A low-grade iron ore beneficiation equipment and method thereof

A mineral processing equipment and mineral processing method technology, applied in the field of mineral processing equipment, can solve the problems of large resource waste, poor effect, low mineral processing recovery rate, etc., and achieve the effect of large transmission power, increased contact area, and large heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

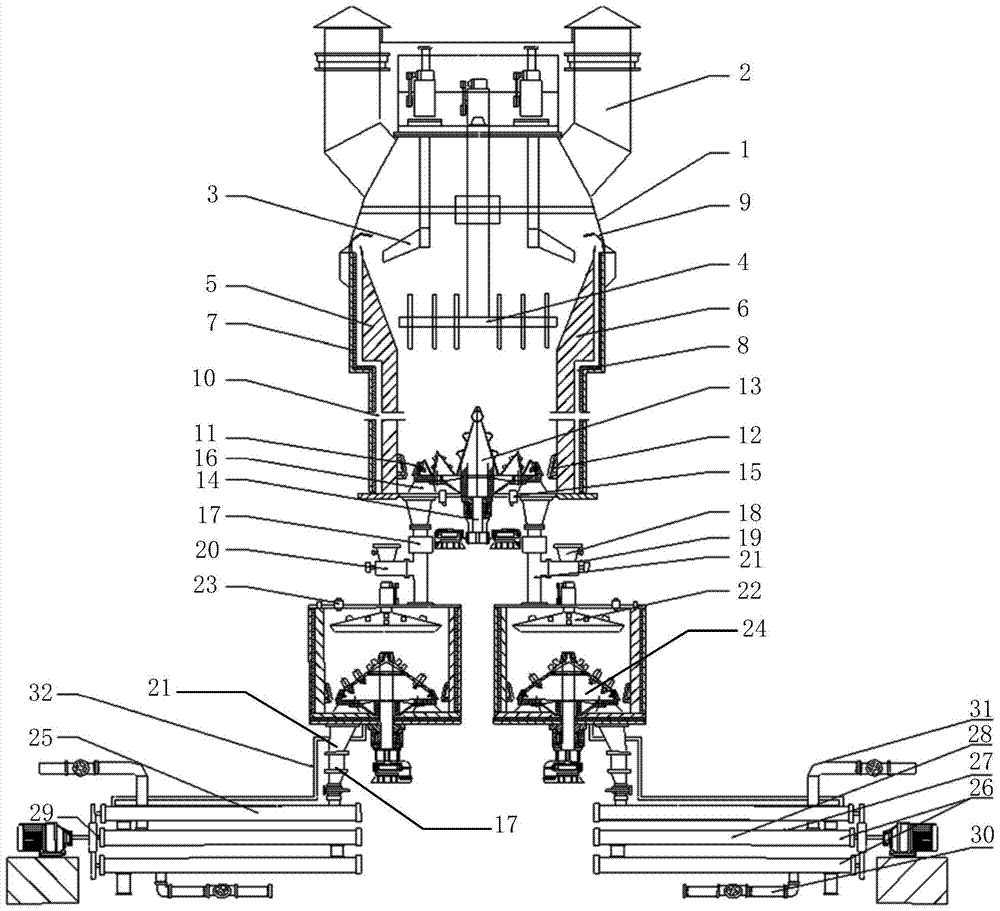

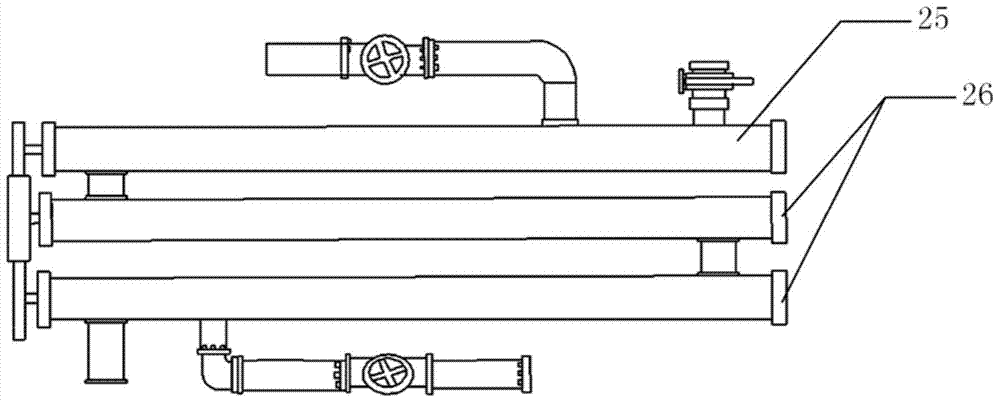

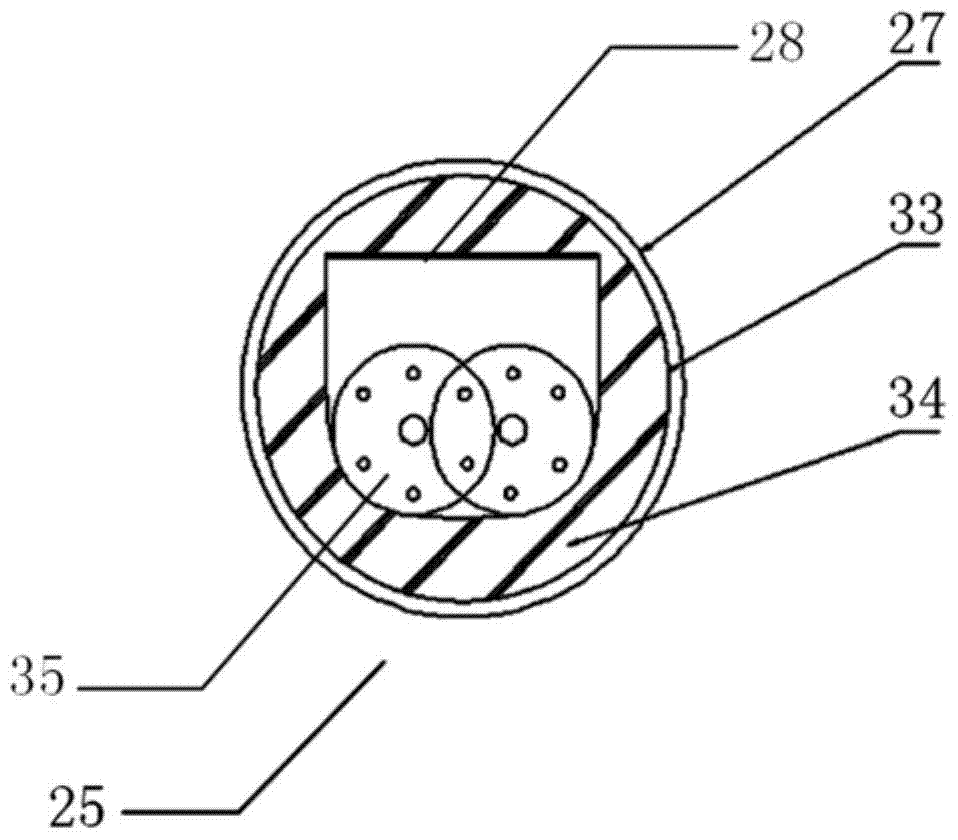

[0049] as attached figure 1 As shown, a specific embodiment of a low-grade iron ore beneficiation equipment includes: No. 1 furnace on the first floor, No. 2 furnace located at the bottom of No. 1 furnace, and a cooling reduction system located at the bottom of No. 2 furnace. Roasting materials generally include a certain proportion of iron ore raw ore powder, coke powder and biomass. The roasted material including low-grade iron ore enters the inside of the barrel 1 of the No. 1 furnace through the top of the No. 1 furnace for distribution, dehydration, drying, preheating and low-temperature roasting. After low-temperature roasting, the calcined material and reducing agent enter the No. 2 furnace, where unloading, mixing and reduction reactions are carried out, and then enter the cooling reduction system. When mixing and reducing in the No. 2 furnace, waste heat is used for heat preservation. The reduced roasted material passes through the reduction pipe of the cooling redu...

Embodiment 2

[0057] as attached Figure 7 As shown, it is a complete operation process of low-grade iron ore beneficiation method, including the following steps:

[0058] Crushing and grinding of alternative low-grade iron ore;

