatter into the roasting discs of the lower layer when transferred from one roasting disc to thenext roasting discs, the materials are roasted in a furnace more safely through a plurality of cycles, the effect is better, and besides, as the materials are continuously roasted, the working efficiency is improved.

Owner:JINGMEN GEM NEW MATERIAL

A microwave high-temperature roasting reduction method for nickel-containing sludge

ActiveCN109517972BAvoid the phenomenon of slow heatingImprove heating efficiencySludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisSludgePhysical chemistry

The invention relates to a microwave high-temperature roasting reduction method for nickel-containing sludge, which mainly uses a double-cavity microwave high-temperature roasting method to fully utilize the waste heat of high-temperature roasting, so that the heated nickel-containing sludge can be dehydrated again before entering the microwave field , and at the same time achieve the best microwave absorption state, effectively avoid the slow temperature rise phenomenon caused by poor material absorption characteristics in the low temperature stage, increase the heating efficiency, and can effectively eliminate the disadvantages of a small amount of microwave radiation leaking from the gas outlet in traditional equipment. In the present invention, dry air is introduced during the heating and roasting process, so as to fully preheat the nickel-containing sludge and improve the high-temperature roasting effect of the nickel-containing sludge. The invention utilizes microwave heating technology to enrich valuable metals, and at the same time peels off the coating layer formed by gelled insoluble matter and gangue components in the material, providing conditions for the extraction of valuable metals in waste residues.

