Coating apparatus for active coating on carrier in exhaust particulate trap

A technology of tail gas particles and active coating, which is applied in the direction of liquid coating devices, coatings, and pretreatment surfaces, etc., which can solve the problem of increased back pressure in the exhaust system, inconsistent thickness of active coating, and reduced combustion temperature of particulate matter And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

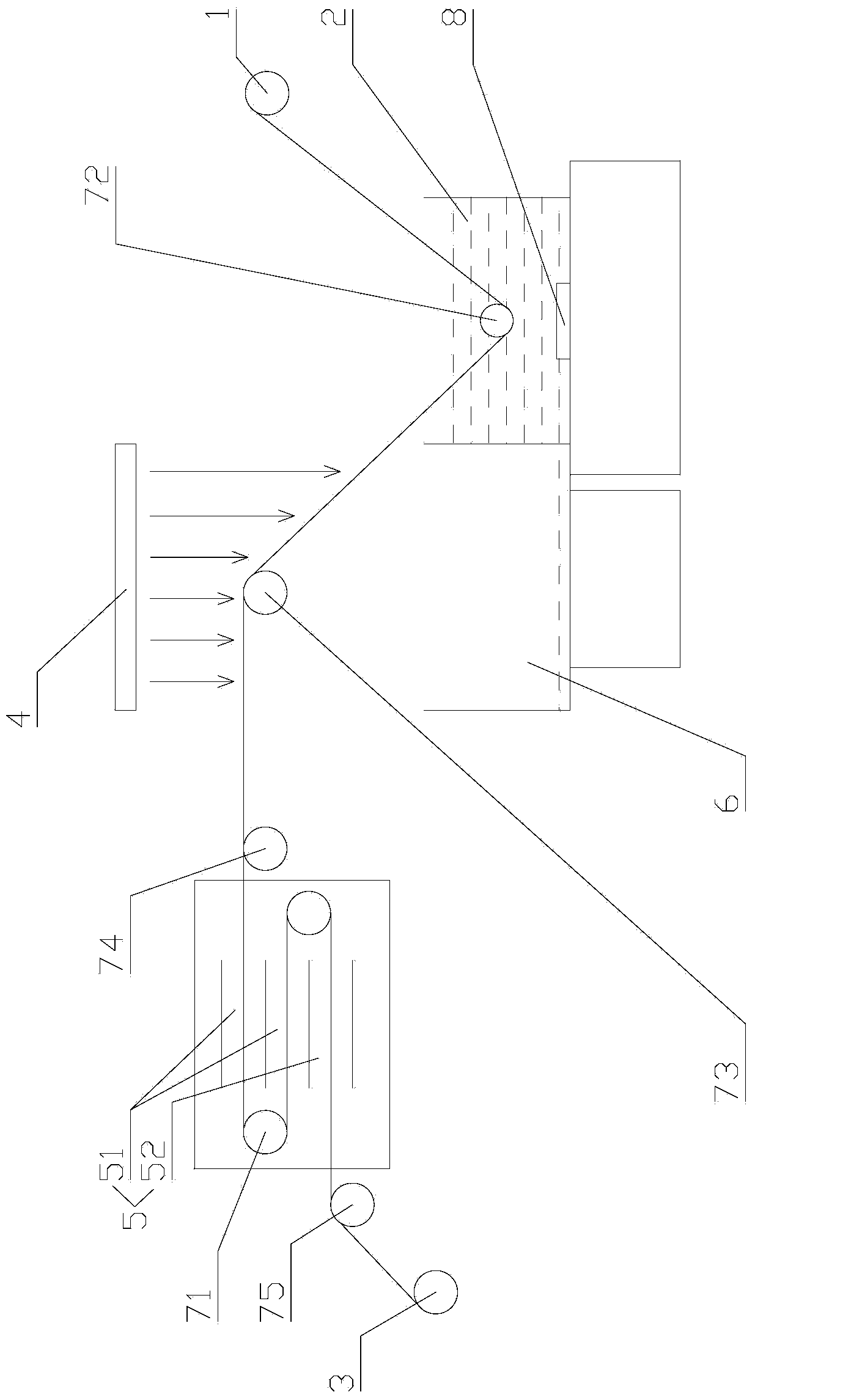

[0014] Such as figure 1 As shown, a coating device for the active coating on the carrier in the exhaust gas particulate filter is arranged in sequence along the conveying direction of the carrier with the unwinding reel 1, the coating pool 2, the fast dryer 4, the tunnel kiln 5 and the reeling reel 3. The limited shaft 72 is connected to the coating pool, and the limited shaft is immersed in the paint, and the carrier output on the unwinding shaft bypasses the limited shaft and enters the working area of the fast dryer. A support shaft 73 is arranged in the working area, and the carrier is supported on the upper end of the support shaft. The entrance of the tunnel kiln is provided with a positioning shaft 74, and the carrier enters the tunnel kiln through the positioning shaft 1, and the exit of the tunnel kiln is provided with a positioning shaft. Two 75, the carrier passing through the tunnel kiln is input to the input reel through the positioning shaft two. The tunnel kil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com