[0059] Formulate alternative low-grade iron ore, mainly by adding biomass and coke powder;

[0060] Granulate the selected low-grade iron ore that has been formulated into a roasted material;

[0061] The roasted material is dehydrated, dried and preheated in the No. 1 furnace;

[0062] The roasted material is roasted at a low temperature in the No. 1 furnace;

[0063] The roasted material roasted at low temperature undergoes reduction reaction in the No. 2 furnace;

[0064] The calcined material after the reduction reaction is reduced and cooled in the cooling reduction system;

[0065] After reduction and cooling, the roasted material is quenched and then subjected to magnetic separation.

specific Embodiment

[0066] A specific embodiment of a method for utilizing the above-mentioned equipment to carry out low-grade iron ore beneficiation, comprising the following steps:

[0067] S101: The roasted material including low-grade iron ore enters the cylinder body 1 of the No. 1 furnace through the top of the No. 1 furnace, and carries out distribution, dehydration, drying, preheating and low-temperature roasting;

[0068] S102: The roasted material (also known as clinker) and the reducing agent after low-temperature roasting enter the No. 2 furnace, and enter the cooling reduction system after unloading, mixing and reduction reactions in the No. 2 furnace;

[0069] S103: The reduced roasted material passes through the reduction pipe of the cooling reduction system for secondary reduction, and then is cooled by the cooling pipe, and then sent to the quenching pool for quenching operation;

[0070] As a preferred specific embodiment of the method of the present invention, the above-mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com