Owner:HEFEI WISDOM DRAGON MACHINERY DESIGN CO LTD

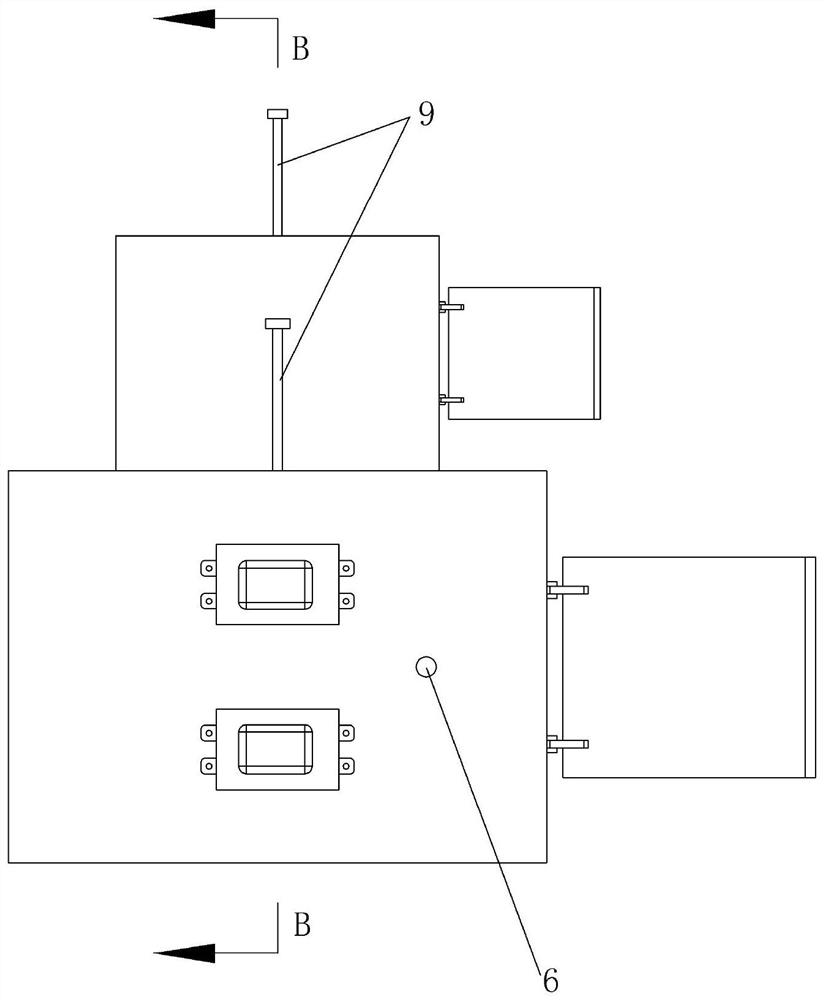

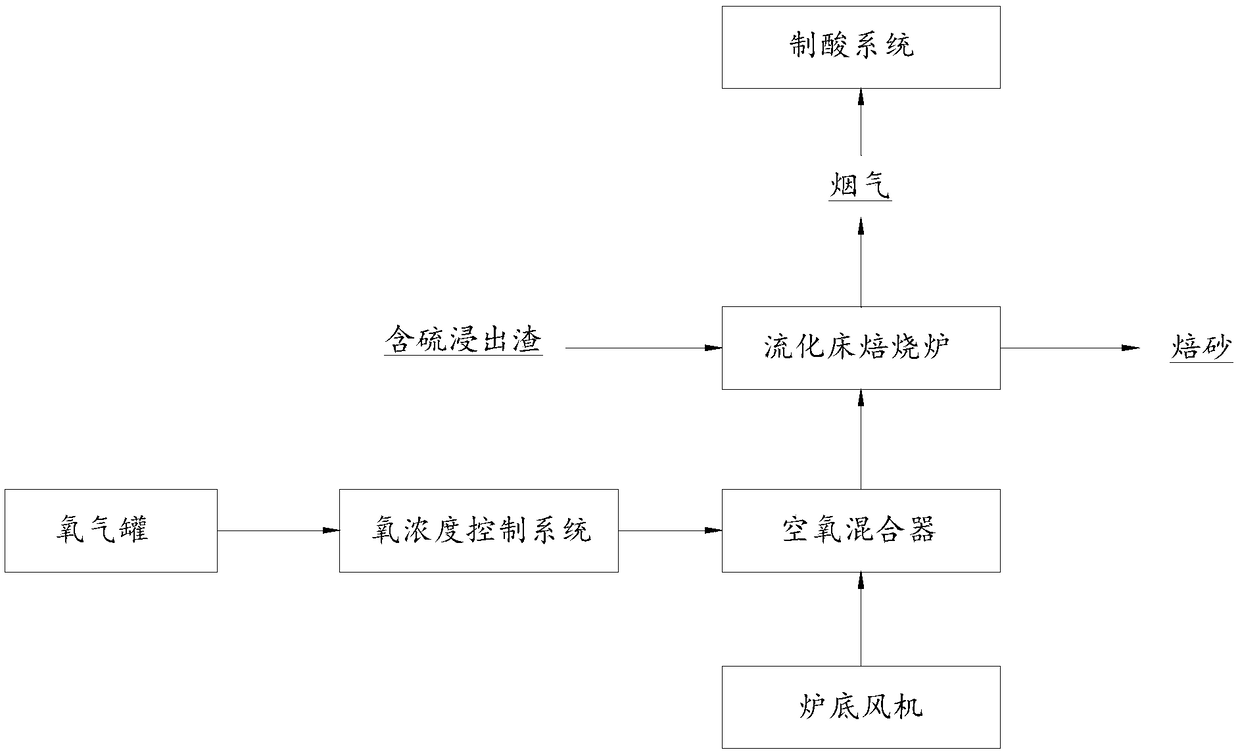

Treatment method for sulfur-containing leaching residues, and application thereof

InactiveCN108754168AIncrease concentrationReduce the amount requiredProcess efficiency improvementHydrometallurgySulfur containing

The invention relates to the field of metallurgy, and discloses a treatment method for sulfur-containing leaching residues, and an application thereof. The treatment method for sulfur-containing leaching residues is characterized in that the sulfur-containing leaching residues which are in a fluidized state in a mixed gas are calcined, and the mixed gas comprises above 22 volume% of oxygen. The method can be used to make valuable metals in the sulfur-containing leaching residues enriched in calcine in order to achieve reuse. Combustion in an oxygen-rich atmosphere increases the calcination efficiency and makes the calcination complete and thorough. High oxygen content makes smoke obtained after the calcinations of the same amount of the sulfur-containing leaching residues have a small total amount and improves the concentration of SO2 in the smoke, so the SO2 can be easily recovered by an acid preparation system, and the investment and the energy for the acid preparation are reduced. The treatment method also improves the recovery efficiency of waste heat, so the steam output is increased, and the steam provides a heat source for production or life, thereby the energy saving effectis good. The treatment method for sulfur-containing leaching residues can be applied to a hydrometallurgical process.

