How to fill the inside of the sagger with powder

A powder and saggar technology is applied in the field of filling powder into the saggar, which can solve the problems of inability to perform wet filling, fear of contact with moisture, difficult to form, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0026] In this embodiment, the sagger is a square graphite sagger, and the powder is ceramic powder used as a positive electrode material of a lithium battery. The particle diameter of the powder is 2-15 μm, and it is a material that is afraid of contact with moisture. In addition, firing was performed in a nitrogen atmosphere. However, the present invention is not limited to this embodiment.

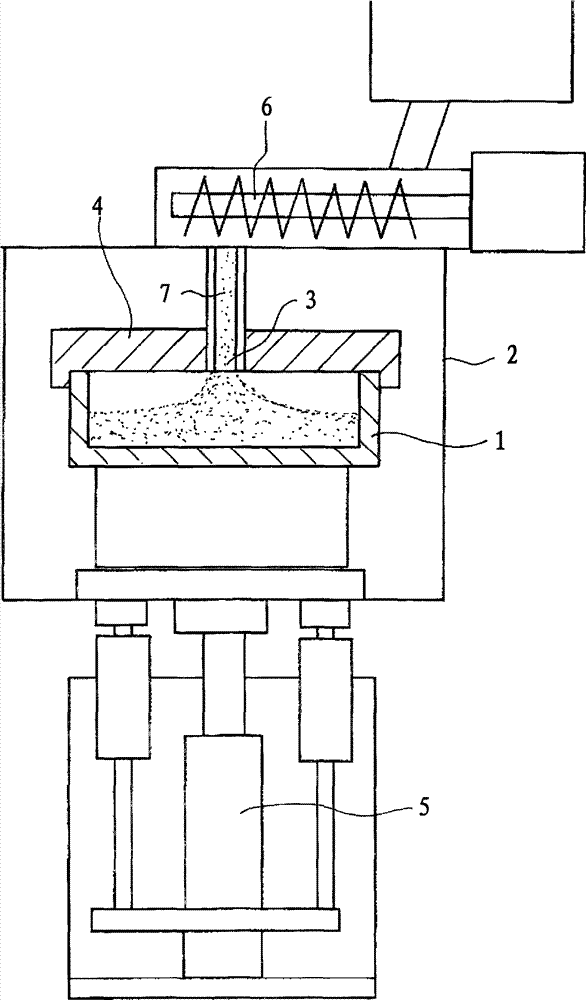

[0027] First, to the inside of the empty sagger 1 conveyed by a suitable conveying unit (not shown) such as a roller conveyor, as shown in FIG. figure 1 Feed the powder as shown. The sagger 1 is supported inside the decompression tank 2, and is supplied from above by the screw feeder 6 while being lifted by the sagger lifting unit 5 to a position close to the cover 4 having the powder supply port 3 Powder. It is preferable to keep the amount of powder supplied to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com