Chain grate-tandem rotary kiln whole-particle fraction magnetic roasting process for refractory low-grade iron ore

A magnetized roasting and iron ore technology, which is applied in magnetic separation, chemical instruments and methods, solid separation, etc., can solve problems such as ringing metal recovery rate, large particle size difference, and uneven roasting quality in the kiln body, and achieve contact Increased area, improved filling rate, and uniform firing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

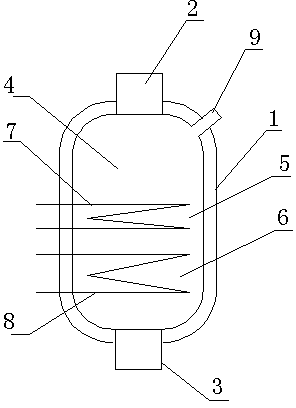

Image

Examples

Embodiment 1

[0035] A kind of refractory low-grade iron ore grate machine-tandem rotary kiln full-grain magnetization roasting process, including the following process steps:

[0036] (1) Iron ore particle size classification: Iron ore with a particle size greater than 15mm is crushed to make the particle size below 15mm, and the iron ore with a particle size of 0-15mm is first screened, and the 0-15mm iron ore is sorted out. 5mm, 5~15mm iron ore, and then adopt the method of winnowing to separate the 0~1mm, 1~3mm and 3~5mm iron ore from the iron ore with a particle size of 0~5mm. Ore; in terms of mass, the material ratio of iron ore in each particle size range is: 25 parts for 5-15mm particle size, 12 parts for 3-5mm particle size control, 13 parts for 1-3mm particle size control, 0-1mm particle size control is 28 parts;

[0037] (2) Grate heating and oxidation: Iron ore with a particle size of 5-15mm is added from the inlet of the grate. When the iron ore passes through the grate, the h...

Embodiment 2

[0045] The difference between embodiment 2 and embodiment 1 is:

[0046] In step (1), the material ratio of iron ore in each particle size range is: 30 parts for 5-15mm particle size, 10 parts for 3-5mm particle size control, 15 parts for 1-3mm particle size control, 0 ~1mm particle size control is 25 parts;

[0047] In step (2), the heating time of the control material is 15 minutes;

[0048] In step (3), the 900-950°C iron oxide ore discharged from the grate is mixed with 3-5mm grain-sized iron ore and 5 parts of 0-3mm grain-sized coal, and then added to the primary magnetization rotary kiln; When the ore moves to the middle area of the rotary kiln, iron ore with a particle size of 1-3mm and 3 parts of coal powder with a particle size of 0-1mm are injected from the kiln head of the primary magnetization rotary kiln, and the mixed material is mixed with iron ore with a particle size of 1-3mm and 0 Coal powder with a particle size of ~1mm is mixed twice and then magnetized...

Embodiment 3

[0053] The difference between embodiment 3 and embodiment 1 is:

[0054] In step (1), the material ratio of iron ore in each particle size range is: 35 parts for 5-15mm particle size, 15 parts for 3-5mm particle size control, 10 parts for 1-3mm particle size control, 0 ~1mm particle size control is 35 parts;

[0055] In step (2), the heating time of the control material is 25 minutes;

[0056] In step (3), the 900-950°C iron oxide ore discharged from the grate is mixed with 3-5mm grain-sized iron ore and 2 parts of 0-3mm grain-sized coal, and then added to the primary magnetization rotary kiln; When the ore moves to the middle area of the rotary kiln, iron ore with a grain size of 1-3mm and 5 parts of coal powder with a grain size of 0-1mm are sprayed from the kiln head of the primary magnetization rotary kiln, and the mixed material is mixed with iron ore with a grain size of 1-3mm and 0 Coal powder with a particle size of ~1mm is mixed for the second time and continues t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com