Owner:CHINA NERIN ENG

A Calculation Method for Opening Quantity of Inlet Fans on the Top of Brick-fired Tunnel Kiln

The invention relates to a method for calculating the opening quantity of air inlet fans at the top of a brick-burning tunnel kiln. The method comprises the following steps of measuring the fuel heatquantity F required per hour for a certain section of a roasting kiln and the actual air quantity K required for complete combustion of every 1000 kilocalories of fuel, and calculating the air quantity Q required per hour for a certain section of the roasting kiln according to the formula Q=K*F so as to calculate the opening quantity n of feeding fans according to the quantity q of air conveyed per hour by each fan. According to the method, the feeding fans are arranged at the top of a heat preservation zone area, and sufficient oxygen is conveyed into a high-temperature roasting zone area through the feeding fans, so that roasting under the condition of no sufficient oxygen, caused by hot air extraction in a cooling zone area, in the high-temperature roasting zone area is prevented, sufficient roasting of brick blanks can be ensured, and the role of improving the practical performance can be played.

Owner:CHANGZHOU GUICHENG BUILDING MATERIALS CO LTD

Method for recycling indium and germanium from alkali slag

ActiveCN101476042BGuaranteed to blockIncrease relative volatilityProcess efficiency improvementChemical industryIndium

Owner:YANGZHOU NINGDA NOBLE METAL CO LTD

Coating device for active coating on carrier in exhaust gas particle trap

ActiveCN103817044BConsistent thicknessSimple structurePretreated surfacesCoatingsRegulation temperatureTunnel kiln

The invention discloses a coating apparatus for an active coating on a carrier in an exhaust particulate trap. The coating apparatus is equipped with a unreeling shaft, a coating tank, a rapid drier, a tunnel kiln and a reeling shaft in sequence along a conveying direction of the carrier, wherein the tunnel kiln comprises M (M is an integer and is larger than or equal to 2) isolation areas which are arranged from up to down; the carrier passing through the former isolation area enters into the following isolation area through a steering shaft; N isolation areas (N is an integer and N is smaller than M but larger than or equal to 1) disposed at the upper part are roasting areas, each roasting area being connected to a first control unit for adjusting temperature and hot wind power; the temperature at a following roasting area is higher than that of the former roasting area; and M-N isolation areas disposed at the lower part are cooling areas, each cooling area being connected to a second control unit for adjusting cold wind volume and measuring the temperature of the cooling area. The coating apparatus realizes integrated operation from coating, drying, roasting and winding and shaping. The coating apparatus is simple in structure and low in cost, is simple and convenient for operation, saves labor and is uniform in coating.

Owner:ZHEJIANG DA FENG AUTOMOBILE TECH

A low-grade iron ore beneficiation equipment and method thereof

The invention discloses a low-grade iron ore beneficiation equipment and a method thereof. The equipment includes a No. 1 furnace, a No. 2 furnace, and a cooling reduction system. The roasted material enters the cylinder of the No. 1 furnace through the top of the No. 1 furnace for distribution, dehydration, drying, preheating and low-temperature roasting. After low-temperature roasting, the roasted material and reducing agent enter the No. 2 furnace, where they are mixed and reduced, and then enter the cooling reduction system. The reduced roasted material passes through the reduction pipe of the cooling reduction system for secondary supplementary reduction, and then passes through the cooling pipe for cooling, and then is sent to the quenching pool for quenching operation. Cloth, dehydration, drying, preheating, low-temperature roasting, unloading, reduction, secondary reduction and cooling operations are all carried out in a rotating state. The invention can overcome the technical defects of poor beneficiation effect on low-grade iron ore, low beneficiation recovery rate and large waste of resources in the existing beneficiation method.

