Continuous roasting furnace for vanadium pentoxide

A vanadium pentoxide and roasting furnace technology, which is applied in the direction of furnaces, furnace types, lighting and heating equipment, etc., can solve problems such as difficulty in continuous roasting, and achieve the effects of improving performance, high roasting efficiency, and expanding the use and scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

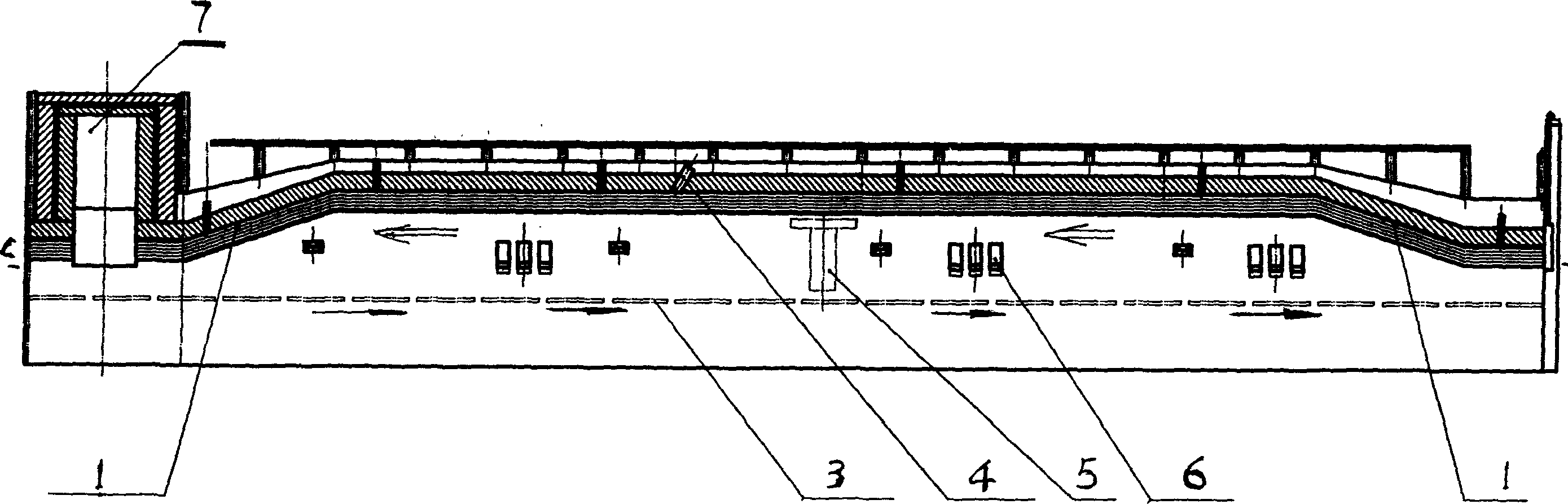

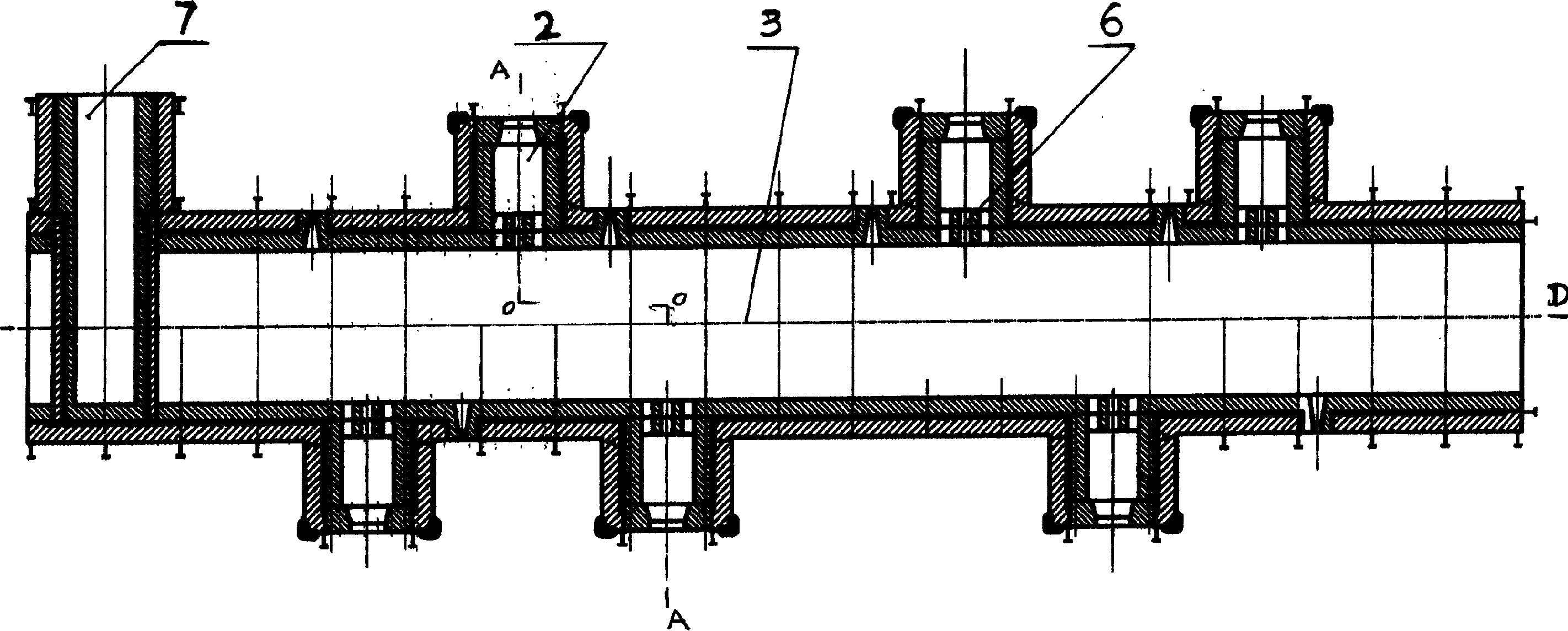

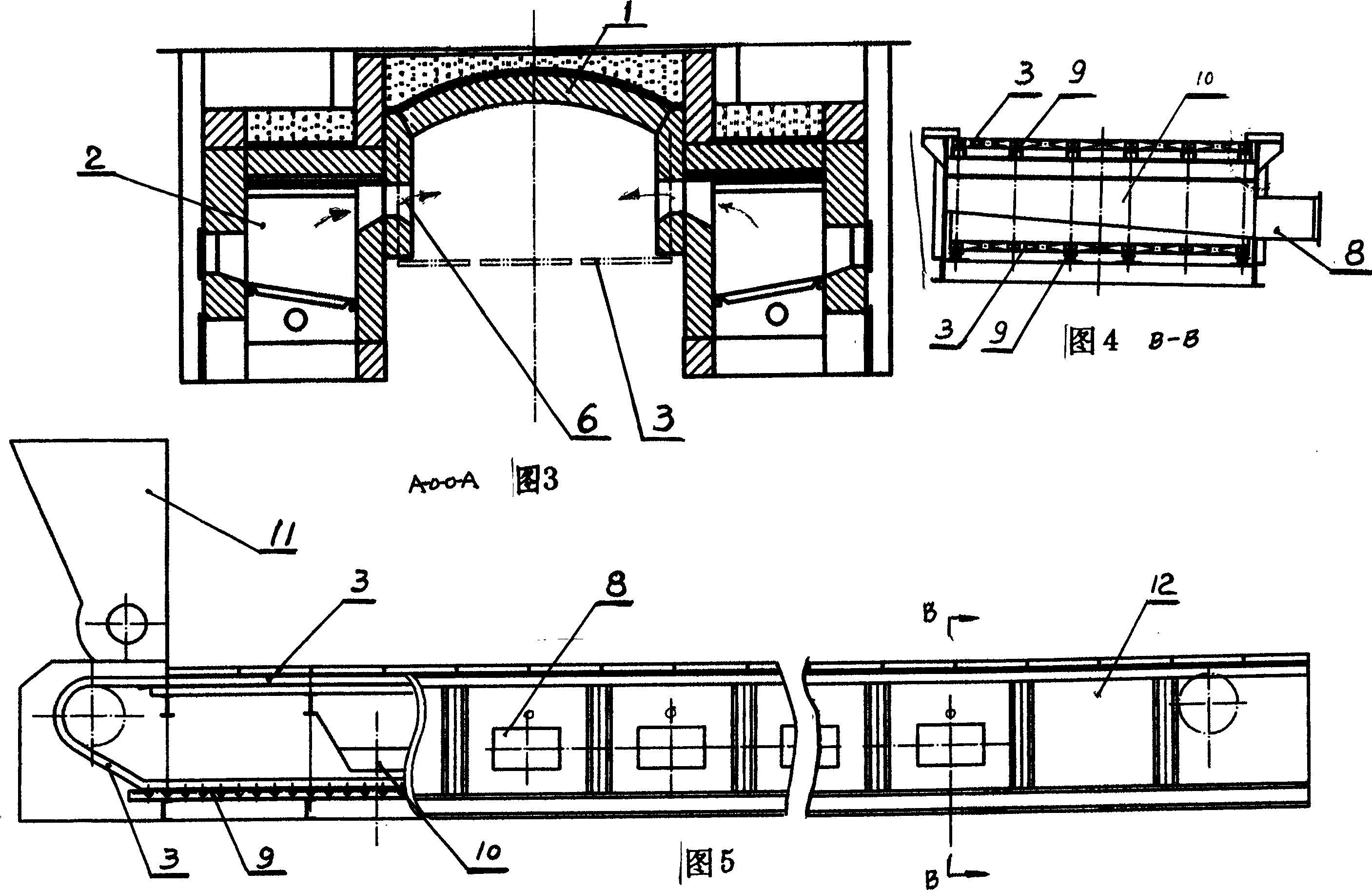

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. In Fig. 1, Fig. 2 and Fig. 3, the continuous ore roasting furnace has a vertical and horizontal structure, and the main materials are commonly used materials such as refractory, heat preservation, and steel structures. The two sides of the roasting furnace can be evenly or unevenly distributed. The combustion spout 6 of the vault 1 above it leads to the hearth of the roasting furnace, and the crawler belt 3 running in the raw material conveyor 12 in the furnace is placed on ores, such as vanadium pentoxide, magnesium ore dolomite, manganese ore and other ores. Run slowly to the right, the left end of the roasting furnace is the flue 7, and there are several oxygen injection holes 4 on the top of the roasting furnace, and the inclined angle α can be any angle between 15° and 60°, such as: 15°, 18° , 20°25°, 30°, 35°, 40°, 45°, 50°, 55°, 60°. The direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com