Owner:俞佳鹏

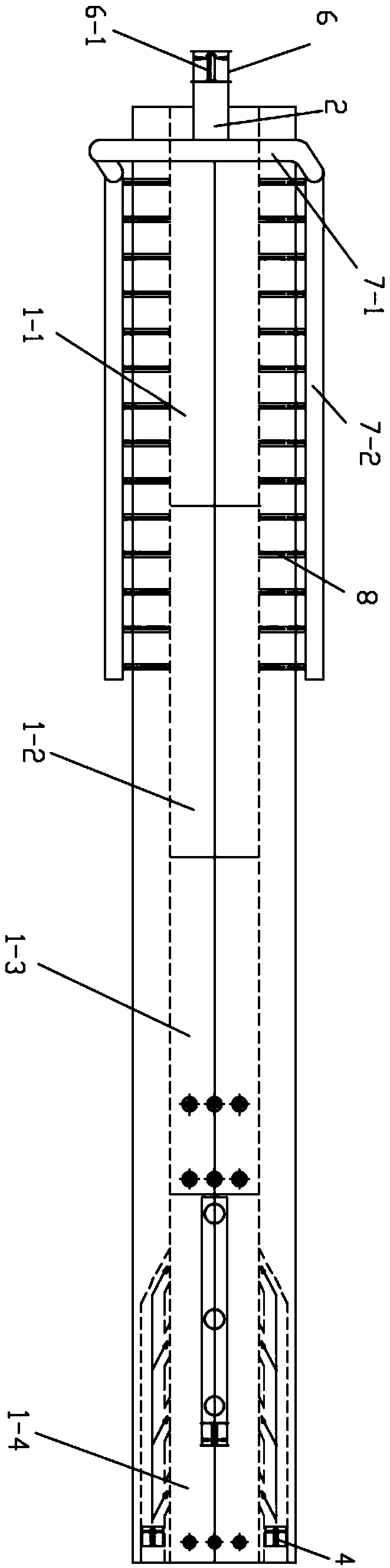

Necking-type rotary kiln for vanadium extraction of stone coal

ActiveCN103557694BProlong oxidation roasting timeFully roastedRotary drum furnacesHydraulic cylinderEngineering

The invention relates to a necking-type rotary kiln for vanadium extraction of stone coal. The technical scheme adopted by the invention is as follows: a left necking-section kiln body, a straight barrel-section kiln body and a right necking-section kiln body of a kiln body (3) are of a coaxial overall structure; a material outlet (9) is formed at a position adjacent to the left end of the kiln body (3), and a material inlet (1) is formed at a position adjacent to the right end of the kiln body (3); the left end of the interior of the kiln body (3) is coaxially and fixedly provided with a sleeve-type burner (10), and the center of the end face of the right end of the kiln body (3) is provided with a fume outlet (2); the excircle of the straight barrel-section kiln body is provided with a first jockey pulley group (6) and a second jockey pulley group (4); the first jockey pulley group (6) is mounted on a foundation platform (8) by virtue of a rotation pair (7); a bracket of the second jockey pulley group (4) is articulated with a piston rod of a hydraulic cylinder (5). The necking-type rotary kiln for vanadium extraction of stone coal has the characteristics of prolonging the burning time of materials in the rotary kiln, regulating the inclination angle alpha of the central line of the rotary kiln and improving the low-price vanadium conversion rate.

Owner:WUHAN UNIV OF SCI & TECH

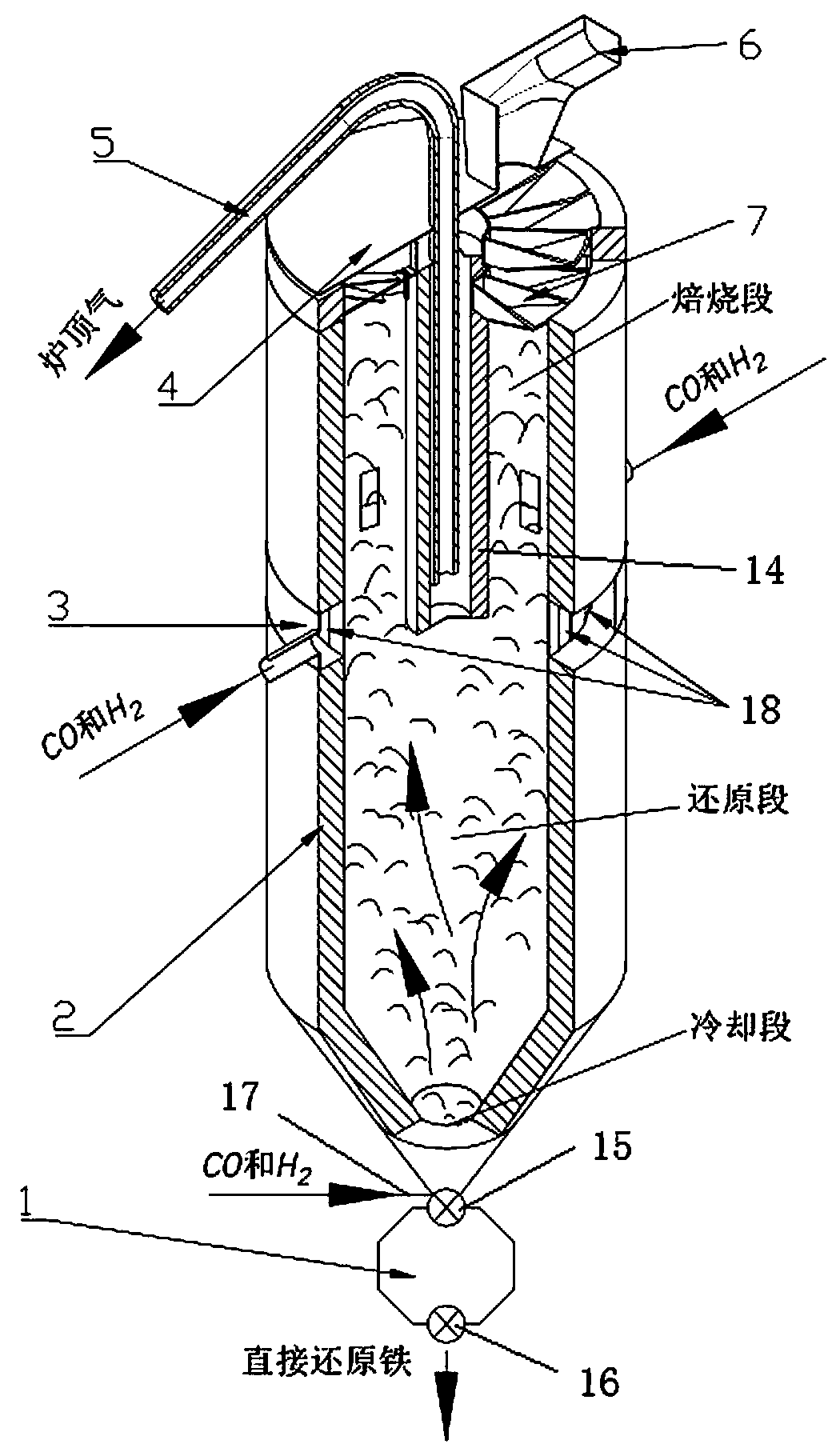

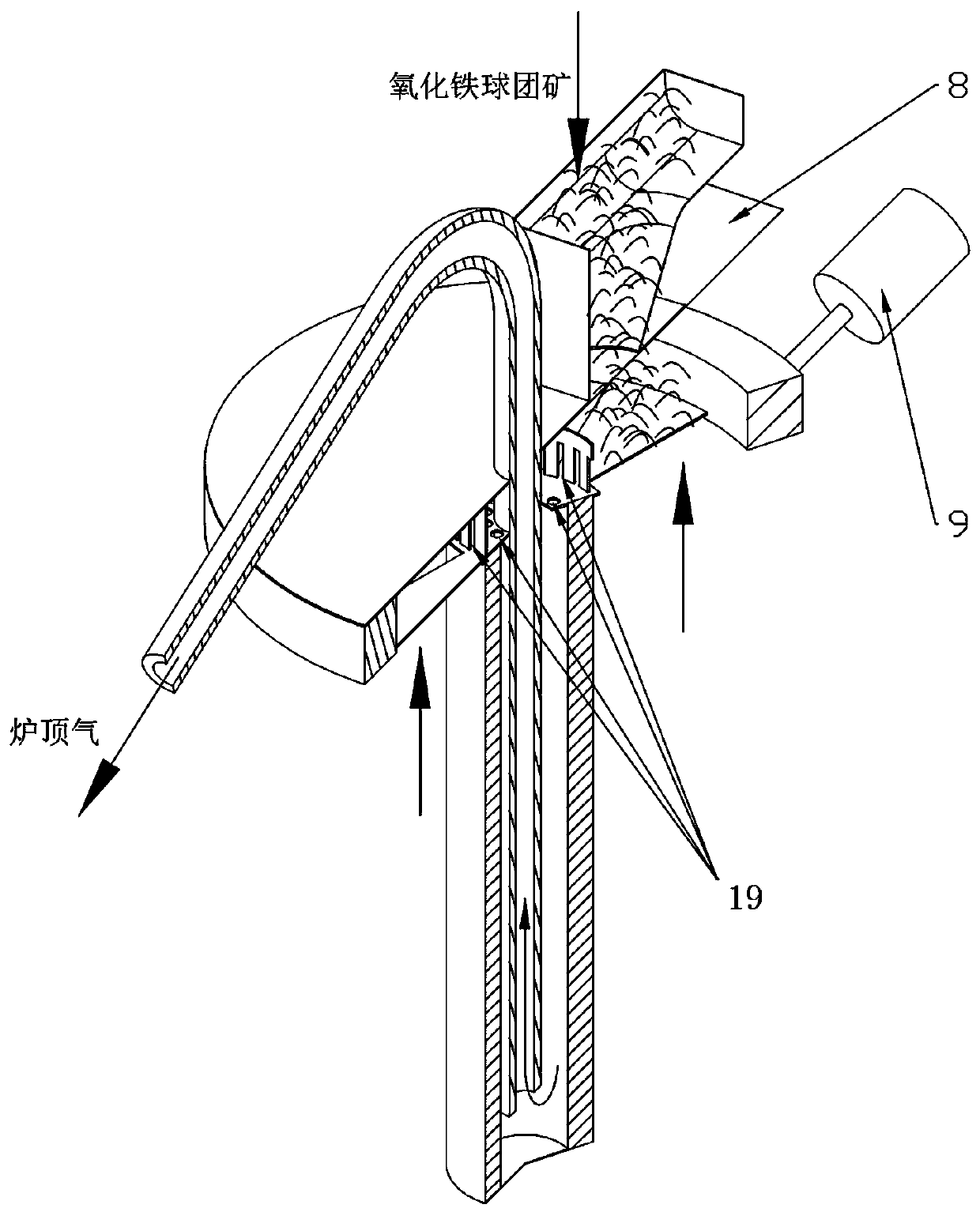

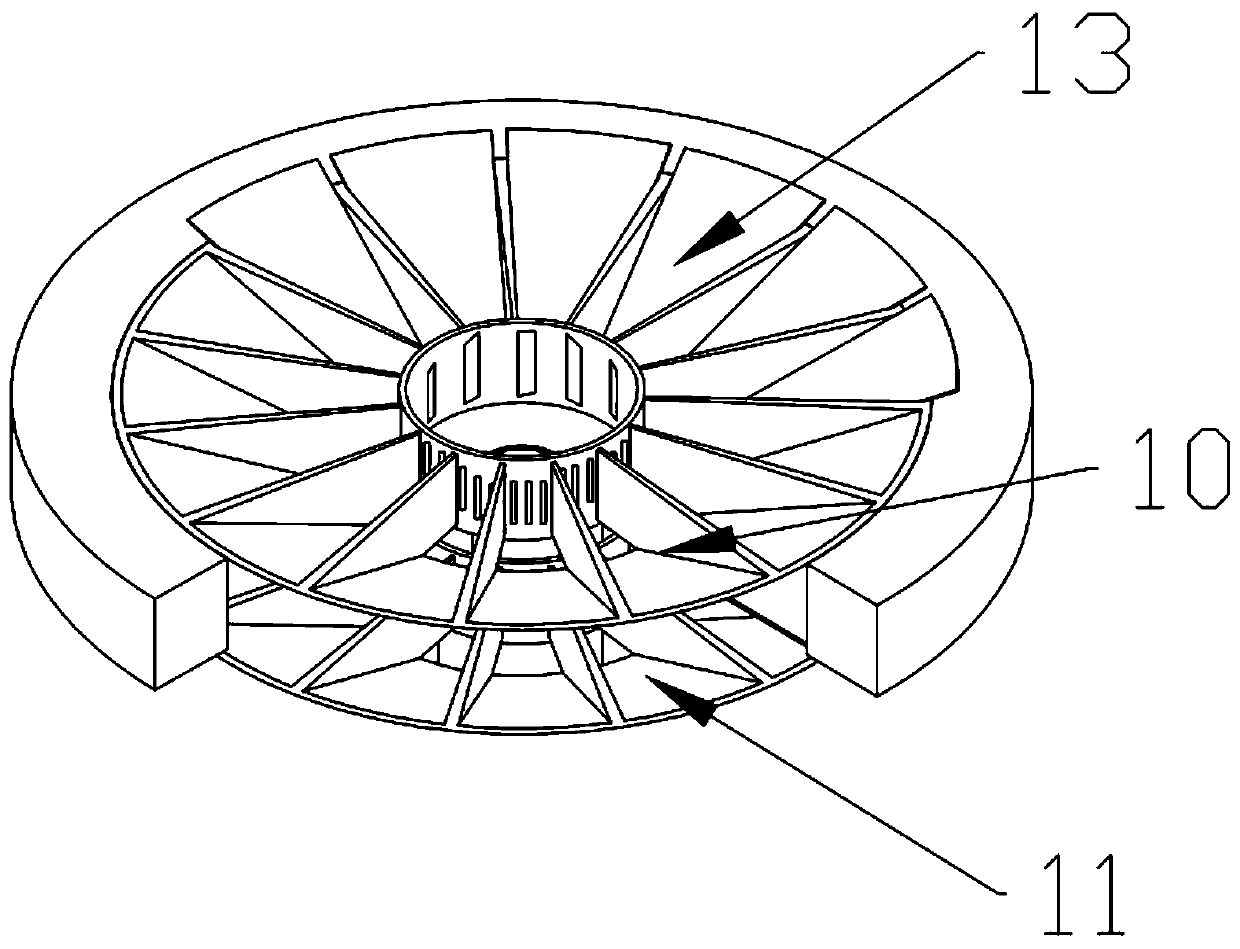

Device for directly preparing reduced sponge iron from pellets

PendingCN110669893AReduce redundant troublesome operationsReduce consumptionShaft furnaceProcess engineeringShaft furnace

The invention belongs to the technical field of pellet equipment, and particularly relates to a device for directly preparing reduced sponge iron from pellets. The device is characterized by comprising a reaction shaft furnace, a feeding bin, a logistics conveying mechanism connected with the feeding bin, an exhaust pipe section arranged in the reaction shaft furnace and located at the top, a furnace top air outlet pipe located in the exhaust pipe section, a sector rotary feeding mechanism arranged in the reaction shaft furnace around the exhaust pipe section, a discharging bin arranged at thebottom of the reaction shaft furnace, an annular air inlet structure arranged on the side wall of the reaction shaft furnace and located on a roasting section, and an air inlet hole II formed betweenthe discharging bin and the reaction shaft furnace. According to the device, drying, roasting, reducing and cooling of the pellets are completed in one tank, the unnecessary redundant and troublesomeoperation of drying, roasting, cooling, reheating, reducing and cooling in the original process of preparing reduced iron from the pellets is reduced, and redundant equipment in the production process is removed.

Owner:UNIV OF SCI & TECH LIAONING

A rare earth ore processing device

The invention relates to a rare-earth ore treatment device comprising a rotary hearth furnace, a slag-iron separation device, a roasting furnace and a leaching pool. By improving of the devices, especially the specific structure of the roasting furnace, the whole rare-earth ore treatment process of treating in the rotary hearth furnace, separating, roasting and leaching is smoother, energy consumption is lower, the environmental-friendly degree is improved, and the rear earth separation efficiency and effect are improved.

Owner:北京安康科创节能环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com